Beruflich Dokumente

Kultur Dokumente

TLV - Sight Glass PDF

Hochgeladen von

sirballesterosOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

TLV - Sight Glass PDF

Hochgeladen von

sirballesterosCopyright:

Verfügbare Formate

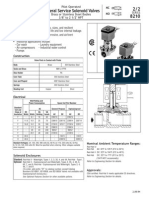

Pamphlet M4404

PRESSURE SHELL DESIGN CONDITIONS (NOT OPERATING CONDITIONS):

Maximum Allowable Pressure (MPaG) PMA: 1.0 (T5N), 1.57 (T8N/TF8N, T10N/TF10N)

Maximum Allowable Temperature ( C) TMA: 120 (T5N), 200 (T8N/TF8N, T10N/TF10N)

1 MPa = 10.197 kg/cm

2

To avoid abnormal operation, accidents or serious injury, DO NOT use this product outside of the

specification range. Local regulations may restrict the use of this product to below the conditions quoted.

CAUTION

120

1.0

200

1.57

15, 20, 25 15, 20, 25, 32, 40, 50

Check Line Flow at a Glance...

Find Steam Leaks Fast!

STANDARD MODELS

Model

MODEL SELECTION CHART

Pressure (MPaG)

T

e

m

p

e

r

a

t

u

r

e

(

C

)

0

0

120

200

1.0 1.57

The ball moves violently

due to flow pressure.

When line flow is

normal:

If flow rate is small or

steam is leaking:

The ball moves only

slightly.

OPERATION

sight glasses save time and money. A few

seconds is all it takes to check the line flow of

cooling water, lubricants, or slurry; or monitor

the mixing of fluids in a tank. These compact,

lightweight sight glasses save space, and are

dependable because of their high performance

and durability. makes the perfect sight glass

for your application. For any fluid----air, water, hot

water, or steam----under any operating pressure

or temperature, choose the most appropriate

model from the line. The T10N and TF10N are

recommended for higher flow rates because of

the through-hole in the partition wall between

the inlet and outlet.

Sizes (mm)

Connection Screwed Rc(PT) Screwed Rc(PT) Flanged

FC250

Screwed

Cast Iron

Flanged

Body Material

Max. Operating

Temperature

TMO (C)

Max. Operating

Pressure PMO

(MPaG)

(mm)

T8N/T10N Screwed*

Flanged

( ) No ASME standard exists for cast iron; machined to fit steel flanges

Class 125 FF can connect to 150 RF, 250 RF can connect to 300 RF

Other standards avilable, but length and weight may vary

* Weight is for Class 250 RF [300 RF] ** TF10N only

Size

(15)

(20)

25

32

40

50

L

ASME Class

Weight*

(kg)

[2.9]

[

4.6

]

4.8

5.8

8.2

10

H1

64

61

64

69

71

76

Through-

hole dia**

10

15

18

20

25

30

* Rc (PT), other standards available ** T10N only

T5N

TF8N/TF10N

Size

15

20

25

32

40

50

L

68

75

79

120

126

Weight (kg)

0.9

1.0

1.2

1.9

2.1

2.7

H1

63

67

69

75

78

85

Through-hole dia.**

10

15

18

20

25

30

(150RF)

175

180

200

250RF

184

200

204

(300RF)

175

180

184

200

204

125FF

180

200

Ball movement indicates the flow status.

Cylindrical structure allows to monitor

the flow from the side.

Compact and lightweight.

FEATURES

Ball movement indicates the flow status.

Compact and lightweight.

FEATURES

/

Sight Glass

(Heat resistant

reinforced glass)

Glass Holder

(Cast iron)

Ball

(PTFE)

Body

(Cast iron)

Sight Glass

(Heat resistant

reinforced glass)

Glass Holder

Ball

(PTFE)

Body

(Cast iron)

Through-hole

(T10N/TF10N)

DIMENSIONS

DIMENSIONS

Size L H1

15

20

25

68

75

79

70

75

79

1.1

1.3

1.4

Weight

(kg)

To check the flow of cold water,

hot water, air and steam.

APPLICATION

Do not use for toxic, flammable or otherwise hazardous fluids

To check the operation of steam traps.

To check the flow of cold water,

hot water, air and steam.

APPLICATION

Do not use for toxic, flammable or otherwise hazardous fluids

0.02 0.01

500

600

800

1000

2000

4000

6000

8000

10000

20000

30000

0.04 0.06 0.1 0.2 0.4 0.6 0.8 1.0 1.57

CAPACITIES

Differential Pressure (kg/cm

2

)

Differential Pressure (MPa)

M

a

x

i

m

u

m

F

l

o

w

R

a

t

e

(

k

g

/

h

)

1. Capacities are based on continuous discharge of condensate 6C below saturated steam temperature

(or continuous discharge of water at room temperature if so stated).

2. Differential pressure is the difference between the inlet and outlet pressure ofthe sight glass.

PRECAUTIONS REGARDING USE

1. Select the proper model for the job.

2. Be sure to replace the heat-resistant, reinforced

glass every year.

3. Protect the line against water hammer before

installing the sight glass. In lines in which there

is a danger of water hammer, connect a check

valve (CK) on the outlet side.

4. Install so that the arrow on the body agrees

with the direction of flow.

5. Install only in a horizontal line with the sight

glass facing up.

6. Loosen the glass holder to remove the glass for

cleaning or replacement.

7. When dismantling or assembling, do not use a

pipe wrench or other type of tool that applies

stress directly to the glass.

8. If leaking occurs after the glass holder has

been tightened with the proper torque, the

gasket is probably deformed or damaged. Do

not tighten further. Replace the gasket with a

new one.

(water at room temp.)

(water at room temp.)

0.1 0.2 0.4 0.6 1 2 4 8 10 16 6

Internet World Wide Web URL http:

//

www.tlv.com

Pamphlet M4404 Rev. 2/2009

Specifications subject to change without notice.

881 Nagasuna, Noguchi, Kakogawa, Hyogo 675-8511, JAPAN

Phone: [81]-(0)79-427-1818

Fax: [81]-(0)79-425-1167

E-mail: tlv-japan@tlv.co.jp

Manufacturer

Kakogawa, Japan

is approved by LRQA Ltd. to ISO 9001/14001

ISO 9001/ ISO 14001

(M)

Das könnte Ihnen auch gefallen

- FF Side Mounting Float Switch - B0Dokument15 SeitenFF Side Mounting Float Switch - B0giathinh123456789Noch keine Bewertungen

- Tozen Flex - RubberDokument4 SeitenTozen Flex - Rubberkingathur26681Noch keine Bewertungen

- Socla 895Dokument4 SeitenSocla 895Miguel-Angel RuizNoch keine Bewertungen

- TSF-13CF Manual enDokument18 SeitenTSF-13CF Manual entienNoch keine Bewertungen

- Perrin High Pressure Valves For Hydrogen ServiceDokument12 SeitenPerrin High Pressure Valves For Hydrogen ServiceKunming Wang100% (1)

- C 800Dokument8 SeitenC 800rodonietoNoch keine Bewertungen

- Aluminum Solenoid Valves SpecsDokument4 SeitenAluminum Solenoid Valves SpecsBilly Isea DenaroNoch keine Bewertungen

- 31 ARC enDokument6 Seiten31 ARC enlggomezupbNoch keine Bewertungen

- Catálogo Válvula DirecionalDokument20 SeitenCatálogo Válvula DirecionalcristianoclemNoch keine Bewertungen

- TITANIA 1138enDokument4 SeitenTITANIA 1138enalexprgNoch keine Bewertungen

- Model GP-1000 Series Pressure Reducing Valve Installation & Operation ManualDokument14 SeitenModel GP-1000 Series Pressure Reducing Valve Installation & Operation ManualJefanthony StevanoyaNoch keine Bewertungen

- Walvoil Cartridge Ventielen HICDokument20 SeitenWalvoil Cartridge Ventielen HICddNoch keine Bewertungen

- Manual Rotámetro - 0.02 - 1.2 LPM Key InstrumentsDokument2 SeitenManual Rotámetro - 0.02 - 1.2 LPM Key InstrumentsMax SdNoch keine Bewertungen

- Pulsation Dampener PD8100 SeriesDokument2 SeitenPulsation Dampener PD8100 SeriesDaniel ArgumedoNoch keine Bewertungen

- TLV JA3 Air Drain TrapDokument2 SeitenTLV JA3 Air Drain TrapMONANoch keine Bewertungen

- Pilot Operated Solenoid Valves for Industrial ApplicationsDokument6 SeitenPilot Operated Solenoid Valves for Industrial ApplicationsMARACO46Noch keine Bewertungen

- Convertidor Mechanical S108KDokument8 SeitenConvertidor Mechanical S108KALBERTONoch keine Bewertungen

- Astma 269Dokument4 SeitenAstma 269Raúl TinocoNoch keine Bewertungen

- S108T02 Series S208T02 Series: I (RMS) 8A, Zero Cross Type Low Profile SIP 4pin Triac Output SSRDokument13 SeitenS108T02 Series S208T02 Series: I (RMS) 8A, Zero Cross Type Low Profile SIP 4pin Triac Output SSRmplokijuhyNoch keine Bewertungen

- Microsole Solenoid ValvesDokument4 SeitenMicrosole Solenoid ValvesMangesh RasoteNoch keine Bewertungen

- Fisher - 98HDokument16 SeitenFisher - 98HEduardo RodriguesNoch keine Bewertungen

- 15-ScanJet SC 15TW Instruction ManualDokument43 Seiten15-ScanJet SC 15TW Instruction Manualogurmehmetali07Noch keine Bewertungen

- SEVO 1230 Technical Data Sheets - All PDFDokument18 SeitenSEVO 1230 Technical Data Sheets - All PDFYeni Paola SierraNoch keine Bewertungen

- Catálogo General Medidor para Agua WoltmanDokument8 SeitenCatálogo General Medidor para Agua WoltmanLuis David LopezNoch keine Bewertungen

- General Service Solenoid Valves: NC NODokument6 SeitenGeneral Service Solenoid Valves: NC NOAngel Azathoth GoetzNoch keine Bewertungen

- Safety Manual for Welder OperationDokument11 SeitenSafety Manual for Welder OperationColin Danger AmorosoNoch keine Bewertungen

- Series LF288A Specification SheetDokument2 SeitenSeries LF288A Specification SheetWattsNoch keine Bewertungen

- TC Coolant Pump Userguide - 2020 - V2Dokument10 SeitenTC Coolant Pump Userguide - 2020 - V2Luc DuchesneNoch keine Bewertungen

- Product Specifications for FOXTOP Control Valve System PSS 4-24A1 FDokument0 SeitenProduct Specifications for FOXTOP Control Valve System PSS 4-24A1 Fcico_ctNoch keine Bewertungen

- Tacmina Dosing Pump Cs2Dokument8 SeitenTacmina Dosing Pump Cs2rosiNoch keine Bewertungen

- AE AccessoriesDokument16 SeitenAE AccessoriesmisaelzaNoch keine Bewertungen

- SS2 Agv200 0300 01Dokument12 SeitenSS2 Agv200 0300 01RaymondIlyasNoch keine Bewertungen

- Rotametro KeyDokument2 SeitenRotametro Keydocumentos.envirotestNoch keine Bewertungen

- IQA Report Summary Sheet - Bolt & Zest Front Strut: 1 Mounting of PartDokument33 SeitenIQA Report Summary Sheet - Bolt & Zest Front Strut: 1 Mounting of PartJetesh DevgunNoch keine Bewertungen

- Brooks Rotameter Variable AreaDokument22 SeitenBrooks Rotameter Variable Areamhidayat108Noch keine Bewertungen

- Thermostatic liquid level regulatorsDokument8 SeitenThermostatic liquid level regulatorsLucioRimacNoch keine Bewertungen

- Fisher 1190 Low-Pressure Gas Blanketing RegulatorDokument20 SeitenFisher 1190 Low-Pressure Gas Blanketing Regulatorneurolepsia3790Noch keine Bewertungen

- 02 Floater Switch Specpage 18Dokument28 Seiten02 Floater Switch Specpage 18Kia GabriellaNoch keine Bewertungen

- BC M514 - Olympus AU400Dokument41 SeitenBC M514 - Olympus AU400maran.suguNoch keine Bewertungen

- Nuflo Ez-InDokument8 SeitenNuflo Ez-InAnonymous Wu6FDjbNoch keine Bewertungen

- Ball Data SheetDokument4 SeitenBall Data Sheetshashikanth79Noch keine Bewertungen

- Ti 2 516 UsDokument2 SeitenTi 2 516 Uswill_streetNoch keine Bewertungen

- Grundfos MTS Screw Spindle PumpDokument68 SeitenGrundfos MTS Screw Spindle PumpAnonymous lswzqlo100% (1)

- Liquid Level Switches: MLS SeriesDokument2 SeitenLiquid Level Switches: MLS SeriesfharishputraNoch keine Bewertungen

- TWINFLEX twin-sphere rubber jointDokument3 SeitenTWINFLEX twin-sphere rubber jointYuda PakpahanNoch keine Bewertungen

- Sae and Din HosesDokument5 SeitenSae and Din Hosesapi-247972389Noch keine Bewertungen

- HF2100 enDokument4 SeitenHF2100 enBhakti PermanaNoch keine Bewertungen

- Steel SAE O-Rings AdaptersDokument3 SeitenSteel SAE O-Rings Adaptersgeav25653855Noch keine Bewertungen

- SY-5 Manual enDokument7 SeitenSY-5 Manual entienNoch keine Bewertungen

- S108T02 Series S208T02 Series: I (RMS) 8A, Zero Cross Type Low Profile SIP 4pin Triac Output SSRDokument13 SeitenS108T02 Series S208T02 Series: I (RMS) 8A, Zero Cross Type Low Profile SIP 4pin Triac Output SSRnetiksNoch keine Bewertungen

- Air Fuses: In-Line Excess Flow Shut-Off ValvesDokument3 SeitenAir Fuses: In-Line Excess Flow Shut-Off ValvesAttila VáczNoch keine Bewertungen

- Valvulas Sole No Ides IsDokument12 SeitenValvulas Sole No Ides Isaaa3131Noch keine Bewertungen

- Valvulas de Bola - JAMESBURYDokument4 SeitenValvulas de Bola - JAMESBURYcasv9Noch keine Bewertungen

- Caterpillar 3208 Diesel Engine SM Manual Copy OneDokument350 SeitenCaterpillar 3208 Diesel Engine SM Manual Copy Oneswoods71588% (25)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsVon EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNoch keine Bewertungen

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitVon EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNoch keine Bewertungen

- Code of Safe Working Practices for Merchant Seafarers: Consolidated edition (incorporating amendments 1-6)Von EverandCode of Safe Working Practices for Merchant Seafarers: Consolidated edition (incorporating amendments 1-6)Noch keine Bewertungen

- Catalogo Termocupla Daily Modelo 210Dokument1 SeiteCatalogo Termocupla Daily Modelo 210sirballesterosNoch keine Bewertungen

- Cargoboss - The Marine Monitoring SoftwareDokument2 SeitenCargoboss - The Marine Monitoring SoftwaresirballesterosNoch keine Bewertungen

- Solutions For Improved Thermal Process Performance: Field ProductsDokument8 SeitenSolutions For Improved Thermal Process Performance: Field ProductssirballesterosNoch keine Bewertungen

- Safety ManualDokument24 SeitenSafety ManualsirballesterosNoch keine Bewertungen

- TLV - Trapman PDFDokument8 SeitenTLV - Trapman PDFsirballesterosNoch keine Bewertungen

- CA 08-GB 05 I Storage-Radar GaugeDokument5 SeitenCA 08-GB 05 I Storage-Radar GaugesirballesterosNoch keine Bewertungen

- Hydrocarbon Engineering Spring2016 HPCLDokument3 SeitenHydrocarbon Engineering Spring2016 HPCLsirballesterosNoch keine Bewertungen

- TLV - Manifolds Vapor y Condensado PDFDokument4 SeitenTLV - Manifolds Vapor y Condensado PDFsirballesterosNoch keine Bewertungen

- TLV - Reducing Valve For Steam and Air PDFDokument2 SeitenTLV - Reducing Valve For Steam and Air PDFsirballesterosNoch keine Bewertungen

- TLV - Air and Drain Traps PDFDokument8 SeitenTLV - Air and Drain Traps PDFsirballesterosNoch keine Bewertungen

- IR5500 Data SheetDokument2 SeitenIR5500 Data SheetsirballesterosNoch keine Bewertungen

- TLV - Electro-Pneumatic Control Valve For Steam PDFDokument2 SeitenTLV - Electro-Pneumatic Control Valve For Steam PDFsirballesterosNoch keine Bewertungen

- Laplace Transform AssignmentDokument1 SeiteLaplace Transform AssignmentMohamad DuhokiNoch keine Bewertungen

- r48 2000e3 Rectifier User ManualDokument26 Seitenr48 2000e3 Rectifier User Manualjose luis rivera sotoNoch keine Bewertungen

- Assignment 1 Systems Analysis - EME5601Dokument7 SeitenAssignment 1 Systems Analysis - EME5601Travis GrantNoch keine Bewertungen

- PV Elite ResultDokument18 SeitenPV Elite ResultVeny MartianiNoch keine Bewertungen

- Hanoi 2023 Peoples Picks AwardsDokument113 SeitenHanoi 2023 Peoples Picks AwardsNguyen Anh VuNoch keine Bewertungen

- College of Nursing: Assignment ON Nursing ClinicDokument5 SeitenCollege of Nursing: Assignment ON Nursing ClinicPriyaNoch keine Bewertungen

- Contact Details For Medical Schools by PostcodeDokument13 SeitenContact Details For Medical Schools by PostcodeHeena R ModiNoch keine Bewertungen

- Sony Ericsson K610i, K610m, and V630i Service ManualDokument53 SeitenSony Ericsson K610i, K610m, and V630i Service ManualJane TodoroskiNoch keine Bewertungen

- Never Fear, Never Quit - A Story of Courage and Perseverance PDFDokument68 SeitenNever Fear, Never Quit - A Story of Courage and Perseverance PDFnaveen100% (2)

- Final StereogramDokument16 SeitenFinal StereogramsimNoch keine Bewertungen

- Solving Problems Involving Kinds of Propotion StudentDokument18 SeitenSolving Problems Involving Kinds of Propotion StudentJohn Daniel BerdosNoch keine Bewertungen

- BSC Ag Syllabus 5th DeanDokument150 SeitenBSC Ag Syllabus 5th Deansaurabh rNoch keine Bewertungen

- ABRACON's Tuning Fork Crystals and Oscillators for 32.768kHz RTC ApplicationsDokument13 SeitenABRACON's Tuning Fork Crystals and Oscillators for 32.768kHz RTC Applicationsdit277Noch keine Bewertungen

- 10 Tips To Protect Yourself From Unhealthy AirDokument2 Seiten10 Tips To Protect Yourself From Unhealthy AirAnonymous XuFb6TNoch keine Bewertungen

- 123 Rule For TRS MMD DG ShippingDokument2 Seiten123 Rule For TRS MMD DG ShippingGurjit SinghNoch keine Bewertungen

- MỘT SỐ CÂU HỎI TRẮC NGHIỆM ÁP DỤNG CHUYÊN ĐỀ GIỚI TỪ TRONG ĐỀ THI ĐHDokument6 SeitenMỘT SỐ CÂU HỎI TRẮC NGHIỆM ÁP DỤNG CHUYÊN ĐỀ GIỚI TỪ TRONG ĐỀ THI ĐHPhương ThảoNoch keine Bewertungen

- Aqua Mon 4000 PH Red Ox AnalyserDokument4 SeitenAqua Mon 4000 PH Red Ox Analyserarvindgupta_2005Noch keine Bewertungen

- Complete The Table With The Missing WordsDokument2 SeitenComplete The Table With The Missing WordssoniaNoch keine Bewertungen

- Renal Cortical CystDokument2 SeitenRenal Cortical Cystra222j239Noch keine Bewertungen

- Week 2 - Risk AssessmentDokument35 SeitenWeek 2 - Risk AssessmentTahir BashirNoch keine Bewertungen

- Manual CastingDokument64 SeitenManual CastingDjRacksNoch keine Bewertungen

- Chapter 6 Exercises (Bonds & Interest)Dokument2 SeitenChapter 6 Exercises (Bonds & Interest)Shaheera SuhaimiNoch keine Bewertungen

- Reviewer On Nervous System Grade VIDokument4 SeitenReviewer On Nervous System Grade VIKent Francis LayaguinNoch keine Bewertungen

- Megger FORMDokument1 SeiteMegger FORMCOSMOPOLITAN M&ENoch keine Bewertungen

- Audit Reveals Optimization Opportunities for Cement Ball Mill SystemDokument19 SeitenAudit Reveals Optimization Opportunities for Cement Ball Mill SystemVijay Bhan100% (2)

- 7 Must Have Equipment Items For Your Church Safety TeamDokument7 Seiten7 Must Have Equipment Items For Your Church Safety TeamhmareidNoch keine Bewertungen

- Toxicology Compendium PDFDokument602 SeitenToxicology Compendium PDFJUANNoch keine Bewertungen

- Khalid DL 01 ProfileDokument2 SeitenKhalid DL 01 ProfileRipunjay MishraNoch keine Bewertungen

- GPS Navigator: ModelDokument99 SeitenGPS Navigator: ModelMain UddinNoch keine Bewertungen

- 06 Scaffold Erection and Dismantling (JHA-JSA)Dokument4 Seiten06 Scaffold Erection and Dismantling (JHA-JSA)AmanNoch keine Bewertungen