Beruflich Dokumente

Kultur Dokumente

DR Response Sheet

Hochgeladen von

Bahtiar Anak LaNangOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

DR Response Sheet

Hochgeladen von

Bahtiar Anak LaNangCopyright:

Verfügbare Formate

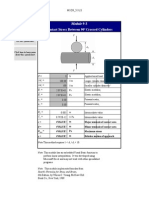

Subject: BPA1302317; JN 1046 Debutanizer Reboiler (20-HA-005)

Our Ref: BPA1302317; Our comments are as follows: 1) Manufacturers calculations : Girth Flange (i) Tube sheet (i) (ii)

It appears that girth flange calculations are not performed. It appears from our calculations that bolting would be inadequate. Please clarify.

It appears manufacturer has not performed tube sheet calculations. We conclude that mean metal temperature for shell side is 219 deg C and 193 deg C for tube side. Please confirm.

Lug Support calculations ( i) Operating weight is 19527 kg shown in the drawing. Operating weight calculated 14062 kg in PVElite elements and Detail weights. Operating weight considered in support lug calculation is 30915 kg. This discrepancy in weight values is not clear. ( ii) Manufacturers basis of arriving at moment of lug Mlug for blast and operating condition is requested. It is requested to submit a calculation for Mlug for better understanding. (iii) Acceleration values for transportation are not shown and Calculations for transportation conditions are not performed.

The stresses in shell and lug supports due to wind and accelerations loads would be review after receipt of clarification to above points. Nozzle Calculations: (i) Manufacturers basis of performing Fatigue analysis at Nozzle is requested. (ii) We conclude that pressure fluctuation (cyclic loads) are not applicable (as confirmed for earlier jobs). Please confirm. If this pressure cyclic load is applicable, all 50 NB nozzles would require reinforcement calculations. It appears that reinforcement of all 50 NB nozzles is inadequate at present. The local loads shown in the drawing and in the calculations do not match. Please clarify.

(iii)

2) It is concluded that equipment is not intended for lethal service.

3) Manufacturers attention is drawn to Clause UCS-67 (a) (3) for requirement of impact testing of welding procedure when MDMT is colder than -29 deg C.

4) We note that Manufacturer has shown a PED category for the equipment as category IV. Manufacturer should indicate the volume as per Article-9 and State of Fluid (Liquid/gas) as per Article-3 of Directive. This should be clearly shown on the drawing. The Category of the vessel as per Annexure-II of the Directive will be checked upon receipt of above details. 5) It is concluded that equipment is designed for steady state loads. Fatigue analysis at lug supports locations is not required.

6) PED Documents: (i) (ii) (iii) (iv) (v) (vi) Operating Manual is to be submitted. The corrosion allowance in Hazard Analysis for tube side is incorrect. Please correct. Impact test at -10 deg C in Hazard Analysis is not clear. Please correct. In PMA, impact test temperature for SA 333 Gr. 6 should be -45 deg C as per SA 333 Gr. 6 material specification. Please clarify. PMA for bolting is to be submitted. The tube sheet to shell weld detail is not shown, Please clarify or show the detail in the drawing.

Das könnte Ihnen auch gefallen

- Asme Viii CalcsDokument20 SeitenAsme Viii CalcsSriram VjNoch keine Bewertungen

- Liquid Fuel Measurements and ConversionsDokument4 SeitenLiquid Fuel Measurements and ConversionsrhazoorNoch keine Bewertungen

- Pipe Schedule PDFDokument1 SeitePipe Schedule PDFSrinivasan SeenuNoch keine Bewertungen

- Boiler Performance CalculationDokument1 SeiteBoiler Performance Calculationagusnnn50% (2)

- Jis G3452Dokument7 SeitenJis G3452Bahtiar Anak LaNangNoch keine Bewertungen

- Design of Lifting Lug: InputsDokument4 SeitenDesign of Lifting Lug: InputsBahtiar Anak LaNangNoch keine Bewertungen

- Design of Lifting Lug: InputsDokument4 SeitenDesign of Lifting Lug: InputsBahtiar Anak LaNangNoch keine Bewertungen

- Petrol TanksDokument58 SeitenPetrol TanksKroya HunNoch keine Bewertungen

- 3-Leg Calculation for Vertical Vessel SupportDokument21 Seiten3-Leg Calculation for Vertical Vessel SupportBahtiar Anak LaNangNoch keine Bewertungen

- Rectangular Tank CalculationDokument9 SeitenRectangular Tank CalculationFabrício Menegassi75% (4)

- Flare Boom vs. Vent BoomDokument18 SeitenFlare Boom vs. Vent BoomUmdpmg Ursa100% (3)

- 4140 High Tensile Steel PDFDokument3 Seiten4140 High Tensile Steel PDFFikri SiplhoNoch keine Bewertungen

- MFLLC 704 PLDokument3 SeitenMFLLC 704 PLBahtiar Anak LaNangNoch keine Bewertungen

- 4140 High Tensile Steel PDFDokument3 Seiten4140 High Tensile Steel PDFFikri SiplhoNoch keine Bewertungen

- Tabel Plat BajaDokument6 SeitenTabel Plat BajaAlexander Ignatius100% (2)

- Heat Conduction Pipe InsulationDokument1 SeiteHeat Conduction Pipe InsulationBahtiar Anak LaNangNoch keine Bewertungen

- 4140 High Tensile Steel PDFDokument3 Seiten4140 High Tensile Steel PDFFikri SiplhoNoch keine Bewertungen

- Contact Stress Between 90 Crossed Cylinders: Module 9-3Dokument2 SeitenContact Stress Between 90 Crossed Cylinders: Module 9-3Bahtiar Anak LaNangNoch keine Bewertungen

- Overall Heat Transfer CoefficientDokument1 SeiteOverall Heat Transfer CoefficientBahtiar Anak LaNangNoch keine Bewertungen

- Section Viii Div 1 Div 2 Div ComparisonDokument2 SeitenSection Viii Div 1 Div 2 Div Comparisonapparaokr100% (5)

- DR Response SheetDokument2 SeitenDR Response SheetBahtiar Anak LaNangNoch keine Bewertungen

- Contact Stress Between 90 Crossed Cylinders: Module 9-3Dokument2 SeitenContact Stress Between 90 Crossed Cylinders: Module 9-3Bahtiar Anak LaNangNoch keine Bewertungen

- Overall Heat Transfer CoefficientDokument1 SeiteOverall Heat Transfer CoefficientBahtiar Anak LaNangNoch keine Bewertungen

- Overall Heat Transfer CoefficientDokument1 SeiteOverall Heat Transfer CoefficientBahtiar Anak LaNangNoch keine Bewertungen

- Overall Heat Transfer CoefficientDokument1 SeiteOverall Heat Transfer CoefficientBahtiar Anak LaNangNoch keine Bewertungen

- Wrench StandardDokument0 SeitenWrench StandardBahtiar Anak LaNangNoch keine Bewertungen

- Overall Heat Transfer CoefficientDokument1 SeiteOverall Heat Transfer CoefficientBahtiar Anak LaNangNoch keine Bewertungen

- Bolt Torq. (Moss+Farr)Dokument9 SeitenBolt Torq. (Moss+Farr)Bahtiar Anak LaNang100% (1)

- Pipe LineDokument62 SeitenPipe LineBahtiar Anak LaNang100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Septic Vault Plan: National Housing AuthorityDokument1 SeiteSeptic Vault Plan: National Housing AuthorityDJNoch keine Bewertungen

- Useful ECBC Tables and TermsDokument17 SeitenUseful ECBC Tables and TermsAnoop SharmaNoch keine Bewertungen

- Guide For Fire Protection and Detection SystemDokument50 SeitenGuide For Fire Protection and Detection SystemGreenbuild ZM-JV100% (1)

- 105 0020 4100B - Nov2018 PDFDokument4 Seiten105 0020 4100B - Nov2018 PDFdevendra bansalNoch keine Bewertungen

- Plate Heat Exchanger Design & Application GuideDokument56 SeitenPlate Heat Exchanger Design & Application GuidefelitosegundoNoch keine Bewertungen

- Selecting HEX in OffshoreDokument44 SeitenSelecting HEX in OffshoreRendy CkNoch keine Bewertungen

- Core permeability and porosity test resultsDokument7 SeitenCore permeability and porosity test resultsJordan WongNoch keine Bewertungen

- Hydrau EXAM-4 - ActualDokument1 SeiteHydrau EXAM-4 - ActualGeraldNoch keine Bewertungen

- CV Calculator Explanation PDFDokument2 SeitenCV Calculator Explanation PDFBill M. SpragueNoch keine Bewertungen

- Pool Equipment Installation GuideDokument29 SeitenPool Equipment Installation GuideIoan BogdanNoch keine Bewertungen

- BORSIG Process Heat Exchanger - Transfer Line ExchangersDokument28 SeitenBORSIG Process Heat Exchanger - Transfer Line ExchangersKarna2504100% (1)

- Ultra-Frac High Performance TraysDokument4 SeitenUltra-Frac High Performance Traysnatee8632Noch keine Bewertungen

- Omega - 1384.021-10 - LeafletDokument2 SeitenOmega - 1384.021-10 - LeafletJorge VillalobosNoch keine Bewertungen

- Brunner-Emmett-Teller Theory: Presented By: Tehseen Zehra Uswa Zahra Muntaha Nasir Summayya ShafiqueDokument22 SeitenBrunner-Emmett-Teller Theory: Presented By: Tehseen Zehra Uswa Zahra Muntaha Nasir Summayya ShafiqueSummayya ShafiqueNoch keine Bewertungen

- Week 4 - Assignment 1 Multiple Choice QuestionsDokument3 SeitenWeek 4 - Assignment 1 Multiple Choice QuestionschandrakiranNoch keine Bewertungen

- Heat Output Calculation Summary With Mixed Coke Oven GasDokument13 SeitenHeat Output Calculation Summary With Mixed Coke Oven GasRamachandra Bhat HireNoch keine Bewertungen

- 40QBG QBU CatalogDokument4 Seiten40QBG QBU CatalogKhun WunNoch keine Bewertungen

- PPTDokument16 SeitenPPTShrvan HirdeNoch keine Bewertungen

- Env Impact Assessment KelticPetroDokument249 SeitenEnv Impact Assessment KelticPetrorome_n21Noch keine Bewertungen

- NASA Presentation CFD HistoryDokument78 SeitenNASA Presentation CFD Historyjamesmoro0408Noch keine Bewertungen

- Vortex SheddingDokument19 SeitenVortex Sheddingprraaddeej chatelNoch keine Bewertungen

- Estimating Heat Sink Thermal ResistanceDokument6 SeitenEstimating Heat Sink Thermal ResistanceRAHUL VEERNoch keine Bewertungen

- Thermal Energy Storage For Building HVAC SystemDokument20 SeitenThermal Energy Storage For Building HVAC SystemabhijeetNoch keine Bewertungen

- LSTK Contract Areas of Concern with Action PlanDokument106 SeitenLSTK Contract Areas of Concern with Action PlanHarish GundaNoch keine Bewertungen

- ME 309 Experimental Analysis Orifice, Venturi and Rotameter Calibration For Flow Rate MeasurementDokument5 SeitenME 309 Experimental Analysis Orifice, Venturi and Rotameter Calibration For Flow Rate MeasurementAneesh Reddy VallapuNoch keine Bewertungen

- 320 B HydraulicDokument2 Seiten320 B HydraulicRudolph Prieto M81% (21)

- Steam Table 1Dokument111 SeitenSteam Table 1John Rey BarbadoNoch keine Bewertungen

- Models Mems Fluid-Structure Interaction COMSOLDokument18 SeitenModels Mems Fluid-Structure Interaction COMSOLgf-antaresNoch keine Bewertungen

- Flow MeasurementDokument37 SeitenFlow MeasurementVarad DateNoch keine Bewertungen

- Plumbing Objective Type QuestionsDokument6 SeitenPlumbing Objective Type QuestionsmanishNoch keine Bewertungen