Beruflich Dokumente

Kultur Dokumente

1 - Color y Humedad de Soya Deshidratada Con Imagenes Hiperespectrales

Hochgeladen von

pameminCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

1 - Color y Humedad de Soya Deshidratada Con Imagenes Hiperespectrales

Hochgeladen von

pameminCopyright:

Verfügbare Formate

Contents lists available at ScienceDirec t

Journal of Food Engineering

journal homepage: www.elsev i er.com/locate/jfooden g

Journal of Food Engineering 128 (2014) 2430

Prediction of color and moisture content for vegetable soybean during drying using hyperspectral imaging technology

Min Huang a,b, Qingguo Wang a, Min Zhang b,, Qibing Zhu a

a

Key Laboratory of Advanced Process Control for Light Industry (Ministry of Education), Jiangnan University, 214122 Wuxi, Jiangsu, China b State Key Laboratory of Food Science and Technology, Jiangnan University, 214122 Wuxi, Jiangsu, China

a r t i c l ei n f o

abstract

Dried soybean is among the most popular snack foods consumed in numerous countries, and its quality has received considerable attention from processors and consumers. Color and moisture content are two critical parameters used to evaluate dried soybean quality. This study thus aimed to develop regression models for predicting the color and moisture content of soybeans simultaneously during the drying process using a hyperspectral imaging technique. Hyperspectral reflectance images were acquired from fresh and dried soybeans over the spectral region between 400 and 1000 nm for 270 samples. After the automatic segmentation of soybean images at each wavelength based on an active contour model, mean reflectance and image entropy parameters were extracted and tested separately and in combination for predicting the color and moisture content of the processed soybeans. Predicting models were built using the partial least squares regression method. Better prediction results for both color and moisture content were achieved using the mean reflectance data (with correlation coefficients or R P = 0.862 and root-mean-square errors of prediction or RMSEP = 1.04 for color, as well as RP = 0.971 and RMSEP = 4.7 % for moisture content) than when using entropy data (RP = 0.839 and RMSEP = 1.14 for color, as well as R P = 0.901 and RMSEP = 9.2% for moisture content). However, the integration of mean reflectance and entropy data did not show significant improvements in predicting the color or moisture content. Overall, a simple hyperspectral imaging technique involving rapid image preprocessing and single spectral features showed significant potential in measuring the color and moisture content of soybeans simultaneously during the drying process. 2013 Elsevier Ltd. All rights reserved.

Article history: Received 8 July 2013 Received in revised form 2 December 2013 Accepted 5 December 2013 Available online 12 December 2013

Keywords: Dried soybean Color Image entropy Hyperspectral imaging Moisture content Prediction modeling

1. Introduction Vegetable soybean [Glycine Max (L.) Merrill], also known by the Japanese term edamame, is a soybean harvested at approximately 80% maturity (Hu et al., 2006b). Soybean is popularly consumed after blanching in China, Korea, Japan, and other countries for its rich protein, fat, calcium, vitamin, and diet fiber content. Soybean also has potential for cancer prevention and suppression owing to its high genistein content (Hu et al., 2006b, 2007; Hou et al., 2011). Color and moisture content are two of the most important parameters in evaluating the drying quality of dried soybeans (Hu et al., 2006a). Color measurements of vegetable soybeans are performed using conventional colorimeters and spectrophotometers after drying. However, these traditional instrumental techniques are time-consuming because of the repeated measurements required to obtain a representative color profile and to reduce the measurement error (Hu et al., 2006b, 2007). Moreover, these instruments

Corresponding author. Fax: +86 510 580 7976. E-mail address: min@jiangnan.edu.cn (M. Zhang). 0260-8774/$ - see front matter 2013 Elsevier Ltd. All rights reserved. http://dx.doi.org/10.1016/j.jfoodeng.2013.12.008

tics of the sample from grayscale or color images). Near-infrared spectroscopy, although used in a wide range of wavelengths, can only acquire spectral information and cannot obtain the spatial information of the samples. Thus, these methods have limitations in that they cannot provide spectral and spatial information

are designed for color measurements on flat surfaces rather than on curved surfaces, which are found in soybeans. The uncertainty of these instrumental measurements might introduce further error in analysis (Aguilera, 2003). The gravimetric oven method and Karl Fisher titration are commonly used laboratory methods for moisture content measurements of agricultural foods and their products. These methods are destructive measurements, such that the same samples cannot be used for further analysis. Moreover, current methods for measuring color and moisture content cannot measure the two parameters simultaneously. Moreover, existing methods are only suitable for testing a small number of vegetable soybeans. Rapid nondestructive technologies for measuring the drying qualities of agricultural products and food products have been studied extensively. Among these approaches, machine vision and near-infrared spectroscopy are the two main methods (Fernndez et al., 2005; Mendoza et al., 2006; Faustino et al., 2007; Lucas et al., 2008; Wu et al., 2010; Romano et al., 2012). However, the conventional machine vision method can only acquire average image information within the visible range (i.e., external characterissimultaneously, which may result in the loss of useful information. As a relatively novel non-destructive technology, hyperspectral imaging integrates the advantages of machine vision and visibleinfrared spectroscopy, while overcoming the drawbacks of both techniques when used alone. Hyperspectral imaging can provide more detailed or complete information, including internal structure characteristics, morphological information, and chemical composition (Huang et al., 2013). This technology has been applied to the nondestructive measurement of agricultural products for evaluating internal quality (Liu et al., 2006; Ariana and Lu, 2008; Huang et al., 2010; Li et al., 2012) and pesticide residues (Del Fiore et al., 2010; Shahin and Symons, 2011; Peng et al., 2011). Thus, this

M. Huang et al. /Journal of Food Engineering 128 (2014) 2430

25

technology may also be used as an alternative for predicting the color and moisture content of vegetable soybeans during drying. The overall objective of this study is to use a hyperspectral reflectance imaging technique in the wavelength range of 400 1000 nm for predicting the color and moisture content of vegetable soybeans simultaneously during drying. The specific objectives are as follows: To extract image traits from preprocessed hyperspectral reflectance images of dried soybeans using mean and entropy methods; and To evaluate the capability of partial least squares regression (PLSR) models for predicting the color and moisture content of vegetable soybeans during drying.

2. Materials and methods 2.1. Raw materials Two hundred and seventy fresh soybeans [Glycine Max (L.) Merrill] harvested from the Garden of Haitong Food Company in Cixi, Zhejiang Province, during the 2012 harvest season were used in this study. The soybeans were washed, peeled and blanched using the microwave heating method and then stored at 4 C and 95 % relative humidity in a refrigerator before the experiments. The soybeans were used within 3 days.

Photonics Inc., Fitchburg, USA) with a 25 lm slit covering an effective range of 4001000 nm and connected to a zoom lens (10004A-21226 Lens, F/1.4 FL23 mm, Standard Barrel, C-Mount., USA), and a computer for controlling the camera and acquiring the images. The light source system consisted of a 150 W DC light source (halogen lamp, EKE, 3250K, Techniquip, USA) and a single optic fiber coupled to a 9 inch parallel light lamp. The sample handling unit consisted of a horizontal motorized stage. Ten soybeans were placed onto a 20 cm 20 cm black background board in two rows and perpendicular to the scanning line of the hyperspectral imaging unit (see Fig. 1). For each group of samples, 625 scans covering a 50 mm distance were acquired at an exposure time of 250 ms for each hyperspectral reflectance image. The hyperspectral imaging system had 0.15 mm/pixel spatial resolution and 0.644 nm/pixel spectral resolution covering the spectral region of 4001000 nm using a 1392 pixel camera. After 10 spectral binning operations, the resultant hyperspectral reflectance images had 6.44 nm/pixel spectral resolution and 94 wavelengths. Thus, a spatial block of a 1392 625 94 image was created, which was represented by a 2-D image with x-axis and y-axis coordinate information. Another axis was represented by spectral information. The darkness and reflectance images of white Teflon were also acquired for every six groups of samples and used as reference to obtain relative reflectance images. 2.4. Reference measurements A CR-400 Chroma Meter (Konica Minolta Sensing, Inc., Japan) was used for soybean surface color measurements. Color difference (DE) was used to describe the color change in the fresh and dried samples and was calculated as follows:

2.2. Microwave-assisted pulse-spouted bed vacuum-drying Vegetable soybeans were dried using a high-precision laboratory dryer developed at the State Key Laboratory of Food Science and Technology, Jiangnan University, China. This microwave-assisted pulse-spouted bed vacuum-drying (PSMVD) experimental system essentially consisted of seven units: (a) a cylindrical multimode microwave cavity, (b) two circular vacuum drying chambers, (c) a pulse-spouted system as a nitrogen gas source, (d) a refrigeration system with a set of air-cooling refrigeration compressor units, (e) a vacuum system, (f) two energy supply systems, and (g) a water load system to prevent magnetron from overheating using a cooling/heating circulating water unit. A detailed description of the dryer system is given by Wang et al. (2013). In this study, the experimental parameters were set as follows: (1) the pressure was set at 9 1 kPa; (2) the power was set to 516 W; and (3) the samples were spouted in the preselected time interval of 1 s and held for 3 s by allowing nitrogen gas to flow periodically into the drying chamber. Fresh soybeans with a mass of 200 g were used for each trial. To achieve broad sample distribution of color and moisture content, eight groups at different drying times (from 10 min to 80 min, in steps of 10 min) were tested. The experiments were replicated thrice for each drying condition. Fresh and dried samples were measured using the hyperspectral imaging system and then tested using reference methods for color and moisture content. 2.3. Hyperspectral reflectance image acquisition An in-house developed line-scan hyperspectral reflectance imaging system was used to acquire hyperspectral reflectance images of soybeans. The hyperspectral reflectance image system mainly consisted of a hyperspectral imaging unit, a light source, and a sample handling platform. The hyperspectral imaging unit comprised a back-illuminated 1392 1024 pixel charge-coupled device (CCD) camera (Pixelfly QE IC285AL, Cooke, USA), an imaging spectrograph (1003A-10140 Hyperspc VNIR C-Series, Headwall

Fig. 1. Schematic of the hyperspectral reflectance imaging system.

DE qffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffif fiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi a ffiffiffiffiffiffiffiffiffi L0 L2 0 a2 b0 b2 1

where L0; a0 and b0 are the color readings of standard white plate at D65 illumination (L0 97:06; a0 0:04; and b0 2:01). Two measurements were performed per soybean (at each side of the grain), and the average value was recorded as the reference color of each grain sample. The moisture content, expressed in percent wet basis (% w.b.), was measured by the gravimetric method using a convection oven (GB/T8858-88, National Standard of China). The samples dried at different times using the PSMVD experimental system were placed into the oven (Binder FED, Berlin, Germany) at 105 C for 78 h until they reached a constant weight. The weight was measured using an analytical balance (Hengping FA1104, Shanghai, China; 0.0001 g). Finally, moisture content was calculated.

26

M. Huang et al./ Journal of Food Engineering 128 (2014) 24 30

2.5. Data analysis 2.5.1. Image preprocessing To compensate for the light source variation effect, relative reflectance was used and obtained using the following equation:

physical and chemical information on the samples. Image entropy can be used to describe the uniformity or randomness of the pixel intensity in the reflectance image (Zhu et al., 2013; Wu et al., 2008) that resulted from the textural changes during drying of the samples. The mean reflectance and entropy are expressed in following equations:

TR TF TD

T S TD 2 R

1 XM XN TRi;j 5 M N i1 j1

where TR is the relative reflectance; TS and TF are the intensity of the sample and of the reference (i.e., Teflon), respectively; and TD is the dark signal for the CCD detector. Thus, all further analyses were conducted on the relative reflectance images. Segmentation of the soybeans from the hyperspectral image background is a key step in extracting the image features used to develop the prediction models. Among the image segmentation methods, the global threshold approach is a traditional technique with the advantages of easy calculation and high efficiency. However, the segmented image is entirely dependent on the selected threshold value. The active contour model (ACM) is taken as a suitable solution to mitigate the problem of threshold selection. The main idea of ACM is to define the energy function of an arbitrary initial closed curve as well as to drive the evolution of the closed curve by minimizing the energy function until the closed curve reaches the object boundaries. ACM has more advantages for image segmentation because it is region-based, thus enabling the delineation of regions defined by smooth intensity. Moreover, this method does not impose any significant initialization constraint (Chan and Vese, 2001). The energy function E(C, c1, c2) is given by

(a) Contour segmentation results for fresh soybeans

Z EC;c1;c2 lLC vS1C k1

C

jI c1j2dxdy k2

inside

jI c2j2dxdy

Coutside

where C is the variable curve. R and K(x, y) = exp (kx yk2/s2) , which depend on C, are the average intensities of the target region and the background region, respectively. lP 0;vP 0, C, and C are fixed parameters. L(C) and S1(C) are respectively the length of the evolving curve C and the area of the region inside C and are expressed as follows: Z

(b) Contour segmentation results for dried soybeans (30 min)

LC

d/x;yjr/x;yjdxdy ZX 4

X where

S1C H/x;ydxdy

s is the definition domain of the original image C; and s and C are the Heaviside and Dirac functions, respectively. By constructing an EulerLagrange equation for /, the / function is updated by recalculating c1 and c2 in each process of curve evolution. Continuous iterations can be attained once the evolution curve reaches the ultimate target boundary to yield the final segmentation results. Fig. 2 shows the contour segmentation result of representative fresh and dried soybeans (after 30 and 60 min) at a 718.2 nm wavelength. 2.5.2. Feature extraction After the automatic segmentation of the image background at each wavelength, a large amount of spatial and spectral information was obtained from the true image of each soybean. Image analysis mainly aims at the effective extraction of useful information. Considering the apparent changes in the soybean surface and the chemical composition of soybean during the drying process, mean reflectance and entropy methods were applied to extract and predict the color and water content characteristics of the dried grains. Similar to near-infrared spectrum, the mean value of relative reflectance images (mean of the i pixel intensity in the image at each wavelength) provides

(c) Contour segmentation results for dried soybeans (60 min)

Fig. 2. Contour segmentation results for fresh and dried soybeans at a wavelength of 718.2 nm.

XM XN H pijlog2pij

i1 j1

pij TRi;j=

XM XN TRi;j

i1 j1

where R is mean reflectance; H is entropy; TR(i, j) is the relative reflectance intensity of pixel (i, j), (i = 1, 2, ...,M j = 1, 2, ...,N); and M, N are the number of total horizontal and vertical pixels for a soybean, respectively. 2.5.3. Regression analysis PLSR was used to predict the color and moisture content using the mean reflectance and entropy feature parameters. In developing the calibration model, 270 samples were randomly divided into two sets: 3/4 of the samples

M. Huang et al. /Journal of Food Engineering 128 (2014) 2430

27

were used for calibration, and the remaining 1/4 was used for prediction (independent validation) after spectral pre-processing using the five-point moving average smooth method. For the mean reflectance and entropy spectra, the mean-center algorithm was used prior to analysis, whereas the autoscale algorithm was employed for mean reflectance combined entropy spectra because their variables have different units. The PLSR models (i.e., selection of the appropriate number of latent variables) were determined by a full cross-validation of the calibration samples using leave-one-out cross validation until the rootmean-square error of cross validation (RMSECV) reached the minimum. After a calibration model was developed, this model was used to predict the independent set of samples that had not been used in the

value of color difference was 54.8, with a standard deviation of 2.1. The moisture content distribution was in the range of 4.967.7 %, with a mean value of 29.0% and a standard deviation of 20.2 %. 3.1. RGB images of fresh and dried soybeans Representative color images of test samples, including fresh and dried soybeans (at 10, 30, 50, and 70 min) with apparent differences in moisture content, are shown in Fig. 3. The samples with higher moisture content appear smooth and rounded with a homogenous glossy surface. As drying time increases, the moisture content decreases, thus causing the samples to have textured and more brittle surfaces. Shrinkage also occurs as the soybean

(a) Fresh soybeans ( 66.4% moisture content)

(b) Soybeans dried for 10 min (54.7% moisture content)

(c) Soybeans dried for 30 min (30.4% moisture content)

(d) Soybeans dried for 50 min (13.4% moisture content)

(e) Soybeans dried for 70 min (9.3% moisture content)

Fig. 3. Color images of fresh and dried soybeans at different drying times (10, 30, 50, and 70 min). (For interpretation of the references to color in this figure legend, the reader is referred to the web version of this article.)

calibration. The calibration and prediction results may vary depending on how the calibration and prediction samples were actually selected. To compare the performance of the mean reflectance and entropy methods better for predicting the color and moisture content of dried soybeans, the calibration and validation procedure described above was repeated 10 times by electing a random set of samples. The average values of the correlation coefficient (i.e., RC, RCV, and RP) and root-meansquare error for calibration and prediction (i.e., RMSEC, RMSECV, and RMSEP) were calculated to evaluate the performance of the models. The PLSR was run in Matlab (2009b) with PLS-Toolbox 5.0 ( Eigenvector Research, Inc., Wenatchee, WA, USA). Finally, a t-test was performed to determine the statistical differences between mean reflectance and entropy methods for predicting the two evaluated quality parameters.

samples lose moisture content. At longer periods of drying (i.e., longer than 50 min as shown in this experiment), the soybean surfaces show some cracks and brittle-appearing fractures.

Wavelength (nm) 3. Results The instrumental measurement of color difference (DE) for the 270 samples, including fresh and dried soybeans of different drying times (from 10 min to 80 min), ranged from 49.9 to 63.2. The mean

28

M. Huang et al./ Journal of Food Engineering 128 (2014) 24 30

outer layers of the grain cells on the surface become unsaturated with moisture, the drying rate falls sharply because the diameters of pores and capillaries decrease. This condition results in the shrinkage and compactness of the surface microstructure. This compact and brittle structure of the soybean probably explains the increase in relative intensity values observed at 50 and 70 min of drying (Fig. 4(a)). Fig. 4(b) shows the representative spectra of entropy for fresh and processed soybeans at different drying times (10, 30, 50, and 70 min). Based on the definition of entropy, more uniform spatial distribution of light intensity results in greater entropy value. Thus, the spectra of entropy decreased homogenously along the spectral wavelengths with the loss of moisture content and increasing drying time. At approximately 660 nm, a downward peak, which corresponds to the wavelength region of chlorophyll

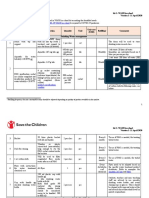

Model Mean Reflectance Entropy Mean Reflectance Combined Entropy

a b RC, c

LVsa 11 19 11

RCb 0.909 0.894 0.908

RMSECc 0.87 0.93 0.87

RCVb 0.881 0.851 0.881

RMSECVc 0.99 1.10 0.99

RPb 0.862 0.839 0.861

RMSEPc,d 1.04

A

RPDe 2.0 1.8 2.0

1.14B 1.04A

Number of LVs. RCV, and RP: correlation coefficient of calibration, cross validation, and prediction, respectively. RMSEC, RMSECV, and RMSEP: root-mean-square error of calibration, cross validation, and prediction, letters (A, B) for the paired RMSEPs in the column indicate significant differences (p 6 0.05) b

respectively. etween prediction m

odels.

d Different e

Ratio of the standard error of performance to the standard deviation of the reference data.

Table 2 Average of 10 calibration and prediction results for moisture content by PLSR models for soybeans. Model LVsa RCb RMSECc (%) Mean Reflectance Entropy Mean Reflectance Combined Entropy

a

RCVb 0.974 0.928 0.972

RMSECVc (%) 4.6 7.5 4.7

RP b 0.971 0.901 0.973

RMSEPc,d (%) 4.7A 9.2B 4.6A

RPDe 4.3 2.1 4.4

15 17 16

0.984 0.954 0.983

3.5 5.9 3.7

Number of LVs. b RC, RCV, and RP: correlation coefficient of calibration, cross validation, and prediction, respectively.

c

RMSEC, RMSECV, and RMSEP: root-mean-square error of calibration, cross validation, and prediction, respectively. d Different letters (A, B) for the paired RMSEPs in the column indicate significant differences (p 6 0.05) between prediction models. e Ratio of the standard error of performance to the standard deviation of the reference data.

Wavelength (nm)

Fig. 4. Relative reflectance (a) and entropy (b) for a fresh soybean at different drying times (10, 30, 50, and 70 min).

absorption, was primarily observed (Fig. 3).

3.3. Prediction models for color and moisture content of dried soybeans Mean, entropy, and their combination were tested for predicting color and moisture content using PLSR models. The color prediction results for the three different feature sets are shown in Table 1. Compared with the entropy method, mean reflectance achieved better results for calibration and prediction models. The average correlation coefficient, R C, of 10 runs was higher by 1.7 %, whereas the average RMSEP values were reduced by 6.4%. For the prediction samples, the mean reflectance model improved the average correlation coefficient RP by 2.7% and the average RMSEP by 8.8%. The paired t-test (p 6 0.05) showed that the PLSR model using entropy had relatively lower prediction results for

3.2. Characterization of relative reflectance and entropy spectra Fig. 4(a) shows the representative relative reflectance spectra for fresh and processed soybeans at different drying times (10, 30, 50, and 70 min). Typical downward peaks were observed in the visible range around 435, 535, and 660 nm, corresponding to carotenoid, anthocyanin, and chlorophyll absorption, respectively. Over the wavelength region of 400920 nm, the relative reflectance for fresh soybeans was generally greater than that for the dried samples. Over the same wavelength range, an evident deTable 1 Average of 10 calibration and prediction results for color by PLSR models for soybeans.

crease in relative intensity was observed at the initial drying periods between 10 and 30 min. Thereafter, the intensity of reflected light tended to increase as observed at 50 and 70 min of drying. At the initial periods of drying, microstructural changes occurred on the surface of the grains because of the evaporation of water in the immediate surroundings of the grain surface. During this initial period, vapor diffusion is the predominant mechanism, and the rate of evaporation or the rate of drying remains constant, thus resulting in discolorations and textural changes on the grain surface going from slight to moderate, as observed between 10 and 30 min of drying (Fig. 3(b) and (c)). However, as soon as the

Actual Color

M. Huang et al. /Journal of Food Engineering 128 (2014) 2430

29

reference data (Huang and Lu, 2010), is an essential parameter in evaluating the performance of prediction models. An RPD between 1.5 and 2 indicates that the model can discriminate low from high values of the response variable. A value between 2 and 2.5 indicates that coarse quantitative predictions are possible, whereas a value between 2.5 and 3 or above corresponds to good and excellent prediction accuracy, respectively (Nicola et al., 2007). In this study, the best RPD values for moisture content models were larger than 4.0, and the best RPD for color prediction models was 2.0. Fig. 5 shows the prediction results for color and moisture content versus the actual measurements for one of the 10 runs using the mean reflectance features. Overall, the relationships for both quality traits confirmed the high correlation values shown in Tables 1 and 2. 4. Discussion Actual Moisture Content (%)

Fig. 5. Prediction of the color (a) and moisture content (b) of soybeans using PLSR models coupled with mean reflectance. (For interpretation of the references to color in this figure legend, the reader is referred to the web version of this article.)

(a) 0.2

0.1 0

LV1 (73.26%)

LV2 (24.02%) -0.1 -0.2 LV3 (2.09%) -0.3 400 500 600 700 800 900 1000

Wavelength (nm)

(b) 0.2

LV1 (65.30%)

0.1 0 -0.1 -0.2

LV3 (2.22%) LV2 (31.75%)

This research demonstrated that the hyperspectral reflectance imaging technique yields good results in predicting the color and moisture content of fresh and dried soybeans during drying. Accurate contours of the soybeans were automatically detected from each spectral image by ACM, which is insensitive to the noise and uneven illumination typical in reflectance images. The ACM segmentation method was easy to implement and exhibited rapid automatic recognition of the weak boundaries and multi-objective images of soybeans, as shown in Fig. 2( a)(c ). Good prediction results for color and moisture content were obtained by the mean reflectance, which can well describe chemical absorption around 660 nm for chlorophyll and 960 nm for moisture. The PLS loadings using mean reflectance (Fig. 6) show that the loading latent variables (LVs) LV2 and LV3 have large loading weights around 960 and 660 nm, respectively, in both calibration models for color and moisture content. These values ensure that color and moisture content information are fully reflected in the PLSR models. Compared with mean reflectance, entropy models yielded inferior results for color and moisture content predictions of dried soybeans. Entropy mainly describes the texture characteristic of an image and appears less sensitive to the change in chemical composition than mean reflectance. This condition results in a relatively lower prediction capability for color and moisture content, as observed in Tables 1 and 2. No statistical differences were found in the prediction results using mean reflectance and a combination of mean reflectance and entropy. One possible reason is that entropy mainly reflects texture information, which cannot express the change in color and moisture directly. Therefore, the combined features cannot offer additional or complementary information for improving the predictions of color and moisture content. The number of LVs is an important factor for describing the performance of calibration models. An excessive number of LVs would deteriorate the reliability and robustness of calibration models. Although slightly more LVs were used in the calibration models,

-0.3 400

500

600

700

800

900

1000

Wavelength (nm)

Fig. 6. Loadings on LV curves for color (a) and moisture content (b) using mean reflectance. (For interpretation of the references to color in this figure legend, the reader is referred to the web version of this article.)

color (RP = 0.839 and RMSEP = 1.14) than that using mean reflectance (RP = 0.862 and RMSEP = 1.04). Moreover, the integration of mean reflectance and entropy data in a regression model were as effective in color prediction as using the mean reflectance data alone. No significant statistical difference was found between these methods (p-value <0.05). Table 2 summarizes the average calibration and prediction results for moisture content. Similar to color prediction, the PLSR model using the mean reflectance achieved the best prediction results for moisture content (RP = 0.973 and RMSEP = 4.7%), which was statistically better than that obtained when using entropy (R P = 0.901 and RMSEP = 9.2%). The ratio of prediction deviation (RPD), that is, the ratio of the standard error of performance to the standard deviation of the

Latent Variable

30

M. Huang et al./ Journal of Food Engineering 128 (2014) 24 30

Latent Variable

Fig. 7. RMSECV versus LV curves for color (a) and moisture content (b). (For interpretation of the references to color in this figure legend, the reader is referred to the web version of this article.)

over fitting was not observed from RMSECV versus latent variable curves (Fig. 7) for the prediction of color and moisture content. According to Shenk et al. (2001), a robust model can be achieved if the corrected standard error of prediction for bias (RMSEPcorrected) does not exceed 1.30 times the RMSEC and when the bias value (BV) does not exceed 0.6 times the RMSEC. In this study, the upper limit values were 1.25 (RMSEPcorrected/RMSEC) and 0.56 (BV/RMSEC), respectively, which indicate that the developed models are robust. Although the models using mean reflectance as features achieved the best results for color and moisture content, more work has to be done to improve prediction accuracy, particularly for color. Future studies would address wavelength-selection approaches to identify the optimal wavelengths among the 94 wavelengths so as to remove the redundant information. Moreover, future works would focus on the evaluation of other image analysis methods for feature extraction (such as Fourier, moments, and fractal analysis). Further improvements would render the technique useful for practical applications. 5. Conclusion Two statistical image features, mean reflectance and entropy, were extracted from hyperspectral images of dried vegetable soybeans in the wavelength range of 4001000 nm and then tested for predicting their color and moisture content using PLSR models. PLSR models with mean reflectance yielded good prediction for color, with RP = 0.862 and RMSEP = 1.04. Compared with the predictions of color, PLSR achieved better results for moisture content (RP = 0.971, RMSEP = 4.7%). The research results indicate that hyperspectral reflectance images over the wavelength range of 4001000 nm can be used to evaluate the color and moisture content of soybeans simultaneously during drying. Acknowledgments The authors gratefully acknowledge the financial support from China 863 HI-TECH R&D Program (No. 2011AA100802), National Natural Science Foundation of China (Grant nos. 61271384 and 61275155), Natural Science Foundation of Jiangsu Province ( China, BK2011148), Postdoctoral Science Foundation of China (Grant nos. 2011M500851 and 2012T50463), the 111 Project (B12018) and PAPD of Jiangsu Higher Education Institutions. References

Aguilera, J.M., 2003. Drying and dried products under the microscope. Food Sci. Technol. Int. 9 (3), 137143.

Ariana, D.P., Lu, R., 2008. Quality evaluation of pickling cucumbers using hyperspectral reflectance and transmittance imagingPart II. Performance of a prototype. Sens. Instrum. Food Qual. Saf. 2 (3), 152160. Chan, T.F., Vese, L.A., 2001. Active contours without edges. IEEE Trans. Image Process. 10 (2), 266277. Del Fiore, A., Reverberi, M., Ricelli, A., Pinzari, F., Serranti, S., Fabbri, A.A., Bonifazi, G., Fanelli, C., 2010. Early detection of toxigenic fungi on maize by hyperspectral imaging analysis. Int. J. Food Microbiol. 144 (1), 6471. Faustino, J.M.F., Barroca, M.J., Guin, R.P.F., 2007. Study of the drying kinetics of green bell pepper and chemical characterization. Food Bioprod. Process. 85, 163170 (3 suppl. C). Fernndez, L., Castillero, C., Aguilera, J.M., 2005. An application of image analysis of dehydration of apple discs. J. Food Eng. 67 (1), 185193. Hou, J., Wang, C., Hong, X., Zhao, J., Xue, C., Guo, N., Gai, J., Xing, H., 2011. Association analysis of vegetable soybean quality traits with SSR markers. Plant Breeding 130 (4), 444449. Hu, Q., Zhang, M., Mujumdar, A.S., Du, W., Sun, J., 2006a. Effects of different drying methods on the quality changes of granular edamame. Drying Technol. 24 (8), 1025 1032. Hu, Q., Zhang, M., Mujumdar, A.S., Xiao, G., Sun, J., 2006b. Drying of edamame by hot air and vacuum microwave combination. J. Food Eng. 77 (4), 977982. Hu, Q., Zhang, M., Mujumdar, A.S., Xiao, G., 2007. Performance evaluation of vacuum microwave drying of edamame in deep-bed drying. Drying Technol. 25 (4), 731736. Huang, M., Lu, R., 2010. Apple mealiness detection using hyperspectral scattering technique. Postharvest Biol. Tecnol. 58 (3), 168175. Huang, M., Wan, X., Zhang, M., Zhu, Q., 2013. Detection of insect-damaged vegetable soybean using hyperspectral transmittance image. J. Food Eng. 116 (1), 4549. Li, J., Rao, X., Ying, Y., 2012. Development of algorithms for detecting citrus canker based on hyperspectral reflectance imaging. J. Sci. Food Agr. 92 (1), 125134. Liu, Y., Chen, Y., Wang, C., Chan, D., Kim, M.S., 2006. Development of hyperspectral imaging technique for the detection of chilling injury in cucumbers; spectral and image analysis. Appl. Eng. Agric. 22 (1), 101111. Lucas, A., Andueza, D., Rock, E., Martin, B., 2008. Prediction of dry matter, Fat, pH, vitamins, minerals, carotenoids, total antioxidant capacity, and color in fresh and freezedried cheeses by visible-near-infrared reflectance spectroscopy. J. Agr. Food Chem. 56 (16), 68016808. Mendoza, F., Dejmek, P., Aguilera, J.M., 2006. Calibrated color measurements of agricultural foods using image analysis. Postharvest Biol. Tecnol. 41 (3), 285 295. Nicola, B.M., Beullens, K., Bolelyn, E., Peirs, A., Saeys, W., Theron, K.I., Lammertyn, J., 2007. Nondestructive measurement of fruit and vegetable quality by means of NIR spectroscopy: a review. Postharvest Biol. Tecnol. 46 (2), 99118. Peng, Y., Zhang, J., Wang, W., Li, Y., Wu, J., Huang, H., Gao, X., Jiang, W., 2011. Potential prediction of the microbial spoilage of beef using spatially resolved hyperspectral scattering profiles. J. Food Eng. 102 (2), 163169. Romano, G., Argyropoulos, D., Nagle, M., Khan, M.T., Mller, J., 2012. Combination of digital images and laser light to predict moisture content and color of bell pepper simultaneously during drying. J. Food Eng. 109 (3), 438448. Shahin, M.A., Symons, S.J., 2011. Detection of fusarium damaged kernels in Canada western red spring wheat using visible/infrared hyperspectral imaging and principle component analysis. Comput. Electron. Agr. 75 (1), 107112. Shenk, J.S., Workman, J.J., Westerhaus, M.O., Bums, D.A., Ciurczak, E.W., 2001. Application of NIR spectroscopy to agricultural products. Pract. Spectrosc. Ser. 27, 419 474. Wang, Y., Zhang, M., Mujumdar, S.A., Mothibe Joseph, K., 2013. Microwave-assisted pulsespouted bed freeze-drying of stem lettuce slices-effect on product quality. Food Bioprocess Tech. 6 (12), 35303543. Wu, D., Yang, H., Chen, X., He, Y., Li, X., 2008. Application of image texture for the sorting of tea categories using multi-spectral imaging technique and support vector machine. J. Food Eng. 88 (4), 474483. Wu, D., He, Y., Nie, P., Cao, F., Bao, Y., 2010. Hybrid variable selection in visible and nearinfrared spectral analysis for non-invasive quality determination of grape juice. Anal. Chim. Acta 659 (12), 229237. Zhu, Q., Feng, Z., Huang, M., Zhu, X., 2013. Maize seed identification using hyperspectral imaging and SVDD algorithm. Spectrosc. Spect. Anal. 33 (2), 517521.

Das könnte Ihnen auch gefallen

- C9 Check Your Progress File 9Dokument5 SeitenC9 Check Your Progress File 9pameminNoch keine Bewertungen

- P4 Practical English Episode 4 What S The DateDokument1 SeiteP4 Practical English Episode 4 What S The DatepameminNoch keine Bewertungen

- C6 Check Your Progress File 6 1Dokument1 SeiteC6 Check Your Progress File 6 1pameminNoch keine Bewertungen

- P6 Practical English Episode 6 Is There A Bank Near HereDokument1 SeiteP6 Practical English Episode 6 Is There A Bank Near HerepameminNoch keine Bewertungen

- PaperDokument11 SeitenPaperpameminNoch keine Bewertungen

- 1 - Color y Humedad de Soya Deshidratada Con Imagenes HiperespectralesDokument7 Seiten1 - Color y Humedad de Soya Deshidratada Con Imagenes HiperespectralespameminNoch keine Bewertungen

- 1 - Color y Humedad de Soya Deshidratada Con Imagenes HiperespectralesDokument7 Seiten1 - Color y Humedad de Soya Deshidratada Con Imagenes HiperespectralespameminNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- 3.1 Radiation in Class Exercises IIDokument2 Seiten3.1 Radiation in Class Exercises IIPabloNoch keine Bewertungen

- EMI-EMC - SHORT Q and ADokument5 SeitenEMI-EMC - SHORT Q and AVENKAT PATILNoch keine Bewertungen

- Double Inlet Airfoil Fans - AtzafDokument52 SeitenDouble Inlet Airfoil Fans - AtzafDaniel AlonsoNoch keine Bewertungen

- A Study On Effective Training Programmes in Auto Mobile IndustryDokument7 SeitenA Study On Effective Training Programmes in Auto Mobile IndustrySAURABH SINGHNoch keine Bewertungen

- Emco - Unimat 3 - Unimat 4 LathesDokument23 SeitenEmco - Unimat 3 - Unimat 4 LathesEnrique LueraNoch keine Bewertungen

- Divider Block Accessory LTR HowdenDokument4 SeitenDivider Block Accessory LTR HowdenjasonNoch keine Bewertungen

- Review Questions Financial Accounting and Reporting PART 1Dokument3 SeitenReview Questions Financial Accounting and Reporting PART 1Claire BarbaNoch keine Bewertungen

- Opel GT Wiring DiagramDokument30 SeitenOpel GT Wiring DiagramMassimiliano MarchiNoch keine Bewertungen

- Vylto Seed DeckDokument17 SeitenVylto Seed DeckBear MatthewsNoch keine Bewertungen

- Ahakuelo IndictmentDokument24 SeitenAhakuelo IndictmentHNNNoch keine Bewertungen

- Fact Pack Financial Services KenyaDokument12 SeitenFact Pack Financial Services KenyaCatherineNoch keine Bewertungen

- Verma Toys Leona Bebe PDFDokument28 SeitenVerma Toys Leona Bebe PDFSILVIA ROMERO100% (3)

- SCHEDULE OF FEES - FinalDokument1 SeiteSCHEDULE OF FEES - FinalAbhishek SunaNoch keine Bewertungen

- Fcode 54 en El SytucDokument2 SeitenFcode 54 en El SytucAga MenonNoch keine Bewertungen

- Triplex (Triple Full Free Panoramic) Mast (5M15D To 5M35D) : Structure and FunctionDokument2 SeitenTriplex (Triple Full Free Panoramic) Mast (5M15D To 5M35D) : Structure and FunctionMaz Ariez EkaNoch keine Bewertungen

- SyllabusDokument9 SeitenSyllabusrr_rroyal550Noch keine Bewertungen

- People V Superior Court (Baez)Dokument19 SeitenPeople V Superior Court (Baez)Kate ChatfieldNoch keine Bewertungen

- Unit List MUZAFFARPUR - Feb 18 PDFDokument28 SeitenUnit List MUZAFFARPUR - Feb 18 PDFPawan Kumar100% (1)

- 14 CE Chapter 14 - Developing Pricing StrategiesDokument34 Seiten14 CE Chapter 14 - Developing Pricing StrategiesAsha JaylalNoch keine Bewertungen

- Contemp World Module 2 Topics 1 4Dokument95 SeitenContemp World Module 2 Topics 1 4Miguel EderNoch keine Bewertungen

- BS As On 23-09-2023Dokument28 SeitenBS As On 23-09-2023Farooq MaqboolNoch keine Bewertungen

- Pet Care in VietnamFull Market ReportDokument51 SeitenPet Care in VietnamFull Market ReportTrâm Bảo100% (1)

- Modeling and Fuzzy Logic Control of A Quadrotor UAVDokument5 SeitenModeling and Fuzzy Logic Control of A Quadrotor UAVAnonymous kw8Yrp0R5rNoch keine Bewertungen

- Kit 2: Essential COVID-19 WASH in SchoolDokument8 SeitenKit 2: Essential COVID-19 WASH in SchooltamanimoNoch keine Bewertungen

- RFM How To Automatically Segment Customers Using Purchase Data and A Few Lines of PythonDokument8 SeitenRFM How To Automatically Segment Customers Using Purchase Data and A Few Lines of PythonSteven MoietNoch keine Bewertungen

- U2 - Week1 PDFDokument7 SeitenU2 - Week1 PDFJUANITO MARINONoch keine Bewertungen

- Moparm Action - December 2014 USADokument100 SeitenMoparm Action - December 2014 USAenricoioNoch keine Bewertungen

- MML3 Journal To CapcomDokument103 SeitenMML3 Journal To CapcomFer BarcenaNoch keine Bewertungen

- Rules On Evidence PDFDokument35 SeitenRules On Evidence PDFEuodia HodeshNoch keine Bewertungen

- Si KaDokument12 SeitenSi KanasmineNoch keine Bewertungen