Beruflich Dokumente

Kultur Dokumente

Horizontal Autoclave Sterilizers Specifications

Hochgeladen von

Bala ReddyCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Horizontal Autoclave Sterilizers Specifications

Hochgeladen von

Bala ReddyCopyright:

Verfügbare Formate

Horizontal High Pressure Steam Sterilizer (Autoclave Horizontal):Main Equipment:1. 2. 3.

It should be High Pressure Steam Sterilizer Bearing ISI mark Is: 38291. Size should e approx. 500mm 900mm (20 36) (diameter length). The chamber material should be constructed of heavy duty SS 316 of 6mm thickness with full argon welding. 4. The chamber material and construction should meet ASME standards for unfired vessels. 5. Door will be constructed of SS 316 grade & should be provided with Silicone gasket, automatic safety locking & unlocking devices. 6. Chamber & door of the sterilizer should be designed for working under positive pressure upto 21 psi at temperature of 115C-121C. 7. The autoclave should be insulated with 50mm thick resin bonded glass wool enclosed with a stainless steel outer skin. 8. Pipes and fitting should be of SS & bronze fitted with ball type & solenoid valve. 9. A multiport valve should be provided for operating cycle in manual mode. 10. Electrical steam generator and Boiler Plate made of Stainless steel and gauge glass tube with protector for viewing of water level. 11. Air over Steam pulsing Pressure System. 12. Safety valves, self sterilizing vacuum drier, Presser Gauge, Compound gauge, Steam trap, Swing Check Valve Y Screen Plug. 13. Pressure control device to be incorporated. 14. Equipment should have warranty of one year and AMC for 5 years of equipment. Optional:1. 2.

Automatic high pressure water feeding pump Digital Temperature gauge.

Purchase of Fully Automatic Horizental Cylinder High Speed Sterilizer Technical Specifications are as under:Technical Specification of P.L.C. controlled Fully Automatic Horizontal Cylindrical High Speed Steam Sterilizer 1. It should be High Speed Steam Sterilizer Bearing BIS MARK IS:3829 2. Size should be approx. 400mm x 600mm (16 x 24) 3. The chamber should be constructed of heavy duty S.S. 316 of 6 mm thickness with full argon welding 4. The chamber material and construction should meet ASME standards for unfired vessels. 5. Door should be constructed of S.S. 304 grade & should be provided with Silicone gasket, automatic safety locking & unlocking devices. 6. Chamber & door of the sterilizer should be designed for working under positive pressure up to 31 psi at temperature of 130 0. C-135 0 C. 7. The autoclave should be insulated with 50 mm thick resin bonded glass wool enclosed with a stainless steel outer skin. 8. Pipes and fittings should be of SS & bronze fitted with ball type & solenoid valve 9. The sterilizer should be complete with a water ring vacuum pump.

10. The autoclave should be fully programmable with PLC based technology to control & monitor different sterilizing cycles depending upon the load. P.L.C. should be of 4 Line display (80 characters) displaying Date, Time, Pressure Temperature & status of the load. 11. The autoclave should be equipped with a printer to record & print the information during the cycle such as temperature, pressure, cycle time etc. 12. A Multiport valve should be provided for operating cycle in manual mode in case of P.L.C. failure. 13. There should be automatic system for operating sterilizer, controlled with Air break contactors, Pressure switches, Solenoid Valves with electronic power supply. Electrical steam generator and Boiler Plate made of Stainless Steel and gauge glass tube with protector for viewing of water level. 14. There should beAir Over Steam Pulsing Pressure System. 15. Automatic high pressure water feeding pump should be supplied 16. Safety valves, Self sterilizing vacuum drier, Pressure gauge, Compound gauge, Steam trap, Swing Check Valve & Screen Plug should be there. 17. The sterilizer should be fitted with 18 KW heaters 18. Equipment should have warranty of two year and AMC for 5 years of equipment.

Das könnte Ihnen auch gefallen

- GS 30RB 27PDDokument9 SeitenGS 30RB 27PDKike PadillaNoch keine Bewertungen

- 2 Microprocessor Chiller Installation Technical SpecsDokument12 Seiten2 Microprocessor Chiller Installation Technical Specsoth369Noch keine Bewertungen

- Medical Gas Pipeline SystemDokument16 SeitenMedical Gas Pipeline Systemshivangiis0796511Noch keine Bewertungen

- WC Centrifugal Chiller 400V-SSDokument8 SeitenWC Centrifugal Chiller 400V-SSAhmadNoch keine Bewertungen

- CHWDokument11 SeitenCHWdeepakajaydasNoch keine Bewertungen

- Central HeatingDokument6 SeitenCentral Heatingsumit11235Noch keine Bewertungen

- Wet Riser SpecificationDokument4 SeitenWet Riser SpecificationshihabnittNoch keine Bewertungen

- Steriline TunnelDokument8 SeitenSteriline TunnelHutHeoNoch keine Bewertungen

- Specification: Electronic Level TransmitterDokument11 SeitenSpecification: Electronic Level TransmitterTushar BhingradiyaNoch keine Bewertungen

- SD G 100 Iqf FreezerDokument7 SeitenSD G 100 Iqf FreezerEric Wang100% (1)

- Boiler Sicc 209 SpteDokument8 SeitenBoiler Sicc 209 SpteMarius Sofariu0% (2)

- Yk Maxe Chiller MEP-10100 SM BLVD: EneralDokument7 SeitenYk Maxe Chiller MEP-10100 SM BLVD: EneralSevero SeveroNoch keine Bewertungen

- Pulsating Vacuum Sterilizer Technical SpecificationsDokument7 SeitenPulsating Vacuum Sterilizer Technical SpecificationsSivaNoch keine Bewertungen

- ASMR620-60 Heated Air Circulating Tunnel Oven Operation ManualDokument23 SeitenASMR620-60 Heated Air Circulating Tunnel Oven Operation ManualanaNoch keine Bewertungen

- M322-Final 2014-4-3Dokument13 SeitenM322-Final 2014-4-3Luis Fernando Flores FigueirasNoch keine Bewertungen

- Adsobtion Chiller SpecDokument6 SeitenAdsobtion Chiller Specioan1946Noch keine Bewertungen

- Chapter - 1 Stack Monitoring Material and Methodology For Isokinetic SamplingDokument97 SeitenChapter - 1 Stack Monitoring Material and Methodology For Isokinetic SamplingAbrahamChongNoch keine Bewertungen

- Labsol Product CatalogDokument108 SeitenLabsol Product Catalogasingh400Noch keine Bewertungen

- Manual ECG - en - v2.1Dokument25 SeitenManual ECG - en - v2.1JeremyYmerehNoch keine Bewertungen

- Part A - Hvac Technical Specifications 1. Hot Water GeneratorDokument25 SeitenPart A - Hvac Technical Specifications 1. Hot Water GeneratorAnand_HvacNoch keine Bewertungen

- Outdoor Air-Cooled Liquid Chiller: HVAC Guide SpecificationsDokument6 SeitenOutdoor Air-Cooled Liquid Chiller: HVAC Guide SpecificationsAbdul Rehman ZafarNoch keine Bewertungen

- VAQ Station For Climate Control: Application NotesDokument11 SeitenVAQ Station For Climate Control: Application NotesAnkit JainNoch keine Bewertungen

- Specification of Multipurpose Fire TenderDokument8 SeitenSpecification of Multipurpose Fire TenderMd SaddamNoch keine Bewertungen

- Refrigerant PipingDokument8 SeitenRefrigerant PipingfaltuNoch keine Bewertungen

- 35,000 kg/hr Water-Tube Boiler Design & Construction SpecDokument7 Seiten35,000 kg/hr Water-Tube Boiler Design & Construction SpecRabindranath Hendy TagoreNoch keine Bewertungen

- Compliance Statement ElmDokument5 SeitenCompliance Statement ElmdeepakjoyinNoch keine Bewertungen

- Hot Water Adsorption Chillers Guide SpecificationsDokument6 SeitenHot Water Adsorption Chillers Guide Specificationsmdalt9180Noch keine Bewertungen

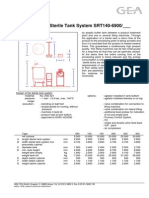

- Technical Data: Sterile Tank System SRT140-6900Dokument2 SeitenTechnical Data: Sterile Tank System SRT140-6900Luis Guillermo Echeverri LopezNoch keine Bewertungen

- 20 ACV Smart 600-800 Carte Tehnica CI 06.01.25 MLDokument6 Seiten20 ACV Smart 600-800 Carte Tehnica CI 06.01.25 MLSoficu DanielNoch keine Bewertungen

- Guide Specifications: Commercial Air-Cooled Condensing Units HVAC Guide SpecificationsDokument4 SeitenGuide Specifications: Commercial Air-Cooled Condensing Units HVAC Guide SpecificationshtanhNoch keine Bewertungen

- Section 2 Water Chilling Unit (Screw) GeneralDokument5 SeitenSection 2 Water Chilling Unit (Screw) GeneralmatzoyekNoch keine Bewertungen

- Iqf Tunnel Freezer, 1000kg Per Hour CapacityDokument12 SeitenIqf Tunnel Freezer, 1000kg Per Hour CapacityEric WangNoch keine Bewertungen

- Fired Heater Specification PDFDokument5 SeitenFired Heater Specification PDFsvnaik14100% (1)

- High Pressure Steam Sterilizer AutoclavesDokument4 SeitenHigh Pressure Steam Sterilizer AutoclavesCarlos Guanipa100% (3)

- Triple Walled Horizontal AutoclaveDokument11 SeitenTriple Walled Horizontal AutoclaveYash KumarNoch keine Bewertungen

- Determination of Low Water Contents in PlasticsDokument5 SeitenDetermination of Low Water Contents in Plasticsyouni_2005Noch keine Bewertungen

- Edta Cleaning PassivationDokument40 SeitenEdta Cleaning Passivationsuleman247100% (1)

- 19DV Guide Specifications, 350 To 800 Nominal Tons (1231 To 2814 Nominal KW) - Published Date 8.4.2020Dokument10 Seiten19DV Guide Specifications, 350 To 800 Nominal Tons (1231 To 2814 Nominal KW) - Published Date 8.4.2020anganNoch keine Bewertungen

- Cooling TunnelDokument7 SeitenCooling TunnelAmit Kumar OjhaNoch keine Bewertungen

- Air Cooled Screw ChillersDokument12 SeitenAir Cooled Screw ChillersAhmadNoch keine Bewertungen

- Boiler SpecificationsDokument19 SeitenBoiler Specificationspaul kioiNoch keine Bewertungen

- Especificaciones Tecnicas Apc Aa InrowDokument6 SeitenEspecificaciones Tecnicas Apc Aa InrowWilder Phill Arzapalo GinesNoch keine Bewertungen

- Steam, Domestic Storage Water HeaterDokument7 SeitenSteam, Domestic Storage Water Heaterbandithaguru6338Noch keine Bewertungen

- Spcification Fo DG SetDokument6 SeitenSpcification Fo DG Setnirmalb21Noch keine Bewertungen

- 1B) Manicooler & Outlet BoxDokument2 Seiten1B) Manicooler & Outlet BoxSonthi MooljindaNoch keine Bewertungen

- Section 4 Air Handling Units - Double Skin ScopeDokument4 SeitenSection 4 Air Handling Units - Double Skin ScopematzoyekNoch keine Bewertungen

- Humidity Conditioning Cabinet HCC cw1602 m44 Secured 2Dokument16 SeitenHumidity Conditioning Cabinet HCC cw1602 m44 Secured 2OMATNoch keine Bewertungen

- Environmental chamber temperature and humidity test rangesDokument3 SeitenEnvironmental chamber temperature and humidity test rangesdéborah_rosalesNoch keine Bewertungen

- Enquiry - FFTG - Sprinkle - ValvesDokument8 SeitenEnquiry - FFTG - Sprinkle - Valvesrkpatel40Noch keine Bewertungen

- MRO 4-V Specifications (6-176)Dokument5 SeitenMRO 4-V Specifications (6-176)jmharrison3196Noch keine Bewertungen

- Rowan University Design Guide 2013Dokument4 SeitenRowan University Design Guide 2013zeliteNoch keine Bewertungen

- Blood Bank Refrigerator SpecsDokument5 SeitenBlood Bank Refrigerator SpecsambitiousamitNoch keine Bewertungen

- Laundry DesignDokument11 SeitenLaundry DesignrajevskumarNoch keine Bewertungen

- Kencana Square Water-Cooled Chiller GuideDokument11 SeitenKencana Square Water-Cooled Chiller Guidejames_chan2178Noch keine Bewertungen

- Optima 7300 V and 8300 Preparing Your LabDokument7 SeitenOptima 7300 V and 8300 Preparing Your LabmvidalaguilarNoch keine Bewertungen

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitVon EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNoch keine Bewertungen

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsVon EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNoch keine Bewertungen

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesVon EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersVon EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNoch keine Bewertungen

- Valve Selection Handbook: Engineering Fundamentals for Selecting the Right Valve Design for Every Industrial Flow ApplicationVon EverandValve Selection Handbook: Engineering Fundamentals for Selecting the Right Valve Design for Every Industrial Flow ApplicationBewertung: 4.5 von 5 Sternen4.5/5 (21)

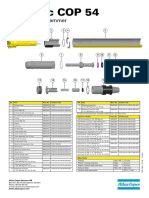

- 9853 1239 01 - COP 54 Service Poster - LOWDokument1 Seite9853 1239 01 - COP 54 Service Poster - LOWValourdos LukasNoch keine Bewertungen

- Schneider LV Switchboard Inspection GuideDokument59 SeitenSchneider LV Switchboard Inspection GuideAlp Arslan Ok100% (1)

- EXPERIMENT 3a and 3b - Aluminum Content Via Redox and ColorimeterDokument13 SeitenEXPERIMENT 3a and 3b - Aluminum Content Via Redox and ColorimeterTrupti soniNoch keine Bewertungen

- Final ReportDokument33 SeitenFinal ReporttsutsenNoch keine Bewertungen

- Government Engineering College Surveying Lab ManualDokument26 SeitenGovernment Engineering College Surveying Lab ManualNittin BhagatNoch keine Bewertungen

- Usn LM2500 Asme Paper GT2010-22811 61410 JalDokument7 SeitenUsn LM2500 Asme Paper GT2010-22811 61410 Jalferrerick0% (1)

- Analysis, Specification and Estimate On Road WorksDokument71 SeitenAnalysis, Specification and Estimate On Road WorksAnonymous BACdUNvPZ280% (5)

- MI MetadataDokument310 SeitenMI MetadataMatthew McCreadyNoch keine Bewertungen

- Minor Project Report On Efficiency Improvement of A Combined Cycle Power PlantDokument40 SeitenMinor Project Report On Efficiency Improvement of A Combined Cycle Power PlantArpit Garg100% (1)

- Design of A Fluidized Drum GranulatorDokument6 SeitenDesign of A Fluidized Drum GranulatorditchcheNoch keine Bewertungen

- Aso Airfield Standards Quick ReferenceDokument66 SeitenAso Airfield Standards Quick ReferenceRahul RanaNoch keine Bewertungen

- Smarter and Safer: Cordless Endodontic HandpieceDokument2 SeitenSmarter and Safer: Cordless Endodontic Handpiecesonu1296Noch keine Bewertungen

- 2 CAD Connecting Rod ForgingDokument56 Seiten2 CAD Connecting Rod ForgingIsrar EqubalNoch keine Bewertungen

- Achievements Under EpiraDokument6 SeitenAchievements Under EpiraLyn Dela Cruz DumoNoch keine Bewertungen

- 50TJDokument56 Seiten50TJHansen Henry D'souza100% (2)

- YZ250 Off-Road Bike Parts CatalogDokument55 SeitenYZ250 Off-Road Bike Parts Catalogdwiyanti20Noch keine Bewertungen

- Network What To ReadDokument2 SeitenNetwork What To ReadTauseef AhmadNoch keine Bewertungen

- Apache Oozie - A workflow scheduler to manage Hadoop jobsDokument5 SeitenApache Oozie - A workflow scheduler to manage Hadoop jobsarjuncchaudharyNoch keine Bewertungen

- Determining The Redundancy FactorDokument6 SeitenDetermining The Redundancy FactorEdris Salehi GolsefidiNoch keine Bewertungen

- Sap MM LSMWDokument18 SeitenSap MM LSMWMani balan100% (1)

- Flash ADCDokument3 SeitenFlash ADCKiran SomayajiNoch keine Bewertungen

- Product Design Recommended Reading ListDokument3 SeitenProduct Design Recommended Reading ListSai Prasath100% (1)

- GOT2000 - UserManual Monitor - SH 081196 I PDFDokument614 SeitenGOT2000 - UserManual Monitor - SH 081196 I PDFFanny Achmad Hindrarta KusumaNoch keine Bewertungen

- SW-TS40T Sub-Miniature Toggle SwitchesDokument4 SeitenSW-TS40T Sub-Miniature Toggle SwitchesVALTERNoch keine Bewertungen

- Guess Questions of Aramco Written Examination For Hse Supervisor / Engineer / OfficerDokument31 SeitenGuess Questions of Aramco Written Examination For Hse Supervisor / Engineer / OfficerAlam Shamsher0% (1)

- UI Sample ResumeDokument6 SeitenUI Sample ResumenazeerNoch keine Bewertungen

- Piping Vibration: Causes, Limits & Remedies: Public Courses In-House Courses Operator TrainingDokument12 SeitenPiping Vibration: Causes, Limits & Remedies: Public Courses In-House Courses Operator Trainingmember1000100% (1)

- Linear Slot DiffuserDokument15 SeitenLinear Slot DiffuserhyderabadNoch keine Bewertungen

- Assessment Clo1 Clo2 Clo3 Clo4 Clo5 Plo1 Plo2 Plo2 Plo1Dokument12 SeitenAssessment Clo1 Clo2 Clo3 Clo4 Clo5 Plo1 Plo2 Plo2 Plo1Ma Liu Hun VuiNoch keine Bewertungen

- Thu Thiem Tunnel Construction - Sequence - Immersed - Tunnel PDFDokument36 SeitenThu Thiem Tunnel Construction - Sequence - Immersed - Tunnel PDFThông PhanNoch keine Bewertungen