Beruflich Dokumente

Kultur Dokumente

Delftship Manual

Hochgeladen von

vigambetkarCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Delftship Manual

Hochgeladen von

vigambetkarCopyright:

Verfügbare Formate

DELFTshipTM user manual

Version Homepage E-mail Contact 3.3 www.delftship.net info@delftship.net Delftship BV Vinkenpolderweg 38 2952 AV Alblasserdam The Netherlands

Delftship BV 2006, 2007, 2008 The Netherlands

DELFTship

Table of Contents

1. License and copyright.........................................................4

1.1 DELFTshipTM program...........................................................4 1.2 DELFTshipTM user manual....................................................4 1.3 DISCLAIMER OF WARRANTY...............................................4

9.5.1 Extrude....................................................................................31 9.5.2 Split.........................................................................................32 9.5.3 Collapse..................................................................................32 9.5.4 Insert.......................................................................................32 9.5.5 Crease.....................................................................................32

2. Registering your software...................................................5 3. Background to surface modeling.........................................6

3.1 Surface modeling.....................................................................6 3.2 Subdivision surfaces................................................................6

3.2.1 Points........................................................................................7 3.2.2 Edges........................................................................................7 3.2.3 Faces.........................................................................................7

9.6 Face.......................................................................................33

9.6.1 New.........................................................................................33 9.6.2 Invert.......................................................................................33

9.7 Curve.....................................................................................34

9.7.1 General information about control curves and fairing...............34 9.7.2 New.........................................................................................35 9.7.3 Fair..........................................................................................35 9.7.4 Convert to marker....................................................................35

3.3 Subdivision explained..............................................................8 3.4 Guidelines to subdivision modeling.........................................9

9.8 Layer......................................................................................36

9.8.1 General layer information.........................................................36 9.8.2 Active layer color.....................................................................36 9.8.3 Auto group...............................................................................36 9.8.4 New.........................................................................................36 9.8.5 Delete empty...........................................................................36 9.8.6 Dialog......................................................................................37

4. Coordinate system adopted by DELFTship......................10 5. Using the hull modeling windows......................................13

5.1 Zooming, panning and rotating..............................................13 5.2 Selecting objects....................................................................13 5.3 Moving control points with the mouse...................................13 5.4 Manually modifying points.....................................................14 5.5 Drawing modes......................................................................14 5.6 Working with background images..........................................15

5.6.1 Visible......................................................................................15 5.6.2 Clear........................................................................................15 5.6.3 Load........................................................................................15 5.6.4 Save........................................................................................15 5.6.5 Origin.......................................................................................16 5.6.6 Set scale..................................................................................16 5.6.7 Transparent color.....................................................................16 5.6.8 Tolerance.................................................................................16 5.6.9 Blending..................................................................................16

10. Display............................................................................39

10.1 Controlnet............................................................................39 10.2 Control curves......................................................................39 10.3 Interior edges.......................................................................39 10.4 Show both sides..................................................................39 10.5 Grid......................................................................................39 10.6 Stations................................................................................40 10.7 Buttocks...............................................................................40 10.8 Waterlines............................................................................40 10.9 Diagonals.............................................................................40 10.10 Hydrostatic features...........................................................40 10.11 Critical points.....................................................................41 10.12 Leak points only.................................................................41 10.13 Flowlines............................................................................41 10.14 Normals..............................................................................41 10.15 Curvature...........................................................................41 10.16 Markers..............................................................................42 10.17 Marker points.....................................................................42 10.18 Tanks.................................................................................42 10.19 Sounding pipes..................................................................42 10.20 Transparent tanks..............................................................42 10.21 Tank names.......................................................................42 10.22 Curvature scale..................................................................42

6. File import ........................................................................17

6.1 Import Surface.......................................................................17 6.2 Import chines.........................................................................18 6.3 Table of offsets......................................................................19 6.4 Background images...............................................................23

7. Program preferences........................................................24

7.1 General..................................................................................24 7.2 Hullform..................................................................................24 7.3 Hydrostatics...........................................................................24 7.4 Report....................................................................................24 7.5 Tanks.....................................................................................24 7.6 Load cases.............................................................................24

8. Project settings..................................................................25

8.1 General..................................................................................25 8.2 Main dimensions....................................................................25 8.3 Hydrostatics...........................................................................26 8.4 Critical points.........................................................................26 8.5 Tanks.....................................................................................27 8.6 Load cases.............................................................................27 8.7 Longitudinal strength.............................................................27 8.8 Probabilistic damage stability................................................28

11. Tools...............................................................................43

11.1 Check model........................................................................43 11.2 Move to baseline..................................................................43 11.3 Remove negative.................................................................43 11.4 Remove unused points........................................................44 11.5 Extract critical points............................................................44 11.6 Subdivide controlnet............................................................44 11.7 Keel and rudder wizard........................................................44 11.8 Markers................................................................................44

11.8.1 Import....................................................................................45 11.8.2 Export....................................................................................45 11.8.3 Delete....................................................................................45

9. Edit options.......................................................................29

9.1 Undo......................................................................................29 9.2 Redo......................................................................................29 9.3 Delete.....................................................................................29 9.4 Point.......................................................................................29

9.4.1 Add..........................................................................................29 9.4.2 Align........................................................................................29 9.4.3 Collapse..................................................................................29 9.4.4 Fair points................................................................................30 9.4.5 Plane intersection....................................................................30 9.4.6 Intersect layers........................................................................30 9.4.7 Copy values.............................................................................31 9.4.8 Lock points..............................................................................31 9.4.9 Unlock points...........................................................................31 9.4.10 Unlock all points.....................................................................31 9.4.11 From markers........................................................................31

11.9 Add box................................................................................45 11.10 Add cylinder.......................................................................45 11.11 Edit criteria.........................................................................46

11.11.1 Section.................................................................................47 11.11.2 Freeboard............................................................................47 11.11.3 Equilibrium angle.................................................................47 11.11.4 Combined heel and trim angle..............................................48 11.11.5 Area under the GZ curve......................................................48 11.11.6 Value of max. GZ.................................................................49 11.11.7 Angle of max. GZ.................................................................49 11.11.8 Metacentric height................................................................49 11.11.9 GM in damaged condition....................................................50 11.11.10 Wind heeling criterion.........................................................50 11.11.11 Passenger crowding angle.................................................51 11.11.12 High speed turning angle...................................................52

9.5 Edge.......................................................................................31

DELFTship

12. Transform........................................................................53

12.1 Scale....................................................................................53 12.2 Move....................................................................................53 12.3 Rotate..................................................................................53 12.4 Mirror....................................................................................53 12.5 Hullform transformation.......................................................53

13. Tanks..............................................................................55

13.1 General information about tanks.........................................55 13.2 Edit.......................................................................................55

13.2.1 Adding a tank.........................................................................56

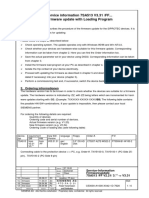

14.2.2.1 Add a new load case........................................63 14.2.2.2 Modify the load case name...............................63 14.2.2.3 Selecting a wind silhouette...............................64 14.2.2.4 Adding weights..................................................64 14.2.2.5 Modifying the different types of weights...........64 14.2.2.6 Selecting a tank or a weight from the weight list ........................................................................................64 14.2.2.7 Add all tanks.....................................................65

14.2.3 Deleting a load case..............................................................65 14.2.4 Copy a load case...................................................................65 14.2.5 Solve a load case...................................................................65 14.2.6 Show report...........................................................................65 14.2.7 Interpreting results.................................................................65 14.2.8 Bending moment and shear force calculations.......................66

13.2.1.1 Abbreviation......................................................56 13.2.1.2 Group................................................................56 13.2.1.3 Tank position.....................................................56 13.2.1.4 Relative density................................................56 13.2.1.5 Intact permeability.............................................57 13.2.1.6 Damage permeability........................................57 13.2.1.7 Non-buoyant.....................................................57 13.2.1.8 Use FSC when slack........................................57

13.2.2 Adding a compartment...........................................................57

14.3 Wind silhouette....................................................................68

14.3.1 Adding a new wind silhouette.................................................69 14.3.2 Modifying wind silhouette data...............................................69

14.4 Wind moment calculation....................................................69

15. View................................................................................70

15.1 Intersections.........................................................................70 15.2 Linesplan..............................................................................71 15.3 Design hydrostatics.............................................................71 15.4 Hydrostatics.........................................................................71 15.5 Inclined hydrostatics............................................................72 15.6 Crosscurves.........................................................................73 15.7 Max VCG'.............................................................................74 15.8 Plate developments.............................................................74 15.9 Resistance...........................................................................76

15.9.1 Delft series.............................................................................76 15.9.2 Kaper.....................................................................................76

13.2.2.1 Type of compartment........................................57 13.2.2.2 Compartment position.......................................58 13.2.2.3 Positive/negative...............................................58 13.2.2.4 Trim at hull........................................................59 13.2.2.5 Use all layers....................................................59 13.2.2.6 Select................................................................59

13.2.3 Copy a tank or compartment..................................................59

13.3 Tank arrangement...............................................................59 13.4 Comparison of internal and external geometry...................60 13.5 Overview..............................................................................60

14. Load cases......................................................................61

14.1 General information about load cases.................................61 14.2 Edit.......................................................................................61

14.2.1 Using the weight list...............................................................63 14.2.2 Editing load cases..................................................................63

15.10 Probabilistic damage stability............................................77

16. Selection.........................................................................78

16.1 Selecting objects in DELFTship...........................................78 16.2 Select all..............................................................................78 16.3 Deselect all..........................................................................78

DELFTship

1.

1.1

License and copyright

DELFTshipTM program.

Copyright 2005-2008 Delftship BV DELFTship is copyrighted and all rights are reserved. The license for use is granted to the purchaser by Delftship BV as a single user license and does not permit the program to be used on more than one machine at one time. Copying of the program to other media is permitted for back-up purposes as long as all copies remain in the possession of the purchaser. 1.2 DELFTshipTM user manual

Copyright 2005-2008 Delftship BV All rights reserved. No part of this publication may be reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any language in any form or by any means, without the written permission of Delftship BV. Delftship BV reserves the right to revise this publication from time to time and to make changes to the contents without obligation to notify any person or organization of such changes. 1.3 DISCLAIMER OF WARRANTY

NO LIABILITY FOR CONSEQUENTIAL DAMAGES. In no event shall Delftship BV or the author of this program or document be liable or responsible for any damages whatsoever (including, without limitation, incidental, direct, indirect and consequential damages, damages for loss of business profits, business interruption, loss of business information, or other pecuniary loss) arising out of the use or inability to use this product and its attendant documentation, even if advised of the possibility of such damages. No Delftship BV distributor, or agent, or employee is authorized to make any modification, extension, or addition to this warranty. No warranty. Any use by licensee is at the licensee's own risk. product is provided for use "as is" without warranty of any kind. To the maximum extent permitted by law, the author disclaims all warranties of any kind, either express or implied, including, without limitation, implied warranties of merchantability, fitness for a particular purpose and non infringement.

DELFTship

2.

Registering your software

After having installed the professional version (not the free version!) of DELFTship you first need to register your software in order to enable the printing and saving features. Registering is done by sending a registration code to support@delftship.net. The registration code is used to generate a license file which will be send to you by email and must be placed in the program directory (default c:\program files\delftship ). Only then the software will be fully functional. The license file depends on several hardware components available in your computer, so the software only runs on the computer(s) where the registration code was generated. If you want to run the software on more than one computer, for example on a PC and a laptop, DELFTship BV can provide you with an extra license on request. If you have made modifications to your computer's hardware you can also request a new license file. Extra licenses will be supplied on a fair use policy. You can find the registration code at the bottom left corner of the about window. The about window is accessible from the main menu and is located under Help => About...

The code consists of several groups of 4 characters each. The groups are divided by spaces. You can either type the code manually into your email client, or copy and paste the code. The easiest way however is to simply press the Send button displayed right next to the registration code. A new email message will be generated automatically with the registration code in the body ready to be sent to Delftship BV.

Illustration 2.1: 2.1: The about window.

DELFTship

3.

3.1

Background to surface modeling

Surface modeling

DELFTship uses a technique called surface modeling to completely define the outer shape of a ship. This technique involves sculpting the hull as if it were a very thin and flexible piece of cloth by pulling and shifting points. It is however not limited to the hull alone as we will see later. Decks, superstructures, masts, keels and rudders can be modeled this way too. The biggest advantage of surface modeling is that the model can be completely and accurately described using only a few points. Illustration 3.1 shows an example of a developable tug that was created with only 54 points. Unlike other programs, DELFTship uses subdivision surfaces for this task. Compared to other types of surface definition, subdivision surfaces give the designer more flexibility in designing any desired shape. But when you want to get the most of this technique it is important to have a basic understanding of some of its underlying principles.

Illustration 3.1: 3.1: Surface modeling.

3.2

Subdivision surfaces

A subdivision surface is a special type of spline-surface. Conventional modeling programs work with parametric spline surfaces like B-Spline surfaces or NURB surfaces. These surfaces are completely defined by a set of control points. These are the points which the user can modify to control the shape of the surface. Any point on the surface can be directly calculated from these control points using a set of parametric formulas. The drawback of these parametric surfaces is that they always require a topologically rectangular grid of points. This grid in reality almost always follows the shape of a hull, so it does not look like a true rectangular grid. But it always has say N points in the longitudinal direction and M points in the vertical direction where both N and M might be any number equal to or larger than 2. On illustration 3.3 N=4 and M=4 and the total number of control points equals 4*4=16. Using Illustration 3.2: 3.2: Inserting a row or column. parametric spline surfaces it is not possible to insert a single new point in the control grid. To maintain the rectangular topology an entire row of points have to be inserted as demonstrated on illustration 3.2. This results in having more control points than actually needed or desired, and more control points means more work to the designer. Also very complex shapes cannot be modeled using a single surface. But when using multiple surfaces the designer is challenged with the difficult task of aligning these surfaces at their boundaries. It is often desirable to maintain a smooth transition along these boundaries. Each time one of these surfaces is modified, the adjacent surface has to be modified by the user to maintain this smooth transition. To overcome these problems DELFTship makes use of subdivision surfaces. Subdivision surfaces also use control points as a modeling handle, just like NURBS or B-Splines and they share the same Illustration 3.3: 3.3: Parametric spline surface. mathematical background. The main difference however is that the formulas are no longer restricted to a rectangular grid of points. The downside is that points on the surface can no longer be directly calculated due to this different approach. Instead the original set of points (called the control mesh) is refined and smoothed in a number of steps. Each step is called a subdivision step, hence the name subdivision

DELFTship

surfaces. Before explaining in detail how subdivision actually works it is important to know something about the internal geometry of subdivision surfaces. The surfaces are build from the following three components:

3.2.1

Points

Points form the basis of the surface. In fact most of the modeling is done by moving points to different locations since this changes the shape of the surface. Additionally, new points may be inserted or existing points can be removed. There are two different types of points:

Ordinary points. These are any points other then corner

points. It is important to realize that these points have a certain offset to the resulting surface. This deviation is larger in surface areas with high curvature. It becomes smaller Illustration 3.4: 3.4: Points, edges and faces. when more points and edges are inserted. Corner points are very specific points, usually connected to 2 or more crease-edges. Just like a crease-edge can be used to specify that two faces have to be connected in a discontinuous way, corner points may be used to do so with two adjacent edges. Corner points are the only type of points actually located on the hull surface. Points where 3 or more crease-edges meet are automatically set to corner points by the program. Corner points are displayed blue.

3.2.2

Edges

All points are connected with lines which are called edges in subdivision surface terminology. Edges also can be divided into two different categories:

Boundary edges. These are edges which are located, just as the name suggests, on the boundary of the surface. A boundary edge is characterized by the fact that it has always only 1 face attached to it. Examples of boundary edges are the sheer line (if the ship is not fitted with a deck) or the centerline of the ship. The centerline, or profile, is in fact a special case. When defining the hull only its port side is created. So all edges on the center plane are boundary edges as they have only one face connected to it. In reality the ship is symmetric, and when performing calculations DELFTship creates a virtual symmetric ship by mirroring the model in the center plane. Internal edges. These are all other edges away from the boundary of the surface, and must always be shared by 2 adjacent faces. Internal edges are drawn as dark gray lines. The two faces connected to an edge are joined smoothly along their shared edge. It is possible however to mark an edge as a crease-edge. When doing so, the two faces are joined in a tangent-discontinuous way. In other words, crease-edges are used to define knuckle lines. A boundary edge is in fact a specific case of a crease edge since there is no second face to make a smooth transition.

3.2.3

Faces

A face is a little piece of the entire surface (sometimes also called a patch) that is completely surrounded by edges and is usually defined with 4 points. In some areas it is desirable to have less (or even more) points, but generally the best results are obtained when most of the faces consist of 4 points. Faces are surrounded by edges where the type of edge determines how the faces should be connected to each other.

DELFTship

3.3

Subdivision explained

Now there is a basic understanding of the underlying geometry the process of transforming the control mesh into the final hull surface will be clarified. Illustration 3.5 shows the process of one subdivision step.

To the left the original control mesh of a beveled cube is visible. The first step in the subdivision process is refining the mesh. This is done by inserting a new point in the middle of each edge (called an edge-point). New points are also inserted at the center of each face (called a face-point) which has more than three points. For faces with three points each new edge-point is Illustration 3.5: 3.5: One subdivision step. connected with the new point of the previous edge, thus creating 4 new triangles. All other faces are subdivided by connecting all surrounding edge-points to the facepoint. This results in a refined mesh which still has the same shape as the original. This process is shown in the middle. Finally all the points in the surface are shifted to a new location in such a way that the refined surface is smoothed. This is called averaging in subdivision terms (right side).

If this process of subdividing is repeated several the resulting mesh will be very fine and smooth. The following illustration shows the same beveled cube after a number of subdivision steps.

Illustration 3.6: 3.6: Original control mesh and resulting surface after 1, 2 and 3 subdivision steps.

Illustration 3.7 shows the same control mesh, but this time a number of edges have been marked as crease-edges (red lines). The result is a sharp knuckle line going around the cube. It is clearly visible that the faces on both sides of the crease-edges are no longer joined smoothly.

Illustration 3.7: 3.7: Crease edges.

DELFTship

3.4

Guidelines to subdivision modeling

In theory almost any control mesh is valid, however when designing ships the fairness of the resulting surface is of uttermost importance. In this paragraph some guidelines are given that will assist you in obtaining the best results.

Use a regular grid whenever possible. A grid is considered regular if all faces consist of four points, and all points are connected to four edges and faces. A point on a boundary edge is considered regular if it has 3 edges and two faces connected to it. Of course this is not always possible. Triangular faces may be used as a means to reduce the number of points in an area. 5-sided faces, or 5 different 4-sided faces can be used to increase the number of points. A truly regular grid would look exactly the same as the B-spline surface from illustration 3.3 on page 6. Always have two faces connected to all edges other Illustration 3.8: 3.8: Regular points. than boundary edges. If more than two faces are connected to an edge, that specific edge will be drawn thicker and in a light green color. This must be avoided at all cost as it messes up hydrostatic calculations. boundary edges are allowed, but once they become submerged hydrostatics will no longer be calculated. (see also paragraph 8.3 on page 26 and paragraph 11.1 on page 43 for leak points). Ensure that the normals of all the faces point outward (in the direction of the water). This is of crucial importance since DELFTship calculates hydrostatics by integrating the enclosed volume at the back of the faces. If the normal of a face points inward, the volume outside the hull would be added to the total volume. By using the actual surface for hydrostatic calculations instead of a number of stations, a higher accuracy is obtained compared to the conventional method of using cross sections. This is especially true if the model has a heeling angle and/or trim, or is fitted with a superstructure. DELFTship can also check the direction of normals automatically. Automatic checking can be disabled in the project settings dialog as explained in paragraph 8.3 on page 26.

Illustration 3.9: 3.9: Example of a highly irregular grid where some of the irregular points have been pointed out by red arrows.

Illustration 3.10: 3.10: Same ship with a more regular grid in the foreship.

DELFTship

4.

Coordinate system adopted by DELFTship

DELFTship uses the coordinate system as displayed on illustration 4.1. The aft perpendicular is always located at the origin of the coordinate system. The axis have the following directions with respect to the ship model:

The X axis corresponds to the longitudinal direction of the ship. The Y axis is oriented transversely. Positive values are located on port side. The Z axis is oriented vertically and points upward.

Positive values for heeling angles are also to portside while for negative values the ship heels to starboard side.

Illustration 4.1: 4.1: DELFTship coordinate system

Illustration 4.2 shows the most important reference lines:

The aft perpendicular which is located at the origin (x=0.0). The forward perpendicular. The location is specified by the user in the project settings and must be a a value greater than zero since the aft perpendicular is located at the origin. The length of the ship is defined as the distance between the two perpendiculars. The base line. The base line corresponds with the horizontal plane through the origin (z=0.0). All drafts are measured with respect to this baseline so it's important that the lowest part of the ship coincides with this plane.

Illustration 4.2: 4.2: Reference lines

Draft is defined as (see illustration 4.3) :

Draft aft: The distance measured along the aft perpendicular from the base plane to the intersection of the water plane with the center plane. Draft forward: The distance measured along the forward perpendicular from the base plane to the intersection of the water plane with the center plane. (Average) draft: The average of both drafts =0.5* (TAft+TForward)

10

DELFTship

These definitions are valid both in upright and heeled conditions. Note that in the event of large heeling angles and small values for the displacement this can lead to negative values for the draft as can be seen to the right of illustration 4.3. The intersection of the water plane and the center plane is located below the base plane resulting in a negative value for the draft.

Illustration 4.3: 4.3: Draft measured when heeled.

Trim is defined as the difference in draft at both perpendiculars (Illustration 4.4).

Trim =TForward-TAft

If the draft aft is greater than the draft forward the trim will be negative. So negative trim values indicate the ship is trimmed by the stern, while for positive trim values the ship is trimmed by the bow.

Illustration 4.4: 4.4: Definition of trim.

11

DELFTship

Finally all values for the various hydrostatic properties are measured with respect to the ships main axis with the ship in upright position. Illustrations 4.6 and 4.5 show a ship with trim and a ship heeled to port side. Rather than heeling the ship the water plane is rotated instead. All dimensions are measured along the three main axis that pass through the origin. Both illustrations show the presentation of the location of the center of buoyancy in 3D space as an example. This presentation will be consistently used throughout the program.

Illustration 4.5: 4.5: Transverse and vertical measurements for a heeled ship.

Illustration 4.6: 4.6: Longitudinal and vertical measurements for a trimmed ship.

12

DELFTship

5.

5.1

Using the hull modeling windows

Zooming, panning and rotating

After opening or starting a new model the program by default adds 4 windows. Each window has a different view on the 3D hull. The area of the window where the model is drawn is called a viewport. These viewports also appear in several other windows, for example when viewing plate developments. Zooming and panning works the same in all viewports used throughout the program. Zooming can be done in different ways: Ctrl-A (zoom all) Move the mouse up or down while keeping the left button pressed. Press Ctrl-I (zoom in) or Ctrl-O (zoom out) Users having a mouse wheel may find it more convenient to zoom in or out using their mouse wheel. By drawing a selection rectangle with your mouse. Zooming is only allowed until the maximum zoom level has been reached. Zooming beyond this level is not possible.

Panning is done by moving the mouse with the right button pressed. If the viewport displays a perspective view then two scrollbars will be visible also, located below and to the right of the viewport. These scrollbars can be used to rotate and tilt the model in order to see your model from a different viewing angle. Another more convenient way to rotate the model is keeping the middle mouse button (or mouse wheel) pressed while dragging the mouse. This also works only in a perspective view.

5.2

Selecting objects

Selecting objects is explained in paragraph 16.1 on page 78.

5.3

Moving control points with the mouse

One of the most important features when it comes to surface modeling is the ability to move points. In order to do this the controlnet must be visible (see also chapter 10). Although it is possible to select points in a perspective view, the actual dragging of the point can only be done in the bodyplan view, profile view or plan view. While dragging a point all geometrical information is updated real-time. This includes intersection curves, control curves, flowlines and tanks, especially when the precision of the model is set to a high level this updating process might become slow due to the amount of calculations involved. If it becomes too slow, try using a lower precision or turning off some of these objects in your display settings.

13

DELFTship

5.4

Manually modifying points

Once a point is selected, the window from illustration 5.1 displays all the information for that point, including the position of the point in 3D space. These properties can be altered manually by typing the new values in the appropriate fields. In addition they can also be altered relative to the current location by typing the character @ in front of the numerical part. If for example the string @ -0.2 is entered in the field for the ycoordinate, then all the y-coordinates of all selected points will be decreased by 0.20. So the y-coordinate for the displayed point becomes 2.10-0.20=1.90. This is a convenient way to shift a number of selected points.

Illustration 5.1: 5.1: Control point form.

Another way of moving points is by pressing the cursor keys in the bodyplan, profile or plan view. The active point moves a certain distance in the direction of the arrow key that was pressed. The magnitude of this distance, called incremental distance is visible on the status bar of the program, next to the amount of undo memory that is in use. By clicking on the text displaying the value for the incremental distance a window is opened in which a new value for the incremental distance can be specified. Another and faster way is to press either the + or key. The incremental distance is then changed by 10%. Finally the black arrows displayed next to each input field on the form can be used to modify the values by the same incremental distance as mentioned above. Chapter 4 on page 10 describes the coordinate system used by DELFTship.

5.5

Drawing modes

DELFTship has several ways of presenting the hull. These drawing modes are accessible from the popup-menu under the right mouse button.

Wireframe (Ctrl-W). Only the points, lines and edges are drawn. Any objects, such as tanks for example, are drawn using line representations. Shade (Ctrl-F). The surfaces are drawn in a solid color, lines and curves are drawn on top of the surfaces. Submerged areas of surfaces can optionally be displayed using a different color. Developability check (Ctrl-D). The surfaces are shaded again, only this time areas of the surface that are developable are colored green while parts that are not developable are colored red. More about developable surfaces can be found in paragraph 9.8.6 on page 37 and paragraph 15.8 on page 74. Gaussian curvature (Ctrl-G), used to check the Illustration 5.2: 5.2: Gaussian curvature display. fairness of a surface. The model is drawn using a range of colors, based on the discrete Gaussian curvature in each point of the subdivided surface. Most surfaces are curved in two directions, called the principal curvature directions. The Gaussian curvature is the product of these two principal curvatures. Now when it comes to the sign of the Gaussian curvature there are 3 possibilities :

Negative Gaussian curvature. One of the curvature components must be positive while the other is negative, meaning that the surface is curved in opposite directions. The area surrounding the point is concave in this case and resembles the shape of a saddle. Areas with negative Gaussian curvature are colored blue. Zero Gaussian curvature. At least one of the two principal curvatures is zero, so the surface is either completely flat or curved in only one direction. In both cases the surface is developable

14

DELFTship

(This is in fact a very important property of developable surfaces). These areas are colored green. Positive Gaussian curvature. The curvature in both directions can be positive or negative, but must have the same sign. These areas are convex and colored red.

Zebra shading (Ctrl-E). Another option to check the model for fairness. Regions with a constant lightreflection intensity are shaded in bands. This is similar to the way the human eye detects unfair spots on a surface since the shininess and shadows vary in those areas. If the edges of the zebra stripes are curved smoothly then the surface is smooth in these areas. At knuckle lines they vary abruptly.

Illustration 5.3: 5.3: Zebra stripe shading.

5.6

Working with background images

DELFTship has the ability to display images in the background of your model. This feature is particularly convenient if you have an existing linesplan on paper and want to recreate the lines in DELFTship. You can load a maximum of three images. Each of these images is assigned to a specific view (profile, plan or bodyplan view). You can not assign an image to the perspective view. All options related to background images are located in the menu that pops up if you press the right mouse button in a viewport. When using background images you should pay special attention to make sure that all horizontal and vertical lines on the images are truly horizontal or vertical.

Illustration 5.4: 5.4: Using background images to trace an existing design.

5.6.1

Visible

Once you have assigned an image to for example the profile view, it will be shown in all viewports showing the profile view on the model. By changing the visible property you can hide the image from a particular viewport.

5.6.2

Clear

The clear command removes the image not only from the current viewport but also from all other viewports displaying the same view. It is entirely removed from the DELFTship model.

5.6.3

Load

Imports a background image. DELFTship only reads bmp and jpg images. For performance reasons you must ensure that the images you are going to use are not too big in size. After having imported an image you must set the origin (paragraph 5.6.5 on page 16) to make sure it is displayed at the right location. You also have to set the scale of the image (paragraph 5.6.6 on page 16) to match the size and scale of your model. For importing several images, including their settings, the user is referred to paragraph 6.4 on page 23.

5.6.4

Save

Exports the background image as a bitmap image to a file.

15

DELFTship

5.6.5

Origin

If you use this option a special cursor is used to indicate you're modifying the origin of your background image. You can simply drag to image to the correct location by keeping the left button of your mouse pressed.

5.6.6

Set scale

Make sure you set the scale of an imported image before opening another image. DELFTship assigns the same scale of the previously imported image to the freshly imported one. This is particularly useful if you have multiple images imported from the same linesplan thus having the same scale. Whenever this option is executed the user is required to click on a point within the actual image of which the location is known. The program uses the same scale for both the horizontal and vertical direction.

5.6.7

Transparent color

Quite often background images are in black and white. Having a huge white area on your viewport can sometimes be distracting. By setting white as the transparent color the program does not draw the white areas. So only the black lines are drawn on your screen. The transparent color is selected by clicking on an area of the background image that has the color you want to hide. If you click on a point that lies outside the physical area of the background image transparency is disabled again. Illustration 5.5 shows an example of a transparently rendered background image.

Illustration 5.5: 5.5: Background image made transparent.

5.6.8

Tolerance

Sometimes images that simple seem just black and white may have a lot of shades of gray in between. This is particularly the case where some of the image quality has been lost due to compression, as is the case with jpg images. If white is the designated transparent color and is filtered out, a lot of nearly white pixels remain as can be seen on illustration 5.6. By increasing the filtering tolerance these pixels can be excluded by the program too. Most of the time setting the tolerance to 30 is sufficient.

Illustration 5.6: 5.6: Example where higher tolerance is needed.

5.6.9

Blending

If the background image is till too dominant it can be blended with the viewport color. By doing so it dissolves in the background and the geometry of your DELFTship model will be better visible.

16

DELFTship

6.

6.1

File import

Import surface

This feature is used to import a number of 3D curves from a text file (make sure a decimal point is used for separating the decimals, not a comma!). The program subsequently fits a lofted surface through these curves. This is a good way to import round bottomed hulls. The curves may have any number of points, and the number of points might differ from curve to curve. Usually the curves run from the bottom of the hull upwards, however longitudinal curves are allowed too, just as long as all the curves have the same orientation and run in the same direction. It is important that the curves do not overlap each other. After opening the data file the user will be prompted to specify the number of points in longitudinal direction (number of columns) and in vertical direction (number of rows) the imported hull must have. Then the program fits a B-Spline surface through these points such that the new surface interpolates the original points. The format used for the file is as follows:

Illustration 6.1: 6.1: Hull defined with transverse curves.

The first line of the file must either be a 0 (zero) or a 1. A zero indicates that all coordinates are in meters while a one indicates that the coordinates are in feet. Each curve is defined by a sequence of X,Y and Z coordinates separated by at least 1 space. After the last coordinate of each curve there should be an empty line. The last line in the file should be 'EOF' in capitals.

Illustration 6.2: 6.2: Hull defined by longitudinal curves.

The following is an brief example of a file containing 3 stations. A more extensive sample file can be found in the subdirectory \ships and is called Round hull import demo.txt. When importing such a text file DELFTship assumes the following:

X-coordinates are longitudinal. Positive Y coordinates correspond with the port side of the ship. The base lies at z=0.0 and the aft perpendicular at x=0.0 All curves have multiplicity of 1. Having 2 curves at the same location leads to errors. Whenever 2 curves exist at the same location, for example if the hull is fitted with a bulbous bow, then these curves must be combined into a single curve by connecting the segments with a line lying on the center plane. These segments can later be removed.

17

DELFTship

6.2

Import chines

Importing a hard chined hull requires a slightly different approach as described in the previous paragraph. Rather then creating a lofted surface ruled surfaces are fitted between two successive chines. The coordinates of each chine are read from an input file with the extension .txt. The input file has the same format as described in paragraph 6.1 on page 17, except for the fact that the type of curves in the file is restricted to longitudinal curves only. Once the data points of each chine have been read from file curves are fitted to those points in such a way that the chines from the DELFTship hull match these curves. The number of control points is the same for each chine and can be specified by the user. The original curves are also added to the model as markers as a reference. The file chines import demo.txt contains a more elaborate demo. It is located in the DELFTship \ships subdirectory. The chines must be ordered from the bottom up with coordinates going from aft to front. At least three curves must be in the file representing: 1. The keel line 2. At least one chine 3. The deck- or sheer line. Control curves are added to the crease edges corresponding to each chine to make it easier to fair the chines.

18

DELFTship

6.3

Table of offsets

Illustration 6.3: 6.3: Information stored in the file header

The following is a description of the file format that is used for importing a table of offsets. The file should have .txt as a file extension and written as a proper ASCII text file. It looks like this: The first line contains the number of waterlines. The second line the number of stations The third line indicates whether data describing the deck line at each station is present (1) or not (0). The fourth line indicates whether data describing the contour line at each station is present (1) or not (0). The fifth line indicates whether data describing the aft contour at each waterline is present (1) or not (0). The sixth line indicates whether data describing the forward contour at each waterline is present (1) or not (0). The seventh line indicates whether data describing the flat of bottom at each station is present (1) or not (0). The next three lines describe the length, beam and draft of the ship as used in the project settings.

Illustration 6.4: 6.4: This line represents the heights of each of the 11 waterlines

19

DELFTship

Illustration 6.5: 6.5: Distance of aft contour line to origin on each waterline.

Illustration 6.6: 6.6: Distance of each of the 20 stations ordered from aft to front.

20

DELFTship

Illustration 6.7: 6.7: Distance of forward contour line to origin on each waterline.

Illustration 6.8: 6.8: Actual offsets data. The intersection of each column and row gives the half beam on that waterline and station. The bottom right value in the green rectangle indicates that on station 11.400 and waterline 1.600 the beam is 0.178.

21

DELFTship

Illustration 6.9: 6.9: Data describing the deck line height (left column) and beam (right column) measured on each station.

Illustration 6.10: 6.10: The last column represents the height of the contour line on each station.

22

DELFTship

6.4

Background images.

Use this option to import a file containing one or more background images that was exported from another DELFTship project. The file does not only contain the images but also all settings applied to these images such as scale origin, transparency etc. To import a single image for use in the current project see paragraph 5.6.3 on page 15

23

DELFTship

7.

Program preferences

You can modify the look and behavior of DELFTship by changing the default settings in the preferences window. The actual appearance of this window might differ from version to version depending on which extensions are included into the software. The following settings can be modified:

7.1

General

Modify the language used by the program. The language files are located in the subdirectory delftship\languages of the program directory and only language files that are located in this specific directory can be selected. A special piece of software is available from www.delftship.net that can be used to maintain existing or create new translations. Additionally the size of control points, amount of undo memory and color of the viewports can be altered.

7.2

Hullform

Change settings of default colors used by the program for displaying various items.

7.3

Hydrostatics

Illustration 7.1: 7.1: Tab pages from the preferences dialog.

Select which hydrostatic properties should be displayed in the hydrostatics report or modify the order of appearance by dragging the various properties in the list. All items will appear in the same order in the report as displayed in the list.

7.4

Report

Modify the font type and size used in the reports throughout the program.

7.5

Tanks

Modify color settings or the amount of transparency used for shading tanks. The transparency must be a value in the range 0..255. A value of 0 means the tanks are completely solid (no transparency) whereas a value of 255 means that they are fully transparent, even to the point where they are no longer visible.

7.6

Load cases

On this page settings for the transparency of the hull surface and tanks used for drawing the load case in the load case editor window can be adjusted. The list to the right shows which items are included in the intact stability report and in what order. The order can be modified by dragging items to a new positions. The check boxes can be used to exclude items from the report.

24

DELFTship

8.

Project settings

In the project settings window you can modify various project settings. It has a number of tab pages that varies depending on the extensions included into the program.

8.1

General

The first tab page is used for general information about the project, such as: Project name Name of the designer Project comment The name of the person who created the file The type of units used for this project. This can either be imperial or metric units.

When changing the unit format the entire model will be scaled to the new format. When switching from meters to feet for example all dimensions are divided by 0.3048.

Illustration 8.1: 8.1: General project settings.

The shade underwater option is used to draw submerged surface areas in a alternate color when viewing the shaded hull, linesplan, plate developments, inclined hydrostatics and load cases. Note: Only surfaces assigned to a layer that is included in the hydrostatics calculations is shaded this way. The save preview options is is used to store a small preview of the project in the file. This preview is primarily used for browsing designs from the on-line design database on the DELFTship website. The simplify intersections option is more or less obsolete. When intersections such as stations are calculated the can contain a large amount of points. This option removes points that do not substantially contribute to the shape of the calculated curves, however in some rare occasions it might lead to inaccurate curves. Only when file size is of importance it might be useful to use this option.

8.2

Main dimensions

The tab sheet to enter the main dimensions looks as shown on illustration 8.2. The project length generally is the length between perpendiculars for large ships or the waterline length for pleasure craft.

The aft perpendicular is assumed to be located at x=0.0. The forward perpendicular is located at the positive x-coordinate that is equal to project length. (see also paragraph 4 on page 10).

Illustration 8.2: 8.2: Main dimensions.

Depending on the hydrostatics settings these dimensions are used for calculating various hydrostatic coefficients such as the block coefficient. By default the midship location lies at half the project length which is generally true for large ships. For some ships different values might be specified. The input values for the three draftmarks are optional and are only visible if the load cases extension is included into the software. The longitudinal location of the three marks can be specified together with the local keel plate thickness. This information is used to calculate the actual draft measured from the keel under heel and trim for load cases.

25

DELFTship

8.3

Hydrostatics

Tab page to modify all hydrostatics related settings, such as the relative density of the surrounding water and the appendage coefficient . This is a factor normally used to compensate for shell thickness and appendages such as the rudder in the displacement calculation, usually in the range 1.005 - 1.010. The professional edition also has an input value for the mean shellplate thickness. This is multiplied with the wetted surface area to obtain the submerged volume of the shell which is added to the displacement. There's also a drop down box which can be used to specify how hydrostatic coefficients, such as the block coefficient and prismatic coefficient should be calculated. This can be done Illustration 8.3: 8.3: Hydrostatics settings. using either the dimensions specified in the project page (standard for large ships) or the actual dimensions of the submerged body (usually for yachts and small boats). In the latter case the submerged length and beam varies with the draft.

The program is not able to check whether the specified length and beam are correct. If one or more incorrect values have been specified the calculated coefficients mentioned above will also be incorrect!

Each time hydrostatic properties need to be calculated, the program checks if the direction of the normals of faces is consistent. It also automatically corrects the direction if necessary. In some rare cases it is possible that the normals point in the wrong direction after this check. If this is the case erroneous hydrostatic values are the result, such as a negative volume and displacement. If this happens it is best to first disable the automatic surface check and then manually correct the normals. When in doubt, always check the direction of normals manually by selecting control faces (paragraph 9.6.2 on page 33). Hydrostatic properties will not be calculated once leak points become submerged.

8.4

Critical points

The critical points page is optional. Critical points are points that deserve special consideration for stability calculations. DELFTship features the following types of critical points:

Marker. These are points of which the user wants to know when they become submerged. Markers have no effect on a ship's stability. Downflooding. Probably the most important type of all. If a downflooding point is submerged it means that the ship will flood and sink. Downflooding points are used to incorporate the location of openings in the hydrostatics calculations. These can be windows, doors, hatches, ventilation openings etc. Another option is to connect a tank to the sea water. If the point becomes submerged the connected tank will be flooded. The actual flooding of the tank is NOT incorporated into the hydrostatics or stability calculations however. To achieve this a tank has to be made non-buoyant (see paragraph 13.2.1.7 on page 57). Weathertight. Openings that are weathertight are very important for damage stability calculations and are treated in a special way. If a damage case has been solved and one or more weathertight openings are submerged in the equilibrium condition then the damage case is solved again but this time the connected tanks will be flooded too. The process is repeated until the ship sinks or no other weathertight openings become submerged in the equilibrium condition.

26

DELFTship

Margin line. For use in the classical deterministic damage stability calculations. Deck line. These points are used to check the amount of freeboard or when the deck edge becomes submerged in the stability calculations which is used in several stability criteria. See paragraph 11.11 on page 46 for a detailed description on the use of stability criteria. Tank connection. This type of critical point is used to connect two tanks for use in the (probabilistic) damage stability calculations. If the first tank is flooded and the water level rises above the location of the critical point then the second tank will be flooded as well.

Critical points are primarily used in the extension for: cross curves, max VCG', the load cases and the probabilistic damage stability. Each point needs a description to identify it and a location in 3D space. In addition you can use the symmetry property if a critical point has a counterpart on the other side of the ship. You can use the Windows Ctrl-C and Ctrl-V shortcuts to quickly copy properties of one critical point and apply it to another.

8.5

Tanks.

On the tab page for tanks (optional) you can specify the preferred use of tank names. If it is set to abbreviation then the tank abbreviation is used throughout the program, else the full name of the tank will be displayed.

8.6

Load cases

Illustration 8.4: 8.4: Settings for tanks.

The load cases page is also optional. Several settings can be altered. The most important of these are the heeling angles that are used to evaluate the stability while solving a load case. For very large ships it is often not necessary to go beyond 60, while for sailing yachts heeling angles up to 180 are not uncommon. Only positive values are allowed for the heeling angles and the first angle must be zero. The more heeling angles are calculated the more accurate the stability curve will be but how longer the entire calculation process will take. The program is able to automatically determine which side the ship heels to, but it is also possible to force it to calculate stability with a heel to either port or starboard. Furthermore you can choose between a short version of the load case report or the default extensive version. See paragraph 14.2.6 on page 65 for more information about the load case report.

Illustration 8.5: 8.5: Load case settings.

8.7

Longitudinal strength

The longitudinal strength tab page (optional). For complex vessels a huge number of weight items need to be evaluated in order to calculate the shear force and bending moment. In the report the results of the calculation are displayed on a regular interval. A smaller interval yields more values. You can also specify the maximum values for the sagging and hogging moments.

Illustration 8.6: 8.6: Longitudinal strength.

27

DELFTship

8.8

Probabilistic damage stability.

Illustration 8.7: 8.7: Probabilistic damage stability

28

DELFTship

9.

9.1

Edit options

Undo

This feature can be used to undo previous editing actions. DELFTship stores all actions into memory. When a new file is read into memory, the undo data associated with the previous model is cleared.

9.2

Redo

Redo a action that has been undone with the undo command.

9.3

Delete

Use this to delete items that have been selected. The program first deletes all selected faces, then the edges and finally the selected points. Any points or edges that remain unused after this process are deleted also.

If a point is deleted all attached faces and edges are deleted too. If an edge is deleted, any attached faces will also be deleted. See paragraph 9.4.3 on page 29 on how to remove a point without deleting the connected faces and edges. Paragraph 9.5.3 on page 32 shows how to remove an edge without deleting the attached faces by using the edge collapse command.

Not only items from the surface geometry can be deleted this way but also markers, control curves, flowlines and tanks.

9.4 9.4.1

Point Add

Adds a new point in 3D space. The new point is by default located at the origin (0.0, 0.0, 0.0). Adding new points is only enabled if the control net is visible.

9.4.2

Align

In the event that multiple points have been selected it is possible to align those points so that they form a straight line. This is done by projecting all the selected points on the line that goes through the first and last selected point. They are projected on the line rather than uniformly distributed to keep the displacement of the points minimal. Additionally you can also choose to only modify certain coordinates of the points. For example: if you have selected multiple control points forming the outer edge of a transom you should only adjust the X-coordinate in order to put all the points in the same plane seen from the profile view. The shape of the transom as seen from the back will in this particular case remain unaltered.

9.4.3

Collapse

This removes selected points without deleting the surrounding geometry. A point can only be collapsed if it is attached to exactly two edges. The point is then removed, and the two edges are replaced by a single edge. If a point is attached to more than 2 edges, the other edges need to be removed first by collapsing these edges as explained in paragraph 9.5.3 on page 32. The process of collapsing a point is shown on illustration 9.1. Note that the point that is to be collapsed is irregular since it has two faces connected to it and two edges. By collapsing the point the number of points of the two attached faces is reduced to 4 and the control net is made more regular making it easier to produce a fair hull surface.

29

DELFTship

Illustration 9.1: 9.1: Removing a point with the collapsing command.

9.4.4

Fair points

You can use the automatic fairing routine in DELFTship to fair the entire surface for you or only selected control points. The automatic fairing routine will only affect internal points of the surface, points that are not located on crease or boundary edges. These edges form feature lines on the hull that are generally very important for the appearance. Therefore it is best to fair those points manually or automatically by using control curves (paragraph 9.7.2 on page 35). As the automatic fairing routine is called by the user the required points are shifted to a new location in such a manner that the overall smoothness of the surface improves. By repeatedly using the command a very smooth surface can be obtained but the deviation of the original surface might be significant. If this method of fairing is applied to models with just a few control points the faired surface might differ considerably from the original surface. This is caused by the fact that the area of influence of a control point decreases with the total number of points. The solution to this is to subdivide the control net to increase the number of points before using the automatic fairing algorithm. This process is described in paragraph 11.6 on page 44.

9.4.5

Plane intersection

The plane intersection algorithm intersects all visible edges with a plane. It inserts a new control point on each edge that intersects that plane. Afterwards faces containing multiple newly inserted points will be split by inserting a new edge. This is a convenient way to insert for example a whole range of points at a certain ordinate location. There is also an option to add a control curve (paragraph 9.7.2 on page 35) to the newly created edges. The type of plane (vertical, horizontal or transverse) can be specified as well as the location by entering the desired distance into the dialog.

9.4.6

Intersect layers

You can use this option to find the intersecting curve of two layers. Obviously this option is disabled in the menu in the event that the model only has one layer. All the edges of the first layer are checked for an intersection with the faces of the second layer. If an intersection exists than the the intersection point is inserted on the edge. All inserted points are connected with new edges which form the intersecting curve of the two layers. Remember that only the first layer is affected by this entire operation, the second layer is left unmodified. Another thing to keep in mind is that points are only inserted in edges, not in faces. Intersecting layers is useful for example to find the intersection of the hull with a keel or rudder.

30

DELFTship

9.4.7

Copy values

If multiple control points have been selected you can copy values from the first selected point to all the other points. This way you can quickly assign all selected points the same X, Y or Z coordinate.

9.4.8

Lock points

All selected points will be locked. Locked points are shown as dark gray points on your screen and cannot be modified. None of the available editing operations has any effect on locked points. This option will only be enabled in the menus if at least one unlocked point is selected.

9.4.9

Unlock Unlock points

This unlocks selected points that have previously been locked, so that they can be modified again. Again this option is only enabled in the menus if at least one locked point has been selected

9.4.10

Unlock all points

All locked points in the model will be unlocked, whether they are selected or not.

9.4.11

From markers markers

Extracts all points from the currently selected markers and adds these as control points to the subdivision surface. These control points are not connected by edges or faces yet.

9.5 9.5.1

Edge Extrude

The most used and preferred way to create new surfaces is by extruding edges. Since an edge may only have a maximum of two faces attached, only boundary edges are allowed to be extruded. The selected edges are copied in the specified direction and new faces are created between each old and new edge. The new faces are assigned to the active layer (see paragraph 9.8.1 on page 36) Illustration 9.2 shows how a deck is easily added by extruding the sheerline. The three stages of the process are:

Select the boundary edges that you want to extrude. Then choose the edit => edge => extrude option from the mainmenu. A window will show up requesting direction of the extrusion. In the example the extrusion direction is (0.0, -2.25, 0.02) meaning that a copy of all selected edges will be created and moved 0.0 units in longitudinal direction, -2.25 units in the transverse direction and 0.02 units upwards. Illustration 9.2: 9.2: Create a deck by extruding edges. The extrusion command creates new faces between each original edge and its copy. These new faces will be assigned to the active layer. After moving the newly created edges to the centerline the deck is finished.

31

DELFTship

9.5.2

Split

Selected edges are split by inserting a new point in the middle. After this operation all newly created points are selected. This is a convenient way to insert new edges. In that case multiple edges can be selected and split in two. All selected points belonging to the same face may then be split by inserting a new edge. The image to the right shows two selected edges before and after the split. Note that this way a face consisting of 6 points is created, resulting in an irregular mesh (see paragraph 3.4 on page 9). The two selected points should preferably be connected, thus splitting the face in two regular faces. This ensures a more regular grid and a smoother surface.

Illustration 9.3: 9.3: Inserting points on an edge.

9.5.3

Collapse

Collapsing an edge removes the edge and combines the two attached faces into one new face. Since edge collapsing requires two faces it can only be applied to internal edges and not to edges on the surface boundary.

9.5.4

Insert

A face can be divided by inserting an edge. To do this at least two points have to be selected. Both points must share the same face, and no edge is allowed to already exist between the selected points. To ensure a fair surface it is recommended to extend inserted edges as those seen on illustration 9.4 to a crease or boundary edge if possible.

Illustration 9.4: 9.4: Inserting an edge.

9.5.5

Crease

Setting selected edges as crease-edges allows the user to add knuckle lines to the hull. The crease property of boundary edges cannot be changed, they are by default treated as crease edges. Illustration 9.5 shows how a hard chine is created. To the left the model without the chine is visible. To the right the yacht with the new knuckle line is displayed. Illustration 9.5: 9.5: Creating knucklelines. In this specific example the knuckle line runs over the full length of the hull. This is not absolutely necessary, knuckle lines may run freely over the surface.

32

DELFTship

9.6 9.6.1

Face New

Creates a new face from selected points. These points have to be selected in the correct order.

9.6.2

Invert

This option can be used to manually flip the direction of normals of selected faces to the other side in case the automatic surface check has failed. All surface normals should point outwards, in the direction of the water. The normals of a face can be visualized by selecting the specific face. Make sure that both interior edges and normals are made visible in your display settings (see chapter 10). Each displayed normal is calculated as the average normal in a point of the refined subdivision mesh. This average is calculated from all faces surrounding that point. Along the boundary of an edge sharing two faces with opposite normal directions, this may seem a bit peculiar as can be seen on the left side of illustration 9.6. The normals along these boundaries look as if they are projected on the surface. The right side of the illustration shows the normals after the face has been inverted and they normals face the right direction.

Illustration 9.6: 9.6: Manually inverting the direction of face normals.

33

DELFTship

9.7 9.7.1

Curve General information about control curves curves and fairing. fairing.