Beruflich Dokumente

Kultur Dokumente

Area of Existence of Involute Gears

Hochgeladen von

danielk32Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Area of Existence of Involute Gears

Hochgeladen von

danielk32Copyright:

Verfügbare Formate

Area of Existence of Involute Gears

Alexander Kapelevich and Yuriy Shekhtman Management Summary

This paper presents a unique approach and methodology to define the limits of selection for gear parameters. The area within those limits is called the area of existence of involute gears (Ref. 1). This paper presents the definition and construction of areas of existence of both external and internal gears. The isograms of the constant operating pressure angles, contact ratios and the maximum mesh efficiency (minimum sliding) isograms, as well as the interference isograms and other parameters are defined. An area of existence allows the location of gear pairs with certain characteristics. Its practical purpose is to define the gear pair parameters that satisfy specific performance requirements before detailed design and calculations. An area of existence of gears with asymmetric teeth is also considered.

Figure 1aStandard 20 pressure angle generating rack; b: its block-contour for the pair of gears with number of teeth n1= 22 and n2 = 35.

Introduction In traditional gear design, the pre-selected basic or generating racks parameters and its X-shift define the nominal, involute gear geometry. The X-shift selection for the given pair of gears is limited by the block-contour (Refs. 23). Borders of the block-contour (Fig.1) include the undercut isograms, the tooth-tip interference isograms, the minimum contact ratio (equal to 1.0 for spur gears) isogram and the isograms of the minimum tooth tip thickness to exclude the gears with the pointed tooth tips. Each point of the blockcontour presents the gear pair with a certain set of parameters and performance. If the basic or generating rack parameters (pressure angle, addendum or whole depth) are changed, the block-contour borders will be changed accordingly and will include the gear pair parameters combinations, which previously could not be achieved yet could present the optimal solution for a particular gear application. Area of Existence for Symmetric Gearing The Direct Gear Design method (Refs. 45) does not use a pre-selected basic or generating rack to define the gear geometry. Two involutes of the base circlethe arc distance between them and the tooth tip circle describe the gear tooth (Fig. 2). The equally spaced teeth form the gear. The fillet between the teeth is not in contact with the mating gear teeth, but this portion of the tooth profile is critical because it is the area of the maximum bending stress concentration. In Direct Gear Design, the selection of parameters for the given gear pair is limited by the area of existence, which was introduced by Prof. E. B. Vulgakov in his Theory of Generalized Parameters (Ref. 1). The angles v1 and v2 are used as a coordinate system for the area of existence of the involute gear pair with number of teeth n1 and n2. The involute profile angles at the tooth tip diameters a1,2 of the mating gears also can be used as a coordinate system for the area of existence. They are:

64

GEARTECHNOLOGY

January/February 2010

www.geartechnology.com

1 n1 (tan a1 u tan a 2 (u 1) tan w ) 2 (tan a1 u tan a 2 (u 1) tan w ) 2

a1,2 arccos

db1,2 d a1,2

(1)

1 u ) tan w u tan a 2 ) tan p1 0 tan(utan(( tan a 2 (u 1) tan w ) tan p1 0 tan((1 u ) tan w u tan a 2 ) tan p1 0

(8)

An area of existence is built for the gear pairs with number of teeth n1 and n2, and for pre-selected relative tooth thicknesses at the gear tooth tip diameters ma1,2. This guara S a1,2 tooth m tips cos 1,2 anteesinv avoiding the (pointed and makes the a1,2 ) gear ( 1,2 ) inv a1,2 n cos area of existence independentd of the gear size. In the metric a1,2 1,2 w system, ma1,2 = Sa1,2 / m, where m is operating module in mm. In the English system, ma1,2 = Sa1,2 x DP, where DP is the operating diametral pitch in 1/in. Typically, thicknesses S a 2 dbm cos a 2 ma1,2 d d b1,2 the / n2range invof ( 20.1 ) inv ( ) 1,2a 2 b1,2 a 2 arccos are in 0.5. arccos a1,2 a1,2 d a 2 d a1,2 n2 cos w a1,2 arccos d d a1,2 a1,2 The relation between the involute profile angles v and a is described by equations: for gears with the external teeth: m cos 1 inv (inv( 1 ) u inv ( )S ) ( ) a1,2 a1,2 a 1,2 w a S m cos 2 S m cos a 1,2 1,2 a 1,2 inv ( ) inv ( ) aa 1,2 1,2 1 1,2 a 1,2a1,2 n1 inv ( ) inv ( ) inv (u ) inv ( ) 1,2 a 1,2 d a1,2 n n1,2 cos w (2) 1,2 a1,2 cos dd n cos a 1,2 1,2 w a1,2 1,2 w for the gear with the internal teeth: d

for the gear root undercut beginning (p2 = 0):

1 tan( 1 u tan tan a1 ) tan p 2 0 w 2 1 u tan( tan w u tan a1 ) tan p 2 0

1 u

u

u 1 0

u

(9)

co co co co

For internal gearing, interference when the pinion root 1,2 1,2 inv( a1,2 ) inv( w ) undercut beginning (p1= 0) is:

tan( u tan (1 u ) tan ) tan 0 0 tan( tan u )1 tan tan au 2( wtan p 1 tan( uu tan )1 tan ) 0 2 p1 an 2a w) w p1 ( cos n cos 2 2 2

(

1

(10)

1 arccos(

w 0 n1 cos u 1 2 u 0 (n1 n2 ) u 1 2 1 2 0

cos a1

cos a1

) (n1 n2 ) (

cos a 2

) continued

where: inv(x) = tan(x) - x involute d function. d b1,2

1 a1,2 arccos d b1,2 S m cos a 2 (u inv ( 2 ) inv( )) ( ) b1,2 am 2inv a 2w d S cos inv /1 n inv ( ) inv ( )1 a 2 a1,2m a 2 a2 arccos u cos 2 2 aS 2a a1,2 ( / n inv ( ) ) 2 a 2 a 2 (3) 2 inv ( 2 d n2 cos d a / n2 2 )2 inv( a 2a) w 1,2 a 2 n cos d 2 w da a n22 cos w 2

a1,2 arccos arccos b1,2 n1 a m d u (tan1 tan a 2 S a( 1 ) tan a1 u a1,2 cos d 1,2 1,2 a 1,2 w) a 1,2 a1,2 An2area existence presents a ( number of isograms 1 inv (of inv ( )u S ) that inv inv inv ( ) ) ) ( m cos 1,2 ) ( a 1,2 1 2 a1,2 a1,2 a 1,2 w inv u inv inv ( ( ) ( ) ) ( ) 1 d n cos u n 1 w 1 ( a1,2 2 )( inv ) acharacteristics, 1,2 1,2 w as the 1 ( such describe inv gear pairs with certain 1,2 ( u 1 inv inv ( w) 1 ) u inv( d2 ) n1)n cos

a1,2 n 1,2 w u 1 1 constant operating pressure angle, contact ratio, interference condition mesh efficiency, etc. n1 or maximum S m cos a S m cos a 1,2 a 1,2 1,2 1 a 1,2 a 1,2 a 1,2 ( 1( u u (tan tan ( ) tan S m cos ainv a 2const w) 1 inv ( ) ( ) 1 inv ( ) inv ( ) The pressure angle = isogram equations ( ) ( u inv inv a 2 a 2inv 1,2 a 1,2 1,2 a 1,2 w )a 2 are w( 2 1 )) 2 / n1 inv ( ) inv ) ( ( ) ( )) ( ) u inv inv inv S m cos n cos 1 u 2 2 ad 2 w a 2 a 2 a2 d n cos 2 1 a 1,2 1,2 w a 1,2 1,2 w /n inv ( ) inv ( ) (Ref. 1): 1 u d n( w cos 2 (u inv 2 ( a2 ( )) ) w 2 ) inv 1 a 2 inv 2 d n cos a2 2 w u 1

tan((1 u ) tan w u tan a 2 ) tan p1 0 for the external gearing: n1 m S m cos cos (tan a1 u tan a 2S ( 1 u ) tan w ) n 2 a a 2 2 a2 2 a 2 1 inv ( ) inv ( ) // n aa22 n21 inv ( ) inv ( tan u u (tan tan (1 aa ) 2 2 a1 w ) 2 2 2)

) 2 1 (inv( ) u inv( d n1 n )cos inv ) ( )w (4) d n cos a 2 a2 2 tan 2 w u inv (inv (1 ) ( 2 ) ( ) u (tan tan ) inv w a1 u1 a 2 (12 w w uu n1) 11 n 2 1 u 1 tan( tan w tan a1 ) 1 tan p 2 0 for the internal u gearing: u n n1 1 (tan a1 u tan a 2 (u 1) tan w ) 1 (tan ) tan w ) a1 u tan a 2 (u 1 12 1 inv inv ( ( ) ( ) ( 2 1 22) )w inv u u inv inv (inv ( ) ( ) ) ( ) (5) ( ( ) ( )) ( )) u inv inv inv n1 1 w 1 ( ( )) ( u inv inv 2 1 ww 2 1 u n 1 u n 1 (tan 1 u 1 a1 u tan a 2 (u 1) 1 u 1tan w ) 2

tan u tan a 2 ) tan p1 0 u) where: u = n2/tan(( n1 1 gear ratio. tan((1 u ) tan w u w tan a 2 ) tan p1 0

nn u( ) tan u tan ))) tan 0) 1 11 ( ) ( ( inv inv inv Thetan(( contact ratio = const isogram equation is: w a 2 p 1 (u ( ( )) (w ) u inv inv inv u (tan u tan ( 1 )) ) w u (tan tan 1 tan tan 2 1 w a a 2 ) 1u a2 w) 11 2 u 1 1a u 1 22 u 1 tan( tan tan ) tan 0 1 u 1 a1 p2 u a1 ) tan p 2 0 tan( u tan w w tan for external gearing:

u u 1 u 1 tan( tan tan a1 ) tan p 2 0 w n n u n 1 1 1 (tan u n u u tan aaa222 ( 1) u u (tan tan ) u u tan (1 1 ) tan tan 1 (tan w a w 1 a1 a w) 1 u (tan tan a1 a 2 (u 1) tan w ) 2 2 2 2

1 1

1 w 12 1 a2 1 a cos (n1) n2tan ) arccos( w 1u 1 tan( u ) tan n( tan( u tan tan u 1 ) tan ) tan )0 0 aa pp11 1 (n n 2 w 2 (n w 2) 1 cos a a1 w1 1 (n1 cos n2 ) cos a1 a1 n1 cos w 2 cos 2 n2 cos w 2 16 (cos ) a ( n n0 )n1 ) 0 n2 (cos w (inv( a1 ) ( ( inv n m m 2 2 u 0 1 2 w a 2 )) 1u 1 a2 1 2 12 2 ) ( n n ) ( ) cos cos n cos cos a 2 inv a1 )) 2 inv 2 1 ( 2 cos 2 an 2 1( cos cos 2 arccos( 1,2 1,2 w a1,2 w ) w )2 ) ( ) ( n n ( 1 a2 a 1 2 cos ) 2 arccos( 1,2 cos invn ( 1,2 w inv ( w cos 2 a1,2 ) (n1 n) ) a1 n 22 cos a w ) 2 arccos( (n n2 ) 2 cos a2 1 n cos w 2 a2 cos (n1 n2 ) cos a 2 w n1 cos n cos w 2 18 2 2 cos 2 tan u tan ) (u 1) tan ( ( n n )n ( a2 0 1 a 2 w) n1 cos)) cos 1) 2 2 2 inv inv ( w w cos inv (n ) inv ( ) (inv( a 2 a ) ( inv n m m ) 0 1,2 1,2 a 1,2 a 2w ( ) ( ( n (2 ) 2a a1 2 1 a 2 cos cos 1,2 1,2 a 1,2 w 1 2) 2 a1 (inv ( ) ( )) 0 inv n m m cos ) a 2 arccos( a1 2 a1 a2 cos a1 cos a 1 1 2 a cos 1 a 2 ) 0 w cos 1 ( arccos( 1 cos a (inv n m m (n1 an ) n2 cos 2 ) inv ( a1 )) n a 1w a 2 2 1 1 0 tan a1 u tan a 2 (1 ncos tan (u n1) cos 2 ) aw cos a1 a1 n cos w 22 w 22 n n22 cos cos cos) 2 1 n 1 1 cos w (( )) m ((n )) 0 16 cos n n n22 2 )2a (( ww (inv( a1 ) inv 1 n cos n1 m cos n 1 a 2 )) a1 a 2 a1 2 16 2 w1 2 cos cos cos cos cos n cos n cos d cos cos (inv ( ) ( )) 0 inv n m m 2 2 2 ( ) ( n n ) ( 2 1 w w cos ac1,2 c1,2 1 a a 1 2 ) ) a a2 wc dc a1 a2 1) a 1 a 2 1 2 a 2 ( ( n n ) ( ) arccos( 11 arccos( 1.0 ) coscos cos cos k 1 cos 2cos a2 n a 1 a 2 a1 cos a cos w 1 2 a1 0 16 arccos( ) w (n d 1 cos cos (inv ( 1,2 inv( n m bd m 2 arccos( n ) ) 2cos d1 1,2 (n n a1 ) ad a 2 )) n a1 wd a2 1 2 1 2) cos w 2 n2 n cos cos cos cos w ( n n ) a 1 a 2 a 1 2 (n1 n1 2) cos a cos 2 a2 18 tan 1 n tan (u 1) tan 0 n w cos n22u cos cos n cos 18 2 a2 w 2 1 w ))2 ((1) n ) 22 tan a1 a u((tan u tan 0 ww) n n n ( ( 1 )2 1 2 1 2) a2 ( w cos cos cos cos aa22 cos cos 1 a 1 a a2 a2 arccos( arccos( ) 18 ) (inv )) 0 inv n n m m 0 (inv (2 ( ))a inv n2 m m a 2 ( a 2) 1 2 a 11) 2 a 2) 1 a 1 a 2 tan ua( tan ( u tan 0 cos n w 2 a1 a2 w w 2 cos tan u tan (1 u ) tan cos cos ((n n )) a 1 w a1 0 n n a1 a2 1 2 1 2 tan a1 u tan a 2 (1 ) tan w 0 cos cos aau 2 2

tan(u tan a 2 (u 1) tan w ) tan p1 0 n1 cos w 2 n2 cos w 2 2 cos w 2 ) (n1 n ( cos (cos ) 2 n2 )n2 aw 2 2 cos ( 1 ) (n ( n2 (inv( a 2 ) inv (n )) n m m 0 u 0 ) cos cos 2 2) 1 w a1cos 2 1n a 2 1) 2 1(a a a 2w ) 2 1 2 ( n n ) ( cos a1 cos 1 arccos( ) 1 2 cos a 2 a1 arccos( cos cos ) u n 0 cos

n2 cos w 2 n cos w 2 ) (n1 n2 ) 2 ( 1 ) cos a 2 cos a1 ) 2 arccos( 1,2 inv ( ) (inv ( 1,2 a1,2 w) n( a cos inv ) 1,2 w inv 2 1,2 1,2 ) w inv ( 1,2 (inv n1 ( n )) 1,2 a1,2 ) 2w cos a2 tan(u tan (u tan ) tan 0 1) (

a2 w p1

ac a 2 (1 w 0 tan u cos tan u tan cos a1 )wc cos d dc 1,2 k 1.0 c1,2 c1,2 cos cos ac1,2 cos cos d cos a a1 dc cos wc cos 1 k 16 a2 2 0 (inv (( ( a( )) n m m 1.0 1,2 cos cos cos d ( )inv )) inv n m a 0 (inv ( inv m a 1) 2 1 a1 m a 2 1,2 wd ( inv n m m a a 1 2 a 1 a a2 1 2 1 a2 0 2 ) ad a 1 )) d 2cos a 1 a2 2 bd cos cos ad cos d cos a 2 bd 1,2 d 1,2 wd cos cos a 1 a2 a1 cos cos cos d

ac1,2

16

(6)

cos ad 1,2

c1,2

cos d 1,2

cos wd

wc

dbd

dc

k 1.0

for internal gearing:

2 2

tan((1 u ) tan w u tan a 2 ) tan p1 0 tan(( 1 u ) tan w u tan a 2 ) tan p1 0 n n 1 1 (tan ) aa11 aa22 ww) u ( 1 u u (tan tan tan (u 1 ) tan tan )

u tan a1 ) tan p 2 0 tan(1 u w tan(( u ) tan tan tan ) tan 0 u

cos aa11 0 cos tan u(( tan (um 1) 16 ((inv (( )a )) inv tan aa22 18 ))a 0 18 16 inv inv n m maa22 0 1 2n w a 1 1 a 1 a 1) 1m a 1 1) tan tan a1 u tan a 2 (u cos cos aa22 w 0

(7)

tan a1 u tan a 2 (1 u ) tan w 0

tan a1 u tan a 2 (1 u ) tan w 0

The external gearing isogram equations are: 1 u interference 1 tan( 1 u tan w 1 tan a1 ) tan p 2 0

pp11 0 tan((1 tan w u tan aa22() tan u u )undercut u w for the pinion root beginning = 0): p1

Figure 2Tooth profile. a: external tooth; b: internal tooth; 18 cos tan cos tan tip dtan w tan u u tan ( (u u 1) 1) tandiameter; 0 0 db18 n: number of d : atooth circle : base ac1,2 c1,2 a 1 2 wc a 1teeth; 2 cos a a kw wc dc 1.0 ac1,2 cos cos cos d dc c1,2 circle diameter; d: reference circle diameter; S: circular cos ad 1,2 cos d 1,2 cos wd dbd k 1.0 tooth thickness the reference diameter; cos ad 1,2 atcos cos dbd v: involute interd 1,2 wd tan u tan (1 tooth u ) 0at the tooth aa1 w tan u ) tan tan a section profile angle; Sa : circular thickness 1 u tan a2 2 (1 w 0 tip diameter.

cos cos ac cc1,2 cos cos cos d wc GEAR cos d dc TECHNOLOGY 65 1,2 1 1 ac 1,2 1,2 1 u u 1 January/February 1.0 k 2010 wc dc k 1.0 tan( 0 tan( tan tan tan tan ) tan tan w aa11) www.geartechnology.com p w p2 2 0 cos cos cos d cos cos cos d u u u u ad d wd bd ad1,2 1,2 d1,2 1,2 wd bd

1,2

1,2

a1,2

a2 ) // n 22)) n22 inv inv( ( inv inv( ( a a2 2)

n For the gear with internal d teeth, the undercut does d n22root cos cos w a a2 2 w not exist. However, there is another tip-tip interference 2 tan(u tan a 2 (1u u 0 1) tan w ) tan p1 0 tan( u tan tan tan p1 0 1) possibility in internal gearing. equation is: a 2 (u Its w)

(11)

p1 tan(u tan (u S )aa tanm ) cos tan 0 1 S ma 2 a w 2 a2 2 cos a2 2

a1,2 w

a1,2 s a1,2 w s w s a2

1 1 u 2 0 0d 1 (inv( ) u inv b b1,2 1,2 u 1( 2 ) inv ) ) w inv inv( (inv(1 ) u ( ) ) ( arccos 2 w) 1 2 a 1,2 a1,2 n 1 u u n 1 1 1 da 1,2 a1,2 where angles: 1,2 1,2 inv( a1,2 ) inv( w )

1,2 1,2 inv( a1,2 ) inv( w ) 1 1 (u inv 1,2 inv ( ) inv ( a)) 1,2 1,2 w) ) ( ) ( inv inv (u inv ( ) ( )) ( ) inv inv ( n cos nw cos 2 1 w a S m cos 2 1( an 1,2 n ) a1,2 1,2 a 1,2 a 1,2 a ( ) ( )1,2 u 1inv( 1,2 u 1 ) inv ( ) 1,2 a 1,2 cosa cos 1,2

1 w 2 2 2 w 2

n11 n w w cos cos n2 cos cos w) 2 w) 2 (( n n22))22 )2 ((n n (( 2 )2 1 1n cos cos cos cos 1 2 a a 1 2 a a )) (13) 11 arccos( arccos( n cos w n 1 1 cos w n ) ((n n n ) 1 2 1 2 cos aa11 cos

os a 2 cos a 2 sw os w

(12)

n 1 cos w w) 2 w) 2 (( n22 cos w n22))22 )2 ((n n (( 1 )2 1 1n cos cos cos aa22 cos aa11 )) arccos( arccos( 22 ucos 0 1 n w 1n 2 2 w (n n ) 2 cos 2 (n n ) 1 2 1 2 cos cos aa22

tan(u tan a a2 2 (u 1) tan w w ) tan p 1 0 1 n cos n cosp

(14)

w)

w) w)

(n n n cos ) w 2 n cos w 2 ( 1n1 cos ) (n1 n ) 2 (1 2n2 2 ) cos cos a1 2 ( cos a1 w ) 2 ( n1 n2 ) 2 ( cos 2 w )2 1 arccos( a2 ) cos a1 cos a n1 cos w arccos( ) n n 1 1 (tan 1 (n n cos 1n 2) u ( 1 ) tan ) w 1 S m cos u u (tan u (tan tan ( 1 ) tan ) aa11 n2 cos n cos a w 2 2 2 a 2 ( n n ) 1 w cos w a2 w 2 a 2 a 2 1 2 1 n a 2 (a n ( a2 ) a2 2 2 ) inv() ) 1 2 ) 2 / n2 cos 2 inv ( 2cos a2 2 a1 a cos

1 w

1 arccos(

a1

da a1,2 1,2 n cos

a2 n1,2 1,2 cos w w

cos The pitch point position isograms separate area of aa22 an cos ((inv aa22)) aa11)) )) 0 inv(( inv inv(( n n22 m maa11 m maa22 0 existence into three zones: cos inv ( ) inv ( ) 1,2 1,2 a 1,2 w cos a1 1,2 1,2 a1,2 w

a1

w) ) w

2 w inv( 1 u inv (a ) inv( )0 (inv( a 2 )( 2 w 1) 2 arccos m )m a2 1,2 a1 )) n 12 a2 n 1 u inv( 1 cos d 1

a1,2

a1

n n 1 1

n cos w n22 cos w cos 2 (n n 1 n2 ) w )2 ( 2n2 cos ) 1 n 2 ( n1 n2 ) 2 ( 1 cos w 2 cos ( cos a 2 w ) (n a1 ) a 12 n2 ) ( cos d 2 arccos( b 1,2 a1 ) cos a 2 cos arccos n2 cos ) 2 arccos( a1,2 w ( n n ) n2 cos w 1 2 d a1,2 ( n n ) cos 1 u u (tan tan ( ) tan ) 1 2 a 2 1 1 u u (tan tan ( ) tan ) a w 1 2 a w 1 2 cos a 2 cos 1,2 inv( ) db) inv (inv( ) aau a 2 (

2 arccos(

a2

da a2 2

a1 n2 )w 2 cos w

with the pitch point position before the active part of the tooth contact line; with the pitch position on the active part of the n1 point n2 cos 2 2 cos cos w cos cos w 2 w 2 w 2 a 1 a 1n ( n1 )m ( (n n cos n2 )2 ( )2 16 )) 0 inv n m ) n ( ) 1 aa11)) ( (inv )) 0 16 inv(( inv(( n m m 1 most 2 ) gears); a 2 1 a 1 a 2 ( tooth contact (typical for aline 2 cos 1 a 1 a 2 cos cos a cos a 1 2 a1 a2 cos cos arccos( ) a 2 arccos( ) 1 a 2 1 n1 cos cos after with the pitch point position the active part of n w w (n n ) (n n2 ) p1 0 1) 2 tan(u tan 2 (u1cos 1) tan tan 1 w the tooth contact aline. cos a 1 a1

cos a 2 (inv( a 2 ) inv( a1 )) n2 ma1 ma 2 cos 0 a2 (inv( a 2 ) inv( a1 )) n2 ma1 ma 2 0 cos a1 S m cos a 1,2 a 1,2 tan(( 1 a1 0 w a 2 )) p1 tan(( u) ) tan tan u tan tan tan tan 1 u u 0 cos a1,2

w ) inv ( a1,2 a) 2 ( 1,2 p1 a1 inv 1inv d a1,2 n1,2 w cos (u ( ( 2 ) invS (cos ( inv ) (inv( a1 ) inv 0w m 2 1 )) a 2 )) n 1 ma1 a 2 w 1 uinv 1( ) inv( ) cos a1,2 ma1,2 cos a1,2 cos a2 1,2 a1,2

)

0

0 0

0 0

a 2 u ) tan tan 0 aa22 u tan tan (1 (1 u ) tan w a1 =aa ,u 1 1w w 0 16 isogramtan 1,2 1,2 inv( a1,2 ) inv( w ) a1 cos (inv( a1 ) inv( a 2 )) n1 ma1 d mn 0 w 16 cos cos a a 1,2 2 a1 a2 2 0 (15) a 1,2 16 ( ( ) ( a inv inv ma (inv( a1 ) inv( a 2 )) n1 ma1 0 m cos a 2 a2 2 a 1 )) n2 2 m a1 1 a2 2 d cos cos a2 cos ac cos cos a 1 a cos d 1,2 c 1,2 1 u 1 wc dc ac 1,2 c 1,2 1 u 1 cos wc dc cos a 1 a 2 inv ( ) inv ( ) 1.0 k a 1 1.0 k tan( tan tan ) tan 0 S m cos 1,2 1,2 a 1,2 w tan( tan w tan aa11 ) tan app 0a 2 22 a2 w ( 2 cos cos dd1,2 cos d u u wd cos cos dbd u n1 / n2 inv u 2 ) inv( a 2 ) ad1,2 1,2 1,2 wd = w,cos isogram ad d n cos w 2 n1 cos nbd 1 (tan a2 2 2 cos w 2 u u tan ( 1 ) tan ) a 2 w 18 tan a1 a( w20 1u tan 2u 1) tan ( ) ( n n ) ( ) a a w 2 1 2 a1 a2 w Sa 2 m cos 2 cos a1 cos a 2 a2 a2 / n inv ( ) inv ( ) arccos( ) 18 cos 2 2 a 2 1 w n tan a1 u tan a 2 (u 1) tan 0 cos18 a1 1 n1 cos w 2 a 2 0 (16) w cos n cos (inv( a ) ( (n )) 16 tan a1 u tan a 2 (u 1) d tan 0 2 n m a2 w 2 a 2 1 (n n a1 1 inv a1 2 1w a 1n a2 2 w ) 2m a (1 n ) ) 1( 2) a 1 2 cos a1cos a tan a1 u tan a 2 (1 u ) tan w 0 cos a1 a2 2 cos a 2 1 arccos( ) n1 cos w 1a)2 tan a1 tan( u (1 u )( tan 0inv( w ) inv (inv 1 u w ) The pitch point position isograms for internal (n1 equations n2 ) 2) tan u tan (1 u ) tan 0 n1 a1 a2 1 (tan u n1w w ) 1 n cos w cos n1 cos w 2 2 a1 2 a1 u tan a 2 (u 1) tan ( 2 2, 3 ) (n ) gearing are from (Refs, and 5): 1 n2 ) ( dc kw 1 a1cos c1,2 a 2cos wc d 2cos ac1,2 cos a 2 cos a1 1.0 inv u inv inv ( ( ) ( ) ) ( ) ) 2 arccos( w cos cos 1 2 cos d ac 1,2 c1,2 n2 cos wc wd cos cos tan a n u tan (u w1) tan w0 18 u n 1 cos nn cos w 2 cos cos ad 1,2 d 1,2 bd k 1.0 1 dd cos cos dc a w 1 (n ac 1,2 c1,2 a1 1 ( 2 a2 2 wc dc ) (n1 n2 )2 )2 1( 2) w 1.0 k cos ad 1,2 1 cos d 1,2 cos wd dbd isogram a1 = w, cos a 2 cos a 2 cos a1 inv cos ad 1,2 cos dbd ) 2 arccos( d 1,2 ( wd ( (u ) )) inv( ) inv cos

tan(u tan a 2 (u 1) tan w ) tan p1 0 n2 cos n1 cos cos w 2 2 n cos n 1w 02 2 2u 2 2 external The pitch point position isograms equations w wfor ) ( n n ( ) 18 ( ) ( (u n1 n ) ( 1 ) 1 2) 18 tan u tan 0 2 aa11 tan ( u2tan tan ( u 1) 1) tan 0 a 2 w cos cos a 2 w cos cos 2 1 a a a 2and 4): a1 gearing are from (Ref. 2 arccos( ) 2 ) 2 arccos( n2 cos 0(n n ) n cos 1 2 w w 2u

cos a 2 cos (n1 1 n2 2)

w tan((1 u 1 tan w tan a tan p w u 2 a2 2 ) 1 p1 1 0 u)

1 (u inv( 2 ) inv( 1 )) inv( w ) u 1 1 u 1 tan( n1 tan tan a tan tan w 1) p2 2 u) (tan (1 0 1 p a1w u tan a 2 a w )

2

n1

u 2

(tan a1 u tan a 2 (1 u ) tan w )

n1

n1

(tan a1 u tan a 2 (u 1) tan w )

(tan a1 u tan a 2 (u 1) tan w )

equation cos d dc = cos 16. cos ac1,2 c1,2 wc isogram w iscos also defined by 1,2 1,2 2 a2 ac (inv ( 0 k ( a1 )) cn ma1 mwc dc a 1.0 a 2 ) inv 2 a2 cos cos ad cos cos d 1,2 d 1,2 wd bd a 1 ad 1,2 d 1,2 wd bd cos a1 The maximum mesh defined by a 2 )) efficiency (inv ( a1 ) inv( n1 ma1 isogram ma 2is 0 16 a2 cosvelocities condition of the equal specific sliding at the tips of cos a1 16 =n H (Ref. 6). These are: the mating teeth H1 (inv(gear ( maequations d axc cos a1 ) inv 2 )) 1 2 0 2 ma1 dc cos a 2 = = k 1.0 for external gearing: cos xd d bd 18 (18) tan a1 u tan a 2 (u 1) tan w 0

w 2 u (n n 2) tan a )1 tan 0 w cos a a(1 a1 1 u tan cos a2 2 a2 2 cos w (inv( ) ( )) 0 (17) inv n m m + a 2 a 1 2 a 1 a 2 (inv( a 2 ) inv( a1 )) n2 ma1 ma 2 cos a 2 0 a 1 cos

n cos

a1

tan((1 u ) tan w u tan a 2 ) tan p1 0

Figure 3Area of existence for the pinion and gear with n1 1 u 1 = 18 and n2 = 25; ma1= 0.25 = 0.35; Accordinglya: tan( tanand w ma 2 tan a1 ) tan p 2 0 u u external gearing; b: internal gearing; 1: family of the pres1 u w = const.; 1 sure angle isograms of the contact tan( a tan w 2: tanfamily a1 ) tan p2 0 ratio isograms ea = const.; interference isograms a = 0, ap2 u u p1 = 0, and tip-tip (for internal gearing); maximum mesh efficiency isograms H1 = H2; aa1= aw and aa2 = aw : isograms separating the gear meshes with the pitch point laying on the active portion of the contact line.

tan((1 u ) tan w u tan a 2 ) tan p1 0

a a w 0 tan u (1 1) )tan for internal gearing: 1 u 2 ( tan tan u tan u tan 0 18

a1 a2 w

a 2 (1 tan tan u ) tan 0 a1 u cos cos cos wc d dc w ac1,2 c1,2 k 1.0 cos ad 1,2 cos d 1,2 cos wd dbd Area cos of existence for external gearing (Fig. 3a) is limited cos c1,2 cos wc d dc ac1,2 1.0 k by the interference isograms d 1,2 and cos ad 1,2 cos cos isogram dbd of the minimum wd

(19) contact ratio (for spur gears it is 1.0). Area of existence of the internal gear pair can also be limited by the tip-tip interference isogram.

66

GEARTECHNOLOGY

January/February 2010

www.geartechnology.com

Every point of the area of existence presents a gear pair with a tan( certain set of the A few of u tan (u geometric 1) tan parameters. a2 w ) tan p1 0 these gear pairs are shown in Figure 3. Some of them do not look conventional, but they may be practical for some appli1 u 2 0 cations. Area of existence is much greater than the block-contour (Fig. 4) of any particular generating rack. It actually includes any gear pair combinations, generated by all possible blockcontours and also the gear pairs, where two different racks 1,2 gears. 1,2 inv ( a1,2 ) inv ( w ) generate the mating Area of Existence for Asymmetric Gearing The design intent of asymmetric gearing is to improve performance of primary expense w 2 profiles 2at the n cosdrive n cos w 2 of per( 1 ) (n1 n2 ) ( 2 ) formance for the opposite coast profiles cos a1 coast profiles. The cos a2 1 arccos( ) w a relatively short work n1 cos are unloaded or lightly loaded during (n1 n2 ) cos a1 also make it possible to period. Asymmetric tooth profiles simultaneously increase the contact ratio and operating presn cos w 2 n cos w 2 sure angle beyond gears ( 2conventional ) (n1 n2 ) 2 limits. ( 1 ) cos cos a1 tooth form 2 Direct Gear Design arepresents the asymmetric ) 2 arccos( 2 cos w base circles (Refs. 7 and by two involutes of two ndifferent (n1 n2 ) cos a 2 8), with the arc distance between them and tooth tip circle describing the gear tooth (Fig. 5). The equally spaced teeth anot cosis form the gear. The fillet between the teeth in contact 2 (inv( a 2 ) inv( a1 )) n2 ma1 ma 2 0 with the mating gear teeth, but this portion the tooth pro a1 cosof cos a 2 bending file ( is critical because it of the maximum ( a 2 ) ))is inv inv( a1 the n2 area ma1 m 0 + a2 cos a1 indepenstress concentration. The fillet profile is designed dently, providing minimum bending stress a1 concentration and cos (inv( 1 ) inv( a 2 )) n1 ma1 m 2 0 16 sufficient aclearance with the mating gear in mesh. a 2toothatip cos The relation between involute profile angles of opposite flanks of an asymmetric tooth is:

Figure 4Area of existence for the gear pairs with n1 = 22 and n2 = 35 and their standard 20 pressure angle generating rack block-contour.

ddc xc tan a1 cos u tan (u 1) tan w 0 a2 = cos xd d = k 1.0

bd

18 (20)

where xd and are involute profile a a 2 (1 tan u tan u ) angles tan w at the 0 dxdb 1 xc diameter. Then:

cos ac1,2 cos ad 1,2

cos c1,2 cos d 1,2

cos wc d dc k 1.0 cos wd dbd

(21)

where k is the asymmetry coefficient. If dbd = dbc, k = 1.0 and tooth is symmetric. The area of existence of asymmetric gears (Fig. 6) is built very similarly to the area of existence of symmetric gears. It basically presents an overlay of two areas of existence: one for the drive flanks and another for the coast flanks of the asymmetric tooth. The isogram equations for asymmetric gears are very similar to the equations for the symmetric gears. Application of Area of Existence A computer program generates the area of existence of involute gears for the given numbers of teeth n1 and n2, relative tooth tip thicknesses ma1 and ma2, and asymmetry coefficient k. Then, any selected point in the area presents a

continued

Figure 5Asymmetric tooth profile (fillet portion red); a: external tooth; b: internal tooth; da: tooth tip circle diameter; db: base circle diameter; d: reference circle diameter; S: circular tooth thickness at the reference diameter; v: involute intersection profile angle; Sa: circular tooth thickness at the tooth tip diameter; subscripts d and c are for the drive and coast flanks of the asymmetric tooth. January/February 2010

GEARTECHNOLOGY

www.geartechnology.com

67

b

Figure 6Area of existence for the asymmetric pinion and gear with: n1= 18 and n2 = 25; ma1 = 0.25 and ma2 = 0.35; and k = 1.2. a: for external gearing; b: internal gearing. The isograms related to the drive flank meshes are thick, the isograms related to the coast flank meshes are thin.

set of gear pair mesh parameters, considering its module (or its diametral pitch) and the face widths of the mating gears equal to one. Selection of the relative tooth tip radii and construction of the fillets between the teeth complete the gear geometry definition. The relative tooth tip radii are: r a1,2 = R a1,2/m in the metric system and ra1,2= Ra1,2 x DP in the English system, where Ra1,2 are the tooth tip radii of the mating gears. Typically, thicknesses ma1,2 are in the range 0.000.05. In traditional gear design, the fillet profile is typically a trajectory of the pre-selected (usually standard) generating gear rack. Any point of the block-contour presents the gear pair with completed (including the fillet) tooth profiles. In Direct Gear Design, the tooth fillet profile is a subject of optimization to minimize bending stress concentration (Refs. 910). However, the tooth fillet profile optimization is a time-consuming process that is used for the final stage of gear design. It is not practical for browsing the area of existence, analyzing many sets of gear pairs in limited time period. The tooth fillet profile should be quickly constructed, without tooth tip-fillet interference, and provide relatively low bending stress concentration. In order to achieve this, the virtual ellipsis arc is built into the tooth tip that is tangent to the involute profiles at the tip of the tooth. As a result, the tooth fillet profile is a trajectory of the mating gear tooth tip virtual ellipsis arc (Fig. 7). This fillet profile can be called pre-optimized because it provides lower bending stress concentration than the standard rack-generated fillet profile. The fillet profile construction completes the mating gears teeth geometry definition. This allows the program to demonstrate an animation of the gear mesh right after selection (clicking on) any point of the area of existence. The next step of area of existence analysis is the calculation of the maximum contact and bending stresses. This stress analysis program procedure requires an input of the operating module (or operating diametral pitch for English system), the face widths for both mating gears and the pinion torque. The modulus of elasticity and Poisson ratio are also required to calculate the Hertzian contact stress. The proprietary 2D FEA sub-routine is used for definition of maximum bending stress for both mating gears. This program assists in finding a suitable gear solution for a particular application, for example: 1. Heavily loaded low-speed gears: Appropriate gears are at intersection of the maximum pressure angle isogram and the maximum mesh efficiency isogram. 2. Lightly loaded high-speed gears: They can be found at intersection of the high contact ratio ( >2.0) isogram and the maximum mesh efficiency isogram. 3. Dissimilar material gears, like a metal pinion and a plastic gear: In this case, the metal pinion should have the minimum and the plastic gear the maximum relative tooth thickness at the tooth tip diameter. The pressure angle should be relatively low. This allows making the plastic gear tooth thicker and the metal pinion tooth thinner to balance

68

GEARTECHNOLOGY

January/February 2010

www.geartechnology.com

the bending strength of the mating teeth. 4. Self-locking gears: These parallel axis gears work essentially like worm gears. The solution can be found at a very high pressure angle (w >> 60, gears are helical) and with pitch point position after the active part of the tooth contact line. Conclusions The area of existence and its program allow for quickly defining limits of parameter selection of involute gears, locating feasible gear pairs, animating them and reviewing their geometry and stress levels. Benefits of using the area of existence are: consideration of all possible gear combinations; instant definition of the gear performance limits; a awareness about non-traditional, exotic gear design options; quick localization of area suitable for particular appli- cation; optimization of the gear design solution.

References: 1. Vulgakov E. B. Gears with Improved Characteristics, Mashinostroenie, Moscow, 1974 (in Russian). 2. Groman M. B. Selection of Gear Correction, Vestnik Mashinostroeniya, No. 2, 1955, 415. (in Russian). 3. Goldfarb V.I. and A.A. Tkachev. New Approach to Computerized Design of Spur and Helical Gears, Gear Technology, January/February 2005, 2632. 4. Kapelevich A. L. and R.E. Kleiss. Direct Gear Design for Spur and Helical Involute Gears, Gear Technology, September/October 2002, 2935. 5. Kapelevich A. L. Direct Design Approach for HighPerformance Gear Transmissions, Gear Solutions, January 2008, 2231. (Presented at the Global Powertrain Congress 2007, June 1719, 2007, Berlin, Germany and published in the Global Powertrain Congress Proceedings, Vol. 3942, 6671. 6. Townsend D. P. Dudleys Gear Handbook, McGraw-Hill, 1991. 7. Kapelevich A. L., Synthesis of Asymmetric Involute Gearing, Mashinovedenie, 1987, 6267 (in Russian). 8. Kapelevich A. L. Geometry and Design of Involute Spur Gears with Asymmetric Teeth, Mechanism and Machine Theory, 2000, Issue 35, pp. 117130. 9. Kapelevich A. L. and Y.V. Shekhtman. Direct Gear Design: Bending Stress Minimization, Gear Technology, September/October 2003, 4449. 10. Kapelevich A. L. and Y.V. Shekhtman. Tooth Fillet Profile Optimization for Gears with Symmetric and Asymmetric Teeth, Gear Technology, September/October 2009, 7379.

Figure 7The fillet profile construction. a: external gears; b: internal gearing; 1: involute profiles; 2: tooth tip lands; 3: fillet profiles; 4: ellipsis arcs that are used to generate the fillet profiles.

Dr. Alexander L. Kapelevich is the owner of the consulting firm AKGears, LLC, developer of modern Direct Gear Design methodology and software. He has 30 years of experience in gear transmission development (ak@ akgears.com).

Dr. Yuriy Shekhtman is an expert in mathematical modeling and stress analysis with 40 years experience. He created a number of computer programs based on FEA and other numerical methods. Dr. Shekhtman is a software developer for AKGears ( ys@ akgears.com).

www.geartechnology.com

January/February 2010

GEARTECHNOLOGY

69

Das könnte Ihnen auch gefallen

- Chpt05-FEM For 2D SolidsnewDokument56 SeitenChpt05-FEM For 2D SolidsnewKrishna MyakalaNoch keine Bewertungen

- Application of Derivatives Tangents and Normals (Calculus) Mathematics E-Book For Public ExamsVon EverandApplication of Derivatives Tangents and Normals (Calculus) Mathematics E-Book For Public ExamsBewertung: 5 von 5 Sternen5/5 (1)

- Uppsala University Systems and Control Final Exam AnswersDokument4 SeitenUppsala University Systems and Control Final Exam AnswersramiyaminNoch keine Bewertungen

- Response of MDOF SystemsDokument28 SeitenResponse of MDOF SystemsSalvador SilveyraNoch keine Bewertungen

- Mathematics 1St First Order Linear Differential Equations 2Nd Second Order Linear Differential Equations Laplace Fourier Bessel MathematicsVon EverandMathematics 1St First Order Linear Differential Equations 2Nd Second Order Linear Differential Equations Laplace Fourier Bessel MathematicsNoch keine Bewertungen

- תקשורת ספרתית- הרצאה 6 - מסננת מתואמת, איפנון בסיסDokument40 Seitenתקשורת ספרתית- הרצאה 6 - מסננת מתואמת, איפנון בסיסRonNoch keine Bewertungen

- Answers 2009-10Dokument19 SeitenAnswers 2009-10Yoga RasiahNoch keine Bewertungen

- DRM SolutionsDokument116 SeitenDRM SolutionsCésar TapiaNoch keine Bewertungen

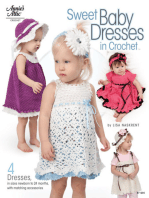

- Sweet Baby Dresses in Crochet: 4 Dresses in Sizes Newborn to 24 Months, with Matching AccessoriesVon EverandSweet Baby Dresses in Crochet: 4 Dresses in Sizes Newborn to 24 Months, with Matching AccessoriesBewertung: 4 von 5 Sternen4/5 (2)

- Appendix 16: Equation Sheet Chapter 1: Review of Modern PhysicsDokument14 SeitenAppendix 16: Equation Sheet Chapter 1: Review of Modern PhysicsDragan SokolovskiNoch keine Bewertungen

- Statistics For Management and Economics, Eighth Edition FormulasDokument16 SeitenStatistics For Management and Economics, Eighth Edition FormulasLeyu WangNoch keine Bewertungen

- Fourier ContDokument3 SeitenFourier Contluiso92Noch keine Bewertungen

- Ufabccapitulo 1Dokument121 SeitenUfabccapitulo 1Leonardo De Avellar FredericoNoch keine Bewertungen

- Formula Rio EDDokument3 SeitenFormula Rio EDrolando_gzaNoch keine Bewertungen

- Random Processes: 3.1 (A) The Mean and Autocorrelation Functions ofDokument21 SeitenRandom Processes: 3.1 (A) The Mean and Autocorrelation Functions ofSudipta GhoshNoch keine Bewertungen

- Coherent States of the Harmonic OscillatorDokument7 SeitenCoherent States of the Harmonic OscillatorZbiggNoch keine Bewertungen

- Convergence of series involving logarithms and powersDokument47 SeitenConvergence of series involving logarithms and powersRaahish KalariaNoch keine Bewertungen

- Formula2 (1) UpdatedDokument3 SeitenFormula2 (1) UpdatedAmm RoehNoch keine Bewertungen

- Answer Test 1 UTHMDokument12 SeitenAnswer Test 1 UTHMraadawadNoch keine Bewertungen

- Functions of Random VariablesDokument28 SeitenFunctions of Random VariablesSahand NoorizadehNoch keine Bewertungen

- Flow Through A Helical Pipe With Rectangular Cross-Section: Md. Mahmud Alam, Delowara Begum and K. YamamotoDokument12 SeitenFlow Through A Helical Pipe With Rectangular Cross-Section: Md. Mahmud Alam, Delowara Begum and K. Yamamotoxoxo777xoxoNoch keine Bewertungen

- 2Dokument13 Seiten2ruydegatreNoch keine Bewertungen

- Problem Set 1Dokument7 SeitenProblem Set 1alfonso_bajarNoch keine Bewertungen

- Integrale Nedefinite Si DerivateDokument2 SeitenIntegrale Nedefinite Si DerivatemirelamanteamirelaNoch keine Bewertungen

- Tutorial - Week9: To MinimizDokument18 SeitenTutorial - Week9: To MinimizKatie CookNoch keine Bewertungen

- Info Sheet t2 2012Dokument4 SeitenInfo Sheet t2 2012Luthando PuzaNoch keine Bewertungen

- Ch. 1: Review of ProbabilityDokument19 SeitenCh. 1: Review of ProbabilityKyusang ParkNoch keine Bewertungen

- Engineering MathsDokument8 SeitenEngineering MathsSanthosh SanNoch keine Bewertungen

- MATH 11L EXERCISES Pg. 90 93Dokument8 SeitenMATH 11L EXERCISES Pg. 90 93ralfhramos24Noch keine Bewertungen

- 4-Noded Rectangular Element Finite Element FormulationDokument27 Seiten4-Noded Rectangular Element Finite Element FormulationMathiew EstephoNoch keine Bewertungen

- EL-4701 Modelos de Sistemas: FormularioDokument9 SeitenEL-4701 Modelos de Sistemas: FormularioEmmanuel AcostaNoch keine Bewertungen

- ENEE 660 HW Sol #3Dokument13 SeitenENEE 660 HW Sol #3PeacefulLion100% (1)

- Response of Bank of Correlators To Noisy Input: A.Raviraja 118W1D8001Dokument12 SeitenResponse of Bank of Correlators To Noisy Input: A.Raviraja 118W1D8001Raviraja AkurathiNoch keine Bewertungen

- System Identification TechniquesDokument243 SeitenSystem Identification TechniquesfonsverbiestNoch keine Bewertungen

- Table of Fourier Transform PairsDokument8 SeitenTable of Fourier Transform PairsmayankfirstNoch keine Bewertungen

- Formula Sheet For MathsDokument5 SeitenFormula Sheet For Mathsbobd123Noch keine Bewertungen

- Matrices and Linear IndependenceDokument3 SeitenMatrices and Linear IndependenceaviralNoch keine Bewertungen

- Waves Scattering Induced by An Interface Crack in A Coated MaterialDokument6 SeitenWaves Scattering Induced by An Interface Crack in A Coated MaterialDarioLampaNoch keine Bewertungen

- ECE 5650/4650 Tables For Exam I: Sequence Sum FormulasDokument3 SeitenECE 5650/4650 Tables For Exam I: Sequence Sum Formulasue06037Noch keine Bewertungen

- NHA2430 Formulae SheetDokument10 SeitenNHA2430 Formulae SheetomarNoch keine Bewertungen

- Integrale Nedefinite Si DerivateDokument2 SeitenIntegrale Nedefinite Si DerivateIonut CatrinaNoch keine Bewertungen

- ME213 Formula SheetDokument3 SeitenME213 Formula SheetRuby SmithNoch keine Bewertungen

- O-H. Kim, Y.C. Kim: 2. TheoryDokument4 SeitenO-H. Kim, Y.C. Kim: 2. Theoryjainrakeshj4987Noch keine Bewertungen

- 12 Nonreciprocal CircuitDokument14 Seiten12 Nonreciprocal CircuitTeerachot SiriburanonNoch keine Bewertungen

- Exercise 13.21Dokument2 SeitenExercise 13.21Leonard Gonzalo Saavedra AstopilcoNoch keine Bewertungen

- A) Sketch The Graph of The Periodic Function Over Interval (-3, 3 )Dokument5 SeitenA) Sketch The Graph of The Periodic Function Over Interval (-3, 3 )Cer No RusNoch keine Bewertungen

- Formulario de modelos de sistemas y transformadas de Fourier y LaplaceDokument9 SeitenFormulario de modelos de sistemas y transformadas de Fourier y LaplaceAngel RamirezNoch keine Bewertungen

- 2.super Position of Periodic MotionsDokument47 Seiten2.super Position of Periodic Motionsvsnmurthy1Noch keine Bewertungen

- Elementary Tutorial: Fundamentals of Linear VibrationsDokument51 SeitenElementary Tutorial: Fundamentals of Linear VibrationsfujinyuanNoch keine Bewertungen

- EE 422G DFT and FFT NotesDokument23 SeitenEE 422G DFT and FFT NotesLam DinhNoch keine Bewertungen

- 10-1 Introduction: Chapter 10 The Discrete Fourier Transform and Fast Fourier Transform AlgorithmsDokument23 Seiten10-1 Introduction: Chapter 10 The Discrete Fourier Transform and Fast Fourier Transform AlgorithmsLtarm LamNoch keine Bewertungen

- Applied Statistics and Probability For Engineers, 5th EditionDokument23 SeitenApplied Statistics and Probability For Engineers, 5th EditionMuhammadHazmiMokhtar75% (4)

- Chapter 10Dokument32 SeitenChapter 10Sudipta GhoshNoch keine Bewertungen

- Introduction To ROBOTICS: Velocity Analysis JacobianDokument32 SeitenIntroduction To ROBOTICS: Velocity Analysis Jacobianal7123Noch keine Bewertungen

- Properties of Continuous and Discrete Fourier TransformsDokument10 SeitenProperties of Continuous and Discrete Fourier TransformsHandi RizkinugrahaNoch keine Bewertungen

- A Practical Approach For Modeling A Bevel Gear: Brendan BijonowskiDokument8 SeitenA Practical Approach For Modeling A Bevel Gear: Brendan BijonowskiPanagiotisNoch keine Bewertungen

- AGMA 2015 915-1-A02Dokument108 SeitenAGMA 2015 915-1-A02danielk32100% (1)

- Tolerances for Pitch-Span DeviationsDokument2 SeitenTolerances for Pitch-Span Deviationsdanielk32100% (1)

- Profile Correction of A Helical Gear Shaping CutterDokument11 SeitenProfile Correction of A Helical Gear Shaping Cutterdanielk32Noch keine Bewertungen

- Effects of The Hob Cutter Regrinding PDFDokument13 SeitenEffects of The Hob Cutter Regrinding PDFdanielk32Noch keine Bewertungen

- Profile CalculationDokument13 SeitenProfile CalculationAtsis PapadopoulosNoch keine Bewertungen

- Cutting Geometry Hypoid GearsDokument7 SeitenCutting Geometry Hypoid Gearsdanielk32Noch keine Bewertungen

- Agma 109.16-1965 Profile and Longitudinal Corrections On Involute GearsDokument25 SeitenAgma 109.16-1965 Profile and Longitudinal Corrections On Involute Gearsdanielk32Noch keine Bewertungen

- Tolerances and Deviations ISODokument1 SeiteTolerances and Deviations ISOdanielk32Noch keine Bewertungen

- DIN 2080-1-1978 Conos ISODokument3 SeitenDIN 2080-1-1978 Conos ISOdanielk3267% (3)

- Din 867Dokument3 SeitenDin 867danielk32Noch keine Bewertungen

- Hot Rolled I Sections DimensionsDokument3 SeitenHot Rolled I Sections Dimensionsg9g9Noch keine Bewertungen

- Chapter 3b Fugacity and Fugacity Coefficient For MixtureDokument26 SeitenChapter 3b Fugacity and Fugacity Coefficient For MixtureSeptiana AyuningtiasNoch keine Bewertungen

- Tank and Vessel Trace Heating Thermon Temperature Maintenance and Frost Protection HeetSheet Spec SheetDokument2 SeitenTank and Vessel Trace Heating Thermon Temperature Maintenance and Frost Protection HeetSheet Spec SheetCarlos SopasNoch keine Bewertungen

- Characterization of Hybrid Aluminum Matrix Composites For Advanced Applications - A ReviewDokument11 SeitenCharacterization of Hybrid Aluminum Matrix Composites For Advanced Applications - A ReviewMr. K.S. Raghul Asst Prof MECHNoch keine Bewertungen

- 4 K53 Code C1 Pre Trip 1Dokument2 Seiten4 K53 Code C1 Pre Trip 1abubakr fingerNoch keine Bewertungen

- Heat Transfer - K. A. GavhaneDokument175 SeitenHeat Transfer - K. A. GavhaneHussainNoch keine Bewertungen

- Heat Transfer ActivityDokument4 SeitenHeat Transfer ActivityMark Angelo UyNoch keine Bewertungen

- Technical Manual Mecanical Bumper SubDokument6 SeitenTechnical Manual Mecanical Bumper SubYeisson Rubio100% (1)

- Keperluan Document Sebagai Dasar Penerbitan SLODokument4 SeitenKeperluan Document Sebagai Dasar Penerbitan SLOFaturrakhman KhairanNoch keine Bewertungen

- Self-Check 1-1: Submitted by On 3/9/2012 5:21:18 PMDokument219 SeitenSelf-Check 1-1: Submitted by On 3/9/2012 5:21:18 PMblue4882Noch keine Bewertungen

- Owners manual for Maveric GK-32A go kartDokument18 SeitenOwners manual for Maveric GK-32A go kartedgar santanaNoch keine Bewertungen

- 640 DradiatorblindDokument2 Seiten640 DradiatorblindMaxy ServiçosNoch keine Bewertungen

- 2014 Miteebite Catalog WebDokument40 Seiten2014 Miteebite Catalog WebDonald NeislerNoch keine Bewertungen

- Coalescer SeparatorDokument1 SeiteCoalescer Separatoramol shindeNoch keine Bewertungen

- Wheatly XDokument2 SeitenWheatly XElinton SarmientoNoch keine Bewertungen

- Lunaire CE0932W 3 ManualDokument47 SeitenLunaire CE0932W 3 ManualDanNoch keine Bewertungen

- Hiab 320Dokument152 SeitenHiab 320Jasbir Jammu Repairing & Maintence LLCNoch keine Bewertungen

- Materi TM-300 28 Feb 2013Dokument26 SeitenMateri TM-300 28 Feb 2013kharimulazizNoch keine Bewertungen

- Mechanism and Robot Kinematics: Anirvan DasguptaDokument122 SeitenMechanism and Robot Kinematics: Anirvan Dasguptaसुमित शर्माNoch keine Bewertungen

- W90 WHEEL LOADER Service ManualDokument321 SeitenW90 WHEEL LOADER Service Manualelshind88% (8)

- Article DetailDokument78 SeitenArticle Detailandi_lb9453Noch keine Bewertungen

- Abs PDFDokument2 SeitenAbs PDFAdonis BasilioNoch keine Bewertungen

- Well DiagramDokument2 SeitenWell DiagramSanjay KapoorNoch keine Bewertungen

- Mould Ejection OptDokument50 SeitenMould Ejection OptMohamed HassanNoch keine Bewertungen

- Lecture 15 Plane Strain and Axisymmetric Structural Elements CommentaryDokument2 SeitenLecture 15 Plane Strain and Axisymmetric Structural Elements CommentaryHenry AbrahamNoch keine Bewertungen

- O&Msec3 CFB Boiler OperationDokument55 SeitenO&Msec3 CFB Boiler Operationbagus efendiNoch keine Bewertungen

- BULLET 350 KS TECHNICAL SPECSDokument2 SeitenBULLET 350 KS TECHNICAL SPECSKamsutra YogiNoch keine Bewertungen

- Sae As 81819 2001 (En) PDFDokument35 SeitenSae As 81819 2001 (En) PDFWilliam LooNoch keine Bewertungen

- Gregory H. Wannier - Statistical Physics-Dover Publ. (1987) PDFDokument564 SeitenGregory H. Wannier - Statistical Physics-Dover Publ. (1987) PDFJosé Vellojín100% (1)

- Gravity Sewer Acceptance Testing Results Sheet: Sewer Pipeline Pressure TestDokument1 SeiteGravity Sewer Acceptance Testing Results Sheet: Sewer Pipeline Pressure TestLulouch Raiz100% (1)

- Assignment No. 1 Design Basis Report G+5 BuildingDokument34 SeitenAssignment No. 1 Design Basis Report G+5 BuildingMerijanNoch keine Bewertungen

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionVon EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionBewertung: 4.5 von 5 Sternen4.5/5 (542)

- 8051 Microcontroller: An Applications Based IntroductionVon Everand8051 Microcontroller: An Applications Based IntroductionBewertung: 5 von 5 Sternen5/5 (6)

- Understanding Automotive Electronics: An Engineering PerspectiveVon EverandUnderstanding Automotive Electronics: An Engineering PerspectiveBewertung: 3.5 von 5 Sternen3.5/5 (16)

- Build Your Own Electric Vehicle, Third EditionVon EverandBuild Your Own Electric Vehicle, Third EditionBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Beginner's Guide to Reading Schematics, Third EditionVon EverandBeginner's Guide to Reading Schematics, Third EditionNoch keine Bewertungen

- High Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsVon EverandHigh Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsBewertung: 4 von 5 Sternen4/5 (1)

- The Fast Track to Your Technician Class Ham Radio License: For Exams July 1, 2022 - June 30, 2026Von EverandThe Fast Track to Your Technician Class Ham Radio License: For Exams July 1, 2022 - June 30, 2026Bewertung: 5 von 5 Sternen5/5 (1)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionVon EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionBewertung: 4 von 5 Sternen4/5 (331)

- 2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersVon Everand2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersBewertung: 5 von 5 Sternen5/5 (1)

- Lithium-Ion Battery: The Power of Electric Vehicles with Basics, Design, Charging technology & Battery Management SystemsVon EverandLithium-Ion Battery: The Power of Electric Vehicles with Basics, Design, Charging technology & Battery Management SystemsBewertung: 5 von 5 Sternen5/5 (2)

- Off-Grid Projects: Step-by-Step Guide to Building Your Own Off-Grid SystemVon EverandOff-Grid Projects: Step-by-Step Guide to Building Your Own Off-Grid SystemNoch keine Bewertungen

- Upcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)Von EverandUpcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)Bewertung: 4.5 von 5 Sternen4.5/5 (2)

- Ramblings of a Mad Scientist: 100 Ideas for a Stranger TomorrowVon EverandRamblings of a Mad Scientist: 100 Ideas for a Stranger TomorrowNoch keine Bewertungen

- Introduction to Power System ProtectionVon EverandIntroduction to Power System ProtectionNoch keine Bewertungen

- The Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesVon EverandThe Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesBewertung: 5 von 5 Sternen5/5 (1)

- The Rare Metals War: the dark side of clean energy and digital technologiesVon EverandThe Rare Metals War: the dark side of clean energy and digital technologiesBewertung: 5 von 5 Sternen5/5 (2)

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeVon EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeBewertung: 5 von 5 Sternen5/5 (8)

- Operational Amplifier Circuits: Analysis and DesignVon EverandOperational Amplifier Circuits: Analysis and DesignBewertung: 4.5 von 5 Sternen4.5/5 (2)

- C++ Programming Language: Simple, Short, and Straightforward Way of Learning C++ ProgrammingVon EverandC++ Programming Language: Simple, Short, and Straightforward Way of Learning C++ ProgrammingBewertung: 4 von 5 Sternen4/5 (1)

- Current Interruption Transients CalculationVon EverandCurrent Interruption Transients CalculationBewertung: 4 von 5 Sternen4/5 (1)

- Digital Gold: The Beginner's Guide to Digital Product Success, Learn Useful Tips and Methods on How to Create Digital Products and Earn Massive ProfitsVon EverandDigital Gold: The Beginner's Guide to Digital Product Success, Learn Useful Tips and Methods on How to Create Digital Products and Earn Massive ProfitsBewertung: 5 von 5 Sternen5/5 (3)

- The Graphene Revolution: The Weird Science of the Ultra-thinVon EverandThe Graphene Revolution: The Weird Science of the Ultra-thinBewertung: 4.5 von 5 Sternen4.5/5 (4)