Beruflich Dokumente

Kultur Dokumente

03

Hochgeladen von

Didik RiswantoOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

03

Hochgeladen von

Didik RiswantoCopyright:

Verfügbare Formate

Midland Combustion Electric Outflow Heaters

Midcom Electric Outflow Heaters are available to work with even the most difficult oils and process fluids when there is no other heating medium available. High viscosity crude oils as well as coal tar, bitumen and a host of process fluids can be heated to specific temperatures and controlled precisely either by traditional thermostat or the more up to date method of solid state electronics offering more accurate temperature control and power saving. Long life low watts density removable ceramic core elements are are designed for optimum trouble free service and ease of maintenance. All Midcom tank mounted Outflow Heaters from EOF range are fitted with adjustable temperature control thermostat and over temperature cut out thermostat fitted into pockets and located within a weather tight enclosure. Depending on how the heating load is arranged multiple heating banks with multiple thermostats are designed for efficient heater control fitted into pockets and located within a weather tight enclosure. They are extensively used in large and small heating applications such as diesel oil systems where there is a need to prevent waxing at low temperatures, combustion systems, furnace applications and all styles of fuel handling arrangements. One advantage of the Midcom Outflow Heater is that a failed electric element can be replace without the need to isolate and drain the storage tank. All heaters in the Midcom range have been supplied for Marine applications requiring rigorous inspections from the likes of Lloyds Register of Shipping, Zurich, ABS etc. Products are hydraulic and electrical tested before they leave the factory. By installing a Midcom Outflow Heater the tank contents can be stored at a lower temperature thus saving energy. The outflow heater will therefore only heat the required oil needed for process. Fuel Oils Viscosity @ 50C Minimum Storage Temperature Minimum Pumping Temperature @ Outflow Heater Outlet 30C 50C 55C

Class F Class G Class H

110 380 600

25C 40C 45C

Midland Combustion Electric Outflow Heaters

Midcom Code

kW Load for Heavy Fuel Oils 3.6 5.4 7.2 9.0 10.8 12.6 14.4

Maximum Heating Throughput Raising Heavy Fuel Oil through 10C (kg/hr) 642 962 1283 1604 1925 2246 2566

Midcom Code

kW Load for Heavy Fuel Oils 64.8 81.0 97.2 113.4 129.6

Maximum Heating Throughput Raising Heavy Fuel Oil through 10C (kg/hr) 11549 14436 17323 20210 23097

EOF 4 - 24 EOF 4 - 36 EOF 4 - 48 EOF 4 - 60 EOF 4 - 72 EOF 4 - 84 EOF 4 - 96

EOF 10 - 48 EOF 10 - 60 EOF 10 - 72 EOF 10 - 84 EOF 10 - 96

EOF 6 - 48 EOF 6 - 60 EOF 6 - 72 EOF 6 - 84 EOF 6 - 96

21.6 27.0 32.4 37.8 43.2

3850 4812 5774 6737 7699

EOF 12 - 60 EOF 12 - 72 EOF 12 - 84 EOF 12 - 96

108.0 129.6 151.2 172.8

19248 23097 26947 30796

EOF 8 - 60 EOF 8 - 72 EOF 8 - 84 EOF 8 - 96

45.0 54.0 63.0 72.0

8019 9623 11277 12831

EOF 16 - 72 EOF 16 - 84 EOF 16 - 96

194.4 226.8 259.2

34646 40420 46194

Midland Combustion Electric Outflow Heater Dimensions

A, Withdrawal Distance H Nom = C = A Immersed Length = A-C Tank Stool Piece, Gasket & Fixings (By Others) Vent G Oil Return Connection if Required B Dia F E Control Wiring Conduit Entry Power Wiring Conduit Entry D D G Oil Outlet Connection

Tank Mounting Flange

Int./External Earth Stud Terminal Enclosure

Elevation Midcom Type mm B mm C mm D mm E mm F

End Elevation mm H Tank Mounting Flange (PN10 BS EN 1092)

NB G

EOF 4

114.3

300

185

85

30

40

146

150NB 85 O/D x 15mm Thick C/W 8 off 22 Holes on 240 Pcd off Ctrs 200NB 340 O/D x 20mm Thick C/W 8 off 22 Holes on 295 Pcd off Ctrs 250NB 395 O/D x 20mm Thick C/W 12 off 22 Holes on 350 Pcd off Ctrs 300NB 445 O/D x 25mm Thick C/W 12 off 22 Holes on 400 Pcd off Ctrs 350NB 505 O/D x 25mm Thick C/W 16 off 22 Holes on 460 Pcd off Ctrs 450NB 615 O/D x 32mm Thick C/W 20 off 26 Holes on 565 Pcd off Ctrs

EOF 6

168.3

300

200

100

55

50

151

EOF 8

219.1

300

230

130

75

50

151

EOF 10

273

300

260

140

105

50

156

EOF 12 323.8

380

350

210

115

80

156

EOF 16 406.4

380

400

275

155

80

250

Length A

24 ins 610

36 ins 915

48 ins 1220

60 ins 1525

72 ins 1830

84 ins 2135

96 ins 2440

Midland Combustion Electric Outflow Heater

400 V 3 PH 50HZ 3 Wire 1 2 3 E 1 CF1 32/2A 10 150VA 12 CF3 20/2A 14 15 110V 13 LK1 Line Heater 3 CF2 32/2A TX1 400V 11 C1 A1 B1 C1 BN GY BK

Electrical Wiring Diagram

Shown as one heating bank. Multi-bank available.

14

IL1 W C1 16 IL2 18 IL3 G

Supply On Line Heater On Line Heater Overtemp A Line Heater Contactor A2 Last Wire No.19

14

SW1

Off On

14 3

2 XS1 1

CS1 Control 3 1

19

A1

C1

Door Layout for Electric Outflow Heater IP65 Control Panel

1. Supply On Light (IL1) 2. Outflow Heater On Light (IL2) 3. Outflow Heater Overtemp Light (IL3) 4. Outflow Heater Off/On Selector Switch 5. Fuse Switch Handle

Das könnte Ihnen auch gefallen

- MSDS-PSF-600,000cSt Silicone Damping FluidDokument5 SeitenMSDS-PSF-600,000cSt Silicone Damping Fluidvictor.ciprianiNoch keine Bewertungen

- 9715efdi Dcmotors v1Dokument35 Seiten9715efdi Dcmotors v1agarwood0% (1)

- G330 IntelysisDokument330 SeitenG330 IntelysisLIBERTADNoch keine Bewertungen

- MMUP Final For Civil EngineersDokument87 SeitenMMUP Final For Civil Engineersahmed97% (68)

- Heritage Architecture (Ivatan House)Dokument45 SeitenHeritage Architecture (Ivatan House)Hazel Acidre100% (1)

- Mechanical Calculation For Static Mixer: (Type Here)Dokument5 SeitenMechanical Calculation For Static Mixer: (Type Here)hcsharma1967Noch keine Bewertungen

- ACI 350.3-06 Seismic Design of Liquid-Containing Concrete Structures and CommentaryDokument67 SeitenACI 350.3-06 Seismic Design of Liquid-Containing Concrete Structures and CommentaryJAVELLA100% (2)

- Masterpact NT: User ManualDokument56 SeitenMasterpact NT: User ManualkubikNoch keine Bewertungen

- Terasaki Tecs MCB Catalogue - v9 PDFDokument12 SeitenTerasaki Tecs MCB Catalogue - v9 PDFshareyhouNoch keine Bewertungen

- AC&M Power TransducersDokument2 SeitenAC&M Power TransducersLare LenangNoch keine Bewertungen

- HCI634H - Winding 311 and 312: Technical Data SheetDokument9 SeitenHCI634H - Winding 311 and 312: Technical Data Sheet3efooNoch keine Bewertungen

- Caterpillar CG260 - 60 y 50 HZDokument5 SeitenCaterpillar CG260 - 60 y 50 HZEdutam67% (3)

- DEIF TCM 2 Datasheet 4921240329ukDokument6 SeitenDEIF TCM 2 Datasheet 4921240329ukAnonymous T3qDfvNoch keine Bewertungen

- Opel Corsa Aircon InstallationDokument18 SeitenOpel Corsa Aircon InstallationMOLL1234100% (1)

- MVR 200 Designers Handbook 4189341221 UkDokument536 SeitenMVR 200 Designers Handbook 4189341221 UkAbhi ETAPNoch keine Bewertungen

- ABB M2QA CatalogueDokument16 SeitenABB M2QA CatalogueMaiPrachanartNoch keine Bewertungen

- Capillary Tube Inst-Tubing PDFDokument4 SeitenCapillary Tube Inst-Tubing PDFEduardoNoch keine Bewertungen

- Pub109-011!00!1114 Soldo Sy-Sw Switchbox FlyerDokument4 SeitenPub109-011!00!1114 Soldo Sy-Sw Switchbox FlyerEric JohnsonNoch keine Bewertungen

- SIEMENS HRC Fuse Type 3NA3Dokument24 SeitenSIEMENS HRC Fuse Type 3NA3erkamlakar2234100% (1)

- Big 40 WGDokument80 SeitenBig 40 WGsquibgo100% (1)

- Sec Etg Series BrochureDokument11 SeitenSec Etg Series BrochurenenaddejanovicNoch keine Bewertungen

- Catalog - Air Cooled Twin Screw VSD YVAADokument54 SeitenCatalog - Air Cooled Twin Screw VSD YVAAdanang hadi saputroNoch keine Bewertungen

- 30XA Product Data PDFDokument36 Seiten30XA Product Data PDFanoopkumar1231150100% (2)

- Ataengine Altronic PDFDokument12 SeitenAtaengine Altronic PDFdg_cd7340Noch keine Bewertungen

- Altronic DD-40NTV-II Installation Instructions (FORM DD-40NTV II)Dokument36 SeitenAltronic DD-40NTV-II Installation Instructions (FORM DD-40NTV II)francis_mouille_iiNoch keine Bewertungen

- Altronic EPC 110-120 Operating Manual (FORM EPC-110/120 OM)Dokument55 SeitenAltronic EPC 110-120 Operating Manual (FORM EPC-110/120 OM)francis_mouille_iiNoch keine Bewertungen

- Synchronous Generator J.Majumder MIE Senior FacultyDokument18 SeitenSynchronous Generator J.Majumder MIE Senior FacultyQuang Tiên100% (1)

- Sailor RE-2100Dokument186 SeitenSailor RE-2100Fernando SuarezNoch keine Bewertungen

- Egcp1 (End User)Dokument160 SeitenEgcp1 (End User)Dat Nguyen Cong100% (1)

- WEG Hazardous Area Motors Usa125 Brochure English PDFDokument124 SeitenWEG Hazardous Area Motors Usa125 Brochure English PDFPustinjak SaharicNoch keine Bewertungen

- Copeland ZR125KC-TF5-950 Scroll Compressor - Carrier HVACDokument3 SeitenCopeland ZR125KC-TF5-950 Scroll Compressor - Carrier HVACjacc42Noch keine Bewertungen

- Leonova Condmaster ManualDokument172 SeitenLeonova Condmaster ManualThomas BembeNoch keine Bewertungen

- Generator TheoryDokument4 SeitenGenerator TheoryRachit KhannaNoch keine Bewertungen

- TAD1640GE: Volvo Penta Genset EngineDokument2 SeitenTAD1640GE: Volvo Penta Genset EngineRenzo zuñiga ahon100% (1)

- Test de RadiadorDokument10 SeitenTest de RadiadorOmar Reinoso TigreNoch keine Bewertungen

- CP SP 1372e 03 PDFDokument40 SeitenCP SP 1372e 03 PDFArribas Quilaton LeoNoch keine Bewertungen

- KAT Series PDFDokument27 SeitenKAT Series PDFRashel HasanNoch keine Bewertungen

- 42-683.16 Switch MechanismsDokument36 Seiten42-683.16 Switch MechanismsJonathan AntillonNoch keine Bewertungen

- Pressure TransducerDokument17 SeitenPressure TransducerDian PramadiNoch keine Bewertungen

- RMC-131D, Installation Instructions 4189340121 UKDokument4 SeitenRMC-131D, Installation Instructions 4189340121 UKUday PowarNoch keine Bewertungen

- DMN FST Manual Sp-Ec-Rot-Mt Reset Module en 20100713-MsDokument2 SeitenDMN FST Manual Sp-Ec-Rot-Mt Reset Module en 20100713-MsadrianpashnicNoch keine Bewertungen

- Delomatic 3 Installation Instructions 4189230125 UkDokument18 SeitenDelomatic 3 Installation Instructions 4189230125 UkAris MoutskasNoch keine Bewertungen

- 841 VCB HVF&HVG Catalogue 2012.1Dokument56 Seiten841 VCB HVF&HVG Catalogue 2012.1Sergio Ignacio Zurita VargasNoch keine Bewertungen

- Abb BrochureDokument12 SeitenAbb BrochurewindaidenNoch keine Bewertungen

- Valves CatalogueDokument33 SeitenValves CatalogueDheeraj ThakurNoch keine Bewertungen

- Coordination Curve DirectDokument2 SeitenCoordination Curve DirectBryan SalamatNoch keine Bewertungen

- Isomag Brochure enDokument8 SeitenIsomag Brochure enReynaldo RiveraNoch keine Bewertungen

- Delta Electronics Vfd007s23a User ManualDokument186 SeitenDelta Electronics Vfd007s23a User ManualnamvinhNoch keine Bewertungen

- IOM Paquetes DX Precedent RT-SVX22U-EN - 03072018Dokument82 SeitenIOM Paquetes DX Precedent RT-SVX22U-EN - 03072018Mario Lozano100% (1)

- Riello G3X Owner ManualDokument16 SeitenRiello G3X Owner ManualKonstantaras YiannisNoch keine Bewertungen

- Excel ApodysDokument4 SeitenExcel ApodysjeremiahNoch keine Bewertungen

- 20112E ISS3 W Alum IE2 IE3Dokument20 Seiten20112E ISS3 W Alum IE2 IE3Ashraf IrfanNoch keine Bewertungen

- Catalogue FSA 50Hz Rev.02Dokument6 SeitenCatalogue FSA 50Hz Rev.02Heri SulasionoNoch keine Bewertungen

- Actua DorDokument4 SeitenActua DorAnonymous dYYLURMNoch keine Bewertungen

- Aalborg MX PDFDokument3 SeitenAalborg MX PDFJuan Cruz TauterysNoch keine Bewertungen

- HeaterDokument12 SeitenHeaterErwin Paulian SihombingNoch keine Bewertungen

- Stress Relieving Equipment1Dokument9 SeitenStress Relieving Equipment1Erick HoganNoch keine Bewertungen

- Fulton Oil HeaterDokument16 SeitenFulton Oil HeaterarjmandquestNoch keine Bewertungen

- CGAT Catalog0303Dokument2 SeitenCGAT Catalog0303Chinith HengNoch keine Bewertungen

- Big Blue Air Pak: The Power of BlueDokument4 SeitenBig Blue Air Pak: The Power of BlueRaul Izquierdo MoralesNoch keine Bewertungen

- Chiller RecipDokument4 SeitenChiller RecipHerni SuharniriyantiNoch keine Bewertungen

- York Cat LC 2012 enDokument148 SeitenYork Cat LC 2012 enMary Andrews100% (1)

- OI 53 54 55 en de FR Es 9461 PDFDokument52 SeitenOI 53 54 55 en de FR Es 9461 PDFDidik RiswantoNoch keine Bewertungen

- 1SDC010001D0201 PDFDokument117 Seiten1SDC010001D0201 PDFDidik RiswantoNoch keine Bewertungen

- Cascade Control 1Dokument4 SeitenCascade Control 1Didik RiswantoNoch keine Bewertungen

- Gas Shutoff Valves: FeaturesDokument2 SeitenGas Shutoff Valves: FeaturesDidik RiswantoNoch keine Bewertungen

- Cascade TuningDokument18 SeitenCascade TuningDidik RiswantoNoch keine Bewertungen

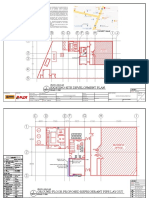

- Burner & Oil Preheater GA DrawingDokument3 SeitenBurner & Oil Preheater GA DrawingDidik RiswantoNoch keine Bewertungen

- A6458SDokument5 SeitenA6458SDidik Riswanto0% (1)

- Econ Safety Relief Valves Closed Type BronzeDokument1 SeiteEcon Safety Relief Valves Closed Type BronzeDidik RiswantoNoch keine Bewertungen

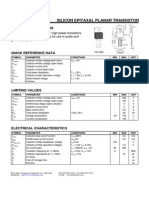

- 2SD401 Silicon Epitaxal Planar Transistor: General DescriptionDokument1 Seite2SD401 Silicon Epitaxal Planar Transistor: General DescriptionDidik RiswantoNoch keine Bewertungen

- 01CBO Procurement Manual EnglishDokument86 Seiten01CBO Procurement Manual EnglishfeteneNoch keine Bewertungen

- GRUNDFOS Heating-Handbook-2020Dokument132 SeitenGRUNDFOS Heating-Handbook-2020Τζίνα ΓιαννοπούλουNoch keine Bewertungen

- 00 Preventing Corrosion in AluminumDokument1 Seite00 Preventing Corrosion in AluminumReylourd PunzalNoch keine Bewertungen

- Settlement of FoundationsDokument18 SeitenSettlement of FoundationsIan Seguritan100% (1)

- Design ProblemsDokument10 SeitenDesign ProblemsCHAKRINoch keine Bewertungen

- CSI Codes - Alphabetical 2004Dokument10 SeitenCSI Codes - Alphabetical 2004ritchie_mayoNoch keine Bewertungen

- De La Cruz, J. C., Del Campo, J. M., & Colorado, D. (Mayo de 2014)Dokument7 SeitenDe La Cruz, J. C., Del Campo, J. M., & Colorado, D. (Mayo de 2014)Jorge GonzalezNoch keine Bewertungen

- KingsPan AccessoriesDokument75 SeitenKingsPan AccessoriesFlorin CîrstocNoch keine Bewertungen

- Resolution PtaDokument3 SeitenResolution PtaMARY JEAN SUMALINOGNoch keine Bewertungen

- Seepage Drainage and Flow NetsDokument1 SeiteSeepage Drainage and Flow NetsDwight AndersonNoch keine Bewertungen

- AISC Properties DatabaseDokument7 SeitenAISC Properties DatabaseShekh Muhsen Uddin AhmedNoch keine Bewertungen

- 00 AWWA StandardsDokument3 Seiten00 AWWA Standardsliviu_dovaNoch keine Bewertungen

- Structural Concepts and SystemsDokument133 SeitenStructural Concepts and Systemsprakashcg123100% (2)

- AMS01 PH2 IFC Package 1Dokument15 SeitenAMS01 PH2 IFC Package 1Adrian DaneaNoch keine Bewertungen

- Development of A Device For Brazing Copper Pipes in HVAC InstallationsDokument8 SeitenDevelopment of A Device For Brazing Copper Pipes in HVAC InstallationsJournal of Interdisciplinary PerspectivesNoch keine Bewertungen

- ACU DDD - TNT Phase 2 PLDT Cauayan ME Plan 17may2021 - JEHAN - UpdatedDokument8 SeitenACU DDD - TNT Phase 2 PLDT Cauayan ME Plan 17may2021 - JEHAN - UpdatedMark Roger II HuberitNoch keine Bewertungen

- JIS FlangesDokument9 SeitenJIS FlangesKhairulUmamNoch keine Bewertungen

- 100-510-45436 - H Hpt-06-Mb1-Eb1 O&m ManualDokument15 Seiten100-510-45436 - H Hpt-06-Mb1-Eb1 O&m ManualMiki 40Noch keine Bewertungen

- Cable Gland Selection ChartDokument4 SeitenCable Gland Selection Chartajeez86100% (2)

- Zone Control With Variable Air Volume Controls (VAV) - KMC ControlsDokument3 SeitenZone Control With Variable Air Volume Controls (VAV) - KMC Controlschenxiangyang_jp100% (1)

- A B C D E: Laboratory Building Ground Floor PlanDokument1 SeiteA B C D E: Laboratory Building Ground Floor PlanEmre ÇilNoch keine Bewertungen

- Extra High Strength Steels - Strenx vs. HardoxDokument1 SeiteExtra High Strength Steels - Strenx vs. Hardoxdavid blecicNoch keine Bewertungen

- 0405A QuestionsDokument9 Seiten0405A QuestionsD01ASSASSINNoch keine Bewertungen

- Ce6505 Notes Rejinpaul PDFDokument146 SeitenCe6505 Notes Rejinpaul PDFIsrael VenkatNoch keine Bewertungen

- Manual For Design Using Etabs PDFDokument46 SeitenManual For Design Using Etabs PDFPankaj Sardana100% (1)

- ASHARE 36 Aee - April - 2021 - Ashrae - Guideline - 36Dokument42 SeitenASHARE 36 Aee - April - 2021 - Ashrae - Guideline - 36Mike KennedyNoch keine Bewertungen