Beruflich Dokumente

Kultur Dokumente

Https Digiprintsupplies - Zendesk.com Attachments Token 9zadretbiapxzss Name Troubleshooting+Print+Head+ (Nozzles) +problems

Hochgeladen von

mehoOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Https Digiprintsupplies - Zendesk.com Attachments Token 9zadretbiapxzss Name Troubleshooting+Print+Head+ (Nozzles) +problems

Hochgeladen von

mehoCopyright:

Verfügbare Formate

Troubleshooting Print Head (Nozzle) Problems

A step-by-step guide (version 1.0, summer 2011)

Troubleshooting common print head problems is not an easy task. It requires fundamental understanding of digital inkjet printing and a systematic, structured approach. This document will help you in identifying the cause of print head troubles and how to address them. PRELIMINARY REMARKS Modern digital inkjet printers and their print heads are sophisticated and, in a way, delicate. In order for them to operate in the best possible way, some criteria need to be taken into consideration. This starts with the installation of the printer: never install the machine in a location where it is tilted or where it may wobble or vibrate. Only when you printer is levelled, good operation of your printer and print head(s) is guaranteed. Also the conditions should be stable and within specications regarding temperature and humidity. Furthermore, the use of good quality media is important too. Cheap media almost always has weak characteristics like uneven coating, bad calendering and a too high tolerance in thickness. This will result in poor looking prints that might even seduce you in thinking that your print head has issues. Finally, there is the ink used. Original inks are your best option, since they have been developed to match the print head used and the temperatures used. Third-party inks often do not take this into consideration enough and some of them are downright killing your print head(s). HOW IT WORKS Almost all modern digital inkjet printers work in the same way, pictured in the scheme below. There might be some additional parts in your printer like ink subtanks or lters, but in general, they all work alike.

INK BOARD INK CARTRIDGE

DPSnotes

MAIN BOARD

HEAD BOARD

DAMPER

PRINT HEAD

WIPER

CAP TOP INK TUBE ELECTRICAL WIRE

PUMP MOTOR

PUMP

www.digiprint-supplies.com

The Ink Cartridge is holding the ink. A damper is a plastic structure with a mesh lter that acts as a one way valve. It has several functions. It can collect a small amount of air, it prevents ink particles from entering the head, it is a one way valve, it holds and dispenses ink. The structure is designed to keep the head performing well. It should be changed ideally once every six months (or when it is clogged by ink particles). The higher the speed of your printer, the bigger the damper should be. The damper then delivers the ink to the (pizo-electric) print head. The print head is driven by the head board (or carriage board) which is controlled by the main board (which controls all electrical parts like the pump motor, ink board, servo board, junction board etc.)

ABOUT INKS (Solvent) ink is made up of a few basic components: Pigment for color, Resin for gloss and adhesion, oil or water based co-solvents, and humectants similar to what is used in hair shampoo and some very proprietary elements. Inks must be ltered to about .2 microns to insure smooth owing through a modern print head. Ink is not a solution. It is a colloidal suspension similar to milk. The pigment and resin make up the solids of ink. A resin is a liquid plastic. Imagine what happens to liquid plastic when it dries. Yes, it becomes a solid. When pigment ink binds with resin, it becomes a colored solid and is often difcult to loosen. This is why a head must be kept lubricated. Over time it will dry out even when at rest on a capping station. By keeping the capping station moist with a lubricant that loosens ink and lubricates the capping station it will keep the head properly moist and free owing. PRINTING CONDITIONS Humidity should be at about 30 to 40 percent and temperature should be about 20 to 25 degrees Celsius. As temperature decreases, the ink becomes thicker which makes owability more difcult. When the temperature rises, the ink viscosity decreases, making the ink thinner. The changes in temperature can also affect the printing color. Low humidity can cause the heads and capping station to dry out causing ink drop out and impropper cleaning. Make sure to put two drops of appropriate cleaning liquid on the capping station each evening and do not let the printer get below 18 degrees Celsius. Never use a cleaning liquid like Windex. Although it will clean, it does not keep the caps moist and they will turn hard, which is a hazard to the print heads. Of course this is also true for your wipers. CLOGGED PRINT HEAD NOZZLES Clogged nozzles are extremely common with printers that have not been cleaned on a continual basis . Think a moment. Do you not change the oil in your car about 10.000 km to keep the engine running smoothly? Most of us do. There are multiple areas that cause problems with nozzles ring well: The Capping Station Pads The Pump(s) The Wiper(s) The Dampers The Print Head

DPSnotes

www.digiprint-supplies.com

The Capping Station is where the head rests and where the head gets cleaned. The capping station has a foam pad touching the head and a tube leading from the capping pad to a pump. Ink gets sucked from the head through the foam pad. When the printer is not used for a while the ink on the pad starts to dry which causes the nozzles in the head to dry as well. Most inks are made of a group of chemicals which include resin. Liquid resin becomes solid plastic when it dries which it is hard to disolve and break up. The capping station pump can wear out which will result in insucient suction. This will prevent proper cleaning. The dampers are the rst line of protection. The tubing from the cartridge goes to the damper which sits directly on the print head. The damper has a lter inside it to capture any particles that could clog the nozzles. After a good deal of ink travels through the damper, you may have particle build up which will prevent the ow of ink causing nozzles to drop out. Dampers should be replaced every six months. The print head contains extremely small nozzles that rened ink ows through. The surface of the head must be kept lubricated in order to prevent the head from drying out the ink. If ink inside the head forms solid particles it will block ink from owing. It is imperative for the capping station pad to be kept moist to prevent the head from drying.

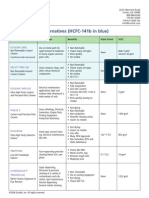

NOZZLE DROP OUT SCENARIOS When the output of your printers indicates missing nozzles (or nozzle drop out), a nozzle test pattern can tell you what is causing it. Please refer to the different nozzle test pattern below to determine the problem you have. 1 - UNSTABLE NOZZLE OUT The missing nozzles change their position after cleaning. POSSIBLE CAUSES Air bubbles in the ink line or print head nozzle area, and it does not come out. The wiper rubber blade is rounded and not sharp enough anymore The wiper rubber blade has gelled ink or dried ink on it. ACTIONS Check the print head for bubbles on the nozzle plate Check the damper and ink lines for air bubbles Check the cartridge valve for good functioning Check, clean and/or replace the wiper blades 2 - STABLE NOZZLE OUT The missing nozzles do not change its position all the time. POSSIBLE CAUSES Some kind of dusts are inside or on the surface of print head nozzles. The print head nozzle surface, cap rubber, and wiper rubber has to be cleaned every day. The print head surface might be damaged by head crash with the media. The print head has been used for a long time with a high head gap which is larger than 3.0 mm ACTIONS Clean the caps, wiper blade and nozzle surface Replace the print head 3 - MULTIPLE ADJACENT MISSING NOZZLES Many adjacent nozzles out at the same time. POSSIBLE CAUSES Poor air seal somewhere inside the ink line. Air bubbles on the cap rubber or broken cap rubber. ACTIONS Check and replace the cap tops Check the damper and ink lines for air bubbles Check the cartridge valve for good functioning Check the pumps for good functioning

DPSnotes

www.digiprint-supplies.com

4 - MIXED COLOR 1 Base color has another color on the nozzle test. Like if Cyan nozzle test has Magenta color on it, and the Magenta color has the normal density POSSIBLE CAUSES Ink mist might be attached on the print head nozzle surface. The wiper rubber blade is rounded and not sharp enough. ACTIONS Clean the print head nozzle surface Check, clean and/or replace the wiper blades 5 - MIXED COLOR 2 If the color is completely mixed. POSSIBLE CAUSES There is a possibility of both ink lines are mixed on the same cap rubber, and it may ow back into the ink line a little bit. The wiper rubber blade and cap rubber may be dirty. ACTIONS Check the cap tops and replace if necessary. Clean and/or replace the wipper blade. Clean and/or replace the cap tops.

DPSnotes

6 - NOZZLE DEFLECTION 1 Nozzles are deected from their correct position to Right-Leftup-Down (but each nozzle is straight). POSSIBLE CAUSES Some kind of dust attached on the print head nozzle surface. The head gap might be too high to print on the media surface, and the red ink can not be straight. The print head data cable has non constant malfunctioning contacts ACTIONS Clean the print head nozzle surface and plate Replace the print head data cable 7 - NOZZLE DEFLECTION 2 Nozzles are deected very badly when compared to nozzle deection 1 (Curled, Dotted line, Fired half size, Crooked). POSSIBLE CAUSES Some kinds of dusts are inside or on the surface of print head nozzles. The print head surface might be damaged by head crash with the media. It had been used for long time with high head gap which is larger than 3.0 mm. ACTIONS Clean the nozzle surface or replace the print head

www.digiprint-supplies.com

8 - EATEN NOZZLE TEST When your nozzle test pattern looks like this, the nozzle shows that their is a problem in the electrical system. POSSIBLE CAUSES The head data cable might be malfunctioning There might be a problem with the head board There might be a problem with the main board ACTIONS Verify the head cables, the fuses on the main board and the head board. Switch head cables with a good working nozzle row (color) and see if the problem moves along with the head cable. If it doesnt: replace the print head. If it does: replace the head cable and check again. 9 - COMPLETELY MISSING When a complete color is missing on the nozzle test pattern POSSIBLE CAUSES There is a problem in the electrical system There is a problem in the ink delivery system. ACTIONS Check the damper and ink lines for air bubbles Check the tubes and pumps for a blockage Check the cartridge valve for good functioning Check the head data cables Check the head (carriage) and main board and their fuses IN CASE OF AIR IN THE INK DELIVERY SYSTEM Check the Ink Cartridge Perform cleaning more than once do a new nozzle test Check leak at the cap - perform a cleaning and watch the head surface before wiping. If there are ink drops on the surface of the head, the cap is not leaking. If the head surface is clean, the ink is not absorbed Check the pump for broken tube, tube clogging etc Check the print head for air bubbles - the way to remove air bubbles in the print head is to either perform a number of cleanings or open the valves of the ink cartridges, switch the cap off and then squeeze the round surface of the damper (of the nozzle row where missing is found). Do this until all nozzles in the row have dropped at least 10 drops of inks. Close the valves and switch the cap on and perform a cleaning Check the ink tubes visually for air bubbles - open the valves of the ink cartridge and switch the cap off. Disconnect the ink tube at the damper and pull ink with a syringe until the air bubbles are gone Check the condition of the dampers and replace when worn or damaged Check the valve and the joint of the ink cartridge - for checking the valve of an ink cartridge, close all valves, disconnect the joint of the cartridge to be checked, connect a syringe, open the valve for the cartridge to be tested and draw the syringe slowly. If you feel you have to pull hard to get ink out of the cartridge, the valve is likely to malfunction and needs to be replaced.

DPSnotes

www.digiprint-supplies.com

JAMMED NOZZLES Nozzles can become completely jammed or blocked when ink has dried in them. This happens when the printer was not in use for a longer period of time or when the head and caps were not moist when the printer was idle. In this case, resin has dried and blocked the nozzles. Sometimes several cleanings in a row help to correct this problem, but usually you need a stronger solution for this problem. We advise strongly against wiping or swabbing the print heads with cleaning liquid. The nozzles are to fragile to whitstand the relative roughness of most wipes and swabs and very often too much pressure is used when doing so. Using an ultrasonic cleaning device (such as DIGIPRINT SUPPLIES Cleansonic ultrasonic cleaner Pro) is a better option here. The ultrasonic waves while mildly vibrate the resin chunks out of the nozzles without damaging the print head.

NEW PRINT HEAD INSTALLATION Please be aware of these guidelines when installing a new print head. Before working on a machine like your printer, always conduct the following steps rst. Switch the power OFF. Remove the electrical cable from the socket. Otherwise, you may suffer electric shock or the machines electric circuits may be damaged. Press the power button again to release all the rest tension in the capacitors. Disconnect all cables from the machine. Not doing so could cause damage to the print head and/or boards

DPSnotes

www.digiprint-supplies.com

Das könnte Ihnen auch gefallen

- Quick Start GuideDokument10 SeitenQuick Start Guidesvic11Noch keine Bewertungen

- PhotoPrint Dither TypesDokument1 SeitePhotoPrint Dither Typesalexandarno1Noch keine Bewertungen

- EagleRIP Offset Presentation-InglesDokument37 SeitenEagleRIP Offset Presentation-InglesJavier Martinez CañalNoch keine Bewertungen

- Heat Exchangers: Efficient Product HeatingDokument11 SeitenHeat Exchangers: Efficient Product Heatingمصطفى- القرقعيNoch keine Bewertungen

- Setup Standard TCP/IP Printer PortDokument11 SeitenSetup Standard TCP/IP Printer PortMallikarjun GMNoch keine Bewertungen

- Encon Thermal Engineers: Answer To The Continued Need For Energy ConservationDokument70 SeitenEncon Thermal Engineers: Answer To The Continued Need For Energy ConservationAtul SaxenaNoch keine Bewertungen

- ItemDokument604 SeitenItemapi-263566460% (1)

- How To Install A Print Server: Important: Print Servers Do Not Work With "Multifunction" or "All in One" MachinesDokument22 SeitenHow To Install A Print Server: Important: Print Servers Do Not Work With "Multifunction" or "All in One" MachinesZubas TevesatNoch keine Bewertungen

- Unveiling The Dynamics of Ultra High Velocity Droplet Impact On Solid SurfacesDokument11 SeitenUnveiling The Dynamics of Ultra High Velocity Droplet Impact On Solid Surfacesxu KNoch keine Bewertungen

- Keil Softwar1Dokument5 SeitenKeil Softwar1Bhargavi BodigeNoch keine Bewertungen

- Assesment G7 PDFDokument6 SeitenAssesment G7 PDFSiddharth SaxenaNoch keine Bewertungen

- Cephalopod-inspired ultralow voltage dielectric elastomer iridophoresDokument40 SeitenCephalopod-inspired ultralow voltage dielectric elastomer iridophoresGeorge SNoch keine Bewertungen

- Time Management MatrixDokument1 SeiteTime Management MatrixArRDM24Noch keine Bewertungen

- POS Printer Ethernet Interface Users ManualDokument10 SeitenPOS Printer Ethernet Interface Users ManualALEXANDRA GALINDEZNoch keine Bewertungen

- Ems Piezon Fs 367 ConnectionDokument4 SeitenEms Piezon Fs 367 Connectionshakil ahmadNoch keine Bewertungen

- Experimental Thermal and Fluid Science: Gangtao Liang, Yali Guo, Xingsen Mu, Shengqiang ShenDokument8 SeitenExperimental Thermal and Fluid Science: Gangtao Liang, Yali Guo, Xingsen Mu, Shengqiang ShenhsemargNoch keine Bewertungen

- Mathcad - Pulse WaveformDokument4 SeitenMathcad - Pulse WaveformNguyễn Sơn LâmNoch keine Bewertungen

- 1225 Main Board 6890NDokument6 Seiten1225 Main Board 6890NMarine JolieNoch keine Bewertungen

- TCP/IP Troubleshooting ToolsDokument10 SeitenTCP/IP Troubleshooting ToolsLoredel Doria LueteNoch keine Bewertungen

- PT DHCP DNS HTTPDokument5 SeitenPT DHCP DNS HTTPPisarenco GrigoreNoch keine Bewertungen

- Print Color Management ISO 12647-2: SystemserviceDokument1 SeitePrint Color Management ISO 12647-2: SystemserviceAngel de LuzNoch keine Bewertungen

- How Do I Connect To A Remote Front Panel That Is Hosted Behind A Remote RouterDokument4 SeitenHow Do I Connect To A Remote Front Panel That Is Hosted Behind A Remote RouterGomia DetuttiNoch keine Bewertungen

- Pattern Recognition & Learning II: © UW CSE Vision FacultyDokument47 SeitenPattern Recognition & Learning II: © UW CSE Vision FacultyDuong TheNoch keine Bewertungen

- Christian Camilo Afanador Marín: Professional ChemistDokument6 SeitenChristian Camilo Afanador Marín: Professional ChemistJOANNE MICHELLE CASTIBLANCO FERNANDEZNoch keine Bewertungen

- Printer Setup GuideDokument12 SeitenPrinter Setup Guidecosmin DarieNoch keine Bewertungen

- NC-DX0406-2018 User ManualDokument46 SeitenNC-DX0406-2018 User Manualसदानंद देशपांडेNoch keine Bewertungen

- EP802 Printer Driver Manual, Ver20220421Dokument20 SeitenEP802 Printer Driver Manual, Ver202204210d serviceNoch keine Bewertungen

- SB006 - Procedures For New Epson PrintheadsDokument4 SeitenSB006 - Procedures For New Epson PrintheadsЗрада ПидарештовNoch keine Bewertungen

- Generate stepper motor speed profiles in real timeDokument10 SeitenGenerate stepper motor speed profiles in real timeSteven Pfeifenroth100% (1)

- Epson Manual Installation GuideDokument68 SeitenEpson Manual Installation GuideLuis RangelNoch keine Bewertungen

- 20110520101701Dokument27 Seiten20110520101701Arie Teckno100% (2)

- Encoder Board MACH3Dokument12 SeitenEncoder Board MACH3Minerva MartinezNoch keine Bewertungen

- Eagle RIP OperatorGuide - ENGDokument151 SeitenEagle RIP OperatorGuide - ENGKingsley Gomes100% (1)

- FiltarationDokument22 SeitenFiltarationAvinash GarikapatiNoch keine Bewertungen

- EagleRIP User GuideDokument181 SeitenEagleRIP User GuideJavier Martinez CañalNoch keine Bewertungen

- Service Guide BookDokument152 SeitenService Guide BookSupport Biomed100% (1)

- Curing Powder Coatings: Infrared Heating SystemsDokument0 SeitenCuring Powder Coatings: Infrared Heating SystemsOrlando1949Noch keine Bewertungen

- CMYK GUIDE - Metamerism PDFDokument6 SeitenCMYK GUIDE - Metamerism PDFMario Daniel ConejoNoch keine Bewertungen

- Measuring CMYK Halftones: The Case For Spot Color Tone Value (SCTV) FormulaDokument24 SeitenMeasuring CMYK Halftones: The Case For Spot Color Tone Value (SCTV) FormulaLong HộiNoch keine Bewertungen

- 2 - Phu Luc 2 - Print - Control - SystemDokument1 Seite2 - Phu Luc 2 - Print - Control - SystemLý Phương NamNoch keine Bewertungen

- Understanding Working Principles Laser Printer: Click To Edit Master Subtitle StyleDokument13 SeitenUnderstanding Working Principles Laser Printer: Click To Edit Master Subtitle StyleJucia ChawNoch keine Bewertungen

- Dot Spread-Dot GainDokument3 SeitenDot Spread-Dot GainMansour SolimanNoch keine Bewertungen

- 600dpi Color TestDokument1 Seite600dpi Color TestAndy LNoch keine Bewertungen

- CISSDokument4 SeitenCISSAyari Supras NadhmiNoch keine Bewertungen

- Thesis R Houben PDFDokument194 SeitenThesis R Houben PDFfishvalNoch keine Bewertungen

- Prinect StandardizationDokument36 SeitenPrinect StandardizationVesna DjurovicNoch keine Bewertungen

- 1582117941-Pfg008 Filtration Catalogue 2020 SmallDokument137 Seiten1582117941-Pfg008 Filtration Catalogue 2020 SmallLord KrsnikNoch keine Bewertungen

- Cmyk Guide - Best Cie Lab ValuesDokument24 SeitenCmyk Guide - Best Cie Lab ValuesKristianto Mathers IIINoch keine Bewertungen

- 00 MediaStandard - Print - 2018Dokument78 Seiten00 MediaStandard - Print - 2018Lý Phương NamNoch keine Bewertungen

- Understanding Paper Whiteness PDFDokument2 SeitenUnderstanding Paper Whiteness PDFSappiETCNoch keine Bewertungen

- X Rite GregtagmacbethDokument21 SeitenX Rite GregtagmacbethdeepanairbalachandraNoch keine Bewertungen

- DeviceLink Profiles Fundamentals and ApplicationsDokument38 SeitenDeviceLink Profiles Fundamentals and Applicationsomar tlebNoch keine Bewertungen

- Printer Maintenance GuideDokument19 SeitenPrinter Maintenance GuideEDU0914100% (1)

- Embedded CDokument60 SeitenEmbedded CShamanthaka ManiNoch keine Bewertungen

- How Photocopiers Work by NafeesDokument47 SeitenHow Photocopiers Work by NafeesnafeesNoch keine Bewertungen

- Press: Flexible. Easy. Intelligent. Accurate Color On All Printing DevicesDokument4 SeitenPress: Flexible. Easy. Intelligent. Accurate Color On All Printing DevicesmigueldemacrolabNoch keine Bewertungen

- Common Offset Print ProblemDokument11 SeitenCommon Offset Print ProblemLisa RodriguezNoch keine Bewertungen

- Printing Ink Problems-Causes and RemediesDokument21 SeitenPrinting Ink Problems-Causes and Remediestiga_blas100% (3)

- Refillable Cartridge Instructions For Epson PXXXX x9xx Universal CartridgesDokument6 SeitenRefillable Cartridge Instructions For Epson PXXXX x9xx Universal CartridgesIon IonutNoch keine Bewertungen

- AS2603109 RevInfo NewsEDokument8 SeitenAS2603109 RevInfo NewsEmehoNoch keine Bewertungen

- Crocus Router 2MDokument366 SeitenCrocus Router 2MmehoNoch keine Bewertungen

- PDFDokument225 SeitenPDFmeho100% (1)

- 10 Secrets High School Test PDFDokument171 Seiten10 Secrets High School Test PDFOlimpiu AntNoch keine Bewertungen

- AS2603009 RevInfo NewsEDokument8 SeitenAS2603009 RevInfo NewsEmehoNoch keine Bewertungen

- TMG Fat Sat Sample Aug 7 01Dokument1 SeiteTMG Fat Sat Sample Aug 7 01Shankey GuptaNoch keine Bewertungen

- 501 Writing PromptsDokument181 Seiten501 Writing Promptspapersue99% (266)

- AS2603009 RevInfoEDokument9 SeitenAS2603009 RevInfoEmehoNoch keine Bewertungen

- 5 04 FinancialFitness PDFDokument9 Seiten5 04 FinancialFitness PDFbook2mindNoch keine Bewertungen

- Defender Owners ManualDokument134 SeitenDefender Owners Manualmeho100% (1)

- MS Thesis Feb. 2009 SaherDokument20 SeitenMS Thesis Feb. 2009 SahermehoNoch keine Bewertungen

- Custody Wash - MimakiDokument12 SeitenCustody Wash - MimakimehoNoch keine Bewertungen

- Product RegistrationDokument2 SeitenProduct RegistrationHéctor MiguelNoch keine Bewertungen

- ds457 PDFDokument5 Seitends457 PDFmehoNoch keine Bewertungen

- Encoder GP1A038RBKLDokument4 SeitenEncoder GP1A038RBKLmehoNoch keine Bewertungen

- Techink Platinum HSDokument5 SeitenTechink Platinum HSmehoNoch keine Bewertungen

- Voc Report - MembersDokument40 SeitenVoc Report - MembersmehoNoch keine Bewertungen

- EMMI 5 CistacDokument2 SeitenEMMI 5 CistacmehoNoch keine Bewertungen

- Organic SolventsDokument5 SeitenOrganic SolventsmehoNoch keine Bewertungen

- Product GuideDokument5 SeitenProduct GuidemehoNoch keine Bewertungen

- Encoder GP1A038RBKLDokument4 SeitenEncoder GP1A038RBKLmehoNoch keine Bewertungen

- B110167 344Dokument3 SeitenB110167 344mehoNoch keine Bewertungen

- Enviro-Solv B6 TDSDokument1 SeiteEnviro-Solv B6 TDSmehoNoch keine Bewertungen

- Solvent SubstitutionDokument3 SeitenSolvent SubstitutionJhon ManuelNoch keine Bewertungen

- 295 sj900-1lDokument7 Seiten295 sj900-1lmehoNoch keine Bewertungen

- Encoder 9720Dokument2 SeitenEncoder 9720mehoNoch keine Bewertungen

- Alim Katalog6Dokument64 SeitenAlim Katalog6mehoNoch keine Bewertungen

- Wide-Format Printing With Solvent-Borne Inks: COSHH Essentials For PrintersDokument3 SeitenWide-Format Printing With Solvent-Borne Inks: COSHH Essentials For PrintersmehoNoch keine Bewertungen

- Encoder H9720Dokument10 SeitenEncoder H9720Marco Antonio Henriquez100% (1)

- hts336555 Philips Manual PDFDokument35 Seitenhts336555 Philips Manual PDFSalomão SouzaNoch keine Bewertungen

- David Kassan DemoDokument3 SeitenDavid Kassan DemokingkincoolNoch keine Bewertungen

- Quality Assurance AnalystDokument2 SeitenQuality Assurance AnalystMalikNoch keine Bewertungen

- Ullit Présentation GénéraleDokument34 SeitenUllit Présentation Généralepvk.p53Noch keine Bewertungen

- OM Sample QPDokument8 SeitenOM Sample QPChandra ShekarNoch keine Bewertungen

- Yearly Lesson Plan LK Form 5Dokument26 SeitenYearly Lesson Plan LK Form 5Nur'ain Abd RahimNoch keine Bewertungen

- FMEA Errata Sheet ENG AIAG VDA FMEA Handbook 202000602 PDFDokument10 SeitenFMEA Errata Sheet ENG AIAG VDA FMEA Handbook 202000602 PDFBonny BonitoNoch keine Bewertungen

- Monopolistic screening in the labor marketDokument6 SeitenMonopolistic screening in the labor marketKand HroppaNoch keine Bewertungen

- 01 LANG Forgiarini Low Energy EmulsificationDokument8 Seiten01 LANG Forgiarini Low Energy EmulsificationDuvánE.DueñasLópezNoch keine Bewertungen

- Mitch Fryling and Linda Hayes - Motivation in Behavior Analysis A Critique PDFDokument9 SeitenMitch Fryling and Linda Hayes - Motivation in Behavior Analysis A Critique PDFIrving Pérez Méndez0% (1)

- Solid State Physics by Kettel Chapter 4Dokument17 SeitenSolid State Physics by Kettel Chapter 4Taseer BalochNoch keine Bewertungen

- SMD - Metal-Sheet Decking DesignDokument10 SeitenSMD - Metal-Sheet Decking DesignAchilles YipNoch keine Bewertungen

- DNSDokument23 SeitenDNSkalugareniNoch keine Bewertungen

- Sub Net Questions With AnsDokument5 SeitenSub Net Questions With AnsSavior Wai Hung WongNoch keine Bewertungen

- Robinair Mod 10324Dokument16 SeitenRobinair Mod 10324StoneAge1Noch keine Bewertungen

- Understanding Negation in Indian LogicDokument10 SeitenUnderstanding Negation in Indian LogicvasubandhuNoch keine Bewertungen

- Ddec IV Application and InstallationDokument148 SeitenDdec IV Application and Installationsptecnico8292% (36)

- Bridge Superstructure DesignDokument276 SeitenBridge Superstructure Designrenzo wilber bernedo beltranNoch keine Bewertungen

- B.Tech (ECE) Course Scheme & Syllabus as per CBCSDokument168 SeitenB.Tech (ECE) Course Scheme & Syllabus as per CBCSRatsihNoch keine Bewertungen

- TS4F01-1 Unit 4 - Document ControlDokument66 SeitenTS4F01-1 Unit 4 - Document ControlLuki1233332Noch keine Bewertungen

- Fault Code 498 Engine Oil Level Sensor Circuit - Voltage Above Normal, or Shorted To High SourceDokument13 SeitenFault Code 498 Engine Oil Level Sensor Circuit - Voltage Above Normal, or Shorted To High SourceAhmedmah100% (1)

- CorrectDokument45 SeitenCorrectaskerman 3Noch keine Bewertungen

- Operation Manual for XMT-808 Digital Temperature ControllerDokument23 SeitenOperation Manual for XMT-808 Digital Temperature Controllerjonathan_calixto_4100% (1)

- Sem NotesDokument39 SeitenSem NotesN NandiniNoch keine Bewertungen

- Lean-burn gas generator sets technical specificationsDokument2 SeitenLean-burn gas generator sets technical specificationsHector IuspaNoch keine Bewertungen

- Kollmorgen S300 Servo Drive ManualDokument134 SeitenKollmorgen S300 Servo Drive ManualCarlos SalazarNoch keine Bewertungen

- New TIP Course 4 (DepEd Teacher)Dokument58 SeitenNew TIP Course 4 (DepEd Teacher)Venessa Mulig100% (2)

- Manual Completo Sinovo SD600Dokument221 SeitenManual Completo Sinovo SD600Felipe de PaulaNoch keine Bewertungen

- Chapter 8Dokument2 SeitenChapter 8Riza Mae AlceNoch keine Bewertungen

- Role of Digital Infrastructure in The Post Pandemic World: Preparing For Civil Services Interview-The Right PerspectiveDokument40 SeitenRole of Digital Infrastructure in The Post Pandemic World: Preparing For Civil Services Interview-The Right PerspectiveshekhardfcNoch keine Bewertungen