Beruflich Dokumente

Kultur Dokumente

In Vitro Corrosion Behavior of Bioceramic, Metallic, and Bioceramic Metallic Coated Stainless Steel Dental Implants

Hochgeladen von

MarioOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

In Vitro Corrosion Behavior of Bioceramic, Metallic, and Bioceramic Metallic Coated Stainless Steel Dental Implants

Hochgeladen von

MarioCopyright:

Verfügbare Formate

dental materials

Dental Materials 19 (2003) 188198 www.elsevier.com/locate/dental

In vitro corrosion behavior of bioceramic, metallic, and bioceramic metallic coated stainless steel dental implants

M.H. Fathi a,*, M. Salehi a, A. Saatchi a, V. Mortazavi b, S.B. Moosavi b

a

Department of Materials Engineering, Isfahan University of Technology, Isfahan 84154, Iran b School of Dentistry, Isfahan University of Medical Sciences, Isfahan, Iran Received 4 July 2001; revised 26 November 2001; accepted 18 December 2001

Abstract Objectives: The most common metals and alloys used in dentistry may be exposed to a process of corrosion in vivo that make them cytotoxic. The biocompatibility of dental alloys is primarily related to their corrosion behavior. The aim of this work was to evaluate the corrosion behavior and thus the biocompatibility of the uncoated and coated stainless steels and compare the effect of type of coatings on corrosion behavior. Methods: Three types of coatings, hydroxyapatite (HA), titanium (Ti), and a double-layer HA/Ti on AISI 316L stainless steel were made. HA coating was produced using plasma-spraying technique and Ti coating was made using physical vapor deposition process. In order to perform a novel double-layer composite coating, a top layer of HA was plasma-sprayed over a physical vapor deposited Ti layer on AISI 316L stainless steel. Structural characterization techniques including XRD, SEM and EDX were used to investigate the microstructure, morphology and crystallinity of the coatings. Electrochemical potentiodynamic tests were performed in physiological solutions in order to determine and compare the corrosion behavior of the coated and uncoated specimens as an indication of biocompatibility. Results: Double-layer HA/Ti coating on AISI 316L SS had a positive effect on improvement of corrosion behavior. The decrease in corrosion current densities was signicant for these coated specimens and was much lower than the values obtained for uncoated and single HA coated specimens. Ti coating on AISI 316L SS also has a benecial effect on corrosion behavior. The results were compared with the results of corrosion behavior of HA coated commercially pure titanium (cpTi) and uncoated cpTi. Signicance: These results demonstrated that the double-layer HA/Ti coated 316L SS can be used as an endodontic implant and two goals including improvement of corrosion resistance and bone osteointegration can be obtained simultaneously. q 2003 Academy of Dental Materials. Published by Elsevier Science Ltd. All rights reserved.

Keywords: AISI 316L stainless steel; Corrosion; HA coating; Ti coating

1. Introduction Biocompatibility is the ability of a material to perform with an appropriate host response in a specic application [1]. This means that the tissue of the patient that comes into contact with the materials does not suffer from any toxic, irritating, inammatory, allergic, mutagenic, or carcinogenetic action [25]. Since the oral environment is particularly favorable for the biodegradation of metals due to its ionic, thermal, microbiological, and enzymatic properties, it can be presumed that the patient is exposed to a certain extent to the products of the corrosion process [6]. The

* Corresponding author. Tel.: 198-311-8912750; fax: 198-3118912752. E-mail addresses: fathi@cc.iut.ac.ir, fathimoh@yahoo.com (M.H. Fathi).

biocompatibility of dental alloys is primarily related to their corrosion behavior [7]. The higher the corrosion of an alloy, the more its elements will be released and the risk of unwanted reactions in the oral tissues may be increased. These unwanted reactions include unpleasant tastes, irritation, allergy or other reaction [7]. Surgical implants are usually made of metallic materials, such as austenitic stainless steel, cobaltchromium alloys, and titanium and its alloys. Among all the metallic materials, the austenitic stainless steels are the most popular materials because of their relatively low cost, ease of fabrication and reasonable corrosion resistance [8]. However, the austenitic stainless steels are prone to localized attack in long-term applications due to the aggressive biological effects. The corrosion products include iron, chromium, nickel and molybdenum, etc. Ions can accumulate in tissues surrounding the implant or be transported to distant parts of

0109-5641/03/$30.00 + 0.00 q 2003 Academy of Dental Materials. Published by Elsevier Science Ltd. All rights reserved. PII: S01 09- 5641( 02) 0002 9-5

M.H. Fathi et al. / Dental Materials 19 (2003) 188198

189

Fig. 1. XRD patterns of the coatings: (a) plasma-sprayed HA coating on cpTi; (b) plasma-sprayed HA coating on 316L SS; (c) double-layer HA/Ti coating on 316L SS.

the body [9]. It has been demonstrated that metallic ions resulting from the in vitro corrosion of austenitic stainless steels cause alteration of the expression of human lymphocyte-surface antigens and inhibit the immune response as assessed by lymphocyte proliferation [10]. The presence of

these ions in vivo not only causes toxic effects in mouse testicular seminiferous epithelium but also alterations in the spleen cellular population [11]. A number of investigations have demonstrated that metal ions can be released from metallic materials as the result of

190

M.H. Fathi et al. / Dental Materials 19 (2003) 188198

Fig. 1. (continued)

corrosion [2,3,810,1214]. Local adverse tissue reactions or elicit allergy reactions caused by metallic implants originate from the release of metal ions. This release of ions depends upon the corrosion rate of the alloy and the solubility of the rst formed corrosion products [15]. Intensive investigations have been carried out on biomaterials in order to study their corrosion behavior, ion release and its effects [14,1625], and toxicity and immunity of alloys [6,1618,2629]. The studies have been more intensive for stainless steels due to their corrosion behavior [14,19 29]. It has been suggested that metal ions associated with 316L stainless steel are toxic to osteogenic cells, affecting their proliferation and differentiation [19]. Stainless steel corrosion products above certain concentrations may disturb the normal behavior of osteoblast-like bone marrow cell cultures [2022,25]. Advanced techniques have been used for determining toxicity and tissue reaction around metal implants [24,27,29]. For this purpose, in vivo animal tests have been performed [28]. Ion release rates in vitro can be used to determine the proportionality of release in vivo [3032] but long-term in vivo studies have been made and results indicate that metal ion release increases with the exposure time [33,34]. Release of metal ion in vivo analysis did not demonstrate any consistent differences in the concentrations of metallic elements next to stressed and nonstressed miniplates and screws of stainless steels [35]. A previous in vivo study by the present authors has shown that the type of metallic implants had signicant effects on the clinical success, bone tissue response and histopatho-

logical results of hydroxyapatite coated/uncoated metallic implants in animals [36]. In this previous work, endodontic implants consisting of plasma-sprayed HA coated and uncoated substrates of various materials, namely 316L stainless steel and CoCrMo alloy, were prepared. These implants were subsequently implanted in the mandibular canine of cats. After a healing period of 4 months, osteointegration evaluation and histopathological interpretation were carried out by using scanning electron microscopy (SEM). The results showed that different substrates had pronounced effects on the histopathological response to different HA coated implants [36]. The aim of the present work was to evaluate the corrosion behavior and therefore biocompatibility of the uncoated and coated stainless steels. In order to design and produce a desired coating for improvement of histopathological response, tissue reaction and bone osteointegration around dental implants, the effects of three types of coatings on the behavior of substrates were compared.

2. Materials and methods 2.1. Substrates and coatings Commercially pure titanium (cpTi) and AISI 316L stainless steel were used as substrates. The composition (wt%) of stainless steel was C 0.03, Si 0.80, Mn 1.2, Cr 17.55, Ni 13.65, Mo 3.1, P # 0.040, S # 0.030 and Fe as the balance. The composition (wt%) of cpTi was Ti . 99.5%.

M.H. Fathi et al. / Dental Materials 19 (2003) 188198

191

Fig. 2. SEM micrograph of the coatings: (a) plasma-sprayed HA coating surface showing partially melted with some porosity and microcracks; (b) the top layer of a double-layer HA/Ti coating shows some porosity and microcracks; (c) a physical vapor deposited Ti coating on a 316L SS.

Ti coating (37 mm thickness) was made using physical vapor deposition process on AISI 316L stainless steel. Crystalline hydroxyapatite coatings with 4060 mm were produced using plasma-spraying technique on two types of substrate, i.e. AISI 316L stainless steel and commercially pure Ti. A double-layer composite coating composed of a hydroxyapatite top layer (4060 mm thickness) and a Ti under layer (35 mm thickness) was prepared using a plasma-spraying and a physical vapor deposition process, respectively, on AISI 316L stainless steel. 2.2. Experimental procedure X-ray diffraction (XRD) technique (Philips X'Pert-MPD ) was used to System with a Cu ka wavelength of 1.5418 A analyze the crystalline structure and phases present in the coatings. This technique was also used to estimate the percentage of the crystallinity of the HA coating. SEM and energy dispersive X-ray analysis (EDX) techniques

(Philips XL 30) were used to study the microstructure and morphology of the coatings. EDX analysis was utilized to estimate the ratio of Ca/P of the HA coating and the composition of the coatings. Commercially pure titanium (cpTi) and AISI 316L stainless steel (316L SS) were selected as the sample materials. Coupons of two types of alloys were cut and surface preparations were carried out by wet grinding with a series of SiC papers to 4000-grit followed by thorough cleaning in distilled water, degreasing with acetone and air drying. An electrochemical corrosion polarization test cell was used for in vitro potentiodynamic corrosion tests in physiological solutions. Graphite was used as the counter electrode and saturated calomel electrode (SCE) as the reference electrode. The physiological solutions were the Ringer's solution and physiological normal saline (0.9 wt% NaCl) and the potentiodynamic corrosion tests were performed at 37 ^ 1 8C. Dynamic polarization curves were recorded at a potential scanning rate of 0.5 mV s 21 initiated at 2250 mV

192

M.H. Fathi et al. / Dental Materials 19 (2003) 188198

Fig. 3. SEM EDX of the coatings: (a) HA coating, desirable Ca/P is obtained; (b) and (c) HA layer and Ti layer, respectively, of a double-layer HA/Ti coating.

below the open circuit potential and the atmosphere was open to air. Five replicate tests of each group of specimens were performed. To compare the corrosion behavior between the uncoated and HA coated cpTi, the uncoated 316L SS, HA coated 316L SS and double-layer HA/Ti coated 316L SS, specimens were dynamically polarized in two different types of physiological solutions. Potentiodynamic polarization curves were determined at 37 ^ 1 8C using a EG and G model 263A potentiostat/galvanostat interfaced with a computer and a recorder. The tests were started after a steady open-circuit potential was attained (not more than ^5 mV drift in 5 min). The anodic and cathodic polarization curves were obtained for each specimen and corrosion potentials and corrosion current densities were determined by Tafel extrapolation and linear polarization methods. The mean value and standard deviations of the results were calculated. It is noticeable that two kinds of electrochemical tests were utilized in this investigation. The rst test was referred to as a potentiodynamic anodic polarization-scan because it is dynamic or continuous. It represented a prole of the behavior of the alloy when scanned in a forward direction from anodic to cathodic potential and spans a range of 1 V or more. The straight line segments of these scans are iden-

tied by the Tafel equation. DE b logi=I0 : The expanded form of this equation shows linearity where b is slope and log i0 is the Y intercept. The scans are plotted as potential, E (mV, SCE), vs. log current density, log i (mA cm 21), and are often referred to as Evans Diagrams. The reverse scan was obtained by reversing the direction of the scan, thus obtaining a reverse Evans Diagram. Curve shape, potentials at current discontinuities and absolute values are all important in characterizing corrosion behavior. The second test involved potentiodynamic or continuous scanning but over a much smaller potential range than anodic polarization. Typically, a scan is started 10 mV anodic to the corrosion potential and terminates 10 mV cathodic to it. The scan is plotted directly as E vs. i and is referred to as a linear polarization plot. The slope of the linear segment of the DE vs. Di plot is expressed by the formula: DE=DiDE!0 RP B=icorr where RP is polarization resistance (kV cm 2), (DE/Di) is slope (mV cm 2/mA) and Bconstant b a bc =2:3ba 1 bc where ba and bc are Tafel slopes for the anodic and cathodic proles, respectively. One way to nd the value of the equation involves the determination of Tafel bc and ba from

M.H. Fathi et al. / Dental Materials 19 (2003) 188198

193

Fig. 3. (continued)

potentiodynamic polarization curves and calculation of the resulting value of B.

3. Results 3.1. Structural characterization The XRD patterns of the plasma-sprayed HA coatings on cpTi and 316L SS are shown in Fig. 1(a) and (b), respectively. In the plot of intensity vs. 2u , there are numerous sharp peaks and a low background indicative of highly crystalline HA coating. Fig. 1(c) also shows the XRD pattern of a double-layer HA/Ti coating on 316L SS which is very similar to the XRD pattern of HA coating on 316L SS. The SEM micrograph showing a typical plasma-sprayed HA coating on a metallic substrate is shown in Fig. 2(a). The structure appears to be partially melted and porous and microcracks can be observed scattered throughout the structure, probably as a result of a very rapid cooling rate during the deposition process. Fig. 2(b) is a SEM micrograph showing a typical double-layer HA/Ti coating on 316L SS substrate which also shows that the coating consists of a

porous surface and some microcracks. Fig. 2(c) is a SEM micrograph showing a physical vapor deposited Ti coating on a 316L SS. The porosity of the coating is less than HA coating but microcraks cannot be seen. The result of EDX analysis of HA coating surface is shown in Fig. 3(a). The Ca/P 2 is the desired ratio. Fig. 3(b) and (c) show EDX analysis of HA layer and Ti layer of double-layer HA/Ti coating. 3.2. Corrosion behavior The potentiodynamic polarization curves of the uncoated, HA coated, Ti coated, double-layer HA/Ti coated 316L SS and HA coated/uncoated cpTi in the normal saline solution are shown in Fig. 4. The similar curves that are obtained in Ringer's solution are plotted in Fig. 5. These curves are selected because their extracted data were the most nearest to the mean values of the current densities of each group of specimens. The corrosion current densities of various specimens were determined from the potentiodynamic polarization curves (Figs. 4 and 5) by Tafel extrapolation method. These results align with corrosion potentials, summarized

194

M.H. Fathi et al. / Dental Materials 19 (2003) 188198

Fig. 3. (continued)

in Tables 1 and 2 in normal saline solution and Ringer's solution, respectively. The standard deviations of the corrosion current densities are shown in parentheses in Tables 1 and 2. The corrosion current densities as determined by linear polarization method are also shown in Tables 1 and 2. According to Table 1 and Fig. 4, the uncoated 316L SS possesses lower corrosion resistance and thus higher corrosion current density (icorr 265 nA cm 22) in the normal saline solution. The similar trend can be observed in the Ringer's solution (Table 2). The HA coating decreased the corrosion current density of the HA coated 316L SS (icorr 68 nA cm 22) and HA coated cpTi (icorr 43 nA cm 22). The double-layer HA/Ti coating had a signicant effect on the corrosion behavior of 316L SS so that the corrosion current density of HA/Ti coated 316L SS decreased (icorr 44 nA cm 22) and was exactly similar to single HA coated cpTi (icorr 43 nA cm 22) in normal saline solution. The Ti coating could decrease the corrosion current density of the Ti coated 316L SS in both types of the physiological solutions (Table 1 and 2). 4. Discussion The single HA coating had a positive effect on corrosion

resistance of metallic substrate, i.e. 316L SS and cpTi and decreased the corrosion current density of each type of coated metallic substrate. The polarization curve, (b) in Fig. 4, of the HA coated 316L SS was shifted to the left upper area, compared with curve (a), which is the uncoated 316L SS specimen. It means that the HA coated 316L SS (Ecorr 2105 mV, icorr 68 nA) was more corrosion resistant than the uncoated 316L SS (Ecorr 2174 mV, icorr 265 nA). The corrosion behavior of the HA coated cpTi (Ecorr 2256 mV, icorr 43 nA) was better than uncoated cpTi (Ecorr 2334 mV, icorr 72 nA) up to 200 mV, as manifested by a shift of the polarization curve (f) to the left upper of the uncoated cpTi curve (e). A similar trend can be observed in the Ringer's solution (Fig. 5, curves (a), (b), (e) and (f), Table 2). Therefore, single HA coating on metallic substrate caused signicant changes on corrosion behavior of substrate. This result was in agreement with the results of the other researchers [37]. Single HA coating could decrease the corrosion current density of 316L stainless steel substrate in physiological solutions (Tables 1 and 2 and Figs. 4 and 5) but this effect was not adequately complete. This was due to the fact that the structure and surface morphology of single HA coating consists of a porous surface and some microcracks (Fig. 2) and could not act as a barrier to the release of metal ions

M.H. Fathi et al. / Dental Materials 19 (2003) 188198

195

Fig. 4. Potentiodynamic polarization curves of: (a) the uncoated; (b) HA coated; (c) Ti coated; (d) double-layer HA/Ti coated 316L SS; (e) the HA coated cpTi; (f) uncoated cpTi in the normal saline solution (0.9 wt% NaCl) at 37 8C.

Fig. 5. Potentiodynamic polarization curves of: (a) the uncoated; (b) HA coated; (c) Ti coated; (d) double-layer HA/Ti coated 316L SS; (e) the HA coated cpTi; (f) uncoated cpTi in the Ringer's solution at 37 8C.

from metallic implant to physiological solutions and corrosive environment. The HA coating acted simply as a semi-mechanical barrier. The corrosion rate in this case was drastically reduced, although in the microcracks and pores of the HA coating the substrate came into contact with the solution and some corrosion occurred. Earlier work by the present authors showed that the histoTable 1 Mean values (standard deviation) of corrosion current densities and corrosion potentials in normal saline solution (0.9 wt% NaCl) at 37 8C Material Ecorr (mV) Icorr (nA/cm 2) Tafel Uncoated 316L SS Uncoated cpTi HA coated 316L SS HA coated cpTi HA/Ti coated 316L SS Ti coated 316L SS 2174(20) 2334(11) 2105(10) 2256(10) 2153(15) 288(20) 265 (16) 72 (7) 68 (2) 43 (6) 44 (5) 27 (5) Linear 194 (16) 63 (9) 52 (1) 34 (7) 32 (3) 26 (5)

pathological responses to uncoated 316L SS and uncoated vitallium were not acceptable [36]. These results are in agreement with the studies that have been carried out on endodontic implants [16,17]. Vitallium was originally used but its biocompatibility was questioned when it was shown to undergo surface corrosion. This is an important factor in the success of an endodontic implant. Stainless steel and vitallium have generally lost acceptance and are

Table 2 Mean values (standard deviation) of corrosion current densities and corrosion potentials in Ringer's solutions at 37 8C Material Ecorr (mV) Icorr (nA/cm 2) Tafel Uncoated 316L SS Uncoated cpTi HA coated 316L SS HA coated cpTi HA/Ti coated 316L SS Ti coated 316L SS 2195(20) 2303(5) 2110(21) 2215(14) 2182(20) 261(15) 218 (17) 71 (6) 57 (3) 40 (4) 43 (5) 24 (5) Linear 181 (20) 61 (6) 49 (1) 29 (3) 32 (4) 26 (2)

196

M.H. Fathi et al. / Dental Materials 19 (2003) 188198

Fig. 6. Periapical tissue response to HA coated 316L SS: (a) inammatory connective tissue can be observed ( 25); (b) the same picture ( 100).

no longer available for clinical use as endodontic implants [16,17]. On the other hand, earlier work showed that the type of metallic substrates which were HA plasma-sprayed coated and used for endodontic implants in animals had signicant effects on histopathological response [36]. Statistical analyses of the signicance of the differences between histopathological response to single HA coated vitallium and single HA coated 316L SS were carried out by KruskalWallis method. More tissue damage, inammation and irritation have been observed around single HA coated 316L SS (Fig. 6) in comparison with single HA coated vitallium [36]. This was owing to the inability of the single HA coating to act as a barrier to the release of metal ions to animal's body on the 316L SS implants. The bone osteointegration around single HA coated vitallium alloy and single HA coated 316L SS were almost the same and from the point of the clinical success and osteointegration no signicant difference were observed [36]. This result is also in agreement with the other researchers [38]. It has been observed that there are no differences between osteointegration when stainless steel is used instead of Ti alloy as metallic substrate, conrming that bone responds primarily to coating [38].

Many attempts have been made for improvement and optimization of implant surface conditions by creating a bioceramic coating on implant surface [3943]. In this case, double- or multi-layer coatings have been recently considered by a number of researchers' works [37,4446] for improvement of biomedical applications and offering potential clinical benets in orthopedic and dental surgery. Bioceramic coatings such as Al2O3, TiO2 and ZrO2 on 316L SS have already been considered to increase corrosion resistance [43,4749]. The in vitro electrochemical polarization corrosion test results indicated that novel double-layer HA/Ti coating have a benecial and desired effect on corrosion behavior of 316L SS. This can improve the corrosion resistance (Figs. 4 and 5 and Tables 1 and 2) and subsequently can decrease the release of metallic ions and deleterious effects. Therefore, two goals could be obtained simultaneously by the formation of the double-layer HA/Ti coating. First, the improvement of 316L SS corrosion resistance and decreasing of ion release and consequently prevention of tissue damages, inammation and irritation and obtain desirable histopathological response. The second improvement is in terms of bone osteointegration and bone bonding with the coated implant. The Ti coating had a positive effect on corrosion resistance of 316L SS. The polarization curve, (c) in Fig. 4, of the Ti coated 316L SS was shifted to the left upper area, compared with curve (a), which is the uncoated 316L SS specimen. The Ti coated 316L SS (Ecorr 288 mV, icorr 30 nA) was more corrosion resistant than the uncoated 316L SS. The type of physiological solution had no effect on this trend. It is noticeable that the passive current density (ip) of the Ti coated 316L SS (curve (c) in Figs. 4 and 5) was similar to HA/Ti coated 316L SS (curve (d) in Figs. 4 and 5). This means that the Ti responded primarily to environment and corrosion reaction was essentially between Ti and solution.

5. Conclusion Double-layer HA/Ti coating can have a benecial and desired effect on corrosion behavior of 316L SS and decrease the corrosion current density that is a distinct advantage for prevention of ion release. Corrosion current density of double-layer HA/Ti coated 316L SS was similar and equal to single HA coated cpTi and it suggests that double-layer HA/Ti coated 316L SS can be used as endodontic implant.

Acknowledgements The authors are grateful for the support of this research by Isfahan University of Technology.

M.H. Fathi et al. / Dental Materials 19 (2003) 188198

197

References

[1] Williams DF. Denitions in biomaterials. Proceeding of a Consensus Conference of the European Society for Biomaterials, England. Vol. 4, New York: Elsevier; 1986. [2] Vahey JW, Simonian PT, Conrad EU. Carcinogenicity and metallic implants. Am J Orthod Dentofacial Orthop 1995;24:31924. [3] Arvideon K, Cottler-Fox M, Friberg V. Cytotoxic effects of CoCr alloys on broblast derived form human gingiva. Scand J Dent Res 1986;95:35663. [4] Jacobsen N, Hensten-Pettersen A. Occupational heath problems and adverse patient reactions in orthodontics. Eur J Orthodon 1989;11: 25464. [5] Lin Sun Z, Wataha JC, Hanks CT. Effects of metal ions on osteoblastlike cell metabolism and differentiation. J Biomed Mater Res 1997; 34:2937. [6] Locci P, Lilli C, Marinucci L, Calvitti M, Belcastro S, Bellocchio S, Staffolani N, Guerra M, Becchetti E. In vitro cytotoxic effects of orthodontic appliances. J Biomed Mater Res (Appl Biomater) 2000; 53:5607. [7] Craig RG, Powers JM, Wataha JC. Dental materials, properties and manipulation. 7th ed. St Louis: Mosby-Year book Inc, 2000 p. 2313. [8] Jacobs JJ, Gilbert JL, Urban RM. Corrosion of metal orthopaedic implants. J Bone Joint Surg 1998;80A:26882. [9] Lei MK, Zhu XM. Corrosion resistance of plasma source ion nitrided austenitic stainless steels. Biomaterials 2001;22:6417. [10] Tracana RB, Sousa JP, Carvalho GS. Mouse inammatory response to stainless steel corrosion products. J Mater Sci: Mater Med 1994; 5:596600. [11] Tracana RB, Pereira ML, Abreu AM, Sousa JP, Carvalho GS. Stainless steel corrosion products cause alternations on mouse spleen cellular. J Mater Sci: Mater Med 1995;6:5661. [12] Dobbs HS, Minski MJ. Metal ion release after total hip replacement. Biomaterials 1980;1:1938. [13] Barrett RD, Bishara SE, Quinn JK. Biodegradation of orthodontic appliance. Part I. Biodegradation of nickel and chromium in vitro. Am J Orthod Dentofacial Orthop 1993;103:24350. [14] Staffolani N, Damiani F, Lilli C. Ion release from orthodontic appliances. J Dent 1999;27(6):44954. [15] Long M, Rack HJ. Titanium alloys in total joint replacementa materials science perspective. Biomaterials 1998;19:162139. [16] Larsen RM, Patten JR, Wayman BE. Endodontic endosseous implants: case reports and update of materials. J Endod 1989; 15(10):496500. [17] Parreira FR, Bramwell JD, Roahen JO, Giambarresi L. Histological response to titanium endodontic endosseous implants in dogs. J Endod 1996;22(4):1614. [18] Locci P, Marinucci L, Lilli C, Belcastro S, Staffolani N, Bellocchio S, Damiani F, Becchetti E. Biocompatibility of alloys used in orthodontics evaluated by cell culture tests. J Biomed Mater Res 2000;51:5618. [19] Morais S, Sousa JP, Fernandes MH, Carvalho GS, deBruijn JD, vanBlitterswijk CA. Decreased consumption of Ca and P during in vitro biomineralization and biologically induced deposition of Ni and Cr in presence of stainless steel corrosion products. J Biomed Mater Res 1998;42(2):199212. [20] Morais S, Sousa JP, Fernandes MH, Carvalho GS, deBruijn JD, vanBlitterswijk CA. Effects of AISI 316L corrosion products in in vitro bone formation. Biomaterials 1998;19(1112):9991007. [21] Fernandes MH. Effect of stainless steel corrosion products on in vitro biomineralization. J Biomater Appl 1999;14(2):11368. [22] Morais S, Dias N, Sousa JP, Fernandes MH, Carvalho GS. In vitro osteoblastic differentiation of human bone marrow cells in the presence of metal ions. J Biomed Mater Res 1999;44(2):17690. [23] Kim H, Johnson JW. Corrosion of stainless steel, nickeltitanium, coated nickeltitanium, and titanium orthodontic wires. Angle Orthod 1999;69(1):3944.

[24] Milosev I, Strehblow HH. The behavior of stainless steels in physiological solution containing complexing agent studied by X-ray photoelectron spectroscopy. J Biomed Mater Res 2000;52:40412. [25] Fernandes MH, Costa MA. Proliferation/differentiation of osteoblastic human alveolar bone cell cultures in the presence of stainless steel corrosion products. J Mater Sci: Mater Med 2000;11(3):14153. [26] Grimsdottir MR, Hensten-Pettersen A, Kulmann A. Cytotoxic effect of orthodontic appliances. Eur J Orthodon 1992;14:4753. [27] Shettlemore MG, Bundy KJ. Toxicity measurement of orthopedic implant alloy degradation products using a bioluminescent bacterial assay. J Biomed Mater Res 1999;45(4):395403. [28] Pereira MC, Pereira ML, Sousa JP. Individual study of chromium in the stainless steel implants degradation: an experimental study in mice. BioMetals 1999;12:27580. [29] Uo M, Watari F, Yokoyama A, Matsuno H, Kawasaki T. Tissue reaction around metal implants observed by X-ray scanning analytical microscopy. Biomaterials 2001;22(7):67785. [30] Brown SA, Farnsworth LJ, Merritt K, Crowe TD. In vitro and in vivo metal ion release. J Biomed Mater Res 1988;22(4):32138. [31] Gilbert HL, Smith SM, Lautenschlager EP. Scanning electrochemical microscopy of metallic biomaterials: reaction rate and ion release imaging modes. J Biomed Mater Res 1993;27(11):135766. [32] Marek M. Measurement of metal ion release from biomedical implant alloys. The Proceeding of Compatibility of Biomedical Implants, San Francisco, California, USA; 1994. p. 7384. [33] Jones LC, Hungerford DS, Kenna RV, Braem G, Grant V. Urinary excretion levels of metal ions in patients undergoing total hip replacement with a porous-coated prosthesis: preliminary results. The Proceeding of Quantitative Characterization and Performance of Porous Implants for Hard Tissue Applications, Nashville, Tennessee, USA, 1985. ASTM publications; 1987. p. 15162. [34] Traisnel M, Maguer D, Hildebrand HF, Lost A. Corrosion of surgical implants. Clin Mater 1990;5(2-4):30918. [35] Matthew IR, Frame JW. Release of metal in vivo from stressed and nonstressed maxillofacial fracture plates and screws. Oral Surg Oral Med Oral Pathol Oral Radiol Endod 2000;90(1):338. [36] Fathi MH, Feizi GH, Moosavi SB, Gahanshahi GH, Salehi M, Saatchi A, Mortazavi V. The role of metallic substrate of hydroxyapatite coated dental implants in clinical and pathological success, Esteghlal. IUT J Engng 2001;20(1):189205. [37] Nie X, Leyland A, Matthews A. Deposition of layered bioceramic hydroxyapatite/TiO2 coatings on titanium alloys using a hybrid technique of micro-arc oxidation and electrophoresis. Surf Coat Technol 2000;125:40714. [38] Leali Tranquilli P, Merolli A, Palmacci O. Evaluation of different preparations of plasma-spray hydroxyapatite coating on titanium alloy and duplex stainless steel in the rabbit. J Mater Sci: Mater Med 1994;5(67):3459. [39] Gross KA, Berndt CC, Goldschlag DD, Jacono VJ. In vitro changes of hydroxyapatite coatings. Int J Oral MaxilloFac Implant 1997;12(5): 58997. [40] Suchanek W, Yoshimura M. processing and properties of hydroxapatite-based biomaterials for use as hard tissue replacement implants. J Mater Res 1998;13(1):94117. [41] Hench LL. Bioceramics. J Am Ceram Soc 1998;81(7):170528. [42] Arciola CR, Mantanaro L, Moroni A, Giordano M, Pizzoferato A. Hydroxyapatite-coated orthopaedic screws as infection resistant materials: in vitro study. Biomaterials 1999;20(4):233327. [43] Hsu HC, Yen SK. Evaluation of metal ion release and corrosion resistance of ZrO2 thin coating on the dental CoCr alloys. Dent Mater 1998;14:33946. [44] Silva PL, Santos JD, Monteiro FJ, Knowles JC. Adhesion and microstructural characterization of plasma-sprayed hydroxyapatite/glass ceramic coatings onto Ti6A14V substrates. Surf Coat Technol 1998;102:1916. [45] Ferraz MP, Monteiro FJ, Santos JD. CaOP2O5 glass hydroxyapatite

198

M.H. Fathi et al. / Dental Materials 19 (2003) 188198 Al2O3 Plasma spraying for biomedical applications. Surf Engng 1990;6(3):20912. [48] Gluszek J, Masalski J, Furman P. TiO2 lm as a protective coating on stainless steel. The Proceeding of Fifth Polish Conference Corrosion'96Theory and Practice, Gdansk, Poland, Vol. 3; 1996. p. 78993. [49] Yen SK. Characterization of electrolytic ZrO2 coating on AISI 316L stainless steel. J Electroch Soc 1999;146(4):13926.

double-layer plasma-sprayed coating: in vitro bioactivity evaluation. J Biomed Mater Res 1999;45(4):37683. [46] Ferraz MP, Knowles JC, Olsen I, Monterio FJ, Santos JD. Flow cytometry analysis of effects of glass on response of osteosarcoma cells to plasma-sprayed hydroxyapatite/CaOP2O5 coatings. J Biomed Mater Res 1999;47(4):60311. [47] Santose JDS, Monteiro FJ. Wear behavior of stainless steel after

Das könnte Ihnen auch gefallen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Journal: Role of Ionic Depletion in Deposition During Electrophoretic DepositionDokument6 SeitenJournal: Role of Ionic Depletion in Deposition During Electrophoretic DepositionMarioNoch keine Bewertungen

- Preparation of Zirconia Dental Crowns Via Electrophoretic DepositionDokument8 SeitenPreparation of Zirconia Dental Crowns Via Electrophoretic DepositionMarioNoch keine Bewertungen

- 1 s2.0 S0013468605008200 Main PDFDokument5 Seiten1 s2.0 S0013468605008200 Main PDFMarioNoch keine Bewertungen

- Experimental Design Applied To The Chemical Durability of Sol-Gel-Derived ZirconiasDokument8 SeitenExperimental Design Applied To The Chemical Durability of Sol-Gel-Derived ZirconiasMarioNoch keine Bewertungen

- Milos EvDokument27 SeitenMilos EvMarioNoch keine Bewertungen

- Analysis of Berkovich Indentation: Pergamon 002IK7683 (95) 00033-XDokument28 SeitenAnalysis of Berkovich Indentation: Pergamon 002IK7683 (95) 00033-XMarioNoch keine Bewertungen

- 1 s2.0 S0022309301008225 Main PDFDokument12 Seiten1 s2.0 S0022309301008225 Main PDFMarioNoch keine Bewertungen

- Prospective Observation of CAD/CAM Titanium Ceramic Single Crowns: A Three-Year Follow UpDokument8 SeitenProspective Observation of CAD/CAM Titanium Ceramic Single Crowns: A Three-Year Follow UpMarioNoch keine Bewertungen

- R. Priya, C. Mallika, U. Kamachi Mudali: ArticleinfoDokument11 SeitenR. Priya, C. Mallika, U. Kamachi Mudali: ArticleinfoMarioNoch keine Bewertungen

- EBB 324 Lecture 8Dokument65 SeitenEBB 324 Lecture 8MarioNoch keine Bewertungen

- Titanio y AleacionesDokument7 SeitenTitanio y AleacionesMarioNoch keine Bewertungen

- Electrodeposition of Metals From Non-Aqueous Solutions: Electrochimica ActaDokument13 SeitenElectrodeposition of Metals From Non-Aqueous Solutions: Electrochimica ActaMario100% (1)

- Electrodeposition of Metals From Non-Aqueous Solutions: Electrochimica ActaDokument13 SeitenElectrodeposition of Metals From Non-Aqueous Solutions: Electrochimica ActaMarioNoch keine Bewertungen

- Materials Letters: H.C. Li, D.G. Wang, J.H. Hu, C.Z. ChenDokument4 SeitenMaterials Letters: H.C. Li, D.G. Wang, J.H. Hu, C.Z. ChenMarioNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Test Bank For Sectional Anatomy For Imaging Professionals 4th Edition by KelleyDokument36 SeitenTest Bank For Sectional Anatomy For Imaging Professionals 4th Edition by Kelleymidmaindentals0lle98% (40)

- What Materials Are Used For 3D Printing - Sharretts Plating CompanyDokument9 SeitenWhat Materials Are Used For 3D Printing - Sharretts Plating CompanysureshrnalNoch keine Bewertungen

- Material Property Charts-W4Dokument15 SeitenMaterial Property Charts-W4Fara AsilaNoch keine Bewertungen

- ERIEZ Magnetos Suspendidos (SB-305N)Dokument20 SeitenERIEZ Magnetos Suspendidos (SB-305N)angelsiddhartaNoch keine Bewertungen

- Methods For The Determination of Overall Migration Into Aqueous Simulants Using A PouchDokument7 SeitenMethods For The Determination of Overall Migration Into Aqueous Simulants Using A PouchRamSagareNoch keine Bewertungen

- Defense Scrap Yard HandbookDokument251 SeitenDefense Scrap Yard HandbookAFLAC ............0% (1)

- Processing and Recycling in Mining andDokument2 SeitenProcessing and Recycling in Mining andHenockNoch keine Bewertungen

- Atomic Structure and Periodic TableDokument51 SeitenAtomic Structure and Periodic TableSoumyaa KumarNoch keine Bewertungen

- Chemistry - Ipe Important Questions 2023-24Dokument11 SeitenChemistry - Ipe Important Questions 2023-24AbhijeetNoch keine Bewertungen

- A 879Dokument2 SeitenA 879Gustavo SuarezNoch keine Bewertungen

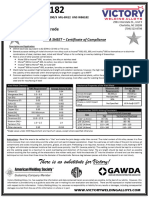

- NI-182 Victory ENICRFE-3 Electrode Data SheetDokument1 SeiteNI-182 Victory ENICRFE-3 Electrode Data SheetgianNoch keine Bewertungen

- Rehovot Engineering ProductsDokument8 SeitenRehovot Engineering ProductsU M NarayananNoch keine Bewertungen

- Thermal Relay Working Principle Construction of Thermal Overload RelayDokument2 SeitenThermal Relay Working Principle Construction of Thermal Overload RelayTuhin ShahNoch keine Bewertungen

- Be Tac CadDokument16 SeitenBe Tac CadAmal SaNoch keine Bewertungen

- Ans cb1c e Unit10-12Dokument35 SeitenAns cb1c e Unit10-12黃淑敏Noch keine Bewertungen

- Assist Gas For Laser Cutting: For Internal Use OnlyDokument8 SeitenAssist Gas For Laser Cutting: For Internal Use OnlymansoorlatifNoch keine Bewertungen

- Ultra-Narrow Gap Fiber Laser Conduction Welding Technology For 304 Stainless Steel Thick Plates and The Mechanical Properties of Welding JointsDokument12 SeitenUltra-Narrow Gap Fiber Laser Conduction Welding Technology For 304 Stainless Steel Thick Plates and The Mechanical Properties of Welding JointsMaxNoch keine Bewertungen

- Sense NichDokument80 SeitenSense NichcarlNoch keine Bewertungen

- Iron Steel IndustryDokument4 SeitenIron Steel IndustryAdit NugrahaNoch keine Bewertungen

- Presentation On Elements-Mixtures-Compounds Notes - 1Dokument31 SeitenPresentation On Elements-Mixtures-Compounds Notes - 1Daniela TecucianuNoch keine Bewertungen

- Corrosion in Stainless Steel ! - Know The Facts !!Dokument22 SeitenCorrosion in Stainless Steel ! - Know The Facts !!faith23dbagulNoch keine Bewertungen

- Stainless Steel - Properties and Applications of Ferritic Grade Stainless Steel by Austral Wright MetalsDokument5 SeitenStainless Steel - Properties and Applications of Ferritic Grade Stainless Steel by Austral Wright Metalsbretariandhika_unsNoch keine Bewertungen

- CMM Nose Wheel Assy LearDokument121 SeitenCMM Nose Wheel Assy LearKornelius LülingNoch keine Bewertungen

- Spark Test For Iron SteelDokument3 SeitenSpark Test For Iron SteelTegar Kukuh Ahmad JulfikarNoch keine Bewertungen

- Plasma-And Laser-Cutting ToolDokument17 SeitenPlasma-And Laser-Cutting ToolRiyan EsapermanaNoch keine Bewertungen

- Construction Materials Used in Marine Diesel EnginesDokument4 SeitenConstruction Materials Used in Marine Diesel EnginesshihabNoch keine Bewertungen

- Test Requirement For REACH Compliance: Sl. Component Required Test Total Cost (USD)Dokument2 SeitenTest Requirement For REACH Compliance: Sl. Component Required Test Total Cost (USD)Ferdous Khan RubelNoch keine Bewertungen

- ASTM D1002 - Apparent Shear Strength of Single-Lap-Joint Adhesively Bonded Metal Specimens by Tension LoadingDokument6 SeitenASTM D1002 - Apparent Shear Strength of Single-Lap-Joint Adhesively Bonded Metal Specimens by Tension LoadingPablo Ortega100% (1)

- Aluminium 6063 Heat TreatmentDokument3 SeitenAluminium 6063 Heat TreatmentManojkumar Mano100% (1)

- Themal Spray To Protect SteelDokument169 SeitenThemal Spray To Protect Steel123vigenNoch keine Bewertungen