Beruflich Dokumente

Kultur Dokumente

Alarm Valve Sprinkler

Hochgeladen von

Kevin TsuiOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Alarm Valve Sprinkler

Hochgeladen von

Kevin TsuiCopyright:

Verfügbare Formate

www.Kidde-Fire.

com

"Automatic" Sprinkler

150 Gordon Drive

Exton, PA 19341 USA

Tel: (610) 363-1400

800-626-2682

Fax: (610) 524-9073

800-858-6857

#SVL100 - Model 353 Alarm Valves

123456

Fire Protection Equipment

i SVL100

TABLE OF CONTENTS

Text Page

General ................................................................................................................................................................... 1

Approvals................................................................................................................................................................ 1

Description / Operation .......................................................................................................................................... 1

Variable Pressure.............................................................................................................................................. 1

Constant Pressure ............................................................................................................................................ 2

Figure 1 - Operation Diagram: Model 353 Alarm Valve with Model B Retard Chamber Set Position................ 2

Figure 2 - Operation Diagram: Model 353 Alarm Valve with Model B Retard Chamber Operating Position ..... 2

Technical Data........................................................................................................................................................ 3

Ordering Information .............................................................................................................................................. 3

"Automatic" Model 353 Valve Assemblies - Parts List ......................................................................................... 4

"Automatic" Model B Retard Chamber - Parts List ............................................................................................... 5

"Automatic" 4 Model 353 Alarm Valve - Flange/Flange

Vertical/Variable Pressure Trim Setup 353-4V with Retard Chamber - Parts Drawing & List ..................... 6

"Automatic" 4 Model 353 Alarm Valve - Flange/Flange

Vertical/Constant Pressure Trim Setup 353-4C - Parts Drawing & List ........................................................ 7

"Automatic" 6 Model 353 Alarm Valve - Flange/Flange

Vertical/Variable Pressure Trim Setup 353-6V with Retard Chamber - Parts Drawing & List ..................... 8

"Automatic" 6 Model 353 Alarm Valve - Flange/Flange

Vertical/Constant Pressure Trim Setup 353-6C - Parts Drawing & List ........................................................ 9

"Automatic" 8 Model 353 Alarm Valve - Flange/Flange

Vertical/Variable Pressure Trim Setup 353-8V with Retard Chamber - Parts Drawing & List ................... 10

"Automatic" 8 Model 353 Alarm Valve - Flange/Flange

Vertical/Constant Pressure Trim Setup 353-8C - Parts Drawing & List ...................................................... 11

Testing and Maintenance ..................................................................................................................................... 12

Testing ............................................................................................................................................................ 12

Testing Alarm Valve and Waterflow Alarm Devices .................................................................................. 12

Flow Test at Main Drain Valve (Main Drain Test) ...................................................................................... 12

Maintenance................................................................................................................................................... 13

Clapper Facing ......................................................................................................................................... 13

Seat Ring.................................................................................................................................................. 13

By-Pass Check Valve ............................................................................................................................... 13

Retard Chamber ....................................................................................................................................... 13

Alarm Line Strainer ................................................................................................................................... 13

SVL100 ii

Alarm Test Valve, Main Drain Valve & Inspection Test Valve .................................................................... 13

Alarm Valve and Trim ............................................................................................................................... 13

Resetting of System ................................................................................................................................. 13

"Automatic" Model 353 Alarm Valves - LPCB Approved .................................................................................... 14

MODEL 353

Alarm Valves

DATA SHEET

#SVL100

www.Kidde-Fire.com

General

The "Automatic" Model 353 Alarm Valve is a waterflow

alarm device designed for installation in the main supply

to a wet pipe sprinkler system. Its purpose is to actuate a

fire alarm when a flow of water from the system equals or

exceeds that of a single sprinkler. The alarm may be ac-

complished in two ways: (1) mechanically by means of a

water flow to a water motor alarm and/or (2) electrically

via a water-pressure-actuated alarm switch (circuit closer)

connected to an electrically operated signaling device such

as a bell or light.

The Model 353 Alarm Valve, available in 4" (101.6 mm), 6"

(152.4 mm) and 8" (203.2 mm) pipe sizes for vertical in-

stallation, may be provided with either of two basic trim

packages. There is one set of trim for variable supply pres-

sure and another for constant supply pressure.

Variable pressure trim is used where the water supply pres-

sure fluctuates. A public water main is an example of such

a supply. To prevent false alarms caused by surges or fluc-

tuations in pressure, the trim set is provided with the "Au-

tomatic" Model B Retard Chamber.

For installations where there is a constant supply pres-

sure, that is, where the water pressure does not fluctuate,

the retard chamber is omitted. For example, constant pres-

sure trim may be used when the water supply is from an

elevated tank or pressure tank.

An excess pressure pump may be required for installtions

where excessive pressure surges or extreme fluctuations

in the water pressure are encountered.

Approvals

! Underwriters Laboratories (UL)

! Factory Mutual (FM)

! Underwriters Laboratories Of Canada (ULC)

! Loss Prevention Certification Board (LPCB)

The valves are listed/approved with specific trim and for

installation in accordance with the applicable requirements

of NFPA 13. Therefore, no substitutions or omissions, in

part or in full, are allowed.

Model B Retard Chambers are listed and approved for use

specifically with the Model 353 Alarm Valves.

All devices are listed/approved for a maximum water work-

ing pressure (WWP) of 175 psi (1206.6 kPa or 12.1 bar).

Description / Operation

The Model 353 Alarm Valve is the type of alarm check

valve which has a grooved seat ring and an external by-

pass. Its operation in a wet pipe sprinkler system is as

follows:

When the sprinkler system is placed into service, water is

allowed to flow into the system until the system pressure

and the supply pressure are equal. The system pressure

then causes the rubber-faced clapper of the alarm valve

to close tightly on the grooved seat ring. It will remain in

this closed position as long as the pressure in the system

is equal to or greater than the supply pressure. See Figure 1.

Variable Pressure. In service, the pressure on the sys-

tem, most often, will be found to be greater than the water

supply pressure. This condition exists because excess

pressure from surges and fluctuations in the water supply

are allowed to pass through the external checked by-pass

to be trapped in th esystem above the alarm valve clap-

per. Normally then, the clapper will remain in a closed po-

sition.

At times, however, sudden surges of greater pressure may

cause the clapper to open momentarily, then close. In such

instances, when the clapper is open, there will be a limited

flow of water through the seat ring openings and into the

retard chamber. There the water can accumulate, then drain

away without causing a false alarm.

When a sprinkler operates, the resulting water flow relieves

the system pressure. The greater supply pressure then

causes the alarm valve clapper to open, thereby permit-

ting an unobstructed flow of water into the system. At the

same time, water flows through the seat ring openings and

123

456

2 SVL100

via alarm line connections into the retard chamber. But

now, with the system operating, the clapper remains in an

open position and the volume of water flowing through the

alarm line is such that the retard chamber drain cannot

keep up with the incoming flow. The chamber quickly fills

and the water flow continues on to sound the water motor

alarm and/or operate the pressure actuated electric alarm

switch. See Figure 2.

Caution: All sprinkler systems contain a certain amount

of confined air. It is possible that a pressure surge could

compress this air and allow the alarm valve clapper to move

off the seat ring. Under some conditions, this could cause

false alarms. It is recommended, therefore, that the installer

bleed off the confind air and fill the system with water to

the fullest extent possible.

Constant Pressure. Under normal conditions the system

and supply pressures will be the same. Since the pres-

sure is constant, there is no need to consider surges and

fluctuations. Therefore, a retard chamber is not provided.

When a sprinkler operates, the system pressure drops,

allowing the alarm valve clapper to open. At the same time

that water enters the system, it also flows through the seat

ring openings and then via the alarm line connections di-

rectly to operate the alarm devices.

SVL100 3

Technical Data

Available Sizes: .................. ! 4" (101.6 mm)

! 6" (152.4 mm)

! 8" (203.2 mm)

Inlet & Outlet: ...................... Class 125 Flanged

Water Working Pressure: .... 175 psi (1206.6 kPa or

12.1 bar)

Setup For: ........................... ! Variable Pressure

! Constant Pressure

Listings & Approvals: .......... ! UL Listed

! FM Approved

! ULC Listed

! LPCB Approved

Pressure Loss:

For use in hydraulic calculations, the pressure loss through

the alarm valve may be expressed as equivalent feet of

pipe:

! 4" Valve = 9 Ft

! 6" Valve = 37 Ft

! 8" Valve = 18 Ft

Conversion Factors:

! 1 inch = 25.4 millimeters (mm)

! 1 psi = 6.895 kilopascals (kPa)

0.0689 bar

! 1 gallon = 3.785 liters (L)

7. 0

(48. 3)

5. 0

(34. 5)

3. 0

(20. 7)

2. 0

(1 3. 8)

0. 5

(3. 4)

1 . 0

(6. 9)

0. 1

(0. 7)

200

(757)

300

(1 1 36)

500

(1 893)

1 000

(3785)

2000

(7570)

3000

(1 1 355)

5000

(1 8925)

Pressure Loss Curves

P

r

e

s

s

u

r

e

i

n

p

s

i

(

k

P

a

)

Fl ow i n gpm (L/mi n. )

4

i

n

.

(

1

0

1

.

6

m

m

)

6

i

n

.

(

1

5

2

.

4

m

m

)

8

i

n

.

(

2

0

3

.

2

m

m

)

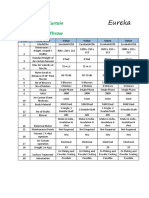

Ordering Information

! "Automatic" Model 353 Alarm Valves - Flange/Flange

4" Valve 6" Valve 8" Valve

Item/Setup

Symbol

Number

Part

Number

Symbol

Number

Part

Number

Symbol

Number

Part

Number

Alarm Valve only (without trim) 353-400 8353704 353-600 8353706 353-800 8353708

Trim setup for Alarm Valve:

For Variable Pressure (less Retard Chamber)

For Constant Pressure

353-4V

353-4C

1404832

1404833

353-6V

353-6C

1404842

1404843

353-8V

353-8C

1404852

1404853

Retard Chamber Automatic Model B

Note: Retard Chamber is to be ordered

separately and in addition to the trim setup

for variable pressure.

8-100 8008100 8-100 8008100 8-100 8008100

Trim Option for Alarm Switch (less Switch) 86-A 1601119 86-A 1601119 86-A 1601119

Alarm Valve, Pre-Trimmed

For Variable Pressure, Retard Chamber

included

- 8353904 - 8353906 - 8353908

4 SVL100

"Automatic" Model 353 Valve Assemblies

Parts List

! "Automatic" Model 353 Alarm Valve Assemblies - Flange/Flange

4 Valve 6 Valve 8 Valve

Item

Number

Part Name Material Symbol

Number

Part

Number

Symbol

Number

Part

Number

Symbol

Number

Part

Number

1

2

Valve Body Subassembly

Body

Seat Ring

-

Cast Iron

Bronze

S353-406

-

-

8353406

-

-

S353-606

-

-

8353606

-

-

S353-806

-

-

8353806

-

-

Handhole Cover

Nameplate

Drive Screws: #0 x 2 required

Handhole Cover Gasket

Hex Head Cap Screws

5/16 18 x 1-1/4 long 6 required

3/8 16 x 1-1/2 long 6 required

13 x 1-1/2 long 6 required

Cast Iron

Aluminum

Steel

Rubber

-

Steel

Steel

Steel

353-403

-

-

353-405

-

-

-

-

8353403

-

-

8353405

-

1420057

-

-

353-603

-

-

353-605

-

-

-

-

8353603

-

-

8353605

-

-

1420073

-

353-803

-

-

353-805

-

-

-

-

8353803

-

-

8353805

-

-

-

1420101

3

4

6

7

8

9

10

11

12

Clapper Subassembly

Clapper

Clapper

Clapper Facing

Retaining Disc

Retaining Disc

Shoulder Bolt

Shoulder Bolt Gasket

Self-Locking Nut: 3/8-16

3/8 16 x 1 Cap Screw (1 req.)

3/8 Lock washer (1 required)

-

Stainless Steel

Bronze

Rubber

Stainless Steel

Bronze

Brass

Rubber

Stainless Steel

Stainless Steel

Stainless Steel

S353-408

353-409

-

353-411

-

-

102-103

-

-

-

-

8353408

1353409

-

1353411

-

4601800020

8102103

1602131

1601381

-

-

S353-608

353-609

-

353-611

353-610

-

353-612

-

-

-

-

8353608

1353609

-

1353611

1353610

-

8353612

1602131

1601381

-

-

S353-808

-

353-809

353-811

353-810

-

-

-

-

-

-

8353808

-

8353809

1353811

1353810

-

-

-

-

1402150

1425078

13

14

15

16

Hinge Pin

Hinge Pin Bushings (2 in Body)

3/8 Plug

1/2 Plug

Stainless Steel

Bronze

Brass

Brass

353-413

-

-

-

8353413

-

2096099

-

353-613

-

-

-

8353613

-

2096099

-

353-813

-

-

-

8353813

-

-

2096103

Handhole cover and related items are not shown in detail.

These items are not field replaceable.

Not required for 8 size.

SVL100 5

"Automatic" Model B Retard Chamber

Parts List

! "Automatic" Model B Retard Chamber

Item

Number Part Name Material

Symbol

Number

Part

Number

1 Retard Chamber Body Cast Iron 8-101 8008101

2 Outlet Plug Assembly

Outlet Plug

Screen

Brass

Brass

S8-105 8008105

3 Drain Plug Assembly

Drain Plug

Screen

Brass

Brass

S8-106 8008106

4 O-Ring Gasket Buna-N - 1419198

6 SVL100

"Automatic" 4" Model 353 Alarm Valve - Flange/Flange

Vertical/Variable Pressure Trim Setup 353-4V

with Retard Chamber

SVL100 7

"Automatic" 4" Model 353 Alarm Valve - Flange/Flange

Vertical/Constant Pressure Trim Setup 353-4C

8 SVL100

"Automatic" 6" Model 353 Alarm Valve - Flange/Flange

Vertical/Variable Pressure Trim Setup 353-6V

with Retard Chamber

SVL100 9

"Automatic" 6" Model 353 Alarm Valve - Flange/Flange

Vertical/Constant Pressure Trim Setup 353-6C

10 SVL100

"Automatic" 8" Model 353 Alarm Valve - Flange/Flange

Vertical/Variable Pressure Trim Setup 353-8V

with Retard Chamber

SVL100 11

"Automatic" 8" Model 353 Alarm Valve - Flange/Flange

Vertical/Constant Pressure Trim Setup 353-8C

12 SVL100

Reference.

NFPA 25, Standard for the Inspection, Testing and Main-

tenance of Water Based Fire Protection Systems.

Testing

Before proceeding with any tests involving water flow, cer-

tain precautions need to be taken.

1. Check the location where the test connection dis-

charges to make sure that all is clear and that there is

no possibility of the water flow causing damage or in-

jury.

2. Check the end of the test connection to make sure

that it is unobstructed. To obtain a satisfactory test,

there must be an unrestricted flow of water when the

test valve is wide open.

3. Check for alarm connections to a central station or

fire department. If such connections are found, give

proper notice to the signal receiving station before

proceeding with the test.

Note: A main drain test will also operate local fire

alarms - unless they are temporarily shut off.

Testing Alarm Valve and Waterflow Alarm Devices.

NFPA 25 recommends that the alarm valve and its

waterflow alarm devices be tested at least quarterly.

The primary way to test this equipment is by opening the

Inspectors Test Connection. This connection, generally

located at the highest and most remote point on the sys-

tem in relation to the alarm valve, consists of a test orifice

and controlling globe valve. Opening of the globe valve

(Inspectors Test Valve), and the subsequent discharge of

water through the test orifice, simulates the operation of a

sprinkler. Therefore, alarm devices should sound and/or

operate when the Inspectors Test Valve is opened.

An alternate means of testing waterflow alarm devices is

to open the Alarm Test Valve provided as part of the alarm

valve trim. It must be noted, however, that opening of this

valve only tests the alarms; it does not test the operation

of the alarm valve since the supply for the alarm test line

is taken from a point below the alarm valve clapper (see

Description/Operation). This means of testing, therefore,

should only be used when weather conditions or other cir-

cumstances prohibit using the Inspectors Test Connection.

Note: If alarms connect to a central station or fire depart-

ment, notify the signal receiving station when all tests have

been completed.

Testing and Maintenance

Flow Test at Main Drain Valve (Main Drain Test).

NFPA 25 recommends that a water flow test be made quar-

terly from the main drain valve at the system riser. The

purpose of this test is to show whether or not the normal

water supply is available to the system. By comparing static

and residual pressure readings with those previously es-

tablished, a main drain test can indicate the possible pres-

ence of closed valves or other obstructions in the supply

piping.

The procedure for conducting a Main Drain Test is as fol-

lows:

1. With the Main Drain Valve closed, note and record

the reading on the lower Pressure Gage at the Alarm

Valve.

2. Open the Main Drain Valve slowly until it is fully open.

Then, check to make sure that a full steady flow of

water is discharging from the main drain pipe.

Note: If a full steady stream is not discharging, check

the main drain piping further for possible obstructions.

3. Allow the water to flow until the reading on the lower

Pressure Gage drops and stabilizes. Then, record this

reading.

Note: The first and higher pressure reading is the static

pressure. The second, lower reading is the residual

pressure with a given flow discharging from the main

drain pipe.

4. Close the Main Drain Valve slowly.

Caution: If alarms have been temporarily shut off, they

must be returned to service. If alarms connect to a

central station or fire department, notify the signal re-

ceiving station when the test has been completed.

5. Compare both pressure readings with previously es-

tablished or normal readings.

Note: If the readings compare favorably, the water

supply may be considered satisfactory. If, however,

the pressure readings vary to any great extent, the

condition should be investigated to determine the

cause. Some possible causes are:

Partially or totally closed system control valves.

Clogged or frozen water mains.

Serious leakage at valves or mains.

SVL100 13

Maintenance

The "Automatic" Model 353 Alarm Valve and its related

equipment should be examined periodically to ensure

proper operation and trouble free service. Several areas

to be routinely inspected are:

Clapper Facing. The rubber clapper facing should be

checked for wear or damage, and to determine that it is

free of dirt and other foreign substances. If found to be

worn or damaged (e.g., foreign matter imbedded in the

surface), the facing should be replaced. If it is dirty, it should

be cleaned, but compounds which could damage the rub-

ber facing must never be used.

Seat Ring. The seat ring should be checked for nicks and

for stones, dirt or other foreign matter lodged in the grooves

or holes. It should be cleaned thoroughly. If the seat ring is

found to be severely damaged, the complete alarm valve

assembly should be replaced.

By-Pass Check Valve. The 3/4" check valve in the exter-

nal by-pass should be checked for clapper and seat con-

dition.

Retard Chamber. The outlet plug and drain plug assem-

blies should be checked for obstructions. The screens

should be cleaned thoroughly.

Alarm Line Strainer. The 3/4" strainer in the alarm line of

the constant pressure trim setup should be checked and

cleaned thoroughly.

Alarm Test Valve, Main Drain Valve & Inspection Test

Valve. All controlling valves which are normally closed

when the alarm valve is in the set position should be

checked to be sure that they are fully closed and not leak-

ing.

Alarm Valve and Trim. The overall setup should be

checked for visible leaks and possible physical damage to

the valve and connections (e.g., broken gages).

Resetting of System

The "Automatic" Model 353 Alarm Valve is self-resetting

when testing procedures are followed. When sprinklers

operate, however, there are certain procedures which must

be followed for restoring the system to service.

1. Close the System Control Valve (OS&Y, PIV or other).

Caution: In the event of a fire, the system control valve

is to be closed only after it has been determined, posi-

tively, that the fire has been extinguished.

2. Close the Alarm Control Valve.

3. Open the Main Drain Valve.

Note: It is necessary to drain the system only as re-

quired to allow for sprinkler replacement.

4. Replace the sprinklers which have operated.

5. Close the Main Drain Valve.

6. Open the Inspectors Test Valve.

Note: This valve is opened to permit air to be vented

from the system as it is being filled with water.

7. Slowly open the System Control Valve.

Caution: Open the valve only partially at the stsrt of

water flow into the system. Do not open it fully at this

point. To do so may cause a water hammer to occur

which could either damage the piping or trap large

volumes of air within the system.

8. Continue filling the system until water discharges in a

continuous stream from the Inspectors Test Connec-

tion.

9. Close the Inspectors Test Connection.

10. Turn the System Control Valve to its full open posi-

tion, at the same time observing the Pressure Gages.

Note: The system is filled when both gages are steady

and have the same pressure reading.

11. Conduct a Main Drain Test to make sure the water

supply is satisfactory (see Flow Test at Main Drain

Valve).

12. Open the Alarm Control Valve.

13. Conduct a test of the alarm devices (see Testing Alarm

Valve and Waterflow Alarm Devices).

14. Seal, lock, or otherwise secure the System Control

Valve and Alarm Control Valve in an open position (per

NFPA 25). The system is now ready for service.

15. If alarms connect to a central station or fire depart-

ment, notify the signal receiving station that the sys-

tem has been returned to service.

"Automatic" Model 353 Alarm Valves - LPCB Approved

"Automatic" Model 353 Alarm Valves are also approved by

the Loss Prevention Certification Board (LPCB). For LPCB

approved valves, however, the trim setups differ from those

required for UL/FM/ULC approval.

It must be noted that in a fire situation, with all setups, the

operation of the alarm valve is the same (see Descrip-

tion/Operation). The difference in setup occurs only in

the arrangement of test connections.

With UL/FM/ULC approved valves, the Alarm Test Valve

in the alarm valve trim is just for testing the waterflow alarm

devices. It cannot be used to test the operation of the alarm

valve itself since the supply to the alarm test line is from a

point below the alarm valve clapper ( see Testing Alarm

Valve and Waterflow Alarm Devices).

To meet LPCB approval, a means must be provided at the

alarm valve for testing both the valve and its waterflow

alarm devices. To accomplish this, the alarm test line is

arranged to take its supply from above the valve clapper.

And, in addition to the Alarm Test Valve, an Orifice Union

is provided to simulate the operation of a sprinkler when

the test valve is opened.

For information on LPCB approved alarm valves, refer to

Bulletin 303-FOC.

14 SVL100

"Automatic" Sprinkler

150 Gordon Drive Exton, PA 19341 USA

Tel: (610) 363-1400 800-626-2682

Fax: (610) 524-9073 800-858-6857

This information is only a general guideline. The company reserves the right to change any portion of this information without notice. Terms and

conditions of sale apply and are available on request.

2/02 Printed in USA (SLV100.P65)

Das könnte Ihnen auch gefallen

- Perdele Economic B 2VVDokument4 SeitenPerdele Economic B 2VVakitainupufNoch keine Bewertungen

- Ufgs 33 56 10Dokument38 SeitenUfgs 33 56 10mohamed fathiNoch keine Bewertungen

- Selection of An Air Curtain: (See Charts For Numbers)Dokument2 SeitenSelection of An Air Curtain: (See Charts For Numbers)mechmohsin4745Noch keine Bewertungen

- ASME VIII-1 pressure vessel design code and operating conditionsDokument1 SeiteASME VIII-1 pressure vessel design code and operating conditionsNomi KhanNoch keine Bewertungen

- HPCBS Duct Fitting SavingsDokument6 SeitenHPCBS Duct Fitting SavingsSvetla NikolovaNoch keine Bewertungen

- BOSS™ Pressurisation Units and Expansion Vessels PDFDokument16 SeitenBOSS™ Pressurisation Units and Expansion Vessels PDFRIFASNoch keine Bewertungen

- Combined Sprinkler and Standpipe AssemblyDokument1 SeiteCombined Sprinkler and Standpipe Assemblydesign sseNoch keine Bewertungen

- Eureka Air Curtains CatalogueDokument3 SeitenEureka Air Curtains CatalogueSumit BhandariNoch keine Bewertungen

- HydraulicDokument8 SeitenHydraulicOsama OmayerNoch keine Bewertungen

- Calculation For IPE200Dokument10 SeitenCalculation For IPE200HaymanAHMEDNoch keine Bewertungen

- PEERLEES Fire Pump PDFDokument175 SeitenPEERLEES Fire Pump PDFN. AndradeNoch keine Bewertungen

- Calculation For IPE360Dokument12 SeitenCalculation For IPE360HaymanAHMEDNoch keine Bewertungen

- Tyco Alarm ValveDokument22 SeitenTyco Alarm ValveMohammed BaquarNoch keine Bewertungen

- Specification For Sprinkler LPC - FSD Circular 2006 - 03Dokument46 SeitenSpecification For Sprinkler LPC - FSD Circular 2006 - 03James Li100% (1)

- 1 Beam Fails Ub305x165x54Dokument4 Seiten1 Beam Fails Ub305x165x54Elencheliyan PandeeyanNoch keine Bewertungen

- Design CalculationDokument1 SeiteDesign Calculationapi-3728508Noch keine Bewertungen

- Fire Sprinkler For Non-Storage Facilities PPT Presentation PDFDokument62 SeitenFire Sprinkler For Non-Storage Facilities PPT Presentation PDFMickoAngeloRamirezAquino100% (1)

- Firewater SystemDokument69 SeitenFirewater SystemSyed HameedNoch keine Bewertungen

- Horizontal Sidewall Sprinklers Technical Data SheetDokument6 SeitenHorizontal Sidewall Sprinklers Technical Data SheetAhrian BenaNoch keine Bewertungen

- Vortex Inhibitor VortibreakDokument1 SeiteVortex Inhibitor VortibreakNabil RamehNoch keine Bewertungen

- Hazen Williams EquationDokument1 SeiteHazen Williams EquationNur IzzaidahNoch keine Bewertungen

- Analysis of Double Howe Steel Truss & Cantilever Truss Using Ansys SoftwareDokument6 SeitenAnalysis of Double Howe Steel Truss & Cantilever Truss Using Ansys SoftwareSRINIVAS DNoch keine Bewertungen

- Pressure Volume Calculator 02Dokument6 SeitenPressure Volume Calculator 02Jenny Cecilia Ureña ZuriNoch keine Bewertungen

- 1 PDFsam PDFsam Duct FittingsDokument1 Seite1 PDFsam PDFsam Duct FittingsJosephRusselVizmanosNoch keine Bewertungen

- Remove Oil Grease Water 40Dokument6 SeitenRemove Oil Grease Water 40Sai PrasathNoch keine Bewertungen

- Chilled Water System Introduction, MyanmarDokument20 SeitenChilled Water System Introduction, MyanmaracmvorgNoch keine Bewertungen

- AFSS-Commissioning & Testing..Dokument4 SeitenAFSS-Commissioning & Testing..sanchezdreiNoch keine Bewertungen

- How Do Properly Size A FanDokument4 SeitenHow Do Properly Size A Fanmefaisal75Noch keine Bewertungen

- How To Design Kitchen HoodDokument2 SeitenHow To Design Kitchen HoodSandeep KumawatNoch keine Bewertungen

- Air CoolersDokument18 SeitenAir CoolersPRATIK P. BHOIRNoch keine Bewertungen

- Isle of Wight Fire & Rescue Service: Record of Fire Safety Equipment Testing Fire Drills & TrainingDokument18 SeitenIsle of Wight Fire & Rescue Service: Record of Fire Safety Equipment Testing Fire Drills & TrainingcaptalaaNoch keine Bewertungen

- F 1090 - 87 R97 - Rjewota - PDFDokument4 SeitenF 1090 - 87 R97 - Rjewota - PDFFreddy AlmeidaNoch keine Bewertungen

- Confined Space Ventilation TechniquesDokument16 SeitenConfined Space Ventilation TechniquesTerry A. WaldropNoch keine Bewertungen

- Installing FHC PDFDokument4 SeitenInstalling FHC PDFZaw Moe KhineNoch keine Bewertungen

- Lindab PascalDokument20 SeitenLindab PascalruisengoNoch keine Bewertungen

- Calculating Pressure Loss - Equivalent Pipe Length MethodDokument1 SeiteCalculating Pressure Loss - Equivalent Pipe Length MethodRamachandran VenkateshNoch keine Bewertungen

- Tech PDFDokument3 SeitenTech PDFAwais JalaliNoch keine Bewertungen

- Technical Documentation Sliding DoorDokument23 SeitenTechnical Documentation Sliding DoorLe Ngoc AnhNoch keine Bewertungen

- NBC Part 7Dokument72 SeitenNBC Part 7Shubham AggarwalNoch keine Bewertungen

- Bernoulli Equation: Z P P V G HLDokument2 SeitenBernoulli Equation: Z P P V G HLKorichiKarimNoch keine Bewertungen

- 02 Design Guide Warehouses LoresDokument21 Seiten02 Design Guide Warehouses LoresReinaldo SouzaNoch keine Bewertungen

- Fire Hose Reel SystemDokument7 SeitenFire Hose Reel SystemRedford DonguyaNoch keine Bewertungen

- Sprinkler System FormulasDokument2 SeitenSprinkler System Formulasturbosri_mechNoch keine Bewertungen

- HVWS SystemDokument1 SeiteHVWS Systemabhinay02meNoch keine Bewertungen

- SLXBobinwoundfiltersDokument1 SeiteSLXBobinwoundfiltersKAMALNoch keine Bewertungen

- CO2 Sensor RoomDokument8 SeitenCO2 Sensor RoomTrần Khắc ĐộNoch keine Bewertungen

- Case StudyDokument33 SeitenCase StudyDaryl Gomez TimatimNoch keine Bewertungen

- Design of Ventilation SystemsDokument5 SeitenDesign of Ventilation SystemsSimon LaurentNoch keine Bewertungen

- ATTMA TSL2 Issue 1 PDFDokument32 SeitenATTMA TSL2 Issue 1 PDFDenise Koh Chin HuiNoch keine Bewertungen

- Air Distribution System Case StudyDokument16 SeitenAir Distribution System Case Studytmy3dataNoch keine Bewertungen

- Ozone Treatment of Cooling Tower WaterDokument26 SeitenOzone Treatment of Cooling Tower WaterLh KooNoch keine Bewertungen

- Design of Sprinklered Shopping Centre Buildings For Fire SafetyDokument42 SeitenDesign of Sprinklered Shopping Centre Buildings For Fire SafetyZyron BatacNoch keine Bewertungen

- MIFAB Control Flo Roof DrainsDokument5 SeitenMIFAB Control Flo Roof DrainsjavedwestNoch keine Bewertungen

- DampersDokument25 SeitenDampersmpwasaNoch keine Bewertungen

- TIGERFLOW Booster Sizing Worksheet: I. Pressure RequiredDokument3 SeitenTIGERFLOW Booster Sizing Worksheet: I. Pressure RequiredAnonymous BJ9omONoch keine Bewertungen

- Staircase PressurizationDokument8 SeitenStaircase PressurizationKrishna PATEL100% (1)

- Comparison of Sprinkler Design Criteria 1. Sprinkler Installation Nfpa 13Dokument16 SeitenComparison of Sprinkler Design Criteria 1. Sprinkler Installation Nfpa 13coolth2Noch keine Bewertungen

- Surge Control in Pumping Systems: White PaperDokument15 SeitenSurge Control in Pumping Systems: White PapermaiNoch keine Bewertungen

- Ejector Cloro17Dokument14 SeitenEjector Cloro17Robinson SanchezNoch keine Bewertungen

- Tendon Injury and Repair PerspectiveDokument19 SeitenTendon Injury and Repair PerspectiveKevin TsuiNoch keine Bewertungen

- Why do Multiaxial Fatigue CalculationsDokument77 SeitenWhy do Multiaxial Fatigue CalculationsN.g. NagarajNoch keine Bewertungen

- Fracture and Crack Propagation in WeldmentsDokument66 SeitenFracture and Crack Propagation in WeldmentsKhin Aung ShweNoch keine Bewertungen

- Vibration MeasurementDokument42 SeitenVibration MeasurementChockkalingam Subramanian100% (2)

- AirDistributionGuide March15Dokument75 SeitenAirDistributionGuide March15Kevin TsuiNoch keine Bewertungen

- Effect of Enhanced Mechanical Properties of Weld Metal and Heat Affected Zone On The Strength of The Welded JointDokument5 SeitenEffect of Enhanced Mechanical Properties of Weld Metal and Heat Affected Zone On The Strength of The Welded JointKevin TsuiNoch keine Bewertungen

- SolidWorks Simulation - Avoiding SingularitiesDokument6 SeitenSolidWorks Simulation - Avoiding SingularitiesAnonymous P8Bt46mk5INoch keine Bewertungen

- Fracture and Crack Propagation in WeldmentsDokument66 SeitenFracture and Crack Propagation in WeldmentsKhin Aung ShweNoch keine Bewertungen

- Shaft Mounted Gear Unit Torque GuideDokument542 SeitenShaft Mounted Gear Unit Torque GuideKevin TsuiNoch keine Bewertungen

- AC 43-4aDokument131 SeitenAC 43-4aKevin TsuiNoch keine Bewertungen

- Vehicle AerodynamicsDokument31 SeitenVehicle AerodynamicsNimisha Singh100% (1)

- Technical Reference Guide Fastenal K Factor and MoreDokument62 SeitenTechnical Reference Guide Fastenal K Factor and Moredlight0Noch keine Bewertungen

- The Art of Instrumentation & Vibration AnalysisDokument64 SeitenThe Art of Instrumentation & Vibration AnalysisfrajaprNoch keine Bewertungen

- Introduction To ANSYS MechanicalDokument31 SeitenIntroduction To ANSYS MechanicalKevin TsuiNoch keine Bewertungen

- Tribology BasicsDokument70 SeitenTribology Basicsfeni4kaNoch keine Bewertungen

- Low and High Cycle FatigueDokument85 SeitenLow and High Cycle FatigueKevin TsuiNoch keine Bewertungen

- ISOVERDokument35 SeitenISOVERMadhu RaghuNoch keine Bewertungen

- 39 Space Air DistributionDokument25 Seiten39 Space Air DistributionPRASAD326100% (3)

- Cooling With Dehumidification PDFDokument9 SeitenCooling With Dehumidification PDFKevin TsuiNoch keine Bewertungen

- Ducts and Diffusers DesignDokument106 SeitenDucts and Diffusers DesignFrancis Paul100% (1)

- Trane 4 Chiller Plant ControlsDokument28 SeitenTrane 4 Chiller Plant ControlsEdward Siu100% (3)

- Presentation Chilled WaterDokument40 SeitenPresentation Chilled WaterMurad AliNoch keine Bewertungen

- Pyro-Chem Manual PDFDokument109 SeitenPyro-Chem Manual PDFKevin Tsui100% (4)

- FM 200 - Product Brochure PDFDokument4 SeitenFM 200 - Product Brochure PDFKevin TsuiNoch keine Bewertungen

- ,DanaInfo .AgAjnk1ki8-Jrx1pp1Qs-C-VzA.+FM200 UL-FM Manual Thorn (14A-07 Issue 2)Dokument120 Seiten,DanaInfo .AgAjnk1ki8-Jrx1pp1Qs-C-VzA.+FM200 UL-FM Manual Thorn (14A-07 Issue 2)Kevin TsuiNoch keine Bewertungen

- Fundamental Approach To Sprinkler System DesignDokument66 SeitenFundamental Approach To Sprinkler System DesignKevin Tsui100% (1)

- Explicit Formulas For The Calculation of Regenerated Noise in DuctsDokument5 SeitenExplicit Formulas For The Calculation of Regenerated Noise in DuctsKevin TsuiNoch keine Bewertungen

- Cylinder Data Sheet (FM200 Gas Bottle) PDFDokument4 SeitenCylinder Data Sheet (FM200 Gas Bottle) PDFKevin TsuiNoch keine Bewertungen

- Brecsu Avoid AcDokument38 SeitenBrecsu Avoid AcKevin TsuiNoch keine Bewertungen

- Physics Formula and Notes For Class 12 CBSE Board Chapter 7 ALTERNATING CURRENTDokument11 SeitenPhysics Formula and Notes For Class 12 CBSE Board Chapter 7 ALTERNATING CURRENTrahulNoch keine Bewertungen

- CH 06 Sec 03Dokument12 SeitenCH 06 Sec 03Verra Myza AratNoch keine Bewertungen

- The Rights and PrivilegesDokument50 SeitenThe Rights and PrivilegesM'dth Cal100% (2)

- Creative Writing 12 July Monthly TestDokument4 SeitenCreative Writing 12 July Monthly TestMichelle Labajo Maunes100% (1)

- BS en 10228-3 2016Dokument28 SeitenBS en 10228-3 2016Morteza Shakerien88% (8)

- Lactogrow VS Lactogen 2Dokument3 SeitenLactogrow VS Lactogen 2Mardan Love SunnahNoch keine Bewertungen

- Practice Problems - Groundwater Permeability and Seepage Part 2Dokument2 SeitenPractice Problems - Groundwater Permeability and Seepage Part 2Kok Soon ChongNoch keine Bewertungen

- Estimation of Genetic Variability and DiversityDokument4 SeitenEstimation of Genetic Variability and DiversityCharles WeslyNoch keine Bewertungen

- Esicm Lives 2018: Meetingabstracts Open AccessDokument690 SeitenEsicm Lives 2018: Meetingabstracts Open AccessjasbvbfitnessNoch keine Bewertungen

- ODM BrochureDokument2 SeitenODM BrochuretnkNoch keine Bewertungen

- Opinion About The Drug WarDokument1 SeiteOpinion About The Drug WarAnonymous JusFNTNoch keine Bewertungen

- Module Programming TipsDokument1 SeiteModule Programming TipsMauri accattoliNoch keine Bewertungen

- Easy Do-In Exercises Promote HappinessDokument15 SeitenEasy Do-In Exercises Promote Happinesssale18100% (1)

- Experiment 5Dokument6 SeitenExperiment 5Vinicius GuimarãesNoch keine Bewertungen

- Rede Can Actros 2546 LsDokument8 SeitenRede Can Actros 2546 LsAnonymous xxodw3HGP3Noch keine Bewertungen

- Calcium in SteelDokument39 SeitenCalcium in SteelStutee NandaNoch keine Bewertungen

- Stages of Prophase 1: LeptoteneDokument3 SeitenStages of Prophase 1: LeptotenepixiedustNoch keine Bewertungen

- Guide To Bank Charges Circular To All Banks Other Financial Institutions and Mobile Payments OperatorsDokument69 SeitenGuide To Bank Charges Circular To All Banks Other Financial Institutions and Mobile Payments OperatorsOsemwengie OsahonNoch keine Bewertungen

- HX400D6R AFJE3E 355CC-125 400-3-50 DatasheetDokument1 SeiteHX400D6R AFJE3E 355CC-125 400-3-50 DatasheetNduP78Noch keine Bewertungen

- Act 631 Finance Act 2003Dokument20 SeitenAct 631 Finance Act 2003Adam Haida & CoNoch keine Bewertungen

- Chapter 6 Waves (Teacher's Guide)Dokument35 SeitenChapter 6 Waves (Teacher's Guide)Fahmi AmiNoch keine Bewertungen

- Road Trip ch04 pg2Dokument6 SeitenRoad Trip ch04 pg2Aashish ChoudharyNoch keine Bewertungen

- Hamriyah Free Zone (Hfza)Dokument76 SeitenHamriyah Free Zone (Hfza)Shihabudeen Shihab100% (1)

- As Research Project Q4 Week 7-8Dokument57 SeitenAs Research Project Q4 Week 7-8Ariana FiestaNoch keine Bewertungen

- IV-Year Model Question Paper - 2016-SchemeDokument4 SeitenIV-Year Model Question Paper - 2016-SchemeJeyachithra83% (6)

- Pumpable Shotcrete in LadleDokument9 SeitenPumpable Shotcrete in LadlePartha Pratim Singha RoyNoch keine Bewertungen

- Leon County Sheriff'S Office Daily Booking Report 8-Jun-2021 Page 1 of 4Dokument4 SeitenLeon County Sheriff'S Office Daily Booking Report 8-Jun-2021 Page 1 of 4WCTV Digital Team100% (1)

- Oil Drilling Operation. Pre-DiggingDokument5 SeitenOil Drilling Operation. Pre-DiggingКаролина ЛемешеваNoch keine Bewertungen

- United States Bankruptcy Court District of Colorado Voluntary PetitionDokument64 SeitenUnited States Bankruptcy Court District of Colorado Voluntary Petitionspacecat007Noch keine Bewertungen

- Sponsorship Form 2022Dokument2 SeitenSponsorship Form 2022api-556012725Noch keine Bewertungen