Beruflich Dokumente

Kultur Dokumente

Bin Activators - Cone Valve Dischargers - CMTNC

Hochgeladen von

jmartinezmoOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Bin Activators - Cone Valve Dischargers - CMTNC

Hochgeladen von

jmartinezmoCopyright:

Verfügbare Formate

> Home _______________

> Manufacturers > Equipment

Bin Activator Blenders and Mixers Bulk Bag Systems Dust Collection Feeders & Weigh Systems Mechanical Conveyors Pneumatic Conveying Silos & Tanks > Bolted Silos > Welded Silos >BinActivator Sizing Equipment Tote/IBC Systems

Bin Activator for Material Handling

A standard Bin Activator is hung from a matching flange on the silo. An internal baffle or cone is fixed inside the bin activator and the unit is connected with a high performance rubber sleeve. This allows the bin activator to move freely in an elliptical action. Through the bin activators stationary cone, vibration is imparted vertically, into the material in the silo, thereby consistently promoting material flow. Some of the most common discharge problems in dry material storage are ratholing, bridging, degradation, and segregation. A bin activator solves this by transmitting vibration to the material and allowing mass flow. The Bin Activator that CMT offers has many advantages: * The bin activator Resolves Discharge Problems - Material discharges in a first in/first out basis. The Bin Activator eliminates degradation, segregation, flushing, and bridging, and insures complete discharge. * The bin activator Produces Even Bulk Density - The vibration of the bin activator de-aerates the product and creates an even bulk density. * The bin activator Controlled Product Flow Rate - The product flow rate is controlled controlling the internal annular gap by increasing or decreasing the diameter of the internal cone. * Quality, Experience, and Cost -CMT offers consulting for our low-cost quality bin activators, and we will make sure the bin activators are properly installed.

> Components

_______________

> Literature > Case Histories > Videos > Photo Gallery > Testimonials

_______________

> About CMT > Contact Us > Partners

CMTprovidesafullrangeofbin dischargersincludingstandard eccentricdrivenunits&conevalve units.

Bin activator has No Moving Parts Bin activator promotes Mass Flow

The Soliflo Cone Valve Bin Discharger is bolted directly to the silo, thereby eliminating any potential leak points. The unit works as a bin activator and valve as it completely stops material flow when lowered, providing two functions in one simplistic design: Bin Activator and Shut-Off Valve.

ConeValveBinDischargerin

ConeValveBinDischargerin

ConeValveDischarger

ClosedPosition

OpenPosition

Design An internal pneumatic probe is fitted within the structure of the Cone Valve Discharger. The Cone Volve Discharger has no moving parts. An air actuated Firestone bellow is filled to raise and lower the internal cone, thereby overcoming bridging and consistently promoting material flow.

The Cone Valve Discharger promotes Mass Flow No Moving Parts in our Cone Valve Discharger Bin Activator & Outlet Gate Valve in one The Cone Valve Discharger has No Rubber Sleeve, bolts directly to silo Maintained from bottom with silo full

[Home][Manufacturers][Equipment][Components][Literature][CaseHistories][DataSheets][3Sigma][AboutCMT][ContactUs] 7048463737 [Home][Manufacturers][Equipment][Components][Literature][CaseHistories][3Sigma][AboutCMT][ContactUs]7048463737

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Specifications For Stainless SteelDokument12 SeitenSpecifications For Stainless Steelzyx26100% (2)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Brake Lathe Book 1Dokument47 SeitenBrake Lathe Book 1jmartinezmoNoch keine Bewertungen

- Astm A 276 1 PDFDokument7 SeitenAstm A 276 1 PDFNitinNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Beam Deflection FormulaeDokument2 SeitenBeam Deflection Formulae7575757575100% (6)

- Structural A36 Steel Wide Flange I Beam Section Properties Table Sizes W14 To W25 - Engineers EdgeDokument3 SeitenStructural A36 Steel Wide Flange I Beam Section Properties Table Sizes W14 To W25 - Engineers Edgejmartinezmo100% (1)

- Beam Design Formulas With Shear and MomentDokument20 SeitenBeam Design Formulas With Shear and MomentMuhammad Saqib Abrar100% (8)

- 3 BPI Employee Union-Davao V BPI - DigestDokument1 Seite3 BPI Employee Union-Davao V BPI - DigestRonyr RamosNoch keine Bewertungen

- Variant Configuration Step by Step ConfigDokument18 SeitenVariant Configuration Step by Step Configraghava_83100% (1)

- Torsion of ShaftsDokument8 SeitenTorsion of ShaftsjmartinezmoNoch keine Bewertungen

- Should Always: Exercise 1-1. True or FalseDokument7 SeitenShould Always: Exercise 1-1. True or FalseDeanmark RondinaNoch keine Bewertungen

- Claudius Peters Pneumatic Conveying Brochure en PDFDokument16 SeitenClaudius Peters Pneumatic Conveying Brochure en PDFjmartinezmo100% (1)

- 30972Dokument37 Seiten30972jmartinezmoNoch keine Bewertungen

- MDESIGN Power Screw PDFDokument7 SeitenMDESIGN Power Screw PDFjmartinezmoNoch keine Bewertungen

- Energy in AgricultureDokument20 SeitenEnergy in AgriculturejmartinezmoNoch keine Bewertungen

- Thunderboltex 3: User GuideDokument14 SeitenThunderboltex 3: User GuidejmartinezmoNoch keine Bewertungen

- MD-18 Power Screws PDFDokument4 SeitenMD-18 Power Screws PDFjmartinezmoNoch keine Bewertungen

- Allseals Web LowDokument6 SeitenAllseals Web LowjmartinezmoNoch keine Bewertungen

- Tube Bending2008 PDFDokument2 SeitenTube Bending2008 PDFjmartinezmoNoch keine Bewertungen

- Parker O-Ring Compound Numbering Systems: Polymer CodesDokument11 SeitenParker O-Ring Compound Numbering Systems: Polymer CodesjmartinezmoNoch keine Bewertungen

- Steel St3sp - St3Dokument3 SeitenSteel St3sp - St3jmartinezmoNoch keine Bewertungen

- Peer Bearing - SSUCT205-16 - Motion IndustriesDokument2 SeitenPeer Bearing - SSUCT205-16 - Motion IndustriesjmartinezmoNoch keine Bewertungen

- WEG Roller Table 50040456 Brochure EnglishDokument12 SeitenWEG Roller Table 50040456 Brochure EnglishjmartinezmoNoch keine Bewertungen

- Cadalyst CAD Tips - WWW - CadalystDokument3 SeitenCadalyst CAD Tips - WWW - CadalystjmartinezmoNoch keine Bewertungen

- Classification of Filters, Filter Properties and Typical Examples of Use - KS Klima-ServiceDokument4 SeitenClassification of Filters, Filter Properties and Typical Examples of Use - KS Klima-ServicejmartinezmoNoch keine Bewertungen

- Article - Screw Threads DesignDokument7 SeitenArticle - Screw Threads DesignjdfdfererNoch keine Bewertungen

- Downflo Dust Collectors: Models DFT 2-4 Through 4-128Dokument6 SeitenDownflo Dust Collectors: Models DFT 2-4 Through 4-128jmartinezmoNoch keine Bewertungen

- Bin Activator BookDokument4 SeitenBin Activator BookjmartinezmoNoch keine Bewertungen

- Vertical Stresses Within Granular Materials in Silos: Sankha - Widisinghe@my - Jcu.edu - Au Siva - Sivakugan@jcu - Edu.auDokument6 SeitenVertical Stresses Within Granular Materials in Silos: Sankha - Widisinghe@my - Jcu.edu - Au Siva - Sivakugan@jcu - Edu.aujmartinezmoNoch keine Bewertungen

- 31 1 Pendulum Bucket Elevator 10 20 GBGBDokument1 Seite31 1 Pendulum Bucket Elevator 10 20 GBGBjmartinezmoNoch keine Bewertungen

- Architectural Roofing Metal RyersonDokument2 SeitenArchitectural Roofing Metal RyersonjmartinezmoNoch keine Bewertungen

- AISC Shapes TablesDokument64 SeitenAISC Shapes TablesJose ManuelNoch keine Bewertungen

- Engineering Drawings Lecture Detail Drawings-Book44Dokument28 SeitenEngineering Drawings Lecture Detail Drawings-Book44mlkz_01100% (1)

- Catalog Profile PDFDokument57 SeitenCatalog Profile PDFTănase FlorianNoch keine Bewertungen

- Getting Started With DAX Formulas in Power BI, Power Pivot, and SSASDokument19 SeitenGetting Started With DAX Formulas in Power BI, Power Pivot, and SSASJohn WickNoch keine Bewertungen

- COA (Odoo Egypt)Dokument8 SeitenCOA (Odoo Egypt)menams2010Noch keine Bewertungen

- Offer Letter - Kunal Saxena (Gurgaon)Dokument5 SeitenOffer Letter - Kunal Saxena (Gurgaon)Neelesh PandeyNoch keine Bewertungen

- How To Generate Your First 20,000 Followers On InstagramDokument44 SeitenHow To Generate Your First 20,000 Followers On InstagramAdrian Pratama100% (1)

- AXIS Camera Station Installation and Migration Guide: User ManualDokument7 SeitenAXIS Camera Station Installation and Migration Guide: User ManualCORAL ALONSONoch keine Bewertungen

- Final Year Project A Report Assessment Form (10%)Dokument5 SeitenFinal Year Project A Report Assessment Form (10%)Chong Ru YinNoch keine Bewertungen

- MongoDB vs RDBMS - A ComparisonDokument20 SeitenMongoDB vs RDBMS - A ComparisonShashank GuptaNoch keine Bewertungen

- TVS Sport User Manual BS6Dokument69 SeitenTVS Sport User Manual BS6tonemetoneNoch keine Bewertungen

- Csit 101 Assignment1Dokument3 SeitenCsit 101 Assignment1api-266677293Noch keine Bewertungen

- Rodriguez, Joseph Lorenz Ceit-08-402ADokument7 SeitenRodriguez, Joseph Lorenz Ceit-08-402AJOSEPH LORENZ RODRIGUEZNoch keine Bewertungen

- Common Size Statement: A Technique of Financial Analysis: June 2019Dokument8 SeitenCommon Size Statement: A Technique of Financial Analysis: June 2019safa haddadNoch keine Bewertungen

- Supply AnalysisDokument5 SeitenSupply AnalysisCherie DiazNoch keine Bewertungen

- Coronary artery diseases reviewDokument43 SeitenCoronary artery diseases reviewKeputrian FKUPNoch keine Bewertungen

- Panameterics GF 868 Flare Gas Meter PDFDokument8 SeitenPanameterics GF 868 Flare Gas Meter PDFDaniel DamboNoch keine Bewertungen

- Balanced Modulator and Demodulator ExperimentDokument6 SeitenBalanced Modulator and Demodulator ExperimentShubham SharmaNoch keine Bewertungen

- BUS 301 Final AssesmentDokument15 SeitenBUS 301 Final AssesmentTanzim ShahriarNoch keine Bewertungen

- Engineered Cementitious Composites: Practical ApplicationsDokument26 SeitenEngineered Cementitious Composites: Practical Applicationsmubashir ahmedNoch keine Bewertungen

- MTD Microwave Techniques and Devices TEXTDokument551 SeitenMTD Microwave Techniques and Devices TEXTARAVINDNoch keine Bewertungen

- Fin 464 Chapter-03Dokument18 SeitenFin 464 Chapter-03Shantonu Rahman Shanto 1731521Noch keine Bewertungen

- DX DiagDokument31 SeitenDX DiagJose Trix CamposNoch keine Bewertungen

- Chrysler Corporation: Service Manual Supplement 1998 Grand CherokeeDokument4 SeitenChrysler Corporation: Service Manual Supplement 1998 Grand CherokeeDalton WiseNoch keine Bewertungen

- Makerere University: Office of The Academic RegistrarDokument2 SeitenMakerere University: Office of The Academic RegistrarOPETO ISAACNoch keine Bewertungen

- RAMA - 54201 - 05011381320003 - 0025065101 - 0040225403 - 01 - Front - RefDokument26 SeitenRAMA - 54201 - 05011381320003 - 0025065101 - 0040225403 - 01 - Front - RefMardiana MardianaNoch keine Bewertungen

- FFTW Installation On WindowsDokument6 SeitenFFTW Installation On WindowsDebora SchwarzNoch keine Bewertungen

- Caf 8 Aud Spring 2022Dokument3 SeitenCaf 8 Aud Spring 2022Huma BashirNoch keine Bewertungen

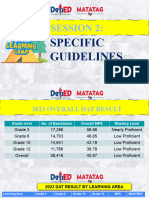

- FINAL Session 3 Specific GuidelinesDokument54 SeitenFINAL Session 3 Specific GuidelinesBovelyn Autida-masingNoch keine Bewertungen

- Request For Information (Rfi) : Luxury Villa at Isola Dana-09 Island - Pearl QatarDokument1 SeiteRequest For Information (Rfi) : Luxury Villa at Isola Dana-09 Island - Pearl QatarRahmat KhanNoch keine Bewertungen