Beruflich Dokumente

Kultur Dokumente

ATEX Operation Manual Rev94 GB2

Hochgeladen von

Angel Eduardo PeñaOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ATEX Operation Manual Rev94 GB2

Hochgeladen von

Angel Eduardo PeñaCopyright:

Verfügbare Formate

Instruction and Operation Manual for ATEX Approved Load Cells

Table of contents

0. Valid for Load Cells 1 . Preamble 2 . Equipment Function

2.1 Details 2.2 Connection of the Standard Version 2.2.1 Examples of suitable circuits with approved safety barriers : 2.3 Connections of the 6-wire Version 2.4 Advice for Interconnections 2.5 Coding of the Load Cells 2.6 Reference notes concerning electrostatics 2.7 Special notes to the relative inductance and capacities of cables within intrinsically safe circuits

2 2 2

2 2 3 4 4 4 4 5

3. Designation

3.1 Standard Label 3.2 Categorie - Designation

5

5 5

4. Commissioning and Installation 5. Usage 6. Maintenance 7. Repair 8. Waste Disposal 9. EC-Declaration of Conformity 10. EC- Type Examination Certificate

6 6 6 6 6 7 8

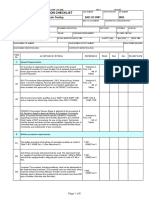

issued

checked

released

Date Signatures

30.06.2004 Greulich

22.09.2010 Kmper

29.09.2010 Dr. Achenbach

Last change: 05.01.2011

Revision: 9.4

Page 1 / 10

Date of 1st issue: 03.06.2002

Instruction and Operation Manual for ATEX Approved Load Cells

0. Valid for Load Cells

BK2, PC1, PC2, PC2H, PC6, PC12, PC22, PC42, PC46, PC60, PCB, SB2, SB4, SB5, SB6, SB8, SB14, SLB, ZLB, RC1, RC2, RC3, UB1, UB5, UB6, ULB

1 . Preamble

This manual covers only the Ex relevant aspects.

2 . Equipment Function

Flintec load cells are designed to be used in various kinds of industrial scales and meet the most stringent accuracy requirements. Certifications have been obtained from Weights & Measures Authorities worldwide. These load cells are available with different maximum capacities and include accuracy classifications according to OIML R 60 and / or NTEP. They offer stainless steel or aluminium construction sealed by welding or improved potting. This makes them suitable for use in tough industrial environments they are designed to withstand shock and fatigue loading. The load cells can be used in all hazardous areas. The basic structure is always the same. All standard equipment is provided with a 4-wire shielded conductor cable; equipment with the coding extension 6w is provided with a 6-wire shielded conductor cable. (See Chapter 2.5 Coding of Load Cells)

2.1 Details

The following table shows the relationship between maximum total power Pi and maximum ambient temperature. Temperature class / coding T6 (gas) T5 (gas) T100C (dust) Ui = 30 V, Pi = 4 W -40C Ta 45C -40C Ta 60C -40C Ta 60C

2.2 Connection of the Standard Version

Supply circuit: Signal circuit: Shield: green (+) and black (-) white (+) and red (-) yellow and / or metallic

The intrinsically safe circuit including the load cells must be built up with approved safety barriers or isolation amplifiers, matching the connected weighing indicator.

Last change: 05.01.2011

Revision: 9.4

Page 2 / 10

Date of 1st issue: 03.06.2002

Instruction and Operation Manual for ATEX Approved Load Cells

2.2.1 Examples of suitable circuits with approved safety barriers : Warning: Example: The specialist who installs the equipment must take responsibility for proper operation in combination with various measuring equipment . With safety barriers for single-ended supply

Hazardous area

+ Ex

Safe area

- sig L/C 1 - Ex

safety barriers Weight indicator

1 + Ex 2 - sig 8 +5V Excitation 7 0V

+ sig

Z710

L/C 2 - Ex

+

Sense

Z961.H

4 5

+ sig 1 + Ex 4 - sig L/C 3 - Ex Lapp Li2YCY PiMF 3 x 2 x 1,0 CL = 6 (3) x 14,45 nF LL = 1 x 68 nH L = 170 m 8

+

Signal

Z961.H

5

0V PA PA

+ sig

+ Ex

E II (1) GD [EEx ia] IIC (-20C<Ta<+60C)

BAS 01ATEX7005 P+F Z710 Uo = 9,56 V Io = 195 mA Po = 0,47 W Rmin = 49 Ohm CoIIC = 3 F LoIIC = 0,86 mH

- sig L/C 4 - Ex

E II (1) GD [EEx ia] IIC (-20C<Ta<+60C) BAS 01ATEX7005 P+F Z961.H Uo = 8,7 V Io = 25 mA Po = 0,05 W Rmin = 352,8 Ohm CoIIC = 4,9 F LoIIC = 57 mH

+ sig

cable capacitance (total): CLg = 127,5 nF cable inductance (total) CLg = 80 nH

EX- junction box KPEX-4, Ex ia IIC T6 (accessory)

Please note the max. allowable cable lengths

Wiring diagrams of different circuit examples are available on request.

Last change: 05.01.2011

Revision: 9.4

Page 3 / 10

Date of 1st issue: 03.06.2002

Instruction and Operation Manual for ATEX Approved Load Cells

2.3 Connections of the 6-wire Version

Supply circuit: Signal circuit: Sense circuit: Shield: green (+) and black (-) white (+) and red (-) blue (+) and brown (-) yellow and / or metallic

The intrinsically safe circuit including the load cells must be built up with approved safety barriers or isolation amplifiers, matching the connected weighing indicator.

2.4 Advice for Interconnections

a) Follow and respect the formation-regulations of the application-country, e.g. in Germany follow the regulations EN 60079-14 and EN 61241-14. b) It is ONLY permitted to use approved safety barriers or isolation amplifiers for explosive-areas. In Europe, it is a requirement to have an EC-Type Examination Certificate from a nominated certifying body for the Zones 0 / 1 / 20 / 21. c) The rated power, Po ,of all excitation devices must be equal to or less than the power, Pi, of one load cell. d) The excitation voltage Uo must be equal to or less than the voltage Ui of one load cell. e) The current, Io ,of all excitation devices must be equal to or less than the current, Ii ,of one load cell. f) To ensure a potential equalisation with -6w versions, a ground connection between the load cell housing and the safety barriers ground connector is required. In these installations, the shield of the connection cable is connected to ground potential at both ends. g) On usual deliveries up to 10 meters, the inductance and capacitance per unit length of the connection cables is negligible.

2.5 Coding of the Load Cells

The load cells have to be marked according to the following scheme: AAA-BBB-CCC-DDEF-ZZ, e.g. SB8-100kg-C3-6wsc-12 AAA BBB CCC DD E F ZZ = = = = = = = Load cell type Load cell maximum capacity Accuracy class without marking = 4-wire; 6w = 6-wire without marking = screen of cable not connected to load cell body, s = screen of cable connected to load cell body without marking = not coated, c = coated Cable length in meter (plain text) if the load cell cable at delivery is longer than 10 m

2.6 Reference notes concerning electrostatics

The load cells can be covered with a non-conductive protective coating as corrosion prevention. In the type designation code the load cells are marked as "c" in the last position (F). The free projected surface must not be larger than indicated in the following table after mounting the load cells (types ***-*** ***-** *c) and propagating brush discharges must be avoided. Max. free projected surface IIA Zone 0 Zone 1 / 2 Zone 20 Zone 21 / 22 50 cm 100 cm IIB 25 cm 100 cm No limitation of size, but exclusion of propagating brush discharges IIC 4 cm 20 cm

Used in:

Last change: 05.01.2011

Revision: 9.4

Page 4 / 10

Date of 1st issue: 03.06.2002

Instruction and Operation Manual for ATEX Approved Load Cells

If the limiting values of the at maximum tolerable free projected surface cannot be maintained, then mounting can be done by the user (if propagating brush discharges can be eliminated) and he can point to this risk on an ESD- warning label (Clean wet only !) on site and in his explosion protection document. In Zone 2 the installation contractor may permit larger free surfaces on his own responsibility, in accordance with the EX regulations.

2.7 Special notes to the relative inductance and capacities of cables within intrinsically safe circuits

Up to a cable length of 10 meters, the inductance and capacitance of the load cell cables are negligible. The cable lenght is shown as ZZ within the type code. In case the load cell cable length exceeds 10 meter, the inductance and capacitance have to be considered. Following default values can be used (according article 12.2.2.2 of EN 60079-14) : CL = 200 pF/m LL = 1 H/m

3. Designation

All Flintec load cells follow the same electrical design and meet the requirements for category1 equipment. The operating company must ensure that already used load cells must not used in other zones except in the same category. Therefore the label has a corresponding checkbox The ATEX-label is attached to the connection cable close to the load cell body. All allowed designations for this load cell are prepared. The operating company or the specialist who installs the equipment must fill in a checkbox with the valid zone by use of a permanent waterproof marker pen or hole punch at site. Without any entry on the label, the load cell is limited for use in zone 2 or 22!

3.1 Standard Label

3.2 Categorie - Designation

approx. 54 x 44 mm

Last change: 05.01.2011

Revision: 9.4

Page 5 / 10

Date of 1st issue: 03.06.2002

Instruction and Operation Manual for ATEX Approved Load Cells

4. Commissioning and Installation

a) This equipment (load cells) can be used either in zone 0, 1 or 2, or zone 20, 21 or 22 in explosion groups IIA, IIB, IIC, IIIA, IIIB, or IIIC. b) The allowed ambient temperature range is from 40C to 45C/60C. c) This equipment complies to protection class > IP67 / EN 60529. d) This equipment must be electro statically grounded. e) The load cell must not be used if it is defective or shows any visible damage. f) Load cells must not be re-used in an intrinsically-safe circuit if they have already been operated in a circuit in zone 2 or 22.

5. Usage

WARNING: Misuse will cause the loss of warranty and manufacturers responsibility. The load cells are only allowed for professional applications in accordance with the load cell data sheet and Flintec application parts. a) If the load cells are not powered from an intrinsically-safe circuit the connection cables must either be lead out of the hazardous area to terminate them or terminated in suitable junction boxes. b) If used in hazardous dust environment, the dust layer on the load cell body must not exceed 5 mm in thickness. c) The load cell types PC22, PC42, PC46, PC60 and ZLB have an aluminium housing. If used in zone 0, the general precautions for the application of light metals must be followed, e.g. protection against impact energy. d) The load cells type BK2, PC1, PC22, PC42, PC46, PC60, SB5, SLB, UB5, ULB and ZLB have a plastic 2 surface > 4 cm . If used in zone 0 precautions against electrostatic charging must be implemented. e) In zone 0 and in the apparatus group IIC the connecting cables of the load cells must be laid protectedly against static charges

6. Maintenance

Maintenance interventions on the load cells have to be carried out by Flintec personnel only.

7. Repair

This equipment is certified for use in hazardous locations, therefore no modifications are allowed. Repairs must only be performed by personnel specifically trained for repairs of this equipment.

8. Waste Disposal

The waste disposal of package and shipped parts must be done in accordance with the regulations of the country in which the equipment is installed.

Last change: 05.01.2011

Revision: 9.4

Page 6 / 10

Date of 1st issue: 03.06.2002

Instruction and Operation Manual for ATEX Approved Load Cells

9. EC-Declaration of Conformity

EC-DECLARATION OF CONFORMITY

EC-Declaration of conformity of a sub-assembly with the ATEX-Directive 94/9/EC (ATEX95), Amendment X.B The manufacturer Flintec GmbH, Bemannsbruch 9, DE74909 Meckesheim hereby declares that the sub-assembly described below Description: Load cells of types PC1, PC2, PC2H PC6, PC12, PC22, PC42, PC46, PC60, PCB, SB2, SB4, SB5, SB6, SB8, SB14, SLB, BK2, ZLB, RC1, RC2, RC3, UB1, UB5, UB6, ULB, BK2 Serial number see shipping documents Marking: II1G Ex ia IIC T6/T5 Ga or II1D Ex ia IIIC IP67 T100C Da or 2G Ex ia IIC T6/T5 Gb or II2D Ex ia IIIC IP67 T100C Db or II 3G Ex nA IIC T6/T5 Gc or II3G Ex ic IIC T6/T5 Gc or II 3D Ex tD IIIC IP67 T100C Dc complies with the provisions of the following harmonized standards in the version, valid at signature date: EN 60079-0 EN 60079-11 EN 60079-15 EN 60079-26 EN 61241-0 EN 61241-11 Explosive atmospheres - Part 0: Equipment - General requirements Explosive atmospheres - Part 11: Equipment protection by intrinsic safety i Electrical apparatus for explosive gas atmospheres -Part 15: Construction, test and marking of type of protection "n" electrical apparatus Explosive atmospheres - Part 26: Equipment with equipment protection level (EPL) Ga Electrical apparatus for use in the presence of combustible dust - Part 0: General requirements Electrical apparatus for use in the presence of combustible dust. Part 11: Protection by intrinsic safety iD

Also complies with the following European and National Standards and technical provisions in the version, valid at signature date: Technical rules for the operational safety (TBRS) 2153 Avoidance of ignition hazards as consequence of electrostatic charging. The sub-assemblies of category 1 and 2 complies with the model, which has obtained an "EC" type certificate, number BVS 09ATEX E 086X issued by the notified body 0158 DEKRA EXAM, Dinnendahlstrasse 9, DE 44809 Bochum. Meckesheim, July 15 2010

th

i.V. Gisbert Greulich

Project Manager

Last change: 05.01.2011

Revision: 9.4

Page 7 / 10

Date of 1st issue: 03.06.2002

Instruction and Operation Manual for ATEX Approved Load Cells

10. EC- Type Examination Certificate

Last change: 05.01.2011

Revision: 9.4

Page 8 / 10

Date of 1st issue: 03.06.2002

Instruction and Operation Manual for ATEX Approved Load Cells

Last change: 05.01.2011

Revision: 9.4

Page 9 / 10

Date of 1st issue: 03.06.2002

Instruction and Operation Manual for ATEX Approved Load Cells

Last change: 05.01.2011

Revision: 9.4

Page 10 / 10

Date of 1st issue: 03.06.2002

Das könnte Ihnen auch gefallen

- Hochiki Intrinsically Safe Smoke and Heat Detector Installation GuideDokument8 SeitenHochiki Intrinsically Safe Smoke and Heat Detector Installation GuidetetioNoch keine Bewertungen

- How To Calculate An Intrinsically Safe Loop ApprovalDokument7 SeitenHow To Calculate An Intrinsically Safe Loop ApprovalAlexander Ariza Nadjar100% (1)

- NG Uk Ettg 28Dokument4 SeitenNG Uk Ettg 28Kyaw Kyaw AungNoch keine Bewertungen

- Specification For Power Control & Earthing Cables PDFDokument17 SeitenSpecification For Power Control & Earthing Cables PDFg1kumar04100% (1)

- 16310-Dry-Type Transformer 13.8 KVDokument5 Seiten16310-Dry-Type Transformer 13.8 KVAli SaifNoch keine Bewertungen

- CMP IECEx ATEX 01Dokument10 SeitenCMP IECEx ATEX 01rocket-vtNoch keine Bewertungen

- IECEx ULD 18.0013XDokument5 SeitenIECEx ULD 18.0013XRyan Mesina De GuzmanNoch keine Bewertungen

- BBP E Chapter 09 15Dokument6 SeitenBBP E Chapter 09 15kuochuanchuNoch keine Bewertungen

- 17th Ed 2382 Q Paper 2Dokument7 Seiten17th Ed 2382 Q Paper 2cfwong12345Noch keine Bewertungen

- ATEX Operation Manual Rev95 GBDokument12 SeitenATEX Operation Manual Rev95 GBhdq64590Noch keine Bewertungen

- Ex Saf D5000 Ism0156 enDokument17 SeitenEx Saf D5000 Ism0156 enAmin ThabetNoch keine Bewertungen

- IS-7098 PT - 1.Dokument17 SeitenIS-7098 PT - 1.Rishi PalNoch keine Bewertungen

- ABB RCCB F 804Dokument12 SeitenABB RCCB F 804catalinccNoch keine Bewertungen

- IEC PublishesDokument3 SeitenIEC Publishesashumishra007Noch keine Bewertungen

- CXD-Q Amplifiers: User ManualDokument17 SeitenCXD-Q Amplifiers: User Manualtecniloco80Noch keine Bewertungen

- ATEX Safety Instructions: For Liquid Density MeterDokument16 SeitenATEX Safety Instructions: For Liquid Density MeterCristian MartinezNoch keine Bewertungen

- Comp EX 1Dokument120 SeitenComp EX 1Vignesh Madhavan100% (2)

- Surge Protection ComponentsDokument7 SeitenSurge Protection Componentswafikmh4Noch keine Bewertungen

- Specification For Surge/Transient Protection: Part 1 - General 1.1 Related DocumentsDokument8 SeitenSpecification For Surge/Transient Protection: Part 1 - General 1.1 Related Documentsmarissa LovaNoch keine Bewertungen

- 16320Dokument9 Seiten16320uddinnadeemNoch keine Bewertungen

- CML 18ATEX3372X BV Iss. 1Dokument5 SeitenCML 18ATEX3372X BV Iss. 1Anderson SilvaNoch keine Bewertungen

- Siemens - Ex-AI 4xTC 2RTD 2-3-4wireDokument3 SeitenSiemens - Ex-AI 4xTC 2RTD 2-3-4wireHerbert RitzerNoch keine Bewertungen

- 18-30 KV Al Rhz1-OlDokument5 Seiten18-30 KV Al Rhz1-OlAna Cristina CedeñoNoch keine Bewertungen

- ALA5 2-Wire 4-20ma ATEX Load Cell AmplifierDokument26 SeitenALA5 2-Wire 4-20ma ATEX Load Cell AmplifierarefNoch keine Bewertungen

- Multicont Transmisor NivelDokument58 SeitenMulticont Transmisor NivelWalter Medina LopezNoch keine Bewertungen

- Is 7098 Part I 1998Dokument17 SeitenIs 7098 Part I 1998Sanjeev DhariwalNoch keine Bewertungen

- Wika Il-10Dokument4 SeitenWika Il-10José MelâneoNoch keine Bewertungen

- Vegawell 51 52 72Dokument8 SeitenVegawell 51 52 72Germán Walter RufanachtNoch keine Bewertungen

- Remarks On Diff BW TI - SPC - PSI - PROTCT - 6071 & 6072 DraftDokument6 SeitenRemarks On Diff BW TI - SPC - PSI - PROTCT - 6071 & 6072 DraftRAJADEVANNoch keine Bewertungen

- CT720g S774AAR5S2NCDokument45 SeitenCT720g S774AAR5S2NCAnonymous CJnGHNNoch keine Bewertungen

- Enclosures TechnicalDokument16 SeitenEnclosures TechnicalAnonymous rYZyQQot55Noch keine Bewertungen

- C264 en o C80 PDFDokument828 SeitenC264 en o C80 PDFAnonymous g0InJ4BLBNoch keine Bewertungen

- 27 - 400 - 220 - 132kV - DB - Tandem Isolator R3 Jan 12 PDFDokument30 Seiten27 - 400 - 220 - 132kV - DB - Tandem Isolator R3 Jan 12 PDFAshok KumarNoch keine Bewertungen

- Cable Tray InstallationDokument10 SeitenCable Tray Installationalrwin_b2yNoch keine Bewertungen

- M26 Anti FoulingDokument33 SeitenM26 Anti FoulingVinay Kumar NeelamNoch keine Bewertungen

- Vacon NX Filters User Manual DPD01571A UKDokument70 SeitenVacon NX Filters User Manual DPD01571A UKTanuTiganuNoch keine Bewertungen

- Technical Service Pits Specification KEODokument18 SeitenTechnical Service Pits Specification KEOVijay BarreyNoch keine Bewertungen

- 48 TMSS 04 R0Dokument0 Seiten48 TMSS 04 R0renjithas2005100% (1)

- Alstom KBCH 120 PDFDokument199 SeitenAlstom KBCH 120 PDFnadalllabeedNoch keine Bewertungen

- CM Cc9000 Eng Int C Comp Catalogue - 6Dokument36 SeitenCM Cc9000 Eng Int C Comp Catalogue - 6Amauri SilvaNoch keine Bewertungen

- Manual Servomex Xendos 1800Dokument20 SeitenManual Servomex Xendos 1800Josh MoralesNoch keine Bewertungen

- NI-9213 - 16ch Thermocouple - 374916aDokument38 SeitenNI-9213 - 16ch Thermocouple - 374916aEduardo ChinenNoch keine Bewertungen

- SpecificationsDokument5 SeitenSpecificationsvenkat0236Noch keine Bewertungen

- Explosion Protection Wall Chart BASEEFADokument1 SeiteExplosion Protection Wall Chart BASEEFAweby98Noch keine Bewertungen

- Arial Bunch ConductorDokument10 SeitenArial Bunch Conductorbbakari2000Noch keine Bewertungen

- Package SubstationDokument9 SeitenPackage SubstationuddinnadeemNoch keine Bewertungen

- C264 en o C80Dokument828 SeitenC264 en o C80Natarajan SubramanyanNoch keine Bewertungen

- 1.9.6 Cables Specifications (Type Designation-HT)Dokument2 Seiten1.9.6 Cables Specifications (Type Designation-HT)anurag_pugaliaaNoch keine Bewertungen

- 50" PDP Service Manual Model Panel:: GTW-P50M403Dokument43 Seiten50" PDP Service Manual Model Panel:: GTW-P50M403tobycNoch keine Bewertungen

- User Manual Type KITZ 101, 102 Interface Unit: Handling of Electronic EquipmentDokument25 SeitenUser Manual Type KITZ 101, 102 Interface Unit: Handling of Electronic EquipmentakmezimNoch keine Bewertungen

- B4304Dokument9 SeitenB4304jamesearl_cubillasNoch keine Bewertungen

- D2P2 IECExConf2014 Thurnherr PDFDokument88 SeitenD2P2 IECExConf2014 Thurnherr PDFMakiberNoch keine Bewertungen

- 3Dokument33 Seiten3toogooodNoch keine Bewertungen

- Abb Make Protection Coupler Type Nsd50Dokument11 SeitenAbb Make Protection Coupler Type Nsd50NaveenNoch keine Bewertungen

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsVon Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsBewertung: 4 von 5 Sternen4/5 (1)

- Marine Electrical Practice: Marine Engineering SeriesVon EverandMarine Electrical Practice: Marine Engineering SeriesBewertung: 4 von 5 Sternen4/5 (8)

- The IEE Wiring Regulations Explained and IllustratedVon EverandThe IEE Wiring Regulations Explained and IllustratedBewertung: 4 von 5 Sternen4/5 (14)

- CUB5 Product ManualDokument16 SeitenCUB5 Product ManualHugo DamnNoch keine Bewertungen

- mp5w - Manual - English AUTONICS MP5W PDFDokument4 Seitenmp5w - Manual - English AUTONICS MP5W PDFAngel Eduardo PeñaNoch keine Bewertungen

- Copper For Busbars All SectionsDokument108 SeitenCopper For Busbars All Sectionssusanto_andri_2005Noch keine Bewertungen

- Load cell certificate for BK2 series transducers up to 2,000 kgDokument2 SeitenLoad cell certificate for BK2 series transducers up to 2,000 kgAngel Eduardo PeñaNoch keine Bewertungen

- 2002 Mazda Protege Owners ManualDokument270 Seiten2002 Mazda Protege Owners ManualJohn Kent100% (1)

- ARAMCO UT Inspection Checklist - SAIC-UT-2001Dokument6 SeitenARAMCO UT Inspection Checklist - SAIC-UT-2001Anonymous hBBam1n100% (1)

- HSBC Placement Paper Aptitude ReasoningDokument6 SeitenHSBC Placement Paper Aptitude ReasoningRatnadeep Mitra67% (3)

- Hammer MillDokument4 SeitenHammer MillAnil Kumar KnNoch keine Bewertungen

- Enable Android Auto on Renault Zoe Rlink 1 SystemDokument14 SeitenEnable Android Auto on Renault Zoe Rlink 1 SystemPablo PintoNoch keine Bewertungen

- Ciscenje Hadnjaka HyundaiDokument4 SeitenCiscenje Hadnjaka HyundaiAjdin Herc AhmetovicNoch keine Bewertungen

- Zroute Training Lab v1 0Dokument23 SeitenZroute Training Lab v1 0ChetanNoch keine Bewertungen

- CS Form No. 212 Attachment - Work Experience SheetDokument2 SeitenCS Form No. 212 Attachment - Work Experience Sheetdominic kokoyNoch keine Bewertungen

- Monorail Beam - Topside Platform - OffshoreDokument6 SeitenMonorail Beam - Topside Platform - OffshoreBolarinwaNoch keine Bewertungen

- 02 CNC Lab Manual NIT APDokument3 Seiten02 CNC Lab Manual NIT APDevesh RehanNoch keine Bewertungen

- Documents - MX DPV Vertical Multistage Pumps 60 HZ Technical Data DP PumpsDokument80 SeitenDocuments - MX DPV Vertical Multistage Pumps 60 HZ Technical Data DP PumpsAnonymous ItzBhUGoi100% (1)

- Manual VISSIM 540 e PDFDokument763 SeitenManual VISSIM 540 e PDFEze KA100% (1)

- Market of Turboshaft EnginesDokument22 SeitenMarket of Turboshaft EnginesThomas MouraNoch keine Bewertungen

- FAMILY TIES Lesson 9 Writing 2Dokument2 SeitenFAMILY TIES Lesson 9 Writing 2Atikah AmaranNoch keine Bewertungen

- Bobcat 853 Operator ManualDokument20 SeitenBobcat 853 Operator ManualAbdul KhaliqNoch keine Bewertungen

- Wind Load AnalysisDokument4 SeitenWind Load AnalysisNiraj ShindeNoch keine Bewertungen

- DTFT Analysis in MATLABDokument7 SeitenDTFT Analysis in MATLABRUTUJA MADHURENoch keine Bewertungen

- Clean BotDokument26 SeitenClean BotCrystal FrostNoch keine Bewertungen

- Asme-Bpvc Sec IV Int Vol 57Dokument6 SeitenAsme-Bpvc Sec IV Int Vol 57mostafa aliNoch keine Bewertungen

- CE132P - Det IndetDokument5 SeitenCE132P - Det IndetJanssen AlejoNoch keine Bewertungen

- IaaS Product Line Architecture Fabric Architecture GuideDokument112 SeitenIaaS Product Line Architecture Fabric Architecture GuideChalks Dreaner Alvino VelaNoch keine Bewertungen

- Tone Totke Aur Upay Pitradosh UpayDokument156 SeitenTone Totke Aur Upay Pitradosh Upayajay bhatnagarNoch keine Bewertungen

- Acceptance Criteria Boiler (API 573)Dokument1 SeiteAcceptance Criteria Boiler (API 573)Nur Achmad BusairiNoch keine Bewertungen

- Tenor Ax Voip Multipath/Gateway Switch: Product GuideDokument131 SeitenTenor Ax Voip Multipath/Gateway Switch: Product GuideEdgar A CanizalezNoch keine Bewertungen

- User Manual Eg1150hDokument38 SeitenUser Manual Eg1150hprulufreNoch keine Bewertungen

- MR418-FEM-Top Slewing Tower Cranes Imperial PDFDokument8 SeitenMR418-FEM-Top Slewing Tower Cranes Imperial PDFCompass equipmentNoch keine Bewertungen

- GITAM University Industrial Training ReportDokument6 SeitenGITAM University Industrial Training ReportAkash RanjanNoch keine Bewertungen

- Yodlee CrossSell Case StudyDokument4 SeitenYodlee CrossSell Case StudylocalonNoch keine Bewertungen

- Case Study Outburst & Gas ManagementDokument11 SeitenCase Study Outburst & Gas ManagementAnshuman Das100% (1)

- Implement state machine diagram and develop activity diagram for pharmaceutical order management systemDokument1 SeiteImplement state machine diagram and develop activity diagram for pharmaceutical order management systemDaigree NadiaNoch keine Bewertungen