Beruflich Dokumente

Kultur Dokumente

Coffee Growing Condition

Hochgeladen von

Sunil BharadwajCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Coffee Growing Condition

Hochgeladen von

Sunil BharadwajCopyright:

Verfügbare Formate

Coffee growing condition India cultivates all of its coffee under a well-defined two-tier mixed shade canopy, comprising

evergreen leguminous trees. Nearly 50 different types of shade trees are found in coffee plantations. Shade trees prevent soil erosion on a sloping terrain; they enrich the soil by recycling nutrients from deeper layers, protect the coffee plant from seasonal fluctuations in temperature, and play host to diverse flora and fauna.

Coffee plantations in India are essential spice worlds too: a wide variety of spices and fruit crops like pepper, cardamom, vanilla, orange and banana grow alongside coffee plants. Indias coffee growing regions have diverse climatic conditions, which are well suited for cultivation of different varieties of coffee. Some regions with high elevations are ideally suited for growing Arabicas of mild quality while those with warm humid conditions are best suited for Robustas. Important Varieties of coffee plants Arabica Kents Selection795,5b,6,10,5,4 Cauvery Selection9 Robusta

peridenia selection274 cxr

Regional specifications in terms of Altitude, Rainfall etc. State Place Elevatio n Rainfal l in MM Main coffee Total area under coffee in HA Arabic a karnataka Chikmaglure 7001200m MSL Bababudangr i manjarabad 10001500 9001100 Coorg 7501100 Tamil nadu Anamalais 10001400 Nilgiris 9001400 17502200 10002500 10002500 25003000 16002600 Arabica Robust a Pulneys 6002000 Sheveroys 9001500 Kerala Wayanad 600-900 10001600 8001500 11001200 Travancore 4001600 Andhra Pradesh Brahmaputr a Brahmaputra Araku valley 9001100 8001200 20004000 10001200 15002000 Arabica 5000 300 Arabica 20000 robusta robusta 6700 0 1300 0 3100 9000 54000 Arabica 5000 3000 Arabica 14000 7500 3600 4000 1400 2800 Arabica robusta Arabica robusta Arabica 2500 26000 5600 0 1500 24000 69000 31700 9400 21000 9500 10004500 Arabica Robust a Arabica 15000 10500 37000 Robust a 2300 0 Average production in MT Arabic a 29000 Robust a 30000

Types of coffee

Arabica (Coffea Arabica) This is a glossy leafed shrub or small tree. The leaves are relatively small and the flowers fragrant and white. Arabica coffee usually receives a premium for its superior flavor and aroma. Arabica is more suited to higher cooler climates e.g. 600-2000m above sea level and 15-20C.

Robusta (Coffeacanephora) There are many different Robusta varieties. In general, they can thrive in hotter lowland areas eg below 900m above sea level and over 20C. Robusta coffee is preferred for instant coffee production due to higher soluble solid extraction. Liberica(Coffealiberica) This is a larger tree with large leaves and berries. It can tolerate hot and wet conditions. The coffee produced is bitter. This is preferred in Malaysia and West Asia. Cultivation Coffee plants bear fruit in lines along their branches. The fruit turns cherry-red when it is time to be harvested. In here lies the contradiction since natural Arabica 'typica' will fall off the plant when it is mature. Since the Arabica 'typica' coffee bean matures differently per tree and part of the tree this would normal mean harvesting by hand is manageable. This has given rise to the most extra ordinary type of coffee bean the kopi luwak which originally referenced the animal who enjoyed the fruit, and passed the seed after enjoying the fruit. The animal is the Asian Palm Civet which originally discovered this fruit when man planted the plants in Java and Sumatra. The process is quite similar to a wet process (discussed below), although there are some who believe it a special tasting coffee. We only source the finest coffee, this means that the trees are allowed to mature naturally, and are in some cases grown inside a rain forest at least 15 meters apart so that the natural habitat is not affected, but rather compliments the growth of the tree. A pure coffee tree that

is planted to match Arabica 'typica's specific requirements produces high quality coffees, and this is the type of coffee Quaffee sources Note: There are about 40 major species within the coffeegenus and with the Arabica 'typica' fruit maturing over a 9 month period Harvesting

By definition, 'processing' does not involve harvesting. However, one cannot produce a good product from badly harvested materials. Correct harvesting techniques could be said to be the most important factor in the production of a high quality final product. Correct harvesting is essential. A good coffee cannot be made from poorly harvested coffee cherries. Immature harvesting: This is the most serious problem with coffee harvesting. Under-ripe coffee cherries are very difficult to process and a low quality product is produced. One of the main causes of immature harvesting is the fear of theft. If the farmer picks it in an immature state, it prevents the thief stealing it. Over-ripe coffee: With over-ripe coffee there is a possibility that the cherry will start fermenting which causes deterioration in flavor. Correct harvesting: The coffee cherries should be picked when they are bright red all over. At this stage, the bean can be squeezed out from the pulp by applying light pressure between finger and thumb.

De-pulping After the ripe cherries have been harvested, the next task is to get at the seeds, or coffee beans, inside. To separate the beans from their cherries, a total of four layers must be removed: the tough, shiny outer skin; the sticky, mucilaginous pulp of the fruit; a stiff parchment casing; and the thin, delicate "silver skin" that clings to each bean. There are two popular methods used to isolate the beans: the washed or wet process and the dry process. The method used depends largely on the availability of fresh water and is one of the most important determinants of coffee flavor.

Dry

This is the oldest method of separating the fruit from the treasured coffee seed or

process bean. After the fruit is picked using a rake it is spread out in the sun to dry. The fruits are regularly raked making sure the fruit at the bottom is brought to the top. Drying takes from 10 days to 3 weeks. The commercial dry process uses heaters and mechanical driers. Once the husk is dried it is hard and shriveled it is removed by hand (or mechanically for commercial farms). Our most popular dry processed coffee is Harrar, the original Mocha coffee. Wet Wet processed coffee is divided into two types the classic process ferment and

process wash, and a modern aqua pulping or mechanical demucilaging. Most of the coffees we source use the classic method. Essentially the fruit is soaked so that layer after layer of fruit is removed gingerly. Starting with the outer skin being pulped, then the sticky fruit is removed by the natural enzymes and bacteria (fermentation) There are many opinions about which process produces the best coffee (we have not included the digestion track coffee here), but dry processing adds more complexity and fruitiness. While wet processed coffees tend to be brighter. Note that if the processing is not carefully done it can taint the taste of the coffee especially for dry processed coffees Packing, Warehousing & Transport Pure green bean coffees can be packed in normal Hessian sacks. Once the green coffee is packed they are normally warehoused. Where the coffee is warehoused is important. Coffee warehouse near other crop will absorb that crops taste, and coffee warehoused near the sea, like say at a dock can become musky and fungus can affect the green bean. It is best if coffee is warehouse close to the source it comes from, as that affected the coffee the least.

Process taken in curing

1. BIN (supply of raw material) 2. Then the raw materialin conveyed through elevator to precleanerwhich removes sticks , leaves , forignmaterilas and dusts Then DESTONER which removes stones 3. Supplies material through elevator tohulling where it remove outer layer (husk)from beans then it goes to polisher. 4. supplies material through elevator3 to WINNVOR which separates clean coffee and unpeeled BY gravity it clears good coffee 5. It supplies materials to GRADER and it separates the coffee beans according to their bean size & density (A,B,C,C+,MN,AA,PB1,PB2,BITS) 6. Then the garbling will takescare of defective beans i.e. insect damaged beans ,pulper damaged ,stinkers, pales, malformed beans etc. 7. Then storage and packing according to the needs.. Coffee Beans Classification: Compare with Coffee Beans by Size Many countries will classify and compare coffee beans by using a screen size sorting system. The theory behind this method of coffee bean classification is that coffees of the highest altitudes are more dense and larger in size than at the other altitudes. It is also known that coffees of higher altitudes have the best flavor .Therefore; there is a correlation between coffee bean size, density, and quality. However, this correlation has numerous exceptions and

size classification should only be used to verify that the coffee lot is uniform in size which helps ensure a uniform roast. The different coffee growing regions have their own preferred terminology, but the best indicator of size is to know the screen size. The screen size is usually reported as 17/18, 15/16, 13/14, etc. This means 17/64 of an inch, 18/64 of an inch, etc. 1/64 inch 20 19.5 19 18.5 18 17 16 15 14 13 12 11 10 9 8 8 7.75 7.5 7.25 7 6.75 6.5 6 5.5 5.25 5 4.5 Shells 4 3.5 3 PB Medium Small Large A Very Large AA mm Classification Africa and India

B C

Roasting Coffee Beans The first stage is endothermic. The green beans are slowly dried to become a yellow color and the beans begin to smell like toast or popcorn. The second step, often called the first crack, occurs at approximately 205 C (400 F) in which the bean doubles in size, becomes a light brown color, and experiences a weight loss of approximately 5%. The corresponding Agtron number for this color is between 95-90

In the next step the temperature rises from 205 C to approximately 220 C, the color changes from light brown to medium brown (Agtron # 60-50), and a weight loss of approximately 13% occurs (Davids, 68-69). The resulting chemical process is called pyrolysis and is characterized by a change in the chemical composition of the bean as well as a release of CO2. The second step is followed by a short endothermic period which is followed by another exothermic step called the second crack. This second pyrolysis occurs between 225-230C, and the roast color is defined as medium-dark brown (Agtron #50-45) (Davids, 68-69). The second pop is much quicker sounding and the beans take on an oily sheen. Coffee blending What do you get when you take two or more types of coffee beans and put them together? A coffee blend! By combining different types of beans as well as adding flavors, a coffee professional can give coffee a more complex or balanced taste.

Coffee beans, whether Arabica or Robusta, can have very different tastes if they are from different regions. Some beans may have a good level of acidity but lack aroma, body or color. A blend may be made of up of two or ten different types of beans in varying quantities in order to get a good balanced blend. Roasting is also part of blending, as beans can be heavily roasted to have a strong flavor or lightly roasted for a milder taste. Type of coffee powder Pure coffee Pure Blended coffee 65 % Coffee chicory blend 55 % 45 % 30% 45 % 100 % %of Arabica %of Robusta %of chicory

Based on the taste profile requirements of each state coffee day will roast and send it to each destinations. I.e.Tamilnadu Karnataka Andrapradesh : 100% pure coffee and they Buy chicory separately : : Coffee chicory Blend with 20 % Robusta and 20 % chicory 65% Robusta with 35 % Arabica and 40 % chicory .so each

State is accustomed to one taste from their childhood and they feel its a good coffee. Packaging Roasted Coffee Packaging Roasted coffee requires protection against oxygen and moisture. We recommend using high barrier foil with a one-way degassing valve for longer term freshness or paper tin-ties for retail take away coffee. Heat sealer: Most bags will need to be sealed to protect against oxygen and make it tamper evident. For more information on heat sealers, go to the Equipment section. Labels: Stock bags are generally used in conjunction with pressure sensitive labels. Types of Packing followed at Coffee Day 3 layer packing with Gaglio valve for degassination and for one way valve Nitrogen flushing for 3 layer packing for more shelf life Vacuum packing to eliminate air from the coffee powder packs Whole bean packing to reduce oxidation ,

Supply Exports Roasted bean form caf vending machines customer

B2C Caf mercantile Roast and ground powder FMCG fresh n ground customer

Roasted beans

fresh n ground i.e. 20 kg bags vending machines

customer capsule customer

Roasted and ground powder

Das könnte Ihnen auch gefallen

- Kaki Shooting Draft: Scene 01 - Title Card (Drone Shot)Dokument5 SeitenKaki Shooting Draft: Scene 01 - Title Card (Drone Shot)Sunil BharadwajNoch keine Bewertungen

- Findings Feeling About Their Job: We ObserveDokument4 SeitenFindings Feeling About Their Job: We ObserveSunil BharadwajNoch keine Bewertungen

- Plumbing Materials RequiredDokument2 SeitenPlumbing Materials RequiredSunil BharadwajNoch keine Bewertungen

- Project New Part A - V1Dokument60 SeitenProject New Part A - V1Sunil BharadwajNoch keine Bewertungen

- Curriculum Vitae: Sanand Ganesh J.CDokument6 SeitenCurriculum Vitae: Sanand Ganesh J.CSunil BharadwajNoch keine Bewertungen

- Anand FDokument76 SeitenAnand FSunil BharadwajNoch keine Bewertungen

- Book Review KushvantsingDokument1 SeiteBook Review KushvantsingSunil BharadwajNoch keine Bewertungen

- BROUCHUREDokument2 SeitenBROUCHURESunil BharadwajNoch keine Bewertungen

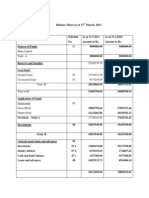

- Balance Sheet As at 31st MarchDokument2 SeitenBalance Sheet As at 31st MarchSunil BharadwajNoch keine Bewertungen

- Anandfin LDokument6 SeitenAnandfin LSunil BharadwajNoch keine Bewertungen

- Ii Internal Management Accounting and Control Systems: 3 MarksDokument5 SeitenIi Internal Management Accounting and Control Systems: 3 MarksSunil BharadwajNoch keine Bewertungen

- SynopsisDokument5 SeitenSynopsisSunil BharadwajNoch keine Bewertungen

- Chapter 3Dokument19 SeitenChapter 3Sunil BharadwajNoch keine Bewertungen

- Prashanth - Resume - 5.5 Years of Exp in GMR Airports - Doha AirportDokument3 SeitenPrashanth - Resume - 5.5 Years of Exp in GMR Airports - Doha AirportSunil BharadwajNoch keine Bewertungen

- Sanand ResumeDokument6 SeitenSanand ResumeSunil BharadwajNoch keine Bewertungen

- Hygenic EditedDokument56 SeitenHygenic EditedSunil BharadwajNoch keine Bewertungen

- Employee Satisfaction StudyDokument80 SeitenEmployee Satisfaction StudySunil BharadwajNoch keine Bewertungen

- Goenka BeveragesDokument3 SeitenGoenka BeveragesSunil BharadwajNoch keine Bewertungen

- Sheshadri QasDokument5 SeitenSheshadri QasSunil BharadwajNoch keine Bewertungen

- Hotel IntruDokument1 SeiteHotel IntruSunil BharadwajNoch keine Bewertungen

- Literature Review 12sjccmib007Dokument5 SeitenLiterature Review 12sjccmib007Sunil BharadwajNoch keine Bewertungen

- Share Khan1Dokument36 SeitenShare Khan1Sunil BharadwajNoch keine Bewertungen

- MBA Student Organizational Study Certificate for Tejkamal Trade LinksDokument1 SeiteMBA Student Organizational Study Certificate for Tejkamal Trade LinksSunil BharadwajNoch keine Bewertungen

- Questionaire 007 MibDokument4 SeitenQuestionaire 007 MibSunil BharadwajNoch keine Bewertungen

- Kiran Firstv DraftDokument78 SeitenKiran Firstv DraftSunil BharadwajNoch keine Bewertungen

- As Per IS 14543: 2004. The Required Undertaking - Cum - Indemnity Bond Is Attached Here With For Your RecordsDokument3 SeitenAs Per IS 14543: 2004. The Required Undertaking - Cum - Indemnity Bond Is Attached Here With For Your RecordsSunil BharadwajNoch keine Bewertungen

- Vision and ValuesDokument5 SeitenVision and ValuesSunil BharadwajNoch keine Bewertungen

- Well ThoughtDokument2 SeitenWell ThoughtSunil BharadwajNoch keine Bewertungen

- Reg No 10dkcma109Dokument88 SeitenReg No 10dkcma109Sunil BharadwajNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5782)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Alcoholic & Non-Alcoholic BeveragesDokument67 SeitenAlcoholic & Non-Alcoholic BeveragesVernon V IsmaelNoch keine Bewertungen

- Cash Crop Production in IndiaDokument44 SeitenCash Crop Production in Indiamodern studioNoch keine Bewertungen

- Mono - Green Coffee Bean Extract - EnglishDokument5 SeitenMono - Green Coffee Bean Extract - EnglishTom DelongeNoch keine Bewertungen

- PT HDokument7 SeitenPT HQuỳnh AnhNoch keine Bewertungen

- Physical Properties of Liberica Coffee (Coffea Liberica) BerriesDokument16 SeitenPhysical Properties of Liberica Coffee (Coffea Liberica) BerriesAnonymous M2KbwbjNoch keine Bewertungen

- Introduction To CoffeeDokument4 SeitenIntroduction To CoffeeTerry FengNoch keine Bewertungen

- Review of Research on Coffee Remains as FertilizerDokument9 SeitenReview of Research on Coffee Remains as FertilizerGedamu KurabachewNoch keine Bewertungen

- Formulation of Body Scrub Cream From Extract of Arabika Green Coffee (Coffea Arabica L.) As AntioxidantDokument6 SeitenFormulation of Body Scrub Cream From Extract of Arabika Green Coffee (Coffea Arabica L.) As AntioxidantPilu Lubiana ZiharaNoch keine Bewertungen

- Coffee Roaters - Case Study - ADokument17 SeitenCoffee Roaters - Case Study - AVipin Kumar0% (1)

- The Essentials of Coffee: A Guide to Beans, Brewing, and Barista SkillsDokument18 SeitenThe Essentials of Coffee: A Guide to Beans, Brewing, and Barista SkillsCharis AbadNoch keine Bewertungen

- Barista ManualDokument36 SeitenBarista ManualCristina CristeaNoch keine Bewertungen

- The Feasibility of Ampalaya Momordica CHDokument22 SeitenThe Feasibility of Ampalaya Momordica CHRich Kimberly DescalsotaNoch keine Bewertungen

- Benefits of AntioxidantsDokument2 SeitenBenefits of AntioxidantsantioxidantcafeNoch keine Bewertungen

- Mineral Oil Hydrocarbons in FoodDokument28 SeitenMineral Oil Hydrocarbons in FoodGladys PanggaNoch keine Bewertungen

- Analytical Methods Applied For The Characterization and The Determination of Bioactive Compounds in CoffeeDokument13 SeitenAnalytical Methods Applied For The Characterization and The Determination of Bioactive Compounds in CoffeeI DeusNoch keine Bewertungen

- Journal of Food Composition and Analysis: Marta Mesías, Francisco J. MoralesDokument5 SeitenJournal of Food Composition and Analysis: Marta Mesías, Francisco J. MoralesAndreea MarinNoch keine Bewertungen

- Cuppers Handbook English IpadDokument137 SeitenCuppers Handbook English IpadFrankie Wong100% (7)

- Determining Coffee Content Accuracy in MixturesDokument6 SeitenDetermining Coffee Content Accuracy in MixturesNovita SariNoch keine Bewertungen

- Cadiz Business Plan CorrectedDokument78 SeitenCadiz Business Plan CorrectedElle XcelsieNoch keine Bewertungen

- Chemical Compounds of Coffee Ground and Spent Coffee Ground For Pharmaceutical ProductsDokument4 SeitenChemical Compounds of Coffee Ground and Spent Coffee Ground For Pharmaceutical ProductsMickey PNoch keine Bewertungen

- Roasting Coffee (Transcript)Dokument5 SeitenRoasting Coffee (Transcript)Limario ManobanNoch keine Bewertungen

- The Coffee Sector in China Aug-2010Dokument31 SeitenThe Coffee Sector in China Aug-2010Jorge SandovalNoch keine Bewertungen

- Dynamics of Indonesian Robusta Coffee Competition Among Major Competitor CountriesDokument10 SeitenDynamics of Indonesian Robusta Coffee Competition Among Major Competitor CountriesNur AiniNoch keine Bewertungen

- Effect of Grinding, Extraction Time and Type of Coffee On The Physicochemical and Flavour Characteristics of Cold Brew CoffeeDokument12 SeitenEffect of Grinding, Extraction Time and Type of Coffee On The Physicochemical and Flavour Characteristics of Cold Brew Coffeeseptian wiraputraNoch keine Bewertungen

- 2023 WCRC Rules and RegulationsDokument34 Seiten2023 WCRC Rules and Regulationsadv baseventNoch keine Bewertungen

- Coffee PulpDokument96 SeitenCoffee PulpIago100% (2)

- Certificado de Origen CafeDokument26 SeitenCertificado de Origen CafeAndresOsorioNoch keine Bewertungen

- Coffee Supply ChainDokument2 SeitenCoffee Supply ChainSatakshi SinghNoch keine Bewertungen

- Quality Control and Assurance Processes for Coffee ProductionDokument5 SeitenQuality Control and Assurance Processes for Coffee ProductionSharifah NuruljannahNoch keine Bewertungen

- JKKH LatestDokument125 SeitenJKKH LatestDino DizonNoch keine Bewertungen