Beruflich Dokumente

Kultur Dokumente

Paveseal Batch 3331 L6 - 3341 L6 - 3351 L6 - 3361 L3 (BS 5212:1990)

Hochgeladen von

sahcristine3968Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Paveseal Batch 3331 L6 - 3341 L6 - 3351 L6 - 3361 L3 (BS 5212:1990)

Hochgeladen von

sahcristine3968Copyright:

Verfügbare Formate

Report request: Client: Report date: Report number: From:

14/06/11 02/08/11

M33/11 Dr. Marino MARINONE

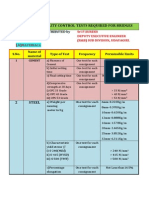

Paveseal PU batch 3331 L6 - 3341 L6 - 3351 L6 - 3361 L3 (BS 5212:1990) DETERMINATION OF MINIMUM APPLICATION LIFE Properties

Determination of minimum application life

BS 5212 T. method 3 Value

60 min.

Requirements

>30 min.

Test method

BS 5212 T. method 3

DETERMINATION OF TACK-FREE CONDITION Properties

Determination of tack-free condition

BS 5212 T. method 4 Value

Not adherence

Req uirements

Not adherence after 16 0.1 h.

Test method

BS 5212 T. method 4

DETERMINATION OF RHEOLOGICAL PROPERTIES Properties

Determination of ability to flow using a horizontal mould at 5 C Determination of ability to flow using a mould inclined at 2.5% slope at 23 2C

BS 5212 T. method 5 Value

1 mm 2mm

Req uirements

Difference in depth < 3mm Difference in depth < 4mm

Test method

BS 5212 T. method 5.3 BS 5212 T. method 5.4

DETERMINATION OF RESISTANCE TO PLASTIC FLOW Properties

Determination of resistance to plastic flow

BS 5212 T. method 6 Value Omm Test method

BS 5212 T. method 6

Requirements

<2mm

DETERMINATION OF PENETRATION AND RECOVERY Properties Requirements

Initial ball penetration <2mm. Recovery >75%

BS 5212 T. method 7 Value

0.5mm 89%

Test method

BS 5212 T. method 7

Determination of penetration and recovery

N.P.T. 51"1 - New Polyurethane Technologies Via Guido Rossa. 2 . 40056 Crespellano Bo . Italy Ph. +39.051.969109 - Fax +39.051.969837 web: www.nptsrl.com - e-mail: npt@nptsrl.com

N.P.T. sri Produzione. Laboratorio di Ricerca e Sviluppo Viale Zanotti. 88 . 27027 Gropello Cairoli . Pv . Italy Ph. +39.0382.815132 Fax +39.0382.815482 web: www.nptsrl.com . email: npt@nptsrl.com

DETERMINATION

OF ADHESION AND COHESION IN TENSION AND COMPRESSION 7d at 23 C and 50% Ur 7d water immersion at 23 C and 50% Ur 3 cycles (l40b.) Properties Requirements Ruptures not exceed 100mm2 area Max and min. first cycle shall not differ from average by more of 20 N or 20% <JOON >40N

BS5212 T. metbod 8

Value Omm 9N 8.33% 126N 88N

Testmetbod

Adhesion and cohesion in tension and compression Difference between specimens Forces in tension and compression

BS 5212 T. method 8

Maximum force Lowest maximum force

DETERMINATION

OF RESISTANCE TO HEAT AGEING 7d at 23 C and 50% Ur Requirements 1055<6% Initial ball penetration <2mm. Recovery >75% Rupttrres not exceed lOOmm2area Max and min. first cycle shall not differ from average by more of 20N or 20% <300N >40N

BS5212 T. method 9 Value 1.52 O.7mm 93% Omm 3N 2% 1S0N 14SN BS 5212 T. method 9.5.1 Test metbod BS 5212 T. method 9.3 BS 5212 T. method 9.4

Properties Determination of mass loss (%) (l4d at 70 e) Determination of penetration and recovery (14d at 70 e) Determination of changes in forces and changes in adhesion and cohesion on extension and compression

Ale

Difference between specimens 14d (at 70 C) 1 cycle

(44h.)

Maximum force Lowest maximum force Mean difference from force in tension and compression without ageing Ale Difference between specimens Maximum force Lowest maximum force

< lOON

24N

28d (at 70 C) 3 cycles

(J40h.)

Ruptures not exceed 100mm2 area Max and min. first cycle shall not differ from average by more of 20N or 20% <300N >40N

0 10.6N 6.50% 163N 145N

BS 5212

T. method 9.5.2

Mean difference from force in tension and compression without ageing

<lOON

37N

DETERMINATION OF FUEL IMMERSION CHARACTERISTICS (1 days at 23 C and 48h. fuel immersion)

Properties Determination of change in mass after fuel immersion

BS5212 T. method 10 Value

increase 4.42% 1.1

Requirements

loss < 10% increase < 5% Initial ball penetration <2mm. Recovery >75%

Test method

BS 5212 T. method 10.5 BS 5212 T. method 10.6

mm

Penetration and recovery Adhesion and cohesion in tension and compression (3 cycles for 140h.) Difference between specimens

89%

Forces in tension and compression (3 cycles for 140h.)

Ruptures not exceed 100mm2 area Max and min. first cycle shall not differ from average by more of 20 N or 20% <300N >40N

0

5.5N 2.64% 208 184

BS 5212 T. method 10.7

Maximum force Lowest maximum force

DETERMINATION OF FLAME RESISTANT PROPERTIES (2600 C for 2 minutes) Properties

Determination of flame resistant properties

BS5212 T. method 11 Value

Pass

Requirements

No evidence of ignition, support of combustion, flow and separation. No hardening or loss of flexibility

Test method

BS 5212 T. method 11

~;~OPJ:IATI 7 (W4,_ ~

flZ"

-/-~R'N7--~

~Iogiesl~~

Das könnte Ihnen auch gefallen

- Pressuremeter Testing: Methods and InterpretationVon EverandPressuremeter Testing: Methods and InterpretationBewertung: 5 von 5 Sternen5/5 (2)

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportVon EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportNoch keine Bewertungen

- Eng SS 108-20090 C3 108-20090Dokument14 SeitenEng SS 108-20090 C3 108-20090daha5395Noch keine Bewertungen

- Nylatron 703 XL - Technical Data Sheet: Properties Test Methods Units Values Iso/IecDokument1 SeiteNylatron 703 XL - Technical Data Sheet: Properties Test Methods Units Values Iso/Iecs_padu3003@yahoo.comNoch keine Bewertungen

- Quality 42crmo4 Chemical Composition: Technical Card Gruppo Lucefin Revision 2012 All Rights ReservedDokument2 SeitenQuality 42crmo4 Chemical Composition: Technical Card Gruppo Lucefin Revision 2012 All Rights ReservedVijayakumar SamyNoch keine Bewertungen

- Feasibility Report 38MnVS6Dokument2 SeitenFeasibility Report 38MnVS6Amit Kumar UkeNoch keine Bewertungen

- Waterproofing Membrane, CharacteristicsDokument2 SeitenWaterproofing Membrane, CharacteristicsyamegNoch keine Bewertungen

- Cement Aggregate Test FrequencyDokument2 SeitenCement Aggregate Test FrequencyEmlin RajNoch keine Bewertungen

- StandardsDokument4 SeitenStandardsflorin_iacob2001Noch keine Bewertungen

- Specification: CL 31 B 104 K B C N N N CDokument2 SeitenSpecification: CL 31 B 104 K B C N N N Cfan1802Noch keine Bewertungen

- TDC Tech Spec For PlateDokument3 SeitenTDC Tech Spec For PlateBantoo RajamandiNoch keine Bewertungen

- Technical Delivery Condition (TDC) : Exhibit 3 - 2 Rev. 0 Dtd. 12.12.2014Dokument3 SeitenTechnical Delivery Condition (TDC) : Exhibit 3 - 2 Rev. 0 Dtd. 12.12.2014shazanNoch keine Bewertungen

- C606 C607 C752 753Dokument2 SeitenC606 C607 C752 753Sol De GabrielNoch keine Bewertungen

- G-Com TDSDokument2 SeitenG-Com TDSSasi Kiran VundamatlaNoch keine Bewertungen

- Astm A572 - 04Dokument1 SeiteAstm A572 - 04Hai TranNoch keine Bewertungen

- Ck45 Mechanical PropertiesDokument3 SeitenCk45 Mechanical PropertiesDaniel CringusNoch keine Bewertungen

- DatasheetDokument30 SeitenDatasheet201Fakhri Naufal Rizqullah RizqullahNoch keine Bewertungen

- VISCOWRAP-HT Product Data Sheet EnglishDokument2 SeitenVISCOWRAP-HT Product Data Sheet EnglishJA BustosNoch keine Bewertungen

- Kocetal K300: Product InformationDokument1 SeiteKocetal K300: Product InformationebercueNoch keine Bewertungen

- Legacy127 19Dokument4 SeitenLegacy127 19isotempNoch keine Bewertungen

- Accutrim™ 1240 (RJ26 Style) : Vishay Foil ResistorsDokument5 SeitenAccutrim™ 1240 (RJ26 Style) : Vishay Foil ResistorsSlavaSH2Noch keine Bewertungen

- TTC 103 NTC ThermistorDokument7 SeitenTTC 103 NTC ThermistorBilly SilvaNoch keine Bewertungen

- 9320A070GDokument7 Seiten9320A070GBaytolgaNoch keine Bewertungen

- Polystyrene Capacitors Max.10nFDokument2 SeitenPolystyrene Capacitors Max.10nFsonic8659Noch keine Bewertungen

- Et Requested Ccecc Test The Sample PVC As Per Et Requirement and Send The Test Result To For Et To Cross Check With Et SpecificationDokument1 SeiteEt Requested Ccecc Test The Sample PVC As Per Et Requirement and Send The Test Result To For Et To Cross Check With Et SpecificationMHEP_DANIELNoch keine Bewertungen

- Nicrom: High Performance Thick Film ResistorsDokument15 SeitenNicrom: High Performance Thick Film ResistorsbekcaNoch keine Bewertungen

- General SpecificationDokument1 SeiteGeneral SpecificationhbardhanNoch keine Bewertungen

- SpecificatiebladpdfDokument1 SeiteSpecificatiebladpdfThinh Tien NguyenNoch keine Bewertungen

- Summary of Quality Control Tests Required For BridgesDokument4 SeitenSummary of Quality Control Tests Required For BridgesV Venkata Narayana100% (3)

- DI-MC 355: Product DescriptionDokument4 SeitenDI-MC 355: Product DescriptionvinodNoch keine Bewertungen

- Shearbox - Gabgapa Project (E)Dokument55 SeitenShearbox - Gabgapa Project (E)abdallah abdurhman aliNoch keine Bewertungen

- 2-8 ÚÀçÈ - TeraOhm - Bridge-Meter - Measurements)Dokument25 Seiten2-8 ÚÀçÈ - TeraOhm - Bridge-Meter - Measurements)robin0903Noch keine Bewertungen

- Specifications: 4.5Mml Chip Type, Wide Temperature RangeDokument1 SeiteSpecifications: 4.5Mml Chip Type, Wide Temperature RangeselocaNoch keine Bewertungen

- PTC Thermistors As Limit Temperature Sensors: Motor Protection, Triple SensorsDokument12 SeitenPTC Thermistors As Limit Temperature Sensors: Motor Protection, Triple SensorsjvtamilanbanNoch keine Bewertungen

- K48-50 Carbon Film ResistorsDokument3 SeitenK48-50 Carbon Film ResistorseminuscloudNoch keine Bewertungen

- SS621 TUV Testing Report (Full Permission)Dokument5 SeitenSS621 TUV Testing Report (Full Permission)Christiano RodriguezNoch keine Bewertungen

- SS621 TUV Testing Report (Full Permission)Dokument5 SeitenSS621 TUV Testing Report (Full Permission)Christiano RodriguezNoch keine Bewertungen

- Crackbridging SummaryDokument8 SeitenCrackbridging SummaryEvgeny ZakharinNoch keine Bewertungen

- PPC04 PolyGuard™ Anti Fog TDS WEBDokument3 SeitenPPC04 PolyGuard™ Anti Fog TDS WEBnox633159Noch keine Bewertungen

- Meterman lcr55Dokument2 SeitenMeterman lcr55Scott TylerNoch keine Bewertungen

- Cristal 55.845Dokument6 SeitenCristal 55.845Emiliano A CuscuettaNoch keine Bewertungen

- 240 Pin VLP DDR-III Soldertail Sockets: Product Design ObjectiveDokument8 Seiten240 Pin VLP DDR-III Soldertail Sockets: Product Design Objectivejerome_testNoch keine Bewertungen

- Stress Vs StrainDokument1 SeiteStress Vs StrainAakashRanjanNoch keine Bewertungen

- Bitumen SpecsDokument5 SeitenBitumen SpecsUsman RanaNoch keine Bewertungen

- Oil Sample report-31.5MVA, Indotech PTR at Turkayamjal SSDokument2 SeitenOil Sample report-31.5MVA, Indotech PTR at Turkayamjal SSMUSHAM217Noch keine Bewertungen

- Test PlanDokument1 SeiteTest PlanOFFICE DANACNoch keine Bewertungen

- NTC Thermistors For Temperature Measurement: Leaded NTCS, Lead Spacing 5 MMDokument61 SeitenNTC Thermistors For Temperature Measurement: Leaded NTCS, Lead Spacing 5 MMMahmoud AhmedNoch keine Bewertungen

- 04product Download PDF DCDC Rdd05Dokument4 Seiten04product Download PDF DCDC Rdd05tilitronNoch keine Bewertungen

- Tmce21 109M315VB76R175M12Dokument5 SeitenTmce21 109M315VB76R175M12raghuNoch keine Bewertungen

- HydroDokument4 SeitenHydroSamir ChaudharyNoch keine Bewertungen

- Technical Solutions PCDokument2 SeitenTechnical Solutions PCAnonymous KdnOsd9Noch keine Bewertungen

- Gid 208 El Aca Ds 58351 r0 400kv CB Datasheet Cat 3Dokument5 SeitenGid 208 El Aca Ds 58351 r0 400kv CB Datasheet Cat 3Santoshkumar GuptaNoch keine Bewertungen

- PHL38 en 1 1Dokument11 SeitenPHL38 en 1 1Carlyle MombaelNoch keine Bewertungen

- Aquarius+ UPVC Industrial Pipe & FittingsDokument16 SeitenAquarius+ UPVC Industrial Pipe & Fittingspanchal harnishNoch keine Bewertungen

- Pilkor PCX2 335MDokument7 SeitenPilkor PCX2 335MadminagentNoch keine Bewertungen

- Physical Testing of Clinker & CementDokument61 SeitenPhysical Testing of Clinker & CementDineshNoch keine Bewertungen

- Material Quality Report: Laboratory Code Material Reference Date in Date Out MQR No. 260406 SeasonDokument1 SeiteMaterial Quality Report: Laboratory Code Material Reference Date in Date Out MQR No. 260406 SeasonAxelsan26Noch keine Bewertungen

- CF D Project Present AbDokument9 SeitenCF D Project Present AbLawrence Abladey SquaredNoch keine Bewertungen

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingVon EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghNoch keine Bewertungen

- Optimization Mueller-Rochow SynthesisDokument8 SeitenOptimization Mueller-Rochow Synthesissahcristine3968Noch keine Bewertungen

- Caracterização Do SiliconeDokument7 SeitenCaracterização Do Siliconesahcristine3968Noch keine Bewertungen

- AdhesivesDokument176 SeitenAdhesivesm_gobara100% (11)

- Orientação ISO 11600Dokument6 SeitenOrientação ISO 11600sahcristine3968Noch keine Bewertungen

- British StandardsDokument12 SeitenBritish Standardsniginp67% (3)

- Paveseal Batch 3331 L6 - 3341 L6 - 3351 L6 - 3361 L3 (BS 5212:1990)Dokument3 SeitenPaveseal Batch 3331 L6 - 3341 L6 - 3351 L6 - 3361 L3 (BS 5212:1990)sahcristine3968Noch keine Bewertungen

- British StandardsDokument12 SeitenBritish Standardsniginp67% (3)

- British StandardsDokument12 SeitenBritish Standardsniginp67% (3)