Beruflich Dokumente

Kultur Dokumente

Eng-Degradation of PE in Natural - Gnanavel.G

Hochgeladen von

Impact JournalsOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Eng-Degradation of PE in Natural - Gnanavel.G

Hochgeladen von

Impact JournalsCopyright:

Verfügbare Formate

IMPACT: International Journal of Research in Engineering & Technology (IMPACT: IJRET) ISSN(E): 2321-8843; ISSN(P): 2347-4599 Vol.

2, Issue 1, Jan 2014, 1-6 Impact Journals

DEGRADATION OF POLYETHYLENE IN THE NATURAL ENVIRONMENT

G. GNANAVEL1, V. P. MOHANA JEYA VALLI2, M. THIRUMARIMURUGAN3 & T. KANNADASAN4

1

Assistant Professor, Department of Biotechnology, Karunya University, Coimbatore, Tamil Nadu, India

2 3

Assistant Engineer, Tamilnadu Pollution Control Board, Coimbatore, Tamil Nadu, India

Associate Professor, Department of Chemical Engineering, Coimbatore Institute of Technology, Coimbatore, Tamil Nadu, India

Professor and Head, Department of Chemical Engineering, Coimbatore Institute of Technology, Coimbatore, Tamil Nadu, India

ABSTRACT

A plastic material is any of a wide range of synthetic or semi-synthetic organic solids that are mouldable. Plastics are typically organic polymers of high molecular mass, but they often contain other substances. It is a white, waxy polymer constituted of only carbon and hydrogen. The drastic rise in the use of non-biodegradable plastic materials during the past decades has not been accompanied by corresponding development procedure for the safe disposal or degradation of these polymers. This research paper is mainly evaluating the oxo-degradable response of a polyethylene film sample containing pro-degradant additive by means of successive accelerated UV and thermal ageing. The results of the successive accelerated UV and thermal ageing test demonstrate that the film sample containing the d2w pro-degradant additive has undergone significant degradation. The film sample containing the additive demonstrates a large change in carbonyl optical density measurement at the conclusion of the test (Figure 1). These results are consistent with the film sample containing the pro-degradant additive being in an advanced state of degradation. The sample containing additive reached a carbonyl optical density value of 0.0361 after 528 hours ageing (inclusive of 48 hours UV pre-ageing). This result is consistent with inclusion of additive promoting degradation in the film sample. This conclusion is confirmed by observation: at the end of the ageing tests the oxo-biodegradable film sample show signs of breakdown (Figure 1). The film containing the additive demonstrated no significant increase in carbonyl optical density measurement at the conclusion of the test (Figure 2). This result is consistent with the film sample having undergone no significant degradation. The absence of degradation of the film sample confirms that the polyethylene is intrinsically stable to thermal ageing. This is consistent with the product having a usable fit for purpose shelflife in storage conditions away from prolonged exposure to UV light and at an average temperature not exceeding 30C. These results are confirmed by observation. At the end of the test the sample remains intact.

KEYWORDS: Additives, Degradation, Plastics, Thermal Ageing, Ultra Violet INTRODUCTION

Plastics were first invented in 1860, but have only been widely used in the last 30 years. The word plastic comes from the Greek word plastikos, which means able to be moulded into different shapes. Plastics are usually high-molecular-weight polymers that at some stage in their existence are capable of flow, but may also be brought into a non-fluid form in which they have sufficient toughness and strength to be useful in self-supporting applications. It is a white, waxy polymer constituted of only carbon and hydrogen. Polyethylene also known as polyethylene or polythene was the first of the polymers to be discovered. Plastics are synthetic organic polymers that exist for just over a century.

G. Gnanavel, V. P. Mohana Jeya Valli, M. Thirumarimurugan & T. Kannadasan

The material has become an essential part of modern everyday life due to its versatility and properties, such as low cost, adjustable transparency, light weight, strength and high durability. Plastics are made up of long chain molecules called polymers. Polymers are made when naturally occurring substances such as coal, natural gas and oil are transformed into other substances with completely different properties. These polymers can then be made into granules, powders and liquids, becoming the raw materials for plastic products. Polyethene is a plastic. It is a polymer produced by reacting oxygen and ethane, in this reaction the small ethane molecules attach together to form long chain polymer molecules. This process is known as addition polymerization. It can also be produced through radical polymerization, anionic addition polymerization, ion coordination polymerization or cationic addition polymerization. Polyethene is manufactured by cracking/decomposing petroleum distillates into small, reactive ethane molecules that can be rearranged. Ethene molecules polymerize to long chains of Polyethene, chains that are kept close to each other by weak bonds to form a material, comparable with the fibers of a felt. Biodegradation of Plastics Biodegradation is the chemical dissolution of materials by bacteria or by other biological means. Recently biodegradable plastics are of great interest. Biodegradation takes place by the action of enzymes, chemical degradation with living organisms. This takes place in two steps. The first step is the fragmentation of the polymers into lower molecular mass species by means of abiotic reactions, like oxidation, photo degradation or hydrolysis, or biotic reactions, like degradations by microorganisms. This step is followed by the bio-assimilation of polymer fragments by the microorganisms and their mineralisation. Biodegradability depends not only on the origin of the polymer, also on its chemical structure and the environmental degrading conditions. The factors, on which the mechanical nature of biodegradable materials depends on, are their chemical composition, production, storage and processing characteristics, their ageing and the application conditions2. Degradable plastic is the one in which the degradation results from the action of naturally occurring microorganisms such as bacteria, fungi, and algae. Biodegradable plastics must biodegrade in specific environments such as soil, compost, or marine environments7. The biodegradable bags are made of polymers that degrade when exposed to sunlight, water or air7.

EXPERIMENTAL PROCEDURE

Successive Accelerated UV and Thermal Ageing This method involves subjecting the substrate to 48 hours accelerated UV pre-ageing before accelerated thermal ageing and monitoring degradation via changes in the carbonyl optical density as determined by FT-IR (Fourier Transform Infra Red) spectroscopy. Thermal Ageing The method involves subjecting the substrate to accelerated thermal ageing and monitoring degradation via changes in the carbonyl optical density as determined by FT-IR (Fourier Transform Infra Red) spectroscopy.

TEST METHODOLOGY

Accelerated Fluorescent UV Ageing The sample was placed in a sample holder, in which the film is sandwiched between two metal plates (35 x 90 mm) with four exposure windows, and exposed to ultraviolet radiation in a Q Panel QUV/se test apparatus fitted with UVA 340 lamps, in general accordance with ASTM D5208. A black panel temperature of 50C was used in

Degradation of Polyethylene in the Natural Environment

conjunction with a humid environment. The irradiance of the lamps was 0.78 W/m2/nm. The test sample with the additive was withdrawn every 48 hours and its carbonyl optical density determined by FT-IR spectroscopy. Accelerated Thermal Ageing Thermal ageing of the sample was carried out in a Memmert UFE 600 fan assisted oven at a temperature of 70C in general accordance with ASTM D5510 Procedure B: Forced Ventilation Oven. The test sample with the additive was withdrawn every 96 hours and its carbonyl optical density determined by FT-IR spectroscopy. Carbonyl Optical Density Measurement The carbonyl optical density (1713 cm-1) of the sample was determined by FT-IR spectroscopy in transmission mode using a Thermo Electron Nicolett FT-IR instrument. The optical density is defined by the magnitude of the carbonyl peak at 1713 cm-1 divided by the sample thickness. Four optical density measurements were taken at each time point and an average determined. Measuring changes in carbonyl optical density is a useful technique for monitoring the rate of degradation of the sample. Carbonyl species (aldehydes, ketones, carboxylic acids etc.) are reaction by-products of the oxidative degradation process and as such their accumulation is indicative of ongoing degradation. XRF Spectroscopy The anticipated presence of the pro-degradant additive in each sample was confirmed by energy-dispersive X-ray florescence (ED-XRF) spectroscopy using a Bruker S2 Ranger A20-X10 bench top spectrometer against reference samples produced by Symphony. The XRF spectrum of each sample was determined in air over 120 s with 40.00 kV, 250 mA X-ray source and 500.0 m aluminum filter. Samples of film were prepared in 38 mm diameter HDPE XRF sample cups and the total thickness made up to ~200 m with 36 m discs cut from the sample using a James Heal 230/10 sample cutter.

RESULTS

Successive Accelerated UV and Thermal Ageing Table 1: Accelerated Successive UV and Thermal Ageing Sample L/LET/01) Film with additive QUV Ageing 0 Hrs 48Hrs 0.000 0.0001 Carbonyl Optical Density Thermal Ageing 144 Hrs 240 Hrs 336 Hrs 432 Hrs 0.0080 0.0144 0.0188 0.0266

528 Hrs 0.0361

Figure 1: Successive Accelerated UV and Thermal Ageing

G. Gnanavel, V. P. Mohana Jeya Valli, M. Thirumarimurugan & T. Kannadasan

Accelerated Thermal Ageing Table 2: Accelerated Thermal Ageing Carbonyl Optical Density Sample 0 Hrs 96 Hrs 192 Hrs 288 Hrs 384 Hrs 480 Hrs 576 Hrs L/LET/01)Film with additive 0.0000 0.0000 0.0000 0.0000 0.0000 0.0000 0.0000

Figure 2: Accelerated Thermal Ageing

DISCUSSIONS

Degradation - Successive Accelerated UV and Thermal Ageing The results of the successive accelerated UV and thermal ageing test demonstrate that the film sample containing the pro-degradant additive has undergone significant degradation. The film sample containing the additive demonstrates a large change in carbonyl optical density measurement at the conclusion of the test (Figure 1). These results are consistent with the film sample containing the pro-degradant additive being in an advanced state of degradation. The sample containing d2w reached a carbonyl optical density value of 0.0361 after 528 hours ageing (inclusive of 48 hours UV pre-ageing). This result is consistent with inclusion of d2w promoting degradation in the film sample. This conclusion is confirmed by observation: at the end of the ageing tests the oxo-biodegradable film sample show signs of breakdown. Shelf life Accelerated Thermal Ageing The film containing the additive demonstrated no significant increase in carbonyl optical density measurement at the conclusion of the test (Figure 2). This result is consistent with the film sample having undergone no significant degradation. The absence of degradation of the film sample confirms that the polyethylene is intrinsically stable to thermal ageing. This is consistent with the product having a useable fit for purpose shelflife in storage conditions away from prolonged exposure to UV light and at an average temperature not exceeding 30C. These results are confirmed by observation. At the end of the test the sample remains intact.

CONCLUSIONS

Plastics wastes accumulate in the environment are posing an ever increasing ecological threat. The most problematic plastic in this regard is probably polyethylene, which is one of the most inert synthetic polymers and being

Degradation of Polyethylene in the Natural Environment

resistant to microbial attack. It is evident for the degradation of polythene films in the natural environment is slow and therefore, posses a serious environmental concern. A new generation of environmental friendly polyethylene containing a minimum of 9% starch and pro-oxident additives are highly recommended for use since their degradation in natural environment is much faster13. Hence it is proved that the usage of plastics is safer as it can be degraded in the soil. The results are confirmed by the weight, tensile strength and decrease in viscosity in some cases, molecular weight distribution, and fragility. The HDPE plastics are showing resistance to soil conditions than LDPE. This research is useful for the evaluation of the oxo-degradable response of a polyethylene film sample containing pro-degradant additive by means of successive accelerated UV and thermal ageing.

REFERENCES

1. Arutchelvi J et al (2008) Biodegradation of polyethylene and polypropylene. Indian journal of Biotechnology. 7: 9-22. 2. 3. 4. Emma Seigel, Lisa Barlow. Biodegradable Plastics. Isabelle Vroman et al (2009) Biodegradable Polymers. Materials., 2, 307-344. Gary T Howard (2002) Biodegradation of polyurethane: a review, International Biodeterioration & Biodegradation.; 49: 245 252. 5. Joel Tickner. (1999) A Review of the Availability of Plastic Substitutes for Soft PVC in Toys, Report Commissioned by Greenpeace International. 6. Jun HS et al (1994) Synthesis of copolyesters containing poly(ethylene terephthalate) and poly(ecaprolactone) units and their susceptibility to Pseudomonas sp. Lipase. J Environ Polym Degrad; 2:918. 7. Kenneth E et al (1993) Degradation of Degradable Starch- Polyethylene Plastics in a Compost Environment. Applied and Environmental Microbiology.; 1155-1161. 8. 9. "Oxo-Biodegradable" (2009) Plastics, Position Paper. Robert Sinclair. Additive Technology for Polyolefin Biodegradation. ECM BioFilms.

10. Sasek V et al (2006) Synthetic Polymers By Composting And Fungal Treatment. Folia Microbial.; 51(5): 425-430. 11. Vijaya. Ch et al (2008) Impact of soil composting using municipal solid waste on biodegradation of plastics, Indian Journal of Biotechnology, Vol 7, April, pp 235-239. 12. Ying Zheng et al (2005) A Review of Plastic Waste Biodegradation, Critical Reviews in Biotechnology; 25:243250. 13. Yukie Akutsu, et al (1998) Purification and Properties of a Polyester Polyurethane-Degrading Enzyme from Comamonas acidovorans TB-35, Applied and Environmental Biotechnology;64:62-67.

Das könnte Ihnen auch gefallen

- Jacaranda Chemistry Units 3 - 4Dokument450 SeitenJacaranda Chemistry Units 3 - 4josh soon100% (1)

- Pipeline Coatings PDFDokument29 SeitenPipeline Coatings PDFAsimNoch keine Bewertungen

- Amendment No. 2 April 2022 To Is 7098 (Part 2) : 2011 Crosslinked Polyethylene Insulated Thermoplastic Sheathed Cables - SpecificationDokument11 SeitenAmendment No. 2 April 2022 To Is 7098 (Part 2) : 2011 Crosslinked Polyethylene Insulated Thermoplastic Sheathed Cables - SpecificationVatsalNoch keine Bewertungen

- PET Plastic RecyclingDokument42 SeitenPET Plastic RecyclingDavid MuneneNoch keine Bewertungen

- ASTM SpecsDokument3 SeitenASTM SpecsdurgeshwardNoch keine Bewertungen

- Power Cable EngineeringDokument38 SeitenPower Cable EngineeringjaimeNoch keine Bewertungen

- Degradation of PolyethyleneDokument79 SeitenDegradation of PolyethyleneRishab Jain100% (2)

- 04-200-R1 Silicon Iron AnodesDokument2 Seiten04-200-R1 Silicon Iron Anodessams1101Noch keine Bewertungen

- Production of Bioplastics From Banana Peels Using Batch ReactorDokument19 SeitenProduction of Bioplastics From Banana Peels Using Batch ReactorUday sonwaneNoch keine Bewertungen

- Biodegradation of Poly (Lactic Acid) - Starch-Coir Biocomposites Under Controlled Composting ConditionsDokument11 SeitenBiodegradation of Poly (Lactic Acid) - Starch-Coir Biocomposites Under Controlled Composting ConditionsLong LeNoch keine Bewertungen

- Petrochemicals - EthyleneDokument41 SeitenPetrochemicals - Ethylenealin_dev100% (2)

- Biodegradabe Film Foodpackaging ApplicationsDokument39 SeitenBiodegradabe Film Foodpackaging ApplicationsMousam ChoudhuryNoch keine Bewertungen

- Experiments in Environmental Chemistry: A Laboratory ManualVon EverandExperiments in Environmental Chemistry: A Laboratory ManualNoch keine Bewertungen

- Edible Films and Coatings Sources Properties and ApplicationDokument12 SeitenEdible Films and Coatings Sources Properties and ApplicationDanielNoch keine Bewertungen

- Contaminant Release From Aged Microplastic: Nicole Bandow, Verena Will, Volker Wachtendorf and Franz-Georg SimonDokument12 SeitenContaminant Release From Aged Microplastic: Nicole Bandow, Verena Will, Volker Wachtendorf and Franz-Georg SimonJavier AlcodoriNoch keine Bewertungen

- Degradation of Polymer by Using Fungi: A ReviewDokument3 SeitenDegradation of Polymer by Using Fungi: A ReviewGRD JournalsNoch keine Bewertungen

- Biodegradable & Conducting PolymersDokument50 SeitenBiodegradable & Conducting Polymersleela777Noch keine Bewertungen

- Tr-18 Weatherability Thermo Pipe SystemsDokument11 SeitenTr-18 Weatherability Thermo Pipe SystemsA.ANoch keine Bewertungen

- Pyrolysis of Plastic Waste To EnvironmenDokument14 SeitenPyrolysis of Plastic Waste To EnvironmenManoj SahuNoch keine Bewertungen

- Biodegradation of Poly (Ethylene Terephthalate) by Bacillus SubtilisDokument4 SeitenBiodegradation of Poly (Ethylene Terephthalate) by Bacillus SubtilisExon PerezNoch keine Bewertungen

- Souza2021 Article TheEffectOfZnONanoparticlesAsADokument18 SeitenSouza2021 Article TheEffectOfZnONanoparticlesAsADuclercfParra DuclrcNoch keine Bewertungen

- Biodegradable Films For Food PackagingDokument13 SeitenBiodegradable Films For Food PackagingAnjal SinghNoch keine Bewertungen

- Degradable PE, Fantasy or RealityDokument11 SeitenDegradable PE, Fantasy or RealityNikita SedushNoch keine Bewertungen

- Jency Joseph 2019 J. Phys. Conf. Ser. 1362 012103Dokument10 SeitenJency Joseph 2019 J. Phys. Conf. Ser. 1362 012103JOEL JOSEPHNoch keine Bewertungen

- Radiation Physics and ChemistryDokument4 SeitenRadiation Physics and ChemistrySilvia AningtyasNoch keine Bewertungen

- Mini Thesis 2Dokument43 SeitenMini Thesis 2gadaubacNoch keine Bewertungen

- 1B EngbergDokument12 Seiten1B EngbergPeter LichterveldNoch keine Bewertungen

- NCL Report - Chapter 4Dokument6 SeitenNCL Report - Chapter 4Aparna YaduNoch keine Bewertungen

- Polystyrene PreparationDokument15 SeitenPolystyrene PreparationZeinab A. ElBhnsawiNoch keine Bewertungen

- Radiation Sterilization Compatibility of Medical Packaging MaterialsDokument11 SeitenRadiation Sterilization Compatibility of Medical Packaging MaterialsPham Thi Thu HongNoch keine Bewertungen

- Comparative Investigation of The UV Stabilization of PC-ABS With Different UV AbsorbersDokument8 SeitenComparative Investigation of The UV Stabilization of PC-ABS With Different UV AbsorbersVictor CastrejonNoch keine Bewertungen

- Evaluation of Plastic Packaging Materials Used in Radiation Sterilized Medical Products and FoodDokument5 SeitenEvaluation of Plastic Packaging Materials Used in Radiation Sterilized Medical Products and FoodPham Thi Thu HongNoch keine Bewertungen

- BIOD CompressedDokument13 SeitenBIOD Compressedelias llamasNoch keine Bewertungen

- A Review of Plastic Waste BiodegradationDokument9 SeitenA Review of Plastic Waste BiodegradationMillennia RischaPurwantiNoch keine Bewertungen

- Book of Abstracts Posters ADokument82 SeitenBook of Abstracts Posters AAlbana HasimiNoch keine Bewertungen

- UV IrradiationDokument7 SeitenUV IrradiationhgfksqdnhcuiNoch keine Bewertungen

- Journal of Cleaner Production: Krit Sirirerkratana, Patiya Kemacheevakul, Surawut ChuangchoteDokument8 SeitenJournal of Cleaner Production: Krit Sirirerkratana, Patiya Kemacheevakul, Surawut ChuangchoteAngle JudieNoch keine Bewertungen

- Tio Films Synthesis Over Polypropylene by Sol-Gel Assisted With Hydrothermal Treatment For The Photocatalytic Propane DegradationDokument14 SeitenTio Films Synthesis Over Polypropylene by Sol-Gel Assisted With Hydrothermal Treatment For The Photocatalytic Propane DegradationrapidremiNoch keine Bewertungen

- Goudarzi2016 PDFDokument20 SeitenGoudarzi2016 PDFRiza Cenzin PradanaNoch keine Bewertungen

- Mechanistic Implications of Plastic Degradation PDFDokument24 SeitenMechanistic Implications of Plastic Degradation PDFsonchemenNoch keine Bewertungen

- Applied Sciences: Ffect of Accelerated Aging Conditions On TheDokument23 SeitenApplied Sciences: Ffect of Accelerated Aging Conditions On TheSameehu TVNoch keine Bewertungen

- Oxidation of Orthopaedic UHMWPE: L. Costa, K. Jacobson, P. Bracco, E.M. Brach Del PreverDokument12 SeitenOxidation of Orthopaedic UHMWPE: L. Costa, K. Jacobson, P. Bracco, E.M. Brach Del PreverJobin VargheseNoch keine Bewertungen

- 2013 Synthesis and Cationic Photopolymerization of A Difunctional Episulfide Monomer PDFDokument6 Seiten2013 Synthesis and Cationic Photopolymerization of A Difunctional Episulfide Monomer PDFMarion ChenalNoch keine Bewertungen

- Production of Conventional Fuel From PlaDokument9 SeitenProduction of Conventional Fuel From PlaManoj SahuNoch keine Bewertungen

- Synthesis of Carbon Quantum Dots From Food Products, Hydrothermal Carbonization MethodDokument5 SeitenSynthesis of Carbon Quantum Dots From Food Products, Hydrothermal Carbonization MethodBunduc Burduhos Nergis DoruNoch keine Bewertungen

- Zhang 2013Dokument6 SeitenZhang 2013Mir Redhwanul Haque SakibNoch keine Bewertungen

- The Effect of PH Temperature On PlasticDokument7 SeitenThe Effect of PH Temperature On Plasticw1wy.leoNoch keine Bewertungen

- Enzymatic Degradation of PBATDokument15 SeitenEnzymatic Degradation of PBATAqsa khanNoch keine Bewertungen

- Antibacterial Activity of Hydrophobic Composite MaDokument7 SeitenAntibacterial Activity of Hydrophobic Composite MaHumberto FujitaNoch keine Bewertungen

- Polymer Testing: Material BehaviourDokument6 SeitenPolymer Testing: Material BehaviourRoshni PattanayakNoch keine Bewertungen

- Packaging Materials and Details PDFDokument107 SeitenPackaging Materials and Details PDFfgdgrte gdfsgdNoch keine Bewertungen

- InTech-Polymers and The EnvironmentDokument34 SeitenInTech-Polymers and The EnvironmentVesna AnticNoch keine Bewertungen

- Abstract 2Dokument8 SeitenAbstract 2Beni PrasetyoNoch keine Bewertungen

- Pet DegradaciónDokument4 SeitenPet DegradaciónAntuanet ToledoNoch keine Bewertungen

- Why Recycle PlasticsDokument23 SeitenWhy Recycle PlasticsRoshan NinaweNoch keine Bewertungen

- Applied Catalysis B: Environmental: SciencedirectDokument8 SeitenApplied Catalysis B: Environmental: Sciencedirectpetru apopeiNoch keine Bewertungen

- Growth of Pseudomonas in Polyurethane MediumDokument5 SeitenGrowth of Pseudomonas in Polyurethane MediumIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNoch keine Bewertungen

- Cinetic Study of Photocatalytic Degradation by The (Tio2/uv) System of Indigo Carmine Dye in Aqueous SolutionDokument8 SeitenCinetic Study of Photocatalytic Degradation by The (Tio2/uv) System of Indigo Carmine Dye in Aqueous SolutionIJAR JOURNALNoch keine Bewertungen

- Bioresource Technology 100 (2009) 2569-2574Dokument6 SeitenBioresource Technology 100 (2009) 2569-2574Pothana GandhiNoch keine Bewertungen

- Review On Recent Technologies For Industrial Wastewater TreatmentDokument8 SeitenReview On Recent Technologies For Industrial Wastewater TreatmentIJRASETPublicationsNoch keine Bewertungen

- Degradation of Various Plastics in The Environment: April 2017Dokument23 SeitenDegradation of Various Plastics in The Environment: April 2017Aidatul FitriyahNoch keine Bewertungen

- Catalysis Today: Raffaele Molinari, Angela Caruso, Teresa PoerioDokument6 SeitenCatalysis Today: Raffaele Molinari, Angela Caruso, Teresa PoerioĐại HảiNoch keine Bewertungen

- Biodegradable Polymers For Food Packaging A Review PDFDokument10 SeitenBiodegradable Polymers For Food Packaging A Review PDFsonchemenNoch keine Bewertungen

- Biological Degradation of Polymers in The Environment: John A. GlaserDokument22 SeitenBiological Degradation of Polymers in The Environment: John A. GlaserRahaf AljboriNoch keine Bewertungen

- Nanocellulose Films - Environmentally Safe AlternativeDokument1 SeiteNanocellulose Films - Environmentally Safe AlternativegoldennanukNoch keine Bewertungen

- Mallannao Raquel RDokument38 SeitenMallannao Raquel Rraquel mallannnaoNoch keine Bewertungen

- Heterogeneous Nanocomposite-Photocatalysis for Water PurificationVon EverandHeterogeneous Nanocomposite-Photocatalysis for Water PurificationNoch keine Bewertungen

- 14-11-2022-1668421406-6-Impact - Ijrhal-01. Ijrhal. A Study On Socio-Economic Status of Paliyar Tribes of Valagiri Village AtkodaikanalDokument13 Seiten14-11-2022-1668421406-6-Impact - Ijrhal-01. Ijrhal. A Study On Socio-Economic Status of Paliyar Tribes of Valagiri Village AtkodaikanalImpact JournalsNoch keine Bewertungen

- 09-12-2022-1670567289-6-Impact - Ijrhal-06Dokument17 Seiten09-12-2022-1670567289-6-Impact - Ijrhal-06Impact JournalsNoch keine Bewertungen

- 19-11-2022-1668838190-6-Impact - Ijrhal-3. Ijrhal-A Study of Emotional Maturity of Primary School StudentsDokument6 Seiten19-11-2022-1668838190-6-Impact - Ijrhal-3. Ijrhal-A Study of Emotional Maturity of Primary School StudentsImpact JournalsNoch keine Bewertungen

- 12-11-2022-1668238142-6-Impact - Ijrbm-01.Ijrbm Smartphone Features That Affect Buying Preferences of StudentsDokument7 Seiten12-11-2022-1668238142-6-Impact - Ijrbm-01.Ijrbm Smartphone Features That Affect Buying Preferences of StudentsImpact JournalsNoch keine Bewertungen

- 19-11-2022-1668837986-6-Impact - Ijrhal-2. Ijrhal-Topic Vocational Interests of Secondary School StudentsDokument4 Seiten19-11-2022-1668837986-6-Impact - Ijrhal-2. Ijrhal-Topic Vocational Interests of Secondary School StudentsImpact JournalsNoch keine Bewertungen

- 09-12-2022-1670567569-6-Impact - Ijrhal-05Dokument16 Seiten09-12-2022-1670567569-6-Impact - Ijrhal-05Impact JournalsNoch keine Bewertungen

- 12-10-2022-1665566934-6-IMPACT - IJRHAL-2. Ideal Building Design y Creating Micro ClimateDokument10 Seiten12-10-2022-1665566934-6-IMPACT - IJRHAL-2. Ideal Building Design y Creating Micro ClimateImpact JournalsNoch keine Bewertungen

- 22-09-2022-1663824012-6-Impact - Ijranss-5. Ijranss - Periodontics Diseases Types, Symptoms, and Its CausesDokument10 Seiten22-09-2022-1663824012-6-Impact - Ijranss-5. Ijranss - Periodontics Diseases Types, Symptoms, and Its CausesImpact JournalsNoch keine Bewertungen

- 28-10-2022-1666956219-6-Impact - Ijrbm-3. Ijrbm - Examining Attitude ...... - 1Dokument10 Seiten28-10-2022-1666956219-6-Impact - Ijrbm-3. Ijrbm - Examining Attitude ...... - 1Impact JournalsNoch keine Bewertungen

- 21-09-2022-1663757902-6-Impact - Ijranss-4. Ijranss - Surgery, Its Definition and TypesDokument10 Seiten21-09-2022-1663757902-6-Impact - Ijranss-4. Ijranss - Surgery, Its Definition and TypesImpact JournalsNoch keine Bewertungen

- 29-08-2022-1661768824-6-Impact - Ijrhal-9. Ijrhal - Here The Sky Is Blue Echoes of European Art Movements in Vernacular Poet Jibanananda DasDokument8 Seiten29-08-2022-1661768824-6-Impact - Ijrhal-9. Ijrhal - Here The Sky Is Blue Echoes of European Art Movements in Vernacular Poet Jibanananda DasImpact JournalsNoch keine Bewertungen

- 06-08-2022-1659783347-6-Impact - Ijrhal-1. Ijrhal - Concept Mapping Tools For Easy Teaching - LearningDokument8 Seiten06-08-2022-1659783347-6-Impact - Ijrhal-1. Ijrhal - Concept Mapping Tools For Easy Teaching - LearningImpact JournalsNoch keine Bewertungen

- 19-09-2022-1663587287-6-Impact - Ijrhal-3. Ijrhal - Instability of Mother-Son Relationship in Charles Dickens' Novel David CopperfieldDokument12 Seiten19-09-2022-1663587287-6-Impact - Ijrhal-3. Ijrhal - Instability of Mother-Son Relationship in Charles Dickens' Novel David CopperfieldImpact JournalsNoch keine Bewertungen

- 23-08-2022-1661248618-6-Impact - Ijrhal-6. Ijrhal - Negotiation Between Private and Public in Women's Periodical Press in Early-20th Century PunjabDokument10 Seiten23-08-2022-1661248618-6-Impact - Ijrhal-6. Ijrhal - Negotiation Between Private and Public in Women's Periodical Press in Early-20th Century PunjabImpact JournalsNoch keine Bewertungen

- 23-08-2022-1661248432-6-Impact - Ijrhal-4. Ijrhal - Site Selection Analysis of Waste Disposal Sites in Maoming City, GuangdongDokument12 Seiten23-08-2022-1661248432-6-Impact - Ijrhal-4. Ijrhal - Site Selection Analysis of Waste Disposal Sites in Maoming City, GuangdongImpact JournalsNoch keine Bewertungen

- 05-09-2022-1662375638-6-Impact - Ijranss-1. Ijranss - Analysis of Impact of Covid-19 On Religious Tourism Destinations of Odisha, IndiaDokument12 Seiten05-09-2022-1662375638-6-Impact - Ijranss-1. Ijranss - Analysis of Impact of Covid-19 On Religious Tourism Destinations of Odisha, IndiaImpact JournalsNoch keine Bewertungen

- 25-08-2022-1661426015-6-Impact - Ijrhal-8. Ijrhal - Study of Physico-Chemical Properties of Terna Dam Water Reservoir Dist. Osmanabad M.S. - IndiaDokument6 Seiten25-08-2022-1661426015-6-Impact - Ijrhal-8. Ijrhal - Study of Physico-Chemical Properties of Terna Dam Water Reservoir Dist. Osmanabad M.S. - IndiaImpact JournalsNoch keine Bewertungen

- 08-08-2022-1659935395-6-Impact - Ijrbm-2. Ijrbm - Consumer Attitude Towards Shopping Post Lockdown A StudyDokument10 Seiten08-08-2022-1659935395-6-Impact - Ijrbm-2. Ijrbm - Consumer Attitude Towards Shopping Post Lockdown A StudyImpact JournalsNoch keine Bewertungen

- Monitoring The Carbon Storage of Urban Green Space by Coupling Rs and Gis Under The Background of Carbon Peak and Carbon Neutralization of ChinaDokument24 SeitenMonitoring The Carbon Storage of Urban Green Space by Coupling Rs and Gis Under The Background of Carbon Peak and Carbon Neutralization of ChinaImpact JournalsNoch keine Bewertungen

- 25-08-2022-1661424544-6-Impact - Ijranss-6. Ijranss - Parametric Metric Space and Fixed Point TheoremsDokument8 Seiten25-08-2022-1661424544-6-Impact - Ijranss-6. Ijranss - Parametric Metric Space and Fixed Point TheoremsImpact JournalsNoch keine Bewertungen

- 25-08-2022-1661424708-6-Impact - Ijranss-7. Ijranss - Fixed Point Results For Parametric B-Metric SpaceDokument8 Seiten25-08-2022-1661424708-6-Impact - Ijranss-7. Ijranss - Fixed Point Results For Parametric B-Metric SpaceImpact JournalsNoch keine Bewertungen

- The Analysis On Tourist Source Market of Chikan Ancient Town by Coupling Gis, Big Data and Network Text Content AnalysisDokument16 SeitenThe Analysis On Tourist Source Market of Chikan Ancient Town by Coupling Gis, Big Data and Network Text Content AnalysisImpact JournalsNoch keine Bewertungen

- 24-08-2022-1661313054-6-Impact - Ijranss-5. Ijranss - Biopesticides An Alternative Tool For Sustainable AgricultureDokument8 Seiten24-08-2022-1661313054-6-Impact - Ijranss-5. Ijranss - Biopesticides An Alternative Tool For Sustainable AgricultureImpact JournalsNoch keine Bewertungen

- The Analysis On Environmental Effects of Land Use and Land Cover Change in Liuxi River Basin of GuangzhouDokument16 SeitenThe Analysis On Environmental Effects of Land Use and Land Cover Change in Liuxi River Basin of GuangzhouImpact JournalsNoch keine Bewertungen

- Evaluation of Septic Tank Systems in TheDokument57 SeitenEvaluation of Septic Tank Systems in TheNesru HamidNoch keine Bewertungen

- B53-35H-011 Polyethylene Copolymer: Typical PropertiesDokument2 SeitenB53-35H-011 Polyethylene Copolymer: Typical PropertiesGabs GabrielaNoch keine Bewertungen

- Astm d6392Dokument6 SeitenAstm d6392Talca CalderónNoch keine Bewertungen

- Astm16 0802Dokument4 SeitenAstm16 0802Kalai ArasiNoch keine Bewertungen

- Cold Plasma: A Novel Non-Thermal Technology For Food ProcessingDokument12 SeitenCold Plasma: A Novel Non-Thermal Technology For Food ProcessingRantau SilalahiNoch keine Bewertungen

- Ms 304 / Fall 2007 / The Project Manufacturing An Industrial Machine: Telling The Untold Story Version 1.0 AlphaDokument107 SeitenMs 304 / Fall 2007 / The Project Manufacturing An Industrial Machine: Telling The Untold Story Version 1.0 AlphaHAKAN100% (2)

- ACL Powerx ABC Final 2008 Pastel ColourDokument48 SeitenACL Powerx ABC Final 2008 Pastel Colour85sunaNoch keine Bewertungen

- Dokumen - Tips - Materials For Architects and Builders 56e45be5b5326 289 306Dokument18 SeitenDokumen - Tips - Materials For Architects and Builders 56e45be5b5326 289 306Lola aulikaNoch keine Bewertungen

- Irjet V5i7235Dokument11 SeitenIrjet V5i7235Ring MasterNoch keine Bewertungen

- Hill Grant Proposal FinalDokument4 SeitenHill Grant Proposal Finalapi-253813522Noch keine Bewertungen

- Polymer Blends and CompositesDokument23 SeitenPolymer Blends and Compositesjacky hansdahNoch keine Bewertungen

- 1 s2.0 S2666790822000556 MainDokument16 Seiten1 s2.0 S2666790822000556 MainShrikant DeshmukhNoch keine Bewertungen

- Polymers: Structure, General Properties and ApplicationsDokument19 SeitenPolymers: Structure, General Properties and ApplicationsDhesa HidayatNoch keine Bewertungen

- Polymer Class 1Dokument14 SeitenPolymer Class 1Ñojib Ëasar ProttoyNoch keine Bewertungen

- Ajay Vikram PPP On MsDokument13 SeitenAjay Vikram PPP On MsSunil YadavNoch keine Bewertungen

- An Experimental Investigation of Self Curing Concrete Incorporated With Light Weight Fine Aggregate and Polyethylene GLYCOLDokument7 SeitenAn Experimental Investigation of Self Curing Concrete Incorporated With Light Weight Fine Aggregate and Polyethylene GLYCOLIJIRSTNoch keine Bewertungen

- Isothermal Crystallization and Spherulite Structure of Partially Miscible Polypropylene-Linear Low-Density Polyethylene BlendsDokument12 SeitenIsothermal Crystallization and Spherulite Structure of Partially Miscible Polypropylene-Linear Low-Density Polyethylene BlendsSiddharthBhasneyNoch keine Bewertungen

- POLYETHYLENE (PE) - Grades & ApplicationsDokument2 SeitenPOLYETHYLENE (PE) - Grades & ApplicationsRizwanSaifiNoch keine Bewertungen

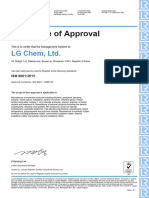

- ISO 9001 - Daesan - General - EN - 201201Dokument1 SeiteISO 9001 - Daesan - General - EN - 201201QcNoch keine Bewertungen

- IAPD Plastics Intro1Dokument4 SeitenIAPD Plastics Intro1eduardo_umNoch keine Bewertungen

- 36-Active Packaging For The Extended Shelf-Life of MeatDokument24 Seiten36-Active Packaging For The Extended Shelf-Life of MeatSaurabh SonawaneNoch keine Bewertungen

- FB2230Dokument3 SeitenFB2230Võ HạnhNoch keine Bewertungen