Beruflich Dokumente

Kultur Dokumente

Condur Eglp

Hochgeladen von

bollidCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Condur Eglp

Hochgeladen von

bollidCopyright:

Verfügbare Formate

Condur EGLP

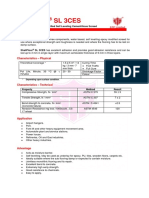

3 COMPONENT LOW EXOTHERM & LONG POTLIFE EPOXY GROUT

DESCRIPTION

Condur EGLP is a three component, high performance, 100% solids, solvent free, epoxy grout system. It is designed to exhibit long potlife and low exotherm during reaction enabling it to be used in mass grouting and large volume placements. Tensile Strength: ASTM C307 Bond Strength: ASTM D4541 Citric Acid 10% Tartaric Acid 10% Acetic Acid 5% Nitric Acid 25% Hydrochloric Acid 25% Sulphuric Acid 50% Sodium Hydroxide 50% Diesel Fuel / Petrol Sugar Solutions Lactic Acid Hydrocarbons Phosphoric Acid 50% Application Temperature: Service Temperature: 7 days > 3 N/mm2 (concrete failure) Excellent Excellent Satisfactory Good Excellent Very Good Excellent Very Good Very Good Very Good Very Good Very Good 15oC - 40oC 5oC - 80oC 7 days 15 N/mm2

Chemical resistance (ASTM D543): :

USES & ADVANTAGES

Cond ur EGLP can be used for grouting heavy machinery Condur base plates, compressors, crane rails, rail tracks, generators, turbines, bridge bearing, steel column base plates, re-profiling and waterproofing pile heads, etc. It is used as the best media to transfer dynamic load effectively. Due to its low exotherm, it is the ideal product for chemical plants, refineries, and the oil & gas industries where thick pours are to be made without causing stress cracks often associated with high exotherm epoxy grouts. Advantages include: Low exotherm with high early mechanical strength development. Long working time, easy to handle and place. Single deep pour up to 300mm. Free flow enables for long pours more than 2 m. Good chemical resistance. Precision alignment under dynamic load conditions. Unaffected by high humidity. Good bonding to most substrates. Adjustable flow at various conditions. Low shrinkage allows final leveling of machine base plates. Prepacked, ready to use. Good impact and vibration resistance.

Note e: - The above data is typical under laboratory conditions and does not constitute a specification. Field trials are recommended. - The working time starts when the hardener is added to the resin material. Do not let the resin and hardener stand still without adding aggregates which may result in shorter working time. Working time will vary depending on the temperature and the quantity mixed. To get the optimum working time keep the material shaded and in a cool place.

SUBSTRATE PREPARATION

Foundation Preparation Concrete should be old enough, if it is newly placed concrete then it needs to be 21-28 days old and to have reached its design strength. Concrete should have attained a minimum compressive strength of 21 MPa, higher strength concrete is

TYPICAL PROPERTIES

Components: Form: Appearance: Mixed Density (kg/ltr): ASTM C905 Working Time: Compressive Strength: ASTM C579 Flexural Strength: ASTM C580 3 (Base, Hardener & Filler) Pourable Black (when mixed) 2.05 + 0.05 2 - 3 hrs 1 day 7 days 14 days 7 days

recommended for optimum performance of grout. All surfaces should be dry, clean, free from standing water, grease, curing compounds, mould oils, all loosely adhered aggregates and cement particles, etc. Chip the concrete surface so aggregates are exposed to ensure all laitance and weak particles are removed. Alternatively use a spray on surface retarder when placing concrete. The exposed aggregate amplitude should not be greater than 10-15 mm.

Rev. 002 : Jul 2010

50 75 85 30

N/mm2 N/mm2 N/mm2 N/mm2

Condur EGLP

3 COMPONENT LOW EXOTHERM & LONG POTLIFE EPOXY GROUT

Chamfer the edges of the concrete 45 degrees to 50 mm. width to avoid sharp corners which helps to reduce the potential for cracking. If anchor bolt sleeves are to be placed, be sure all water is removed and the void completely dry. Shade the foundation from direct sunlight for at least 24 hrs before grouting and 48 hrs after grouting. Equipment Preparation When pouring in multiple layers ensure the previous layer is hardened and cooled. For deep pour applications pouring in a single layer with rebar installed, use Condur EGLP.

MIXING

Before mixing ensure all the components are cool, shaded and dry. If not preconditioned store all components below 25 C for 24 hrs before using. The temperature of grout, baseplate and foundation are more important than the air temperature because they are directly related to affect the flow of grout. Add component A & B in a mixing vessel and mix under slow speed (RPM 400) for approximate 1 minute. Then add component C and continue mixing until a flowing uniform grout is achieved. Avoid excessive mixing which will result in reduction of working time and heat generation.

o

Ensure the surface of base plate to be bonded with grout is free from rust, coatings, wax, oil, grease or scale. Mechanical methods such as grinding, sanding, etc can be used to remove laitance, scale, etc to give a sound and clean surface. Primers can be used when there is a long delay in cleaning and grouting which could allow rusting and contamination of base plate. Formwork Preparation Before placing the formwork ensure the foundation and equipment is protected from rain or moisture. Seal off the areas that will not be grouted. Place forms no greater than 50 to 100 mm away from the edge of individual base plate or sole plate. However this may vary depending on the site requirement and application. Excessive edges/shoulders, may create thermal stress resulting in cracks. For long and narrow placements create a headbox to maintain pressure and to enhance proper placement. Forms should be liquid tight, they should be sealed with sealant, putty, foam or caulk. Do not allow to contact the grout. For long pours it is recommended to install expansion joints or divide the sections not exeeding 1.1m in length. This reduces the opportunity for cracking due to the exothermic reaction of the material and differences in linear thermal expansion & contraction between the epoxy grout and concrete. Deep Pour Recommendations Where ever a deep pour is necessary it is recommended to use rebar of 9 to 14 mm diameter to minimize stress cracking. Grouting should be done in multiple layers if more than the recommended thickness.

APPLICATION

While grouting the base plates ensure there is sufficient pressure head to maintain movement of grout. Base plates with a flat base pour the grout from one side through the other across the short dimensions. Ensure entrapped air can escape when grouting closed areas. Where grout cannot flow or have smooth movement because of the length of pour pushing aids like steel chains, strips of plywood, etc can be used. The base plate with anchor bolts, dowel, starter bar, etc should be grouted first followed by the base plate. If grouting in multiple layers, it is necessary to sprinkle a small amount of 2.5 mm aggregate over the first layer before the grout reaches its setting time. Before placement of 2 layer brush out loose aggregates from the 1 pour. Another method is to scrabble gently the top surface and make it rough when grout reaches near to its setting time.

st nd

GROUTING THICKNESS

Minimum 10 mm to a maximum 300 mm. For grouting more than 70 mm in a single layer it is recommended to use rebar to avoid cracks due to thermal stress.

Condur EGLP

3 COMPONENT LOW EXOTHERM & LONG POTLIFE EPOXY GROUT

TYPICAL DETAIL

3 4 2

Chamfered Edge

FINISHING

A smooth finish may be achieved before the grout reaches its setting time by spraying or brushing the surface with xylene, white spirit or epoxy grade thinner and then by using the steel trowel or wooden trowel level the surface.

1

Waxed Form

CURING

Cure time will depend on the ambient and substrate temperature. For the best results pour the grout and cure above 12oC The grouts setting time will be delayed and will not achieve the desired properties at temperatures below 5oC. For cold weather grouting please contact Cormix Technical Department for assistance.

5 Figure 1 - Regular Equipment 3 4

2 10 1

Figure 2 - Engine with Oil Pan 3 4

IMPORTANT NOTES TO ACHIEVE PRODUCT PERFORMANCE

8 7 2

Do not alter the ratio of resin and hardener. Fillers can be varied as per site requirement. Do not thin the grout with solvent or water to make it

1

more flowable. Always use a headbox to maintain pressure and the grouts flowability. Epoxy based grouts sometimes develop cracks. Cracks are generally caused by thermal stresses, temperature

1 3mm.

5 Figure 3 - Rail or Soleplate 9 7 2 1 Figure 4 - Typical Rail With Expansion Joint Section 3 6 2 1 Figure 5 - Typical Epoxy Chock Application 4 5 8 6

difference, sharp corners and edges, etc. Horizontal edge cracks may occur just below the grout concrete interface especially in outdoor installations. Chamfering the concrete edge helps in reducing such cracks. To reduce/prevent curling use dowels or scabble back to expose rebar. Following proper installation procedures will reduce the amount of crack development. The procedures contained is this data sheet highlight generally accepted field practises for successful grouting. These may be followed, modified or rejected by the user, however, they are not Cormix are responsible for planning & understanding the installation appropriate to the conditions. If planned procedures differ from the data sheet contact Cormix Technical Service Department. If cracks develop use Condur SC (Low viscosity epoxy resin system) to repair the cracks. Consult Cormix.

Key

1. Concrete Foundation 2. Grout 3. Equipment Base 4. Anchor Bolt 5. Anchor Bolt Sleeve Seal 6. Form 7. Soleplate or Rail 8. Shim or Chock 9. Expansion Joint 10. Dowel or exposed rebar

Condur EGLP

3 COMPONENT LOW EXOTHERM & LONG POTLIFE EPOXY GROUT

Make certain the most current version of the TDS & MSDS are being used by cantacting Cormix CS. Proper application is the responsibility of the user, field visits by Cormix personnel are for the purpose of making technical recommendations only & not for supervising or providing quality control at the job site.

TECHNICAL SERVICE

The Cormix International Technical Service Department is available to assist you in the correct use of our products and its resources are at your disposal entirely without obligation.

CLEANING

Clean all tools and equipment immediately with Cormix Cleaner Cleaner.

QUALITY ASSURANCE

ISO 9001 : 2008 verified by TUV Nord.

PACKAGING

A+B+C 10 & 25 kg. pre-measured sets or larger packaging upon request.

CONTACT DETAILS Cormix International Limited

Regional Office, 89 Romklao Rd., Sansab, Minburi, Bangkok 10510 Tel. (66 2) 917 3955-8, 543 8890 Fax. (66 2) 917 3959, 543 8891 http://www.cormix.com E-mail : info@cormix.com

STORAGE & SHELF LIFE

Store in dry conditions between 5oC - 30oC. The shelf life is 12 months when unopened and stored correctly.

HEALTH & SAFETY

Avoid contact with skin and eyes and avoid breathing vapour. Use only in well ventilated areas away from heat sparks or naked flame. Wear suitable protective clothing, gloves and eye protection when mixing or using. If poisoning occurs, contact a doctor or Poisons Information Centre. If swallowed, do NOT induce vomiting give a glass of water. If in eyes, hold eyes open, flush with water for at lease 15 minutes and see a doctor. If skin contact occurs, remove contaminated clothing and wash skin thoroughly with soap and water.

NOTE : Every reasonable precaution is taken in the manufacture of all CORMIX-products to ensure that they comply with CORMIXs high standard of quality. The recommendations and properties of the product are based upon what is believed to be the most reliable information available, and are not intended as recommendations which infringe on other patents. Although all CORMIX-products are subject to rigid quality tests, no specific guarantee can be given, because results depend, not only on quality, but also on other factors beyond our control. We welcome therefore consultation in the event of doubt concerning application, or performance, and point out that oral recommendations, which vary from the instructions contained herein, are not binding without written confirmation by CORMIX. All transactions shall be subject to our terms and conditions of sale-delivery-and-service. This data sheet supersedes the previous one and a reprint may be issued without notice to supersede this edition, as and when deemed necessary. The information given in this leaflet is to the best of our knowledge true and reliable. Field service where provided does not constitute supervisory responsibility.Our guarantee is therefore limited to the quality of materials delivered.

Das könnte Ihnen auch gefallen

- Normac Cement Guide ADS - Rev2Dokument6 SeitenNormac Cement Guide ADS - Rev2kenedi74Noch keine Bewertungen

- Ocbre Spec.Dokument12 SeitenOcbre Spec.Rana MahatoNoch keine Bewertungen

- Euco TopDokument2 SeitenEuco Toppravi3434Noch keine Bewertungen

- Weber Kol Fermafix IngDokument2 SeitenWeber Kol Fermafix IngGökhan PanpaNoch keine Bewertungen

- WEBER Kol SRK KONFOR Konsantre IngDokument2 SeitenWEBER Kol SRK KONFOR Konsantre IngGökhan PanpaNoch keine Bewertungen

- Installation ManualDokument21 SeitenInstallation ManualVarun H RaoNoch keine Bewertungen

- Weber - Kol SRK Konfor en Rev007Dokument2 SeitenWeber - Kol SRK Konfor en Rev007Gökhan PanpaNoch keine Bewertungen

- WEBER Kol SRC Max IngDokument2 SeitenWEBER Kol SRC Max IngGökhan PanpaNoch keine Bewertungen

- Cmci Cmci: High Performance Epoxy Grout SystemDokument2 SeitenCmci Cmci: High Performance Epoxy Grout Systempravi3434Noch keine Bewertungen

- XL70 SolventDokument3 SeitenXL70 SolventRaj K SharmaNoch keine Bewertungen

- Amiantit. Field Installation ProcedureDokument37 SeitenAmiantit. Field Installation ProcedureABAID ULLAHNoch keine Bewertungen

- Jazeera Epo-Mortar SL5000Dokument3 SeitenJazeera Epo-Mortar SL5000Ahmad BougeisNoch keine Bewertungen

- Cmci Cmci: High Flow Epoxy Grout SystemDokument2 SeitenCmci Cmci: High Flow Epoxy Grout Systempravi3434Noch keine Bewertungen

- Rrs 2Dokument18 SeitenRrs 2153-B RAKSHITHANoch keine Bewertungen

- WEBER Kol SRK Ing Sari BantDokument2 SeitenWEBER Kol SRK Ing Sari BantGökhan PanpaNoch keine Bewertungen

- Portland Cement GroutingDokument18 SeitenPortland Cement Groutingapoorv mishraNoch keine Bewertungen

- STP ShaliFloor SL 3CESDokument3 SeitenSTP ShaliFloor SL 3CESRana MahatoNoch keine Bewertungen

- Jazeera Epo-Mortar NBDokument3 SeitenJazeera Epo-Mortar NBAhmad BougeisNoch keine Bewertungen

- FloArm Screed Eco Ver7Dokument4 SeitenFloArm Screed Eco Ver7imsNoch keine Bewertungen

- Method Statement - Plastering, Dated. Jan. 03. 2007Dokument5 SeitenMethod Statement - Plastering, Dated. Jan. 03. 2007mohamed4879Noch keine Bewertungen

- Plastering & Rendering: For Residential Project (Up To 24m) Ard/Project SpecificationsDokument23 SeitenPlastering & Rendering: For Residential Project (Up To 24m) Ard/Project SpecificationsAnjali Kolangara100% (1)

- Weberfloor - 630 - TSC - 01 (1) - 221109 - 183928Dokument3 SeitenWeberfloor - 630 - TSC - 01 (1) - 221109 - 183928Pacific CoastNoch keine Bewertungen

- Tiles BS 5385Dokument10 SeitenTiles BS 5385Kalin83% (6)

- Technical Services: Installation Instructions For Gerflor Homogeneous Vinyl SheetgoodsDokument7 SeitenTechnical Services: Installation Instructions For Gerflor Homogeneous Vinyl SheetgoodsMark GoducoNoch keine Bewertungen

- Squash Court Finish PDFDokument5 SeitenSquash Court Finish PDFFrancis T. TolibasNoch keine Bewertungen

- Jazeera Epo-Mortar SLDokument3 SeitenJazeera Epo-Mortar SLAhmad BougeisNoch keine Bewertungen

- Shaliseal Ps GG: DescriptionDokument3 SeitenShaliseal Ps GG: DescriptionVikas Singh ChandelNoch keine Bewertungen

- Thermobreak Sheet Installation Instructions DuctworkDokument8 SeitenThermobreak Sheet Installation Instructions Ductworkmepnical esNoch keine Bewertungen

- XL70 W Textured Coating Mar 2019Dokument2 SeitenXL70 W Textured Coating Mar 2019Raj K SharmaNoch keine Bewertungen

- Nitomortar HBDokument4 SeitenNitomortar HBBalasubramanian AnanthNoch keine Bewertungen

- Speaker Bio - : Anupam Shil Is Working With STP Limited As SBU HeadDokument38 SeitenSpeaker Bio - : Anupam Shil Is Working With STP Limited As SBU HeadRainakNoch keine Bewertungen

- Renderoc TGDokument4 SeitenRenderoc TGBalasubramanian Ananth100% (1)

- Jazeera Anti-Skid EpoxyDokument3 SeitenJazeera Anti-Skid EpoxyAhmad BougeisNoch keine Bewertungen

- Vitrified TilesDokument3 SeitenVitrified Tilesamitdey_dey18164Noch keine Bewertungen

- TDS - Mastertop 300Dokument3 SeitenTDS - Mastertop 300Venkata RaoNoch keine Bewertungen

- Weberfloor 514 SL TDS SelflevelDokument3 SeitenWeberfloor 514 SL TDS SelflevelMusab yassinNoch keine Bewertungen

- Amer240 Edge CoverageDokument4 SeitenAmer240 Edge CoverageEugene DoyleNoch keine Bewertungen

- Masterflow: Cementitious High Strength Non-Shrink Precision GroutDokument3 SeitenMasterflow: Cementitious High Strength Non-Shrink Precision GroutAydın VarolNoch keine Bewertungen

- Solvent Cementing Literature As On WebsiteDokument5 SeitenSolvent Cementing Literature As On WebsiteNaeemSiddiquiNoch keine Bewertungen

- TDS - Mastertop 100Dokument3 SeitenTDS - Mastertop 100Venkata RaoNoch keine Bewertungen

- Exterior Wall CladdingDokument17 SeitenExterior Wall CladdingSehaj PreetNoch keine Bewertungen

- Laticrete Hydro Ban Installation InstructionsDokument5 SeitenLaticrete Hydro Ban Installation InstructionsAlex LongNoch keine Bewertungen

- Installation MasterStepRubberTileDokument5 SeitenInstallation MasterStepRubberTileShahid Basha SkNoch keine Bewertungen

- ShaliSeal PS PGDokument3 SeitenShaliSeal PS PGpoojaNoch keine Bewertungen

- Eco Application GuideDokument8 SeitenEco Application GuidemsbaupartnerNoch keine Bewertungen

- Joint Guard: General Purpose Ready To Use MasticDokument1 SeiteJoint Guard: General Purpose Ready To Use MasticmrfreshncoolNoch keine Bewertungen

- Cemtop 400SD PDFDokument4 SeitenCemtop 400SD PDFriverwilliamsNoch keine Bewertungen

- Conbextra GP TDSDokument4 SeitenConbextra GP TDSMoataz MedhatNoch keine Bewertungen

- Method Statement - DR - Fixit Flexi PU270iDokument4 SeitenMethod Statement - DR - Fixit Flexi PU270iKiran KumarNoch keine Bewertungen

- SOP-PVC FlooringDokument7 SeitenSOP-PVC FlooringNitish Singh (Monty)Noch keine Bewertungen

- Jazeera Floor GuardDokument3 SeitenJazeera Floor GuardAhmad BougeisNoch keine Bewertungen

- Guia de Especificaciones de Grout PDFDokument7 SeitenGuia de Especificaciones de Grout PDFxtrememikeNoch keine Bewertungen

- Installation GuideDokument3 SeitenInstallation GuideVinka PrintNoch keine Bewertungen

- Preprufe 300R & 160RDokument6 SeitenPreprufe 300R & 160RvelarajanNoch keine Bewertungen

- Estoseal c500PF - Cold Applied SealantDokument2 SeitenEstoseal c500PF - Cold Applied SealantjoshepNoch keine Bewertungen

- Grouting Works: Dfcu - HRRL Project, RajasthanDokument12 SeitenGrouting Works: Dfcu - HRRL Project, Rajasthankranthi kumarNoch keine Bewertungen

- How to Build a Simple Three Bedroom Shipping Container HouseVon EverandHow to Build a Simple Three Bedroom Shipping Container HouseBewertung: 4 von 5 Sternen4/5 (2)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitVon EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNoch keine Bewertungen

- GEM LeafletDokument3 SeitenGEM LeafletbollidNoch keine Bewertungen

- Pump Dab - Brochure En12845Dokument1 SeitePump Dab - Brochure En12845bollidNoch keine Bewertungen

- Resume SamplesDokument3 SeitenResume SamplesbollidNoch keine Bewertungen

- Ral Chart PDFDokument3 SeitenRal Chart PDFErunerNoch keine Bewertungen

- 1 Steel Structure Data 1Dokument1 Seite1 Steel Structure Data 1bollidNoch keine Bewertungen

- 1 Tank - Settlement Criteria PDFDokument1 Seite1 Tank - Settlement Criteria PDFbollidNoch keine Bewertungen

- 1 Steel Structure Data 2Dokument1 Seite1 Steel Structure Data 2bollidNoch keine Bewertungen

- Ceilcote 748Dokument1 SeiteCeilcote 748bollidNoch keine Bewertungen

- Hot Rolled Plates: Size Width WT / SQ FT WT / Sheet Size Width WT / SQ FT WT / SheetDokument1 SeiteHot Rolled Plates: Size Width WT / SQ FT WT / Sheet Size Width WT / SQ FT WT / SheetbollidNoch keine Bewertungen

- 1 Catalog Steel PDFDokument1 Seite1 Catalog Steel PDFbollidNoch keine Bewertungen

- 1 Nucor Yamato SymbolsDokument1 Seite1 Nucor Yamato SymbolsbollidNoch keine Bewertungen

- Pages From Plant Design For Chemical Engineers PDFDokument1 SeitePages From Plant Design For Chemical Engineers PDFbollidNoch keine Bewertungen

- 1 Steel Structure Data 1Dokument1 Seite1 Steel Structure Data 1bollidNoch keine Bewertungen

- NucorDokument1 SeiteNucorbollidNoch keine Bewertungen

- Nucor-Yamato Steel: Hot Rolled Steel Sheet Piling PZ Sheet PilingDokument1 SeiteNucor-Yamato Steel: Hot Rolled Steel Sheet Piling PZ Sheet PilingbollidNoch keine Bewertungen

- X Settlement CriteriaDokument1 SeiteX Settlement CriteriabollidNoch keine Bewertungen

- Devcon Plastic Putty A PDFDokument2 SeitenDevcon Plastic Putty A PDFbollidNoch keine Bewertungen

- X Atlantic IrelandDokument1 SeiteX Atlantic IrelandbollidNoch keine Bewertungen

- X FlaringDokument1 SeiteX FlaringbollidNoch keine Bewertungen

- Glossary of Terms State SteelDokument1 SeiteGlossary of Terms State SteelbollidNoch keine Bewertungen

- European Structural SectionsDokument32 SeitenEuropean Structural Sectionskogi3075100% (3)

- X Well ProductionDokument1 SeiteX Well ProductionbollidNoch keine Bewertungen

- Rolling Practice and Rolling Tolerances: August 2013 General Notes - 4 Nucor-Yamato SteelDokument1 SeiteRolling Practice and Rolling Tolerances: August 2013 General Notes - 4 Nucor-Yamato SteelbollidNoch keine Bewertungen

- 1 Structure CamberDokument1 Seite1 Structure CamberbollidNoch keine Bewertungen

- 1 Nucor Yamato PDFDokument1 Seite1 Nucor Yamato PDFbollidNoch keine Bewertungen

- Nucor-Yamato Steel: Sheet Piling DealersDokument1 SeiteNucor-Yamato Steel: Sheet Piling DealersbollidNoch keine Bewertungen

- 1 Index Steel StructureDokument1 Seite1 Index Steel StructurebollidNoch keine Bewertungen

- 1 Steel Grades PDFDokument1 Seite1 Steel Grades PDFbollidNoch keine Bewertungen

- Rolling Practice and Rolling Tolerances: August 2013 General Notes - 4 Nucor-Yamato SteelDokument1 SeiteRolling Practice and Rolling Tolerances: August 2013 General Notes - 4 Nucor-Yamato SteelbollidNoch keine Bewertungen

- 1 Catalog Steel PDFDokument1 Seite1 Catalog Steel PDFbollidNoch keine Bewertungen

- Engineering Vol 56 1893-10-06Dokument33 SeitenEngineering Vol 56 1893-10-06ian_newNoch keine Bewertungen

- Axis TurbineDokument7 SeitenAxis TurbineBhertrand GomesNoch keine Bewertungen

- Iso AnnealingDokument2 SeitenIso AnnealingPurushottam Sutar100% (1)

- Vacuum Testing of Fixed Roof Welded Storage Tanks As Per API 650,620Dokument7 SeitenVacuum Testing of Fixed Roof Welded Storage Tanks As Per API 650,620Rakesh RanjanNoch keine Bewertungen

- 10 Thermal TechnologyDokument97 Seiten10 Thermal TechnologyNguyenHuanNoch keine Bewertungen

- Group #4: September 25, 2019Dokument5 SeitenGroup #4: September 25, 2019MIKAYLA ELAINE P. DELA CRUZNoch keine Bewertungen

- MOLECONCEPTREDOXREACTIONCOMPLETEPACAKGEDokument52 SeitenMOLECONCEPTREDOXREACTIONCOMPLETEPACAKGENikhil PalNoch keine Bewertungen

- Laboratory SafetyDokument2 SeitenLaboratory Safetyann wamburaNoch keine Bewertungen

- A Guide For Tank InspectionDokument10 SeitenA Guide For Tank InspectionAmer Y KNoch keine Bewertungen

- NTK O2 Sensor HistoryDokument9 SeitenNTK O2 Sensor Historyonukvedat7219Noch keine Bewertungen

- 393Dokument8 Seiten393Ram MohanNoch keine Bewertungen

- The Calorific Value of A Fuel Is TheDokument4 SeitenThe Calorific Value of A Fuel Is TheRana PrathapNoch keine Bewertungen

- BeerDokument21 SeitenBeermichol20140% (1)

- Deocument 9172Dokument21 SeitenDeocument 9172jeffrey.beach2560% (1)

- Reactor DesignDokument27 SeitenReactor Designcheckmeout803100% (3)

- Fan Lub CFM56-7 - HandbookDokument44 SeitenFan Lub CFM56-7 - HandbookANDRANoch keine Bewertungen

- Unit 3: Aldehydes and Ketones: EngageDokument10 SeitenUnit 3: Aldehydes and Ketones: Engagejerome timmangoNoch keine Bewertungen

- Aluminium Silicate - WikipediaDokument2 SeitenAluminium Silicate - Wikipediamovie hunterNoch keine Bewertungen

- Geopolymer Book Chapter1Dokument37 SeitenGeopolymer Book Chapter1Aslam HutagiNoch keine Bewertungen

- Shell Rl3 MsdsDokument8 SeitenShell Rl3 MsdsHitesh ShahNoch keine Bewertungen

- Chemistry 12 - Reaction KineticsDokument16 SeitenChemistry 12 - Reaction Kineticscharanbagh6402Noch keine Bewertungen

- PorosityDokument25 SeitenPorosityMichael AndersonNoch keine Bewertungen

- Module 2 - Drug AbuseDokument35 SeitenModule 2 - Drug AbuseMark Johnuel DuavisNoch keine Bewertungen

- Expt 7 - Unit Cells (Virtual Lab)Dokument9 SeitenExpt 7 - Unit Cells (Virtual Lab)Angel De LoyolaNoch keine Bewertungen

- Pure Substances MixturesDokument2 SeitenPure Substances MixturesShannen Abegail FernandezNoch keine Bewertungen

- Sanitary Engineering Lec.: November 2015Dokument110 SeitenSanitary Engineering Lec.: November 2015Dynamo DSNoch keine Bewertungen

- Prria MemoDokument4 SeitenPrria MemoRebecca C. LewisNoch keine Bewertungen

- Thermocouples and SensorsDokument40 SeitenThermocouples and SensorsEliasNoch keine Bewertungen

- Nadcap 2020Dokument4 SeitenNadcap 2020amirkhakzad498Noch keine Bewertungen

- Manual de Piezómetro Neumático RSTDokument10 SeitenManual de Piezómetro Neumático RSTedgarias00Noch keine Bewertungen