Beruflich Dokumente

Kultur Dokumente

Aurand MP6 - 12rev

Hochgeladen von

cabarbozavOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Aurand MP6 - 12rev

Hochgeladen von

cabarbozavCopyright:

Verfügbare Formate

BEFORE OPERATING: The Aurand MP Pneumatic Tool has been thoroughly tested and shipped complete, but DO NOT

attempt to operate without reading the following instructions. 1. The air line must have automatic filtering and lubrication. The compressed air to the motor must be free of moisture and dirt or damage will occur. The equipment must be capable of handling at least 42 cu. ft. of air per minute at 90 lbs. air pressure. 2. Connect to air line, using a minimum 3/8 inside diameter hose. OPERATING INSTRUCTIONS: 1. Wear safety glasses and hearing protection. 2. Grasp both handles and raise front of tool from surface. 3. Squeeze trigger and allow cutters to come up to speed before applying to surface. 4. Using both hands, guide tool in a forward and backward motion to assure complete coverage. Let weight of tool do the work. Never apply pressure as this will slow down motor speed and cause damage to motor, gears, and cutter bundles. DEPTH ADJUSTMENT: When adjustment is required to compensate for cutter wear: 1. Loosen SCREW (7M) 2. Move DEPTH SHOE (6M) up or down as required. (Cutters should have play in them when touching work surface) 3. Tighten SCREW (7M) CUTTER BUNDLE REPLACEMENT: 1. Install COTTER PIN & WASHER (28M) on both ends of SPINDLE (24M-1 or 24ME-1). Cutter tips must point in direction of rotation. 2. Slide CUTTER BUNDLE (90M) and CUTTER BUNDLE FELT (29M) from SPINDLE. 3. Slide new CUTTER BUNDLE FELT & CUTTER BUNDLES on SPINDLE. CUTTER TIPS must point in direction of rotation. 4. Install COTTER PINS & WASHER on both ends of SPINDLE.

MP6 MP6E

LUBRICATION: Check oil (1245) in Gear Housing after every 8 hours of operation. Remove Screw (4M). With tool sitting level add 1245 Oil through hole. Then replace SCREW & PLUG.

! WARNING

! WARNING

! WARNING

! WARNING

90 p.s.i.g. (6.2 bar/620kPa)

! WARNING

ON OFF

! WARNING

Wear hearing protection when operating this tool.

Wear eye protection when operating or performing maintenance on this tool.

Do not overreach when operating this tool. Keep body stance balanced and firm

Operate at 90 p.s.i.g. (6.2 bar/620kPa) maximum air pressure

Turn off air supply and disconnect air supply hose before installing, removing or adjusting any accessory on this tool, or before performing any maintenance on this tool.

Do not use damaged, frayed, or deteriorated air hoses and fittings.

Parts List & Operating Instructions

Aurand Manufacturing & Equipment Company 1210 Ellis St Cincinnati OH 45223-1843 aurand@fuse.net 800-860-2872 or 513-541-7200 Fax 513-541-3065

We gladly accept:

www.aurand.net

Aurand has manufactured exclusively in the USA since 1937.

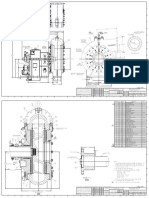

19M 65MP 66MP 42MP 64MP 43MP 7MP 56MP 17MP 2MP 10MP 31M 32M 11MP 3MP 18MP 12MP 5MP-1 769 9MP 14MP 1MP 79MP-1 79MP-2 664 86M 85M 85M 79MP-3 28M 19M 81M 79MP-2 87M 62MP 45MP 31M 86M 29M 21MP 80M 26M 14M 13MP 16M 17M 29MP 4M 5M 7M 27M 79M 78M 31M 3M 16MP 69MP 68MP 64MP 65MP 27M 47MP 49MP 48MP 50MP 15M 29M 28M 46MP 90M 78M 79M 27M 24M-1 25MP 26M 6M 30M-1 2M-1 31M

41MP

1040V-14 1043-V5

90M

1087

PART NUMBERS

664 Screw 769 Ball Valve 1087 Handle Grip 1040V-14 Screw 1043V-5 L Washer 2M-1 Spade Handle 3M Handle Screw & washer 4M Oil Screw 5M Plug 6M Depth Shoe 7M Shoe Screw 14M Worm Key 15M Ball Bearing-Worm 16M Washer, Worm Shaft 17M Screw, Worm Shaft 90M Cutter Bundle 90ME Cutter Bundle (Not Shown) 24M-1 Spindle 24ME-1 Spindle (Not Shown) 26M Worm Wheel Key 27M Ball Bearing 28M Washer & Key 29M Cutter Bundle Felt 30M-1 Guard 30ME-1 Guard (Not Shown) 31M Guard Screw & Washer 32M Housing & Bering Plate 33M Screw & Washer 76M Cotter Pin 78M Side Gasket Plate 79M Shaft Seal 80M Rear Bearing Gasket 81M Side PLate Seal Screw 85M Wheel 86M Washer 87M Stop Nut 1MP Valve Plug 2MP Taper Plug 3MP Screen 5MP Valve Rod 7MP Hub 9MP Valve Spring 10MP Dowel Pin 11MP Adapter 12MP Handle 13MP Worm 14MP Gasket 16MP Screw, Handle 17MP Trigger 18MP Gasket 21MP Bearing Retainer 25MP Worm Wheel 29MP Motor Housing 41MP Rear Plate 42MP Ball Bearing 43MP Spacer Washer 45MP Gasket 46MP Rotor Blade 47MP Cylinder 48MP Rotor 49MP Shaft 50MP Front Plate 56MP Trigger Pin 62MP Jet 64MP Weight 65MP Pin 66MP Plunger Head 68MP Plunger Stem 69MP Spring 70MP Rotor Key 79MP-1 Handle 79MP-2 Handle Support 79MP-3 Axle 1245 Oil (8 oz. Tube)

Das könnte Ihnen auch gefallen

- Sebm013001 PDFDokument140 SeitenSebm013001 PDFZT350100% (1)

- Ebs3 - Electronic Braking SystemDokument44 SeitenEbs3 - Electronic Braking SystemMile Martinov100% (3)

- VOLVO 240 SECT. 2 - ENGINE d20 d24 - Repairs Part 2Dokument96 SeitenVOLVO 240 SECT. 2 - ENGINE d20 d24 - Repairs Part 2Myselvf100% (1)

- P-400 Swivel & UniflexDokument4 SeitenP-400 Swivel & UniflexIvan Villarreal LopezNoch keine Bewertungen

- US Seal MFG Catalog 2015Dokument218 SeitenUS Seal MFG Catalog 2015Eddy OrtegaNoch keine Bewertungen

- Product Presentation - Oct 2016Dokument143 SeitenProduct Presentation - Oct 2016Dwi PutraNoch keine Bewertungen

- TM 9-2350-258-34-1 Tank, Combat, Full Tracked 105-mm Gun M48A5 Hull 1977Dokument116 SeitenTM 9-2350-258-34-1 Tank, Combat, Full Tracked 105-mm Gun M48A5 Hull 1977beppefranz100% (1)

- Model Fa5 and Fa5T: Parts, Operation and Maintenance ManualDokument80 SeitenModel Fa5 and Fa5T: Parts, Operation and Maintenance Manualalfredo_mtz_097100% (2)

- 2020 Product CatalogDokument60 Seiten2020 Product CatalogGasim MohNoch keine Bewertungen

- IPU Spring Starter PDFDokument6 SeitenIPU Spring Starter PDFHumberto Mateus Becerra100% (1)

- Embragues para Motores EstacionariosDokument12 SeitenEmbragues para Motores EstacionariosJiyaYsqn100% (1)

- Catalogo Ramde ColombiaDokument16 SeitenCatalogo Ramde ColombiaSharay Villanova100% (1)

- AF Catalogo de Balatas Malacates PDFDokument28 SeitenAF Catalogo de Balatas Malacates PDFEduardoCastillo100% (1)

- WINCHE FA5A-MR Ingersoll RandDokument65 SeitenWINCHE FA5A-MR Ingersoll RandcabarbozavNoch keine Bewertungen

- Retsco Type B RrvalveDokument2 SeitenRetsco Type B RrvalveGregory Stewart100% (1)

- 5 Alarms and Fault FindingDokument20 Seiten5 Alarms and Fault Findingcengiz kutukcuNoch keine Bewertungen

- Mud King Swivel Cartridge GuideDokument16 SeitenMud King Swivel Cartridge GuideVishal RamsookNoch keine Bewertungen

- 使用说明书Operation ManualDokument84 Seiten使用说明书Operation ManualMohamed el attarNoch keine Bewertungen

- A30 Trailer Mounted Pump Parts ManualDokument100 SeitenA30 Trailer Mounted Pump Parts ManualPaul GuillaumeNoch keine Bewertungen

- Pompe Wilden PDFDokument184 SeitenPompe Wilden PDFverat81100% (1)

- Emsco FC 2200 Pump PartsDokument1 SeiteEmsco FC 2200 Pump PartsleoNoch keine Bewertungen

- ProtoDokument456 SeitenProtoissloNoch keine Bewertungen

- Pz-7 КаталогDokument25 SeitenPz-7 КаталогlionelNoch keine Bewertungen

- Camless Two Stroke Main Propulsion engine-B&W ME - CDokument21 SeitenCamless Two Stroke Main Propulsion engine-B&W ME - CNarayana Prakash96% (52)

- Model 3500 Multi-Pin PDFDokument3 SeitenModel 3500 Multi-Pin PDFAlejandro ZanellaNoch keine Bewertungen

- HH 102 SemitrailerDokument6 SeitenHH 102 SemitrailerleoNoch keine Bewertungen

- Control de Velocidad y Reparto de Carga. Woodward 2301aDokument40 SeitenControl de Velocidad y Reparto de Carga. Woodward 2301acafoncho100% (1)

- CARLYLE OPEN DRIVE COMPRESSORS APPLICATION DATADokument9 SeitenCARLYLE OPEN DRIVE COMPRESSORS APPLICATION DATAAhmed AbdelrahimNoch keine Bewertungen

- Air Starters - Series 150bmpDokument16 SeitenAir Starters - Series 150bmpAntonio SerranoNoch keine Bewertungen

- ARIEL JG AND JGA COMPRESSOR SPECSDokument4 SeitenARIEL JG AND JGA COMPRESSOR SPECSparathasiNoch keine Bewertungen

- MUD PUMP EXPENDABLES Gardner Denver PDFDokument8 SeitenMUD PUMP EXPENDABLES Gardner Denver PDFleoNoch keine Bewertungen

- MSI ProductDokument218 SeitenMSI ProductRaul Costiniuc0% (1)

- 2600 SeriesDokument94 Seiten2600 SeriesFabio Peres de LimaNoch keine Bewertungen

- The Horizontal HD Pump Parts ListDokument17 SeitenThe Horizontal HD Pump Parts ListVictor AlcantaraNoch keine Bewertungen

- Physcis Ac Generator ReportDokument15 SeitenPhyscis Ac Generator ReportVishal HirrtikNoch keine Bewertungen

- Drawwork Cathead Control Panel, Model 9015A030 M851001467-ASM-001Dokument1 SeiteDrawwork Cathead Control Panel, Model 9015A030 M851001467-ASM-001andrei20041Noch keine Bewertungen

- Demco DM Iom PDFDokument24 SeitenDemco DM Iom PDFAshok SureshNoch keine Bewertungen

- Instruction Manual National Reciprocating Pump D901000106-MAN-001Dokument82 SeitenInstruction Manual National Reciprocating Pump D901000106-MAN-001jromero_rpg100% (2)

- Hss 3200 App Iss 2.3 07 11Dokument58 SeitenHss 3200 App Iss 2.3 07 11Luis Carlos80% (5)

- Tdi T50Y Service PDFDokument18 SeitenTdi T50Y Service PDFJosé BelisarioNoch keine Bewertungen

- Type A Air Valves (WABCO) AVENTICSDokument32 SeitenType A Air Valves (WABCO) AVENTICSWILLIAM ROMERO100% (1)

- Pump GDDokument2 SeitenPump GDdelcololalunaNoch keine Bewertungen

- OperacionesDokument86 SeitenOperacionesdiego contrerasNoch keine Bewertungen

- Ir SS800 PDFDokument8 SeitenIr SS800 PDFJuan Asarcado0% (1)

- 1400 Maintenance ManualDokument6 Seiten1400 Maintenance ManualJesus MatteyNoch keine Bewertungen

- T100-V Ipb T1-724Dokument6 SeitenT100-V Ipb T1-724Hugo RodriguezNoch keine Bewertungen

- Thomas Flexible Disc CouplingDokument52 SeitenThomas Flexible Disc Couplingkwakwa4100% (1)

- MasterPack CatalogDokument176 SeitenMasterPack CatalogcabarbozavNoch keine Bewertungen

- Clarification of Rig D3 Desilter and Desander Spare Parts Request (MR No. 103)Dokument4 SeitenClarification of Rig D3 Desilter and Desander Spare Parts Request (MR No. 103)Mohanad HussienNoch keine Bewertungen

- Murphy FluidDokument40 SeitenMurphy FluiddptecnicocmspNoch keine Bewertungen

- WWW - Incar.tw-Kelly Spinner ManualDokument6 SeitenWWW - Incar.tw-Kelly Spinner ManualSachin KumarNoch keine Bewertungen

- Hj22 SimplexDokument1 SeiteHj22 SimplexLuis Manuel Montoya RiveraNoch keine Bewertungen

- Westbrook Manufacturing Contact and Product InformationDokument44 SeitenWestbrook Manufacturing Contact and Product InformationMuhammad Ashabul YZNoch keine Bewertungen

- Aspiradoras RidgidDokument6 SeitenAspiradoras RidgidMarco DiazNoch keine Bewertungen

- PTD 500Dokument2 SeitenPTD 500Samuel HernándezNoch keine Bewertungen

- 200-6504 Heater Gp-Jacket Water PDFDokument1 Seite200-6504 Heater Gp-Jacket Water PDFvictor.ciprianiNoch keine Bewertungen

- 80-0421-13 80-0421-14 Tech Manual REV 20160314 (Hi-Rez)Dokument181 Seiten80-0421-13 80-0421-14 Tech Manual REV 20160314 (Hi-Rez)j1h2o3n4Noch keine Bewertungen

- Catalogue 118 JJDokument132 SeitenCatalogue 118 JJkorpaapNoch keine Bewertungen

- Navalex Intl Fact SheetDokument2 SeitenNavalex Intl Fact Sheetfredy2212Noch keine Bewertungen

- Pump w953Dokument2 SeitenPump w953juanchis650100% (1)

- Pressure-Pro Price Book Feb 23 2012Dokument268 SeitenPressure-Pro Price Book Feb 23 2012pressureproNoch keine Bewertungen

- MUD PUMP EXPENDABLES Emsco PDFDokument9 SeitenMUD PUMP EXPENDABLES Emsco PDFleoNoch keine Bewertungen

- GE Industrial Push Buttons CatalogDokument134 SeitenGE Industrial Push Buttons CatalogMilton SantoNoch keine Bewertungen

- Graco Xtreme 70 1 Airless Spray Pumps Part Numbers and Schematics Guide 206m539Dokument24 SeitenGraco Xtreme 70 1 Airless Spray Pumps Part Numbers and Schematics Guide 206m539Maulana Mufti MuhammadNoch keine Bewertungen

- 279D Combination GearboxDokument1 Seite279D Combination GearboxJorge Vásquez CarreñoNoch keine Bewertungen

- Válve Relay Air Starters CAT E WaukeshaDokument8 SeitenVálve Relay Air Starters CAT E WaukeshaJonatas Barbaglio Gomes PereiraNoch keine Bewertungen

- CLE14000DPcerev9 09 PDFDokument139 SeitenCLE14000DPcerev9 09 PDFAdhie WaelacxhNoch keine Bewertungen

- Fuel SystemDokument34 SeitenFuel Systemwguenon100% (1)

- GD 3000 SGWS Stainless Steel FE Parts List 306TLS997 - ADokument14 SeitenGD 3000 SGWS Stainless Steel FE Parts List 306TLS997 - AYeins Edson OrdoñezNoch keine Bewertungen

- 3.7 - 1270 Pump Assy - 15114504Dokument2 Seiten3.7 - 1270 Pump Assy - 15114504Hery Mardiono HeryNoch keine Bewertungen

- 8V-71 Diesel Engine Spare Parts ListDokument12 Seiten8V-71 Diesel Engine Spare Parts ListSonthi MooljindaNoch keine Bewertungen

- Mezzer Pro Expert Service GuideDokument43 SeitenMezzer Pro Expert Service GuideMatteo QuerellaNoch keine Bewertungen

- Stockham Cast SteelDokument24 SeitenStockham Cast SteelcabarbozavNoch keine Bewertungen

- Maintenance Interval Schedule GENSET 250KVADokument2 SeitenMaintenance Interval Schedule GENSET 250KVARegi HermawanNoch keine Bewertungen

- Tecumseh Engine Parts Manual TVS100 44050GDokument7 SeitenTecumseh Engine Parts Manual TVS100 44050Greply-to-addNoch keine Bewertungen

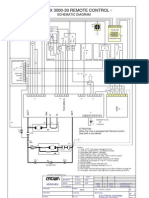

- SX 3000-30 REMOTE CONTROL SCHEMATIC DIAGRAMDokument8 SeitenSX 3000-30 REMOTE CONTROL SCHEMATIC DIAGRAMAngela ZMNoch keine Bewertungen

- Braking of DC MotorDokument18 SeitenBraking of DC MotorBangariNoch keine Bewertungen

- S 353 Ih 6 RDokument68 SeitenS 353 Ih 6 Rmkbuilder2003Noch keine Bewertungen

- Unit 15 Aircraft Propulsion AssignmentDokument18 SeitenUnit 15 Aircraft Propulsion AssignmentTerrence Owens50% (2)

- 14M R9J Schematic PDFDokument8 Seiten14M R9J Schematic PDFJhun HunkNoch keine Bewertungen

- Fiat Stilo Manual Eng - HandbookDokument274 SeitenFiat Stilo Manual Eng - HandbookOvidiu Ivan50% (2)

- VG824 Cut-Grooving ToolDokument4 SeitenVG824 Cut-Grooving ToolMarcos FuentesNoch keine Bewertungen

- Electric Generator Project FileDokument27 SeitenElectric Generator Project Filegudias375Noch keine Bewertungen

- Caterpillar Engine 2Dokument4 SeitenCaterpillar Engine 2fahmi wibowoNoch keine Bewertungen

- Piaggio X9 250evo Owners ManualDokument98 SeitenPiaggio X9 250evo Owners Manuallynhaven1100% (3)

- Short Term Courses at ILP Pasir Gudang 2013/2014Dokument8 SeitenShort Term Courses at ILP Pasir Gudang 2013/2014msanusiNoch keine Bewertungen

- Sai HarishDokument32 SeitenSai HarishPurushottam RoyNoch keine Bewertungen

- My EngineDokument5 SeitenMy EnginescooperwNoch keine Bewertungen

- Operation Manual of Compression Machine 2000 KN CapacityDokument9 SeitenOperation Manual of Compression Machine 2000 KN CapacityFiker Er MarkNoch keine Bewertungen

- Clutch Cable PDFDokument4 SeitenClutch Cable PDFVEERAMANINoch keine Bewertungen

- Mechanics of Machines: Lab ReportDokument52 SeitenMechanics of Machines: Lab ReportMuhammad AbdullahNoch keine Bewertungen

- Hydraulic Crawler Crane: Model: CKL1000iDokument20 SeitenHydraulic Crawler Crane: Model: CKL1000iHema NandhNoch keine Bewertungen

- GP080-120VX Folleto Comercial - CompressedDokument16 SeitenGP080-120VX Folleto Comercial - CompressedhiabyyNoch keine Bewertungen