Beruflich Dokumente

Kultur Dokumente

1 s2.0 0734743X94800244 Main

Hochgeladen von

Rajveer SinghOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

1 s2.0 0734743X94800244 Main

Hochgeladen von

Rajveer SinghCopyright:

Verfügbare Formate

Pergamon

Int. J. Impact Engng Vol. 15, No. 4, pp. 395-405, 1994 Copyright 1994 Elsevier Science Lid Printed in Great Britain. All rights reserved 0734--743X/94 $7.00+ 0.00

AN EMPIRICAL EQUATION FOR PENETRATION DEPTH OF OGIVE-NOSE PROJECTILES INTO CONCRETE TARGETS M. J. FORRESTAL, t B. S. ALTMAN,t J. D. CARGILE ~t and S. J. HANCHAK

tSandia National Laboratories, Albuquerque, NM 87185-5800, U.S.A. ~tWaterways Experiment Station, Vicksburg, MS 39180-6199, U.S.A. ~University of Dayton Research Institute, Dayton, OH 45469-0182, U.S.A. (Received 14 March 1993; in revised form 27 August 1993) Summary--We conducted depth of penetration experiments with ogive-nose projectiles and concrete targets with unconfined compressive strengths of nominally 14 MPa (2 ksi), 35 MPa (5 ksi), and 97 MPa (14 ksi). From our data and the data presented by Canfield and Clator [J. A. CANFIELD and I. G. CLATOR,Development of a scaling law and techniques to investigate penetration in concrete. NWL Report No. 2057, U.S. Naval Weapons Laboratory, Dahlgren, VA (1966)] [1], we developed an empirical equation for penetration depth of ogive-nose projectiles penetrating concrete targets at normal impact. Our penetration equation contains a single, dimensionless empirical constant that depends only on the unconfined compressive strength of the target. We determine the empirical constant from penetration depth versus striking velocity data with six sets of penetration data for striking velocities between 250 and 800 m/s. Predictions are in good agreement with all six data sets.

INTRODUCTION

Brown [2] presents an historical account of empirical equations for penetration and perforation of concrete targets. These empirical equations result from curve-fits with test data and do not provide physically based descriptions. In addition, the empirical equations in [2] are expressed in terms of specific units, so these equations are dimensionally dependent. In this paper, we develop a dimensionally consistent empirical equation for depth of penetration into concrete targets that contains the functional form of recently published, experimentally verified, analytical models [3,4,5].

MODEL FORMULATION

Forrestal and Luk [5] derive an analytical equation for penetration into soil targets that requires triaxial material data from samples cored from the target material. Unfortunately, most penetration studies lack the necessary triaxial test data required for input to analytical and computational models. Many experimental studies do, however, report the unconfined compressive strength f'c for concrete targets. To use this data base, we develop an empirical penetration equation that describes the concrete targets in terms of unconfined compressive strength f'c, a dimensionless empirical constant S that multiplies f'~, and density. The development of the empirical equation starts with the equation for force on the projectile nose given in [5]. For the analytical model in [5] and this empirical equation, we assume normal impact and that the projectile is a rigid body (nondeforming nose). Axial force is given by F =/ra2(zo A + NBpV2), N - 8~b- I 241//2 '

395

(la) (lb)

396

M, J. FORRESTALet

al.

where the projectile has mass m, shank radius a, caliber-radius-head ~O, and rigid-body velocity V. The caliber-radius-head is defined by ff =s/2a where s is the ogive radius and 2a is the shank diameter. The target is characterized by density p and the constants (to A) and B that involve only material parameters obtained from triaxial tests. Previous studies [3,4,5-] showed that B depends mostly on the compressibility of the target material and B has a narrow range; for example, B = 1.1 for aluminum targets [3,4-1, and B = 1.2 for soil targets [5-1. By contrast, (to A) depends mostly on the shear strength of the target materials, and (roA) has a broad range. For this empirical equation, we take B = 1 and ( r o A ) = S f 'c, where S is the dimensionless empirical constant that multiplies unconfined compressive strength. Thus, the empirical equation for axial force takes the form

F---~za2(Sf'c+ NpV2),

z>4a,

(2)

where N is given by Eqn (lb). Equation (2) is limited to penetration depths z>4a. For z < 4a, the process is dominated by surface cratering. Post-test observations of soil and concrete targets show that the cavity after penetration is a conical region with length about two projectile shank diameters, 4a, followed by a circular cylinder with diameter nearly equal to the projectile shank diameter, 2a. Thus, the cavity length 0 < z < 4a is called the crater region, and the cavity length 4a < z < P is called the tunnel region, where z is measured from the target surface and P is final penetration depth. For the soil penetration tests analyzed in [5], P ~ 100a; so the crater region was ignored. However, both the crater and tunnel regions must be taken into account in the analysis of concrete targets. Deceleration data [5] show a rise time during the crater region, followed by a decaying pulse during the tunnel region. For this model, we take force on the projectile nose as F = cz, 0 < z < 4a, (3a) (3b)

F=na2(Sf'~+NpV2),

where c is a constant. From Newton's second law

d2z

4a<z<P,

m ~ t 2 = -- cz,

0 < z < 4a.

(4)

With the initial conditions z(t = 0)= 0 and V(t = 0)= Vs, Eqn (4) has the following solutions for projectile displacement, velocity, and acceleration: z=(~) sin c o t , 0<z<4a, 0 < z < 4a, (5a) (5b)

dz V = - - = V~cos cot, dt dV dt

-

d2z dt 2

ogV~sin cot,

c

O<z<4a,

(5c)

co2 = - . m

(5d)

We define t 1, and V1 as the time and rigid-body projectile velocity at z = 4a. The unknowns t l, VI, and c are found from the conditions of continuity of force, velocity, and displacement at z=4a and t=tx.

An empirical equation for penetration depth of projectiles

397

From Eqns (3) and (5) mcoV~sin o;tx =na2(Sf'c+NpV2), V~cos cot~ = I/1, ( ~ ) sin cot1 =40, Substituting (6c) into (6a) gives 7za , c = --7-(Sf~ + NpV21).

4

at z=4a,

(6a)

at z =4a, at z = 4 0 ,

(6b) (6c)

(7a)

Squaring and then adding (6b) and (6c) gives

C--

m(V 2 - - V 2) 16a2

(7b)

Equating (7a) and (7b) gives the rigid-body velocity at z = 4a as

V 21

-

rn V z

4 ~ a 3 Sf'c

m + 4rta3Np

From (6b),

(7c)

(7d)

Values of tl, V~, and c can be determined with Eqns (7b, c and d). Depth of penetration in the tunnel region is found from m-7-;~ = m V__ = - na2(Sf'~ + Np V 2), tit ~ dz

d2z

dV

4a<z <P.

(8)

Integrating (8) from V1 to zero and 4a to P gives the final penetration depth,

P-2rca2p~ln

m(

l + ~ + 4 a , s]f ~

P>4a,

(9)

where V1 is related to the striking velocity ~ in Eqn (7c). We solve for S in Eqn (9) and obtain

s=NpV2~. 1 fc, ( 1 + 4xa3NP~exp[2~raZ(P_4a)Np~ . . . . m / L m J

(10) 1

For each experiment, all terms on the right side of Eqn (I0) are known, so S can be determined for each data point. We take the average value of S for the data points in each data set and compare results from Eqn (9) and penetration depth. As shown later, this procedure produced accurate data fits for six sets of penetration data.

398 PENETRATION

M.J. FORRESTALet al. EXPERIMENTS AND DATA REDUCTION

We conducted depth of penetration versus striking velocity experiments into concrete targets with unconfined compressive strengths of nominally 14 MPa (2 ksi), 35 MPa (5 ksi), and 97 MPa (14 ksi). Table 1 lists the parameters for our experiments in the first four columns and the parameters for the experiments of Canfield and Clator [1] in the last two columns. 14 MPa (2 ksi) grout targets Grout targets were cast in approximately 305 mm, fiber-reinforced, cardboard tubes commercially available for pouring structural columns, and three 102-mm-diameter, 203-mm-long cylinders were cast for unconfined compressive strength tests. In addition, four 102-mm-diameter, 203-mm-long cylinders and two 50.8-mm-diameter, 109-mm-long cylinders were cored from a target for unconfined compressive strength tests. We tested nine grout cylinders and measuredf'c= 11.7-15.0 MPa with an average of f'c= 13.5 MPa. Penetration and unconfined compressive strength experiments were conducted from 90 to 120 days after the grout was cast. A 12.9-mm diameter, smooth-bore, powder gun launched the 0.0640-0.0642 kg projectiles dimensioned in Figs la,b to striking velocities between 345-945 m/s. Projectiles were machined from 4340 steel rods and heat treated to a hardness of R~ 38-40. These figures show that the projectile has been hollowed out to maintain a nearly constant mass of 0.64 kg. Projectile shank diameters were centerless ground to fit snugly into the gun bore, so projectiles were launched without sabots or obturators. Two laser diode systems measured striking velocities, and orthogonal x-rays measured pitch and yaw angles. Table 2 presents a data summary for these penetration experiments. The value of S in the first two columns of Table 1 is the average of the values calculated from Eqn (10) for each data point. Figure 2 shows results from Eqn (9) with S=21 and the data sets with 0 = 3.0 and 0 = 4.25. 35 MPa (5 ksi) and 97 MPa (14 ksi) concrete targets Concrete targets were cast in galvanised, corrugated steel culverts with approximately 1.22 and 1.37-m-diameter. Target length varied depending on the striking velocity, but all target lengths were greater than twice the depth of penetration. In addition, 152-mmdiameter, 305-mm-long cylinders were cast at the time of pour for each target for unconfined compressive strength tests. Values of f'c for each target are given in Tables 3 and 4. Penetration and unconfined compressive strength experiments were conducted from 30 to 60 days after the concrete was cast. A 83-mm-diameter, smooth bore powder gun launched the 0.898--0.912 kg projectiles dimensioned in Fig. lc to striking velocities between 277 and 800 m/s. Projectiles were machined from 4340 steel rods and heat treated to a hardness of R~ 43-45. The projectiles were fitted with plastic sabots and obturators that fit snugly into the gun bore. Sabots and obturators were stripped aerodynamically prior to striking the targets. Striking velocities and pitch and yaw angles were measured with orthogonal streak cameras. Pitch and yaw angles were always less than one degree. Tables 3 and 4 present a data summary for these penetration experiments.

TABLE 1. PENETRATION PARAMETERS

f'~ (M Pa) p (kg/m 3) m (kg) 2a (mm) N S

13.5 1960 0.0642 12.7 3 0.106 21

13.5 1960 0.0642 12.7 4.25 0.076 21

36.2 2370 0.906 26.9 2.0 0.156 12

96.7 2340 0.904 26.9 2.0 0.156 7

35.1 2310 5.90 76.2 1.5 0.204 13

34.6 2240 0.0059 7.62 1.5 0.204 14

An empirical

equation

for penetration

depth I II

of projectiles +

12.92 mm t

399

~ 6.35 mm II

+21.4lmmjt b-

k-L-4 88.90 mm (a)

--)1

(b)

Filler. Density

= 1.58 Mg/mA3 \ 5.1 mm

<

4

35.6 rnrnb-

\

206.8 mm -4

10.1 mm

26.9 mm t

FIG. 1. Projectile

geometries. In (a) and (b) .L.z 50.8 mm, adjusted to obtain JI = 3.0 for (a), J, = 4.25 for (b), and JI = 2.0 for (c).

m = 0.0640-0.0642

kg.

0.X

.

0.7

w=3. Data

.h

0.5 P Cm) 0.4

0.3

0.2

0.1

I

II 0

200

400 vs (m/s)

600

800

In00

FIG.

2. Penetration

data

and

model

prediction for J:=13.5 MPa,

0.064 S=21.

kg, 12.7-mm-diameter

projectile

with

400

M.J. FORRESTAL et al. TABLE 2. DATA SUMMARYFOR THE 0.064 kg PROJECTILES AND NOMINALLY 14 MPa (2 ksi), 305-ram-DIAMETER, GROUT TARGETS, FOR PITCH AND YAW D=DOWN, U = u P , R=RIGHT, L=LEFT

Shot number

6-2374 6-2363 6-2367 6-2364 6-2370 6-2373 6-2362 6-2365 6-2371

~b

V~

(m/s)

Pitch

(degrees) 0.2 D 0.4 D N/A 0.0 0.5 D 0.4 D 0.0 N/A 0.7 U

Yaw

(degrees) 0.0 0.7 R N/A 0.5 R 0.3 R 0.2 R 1.8 L N/A 0.3 R

P

(mm) 127 312 359 414 640 111 312 439 663

Target length (m)

308 603 632 622 1040 311 622 622 1030

3.0 3.0 3.0 3.0 3.0 4.25 4.25 4.25 4.25

371 590 670 722 945 345 585 722 900

TABLE 3. DATA SUMMARYFOR THE NOMINALLY 0.906 kg PROJECTILES AND 36 MPa (5 ksi) TARGETS

Shot number

~

(m/s)

P

(m)

Target diameter

(m)

Target length

(m) 0.76 0.91 0.91 0.76 1.07 1.83 1.83 1.83 1.83 1.83 1.83

f'c

(MPa)

Projectile mass

(kg)

14 13 15 11 12 2 1 3 4 5 6

277 410 431 499 567 590 591 631 642 773 800

0.173 0.310 0.411 0.480 0.525 0.729 0.513 0.607 0.620 0.866 0.958

1.37 1.37 1.37 1.37 1.37 1.22 1.22 1.22 1.22 1.22 1.22

35.2 37.8 38.1 33.5 38.4 36.9 40.1 35.4 34.7 36.0 32.4

0.906 0.910 0.907 0.912 0.910 0.905 0.901 0.903 0.905 0.901 0.904

TABLE 4. DATA SUMMARY FOR THE NOMINALLY 0.904 kg PROJECTILESAND 97 MPa (14 ksi) TARGETS

Shot number

~

(m/s)

P

(m)

Target diameter

(m)

Target length

(m) 1.22 1.22 1.22 1.22 1.22 1.22

f'c

(MPa)

Projectile mass

(kg)

2 1 3 4 6 5

561 584 608 622 750 793

0.353 0.384 0.422 0.437 0.630 0.605

1.37 1.37 1.37 1.37 1.37 1.37

90.5 91.0 95.0 101.4 94.0 108.3

0.907 0.898 0.908 0.905 0.907 0.900

V a l u e s o f S f o r t h e 35 M P a (5 ksi) a n d 97 M P a (14 ksi) c o n c r e t e s a r e g i v e n i n t h e t h i r d a n d f o u r t h c o l u m n s o f T a b l e 1. F i g u r e 3 s h o w s t h e p e n e t r a t i o n d a t a a n d r e s u l t s f r o m E q n (9). 35 M P a (5 ksi) concrete targets C a n f i e l d a n d C l a t o r [ 1 ] p r e s e n t d e p t h - o f - p e n e t r a t i o n d a t a f o r full-scale (5.90 kg, 76.2-ram-diameter) and one-tenth scale (0.0059-kg, 7.62-ram-diameter) armor-piercing p r o j e c t i l e s . T h e l a s t t w o c o l u m n s o f T a b l e 1 lists t h e o t h e r p a r a m e t e r s for t h e s e e x p e r i m e n t s

An empirical

equation

for penetration

depth

of projectiles

401

. .

0.X

y1=2.1~~=96.7 MPa. Data I+!=?. 1;=96.7 MPa. Equation (9) 4 (9) . / 1 1

1+r=2. f =36.2 MPa. Da, +I=?. 1<=36.2 MPa. Equakm

--

p (m) 0.6

FIG.

3. Penetration

data

and model prediction for 0.906 1:=36.2 MPa, S=12 and f:=96.1

kg, 26.9-mm-diameter MPa, S=l.

projectile

with

(17 0.6 p (m) 0 5 I,.4 03 02 .

FIG. 4. Penetration

data

and

model prediction for 5.9 kg, 76.2-mm-diameter /:=35.1 MPa, S= 13.

projectile

with

0.09

I+I= I .S. Data I+I= I S. Equation (9)

. .

0.08 0.07 0.06

p Cm)

0.05

0.04

0.03

0.02

0.0 I 0 150 300 VI 450 (m/s) 600 750 900

FIG. 5. Penetration

data [l]

and model

prediction for 0.0059 /;=34.6 MPa, S=14.

kg, 7.62-mm-diameter

projectile

with

402

M.J.

FORRESTAL

et al.

and the calculated value of S. Figures 4 and 5 show penetration data and results from Eqn (9) with S = 13 for the full-scale projectile and S = 14 for the one-tenth scale projectile.

An estimate for S versus f' We obtained values of S for six data sets. For the two data sets with nominal 14 MPa (2 ksi) grout targets, S=21; for the three data sets with nominal 35 MPa (5 ksi) concrete targets, S = 12, 13, and 14; and for the single data set with a nominal 97 MPa (14 ksi) concrete target, S =7. The model prescribes that S depends only on f'c, and Eqn (10) shows that S is proportional to 1If'c. Figure 6 shows the calculated values of S and a curve-fit where S is proportional to l/f'c.

RIGID BODY PROJECTILE MOTION In the previous sections, we developed an empirical equation for final penetration depth based on penetration depth versus striking velocity data. Since our model formulation starts with the force on the projectile nose, we can also derive equations for the projectile rigid-body acceleration, velocity, and displacement. Equations for the crater region, 0 < z < 4a, are given by (5a-c). For the tunnel region dV m--= dt

-ga2(Sf'c+NpV2),

4a<z<P,

(11)

where the force on the right side of Eqn (11) is given by Eqn (2). Equation (11) is integrated to give velocity as a function of time V=

\No/

tan t a n - l [ { N P ' ~ l / 2 V ] - n a Z L\ J 1.j - - ~ ( S f c'N P ) '1"2( t - t , )

4a<z<P,

(12)

where V1 and tl are given by Eqns (7c) and (7d). Acceleration as a function of time is given by

dV a=--=

cos tan

- (na2Sf'Jm) 1,'1---(Sf~Np) (t-t~)

4a<z<P.

(13)

22 20 18 16 S 14 12 10 8 6

20

40

60

80

100

f' (MPa)

FIG. 6. Dimensionlessempiricalconstant versus unconfinedcompressivestrength.

An empirical equation for penetration depth of projectiles

---T V .... 0.8

_ _

403

= 400 m/s

i --

]--

:-

V = 6 0 0 m/s

f J

V =800m/s

E

0.6

# I

0.4

E o

?5

0.2

/ / /#

I

#

"

(/

i !

I

0 0

0.5

1.5

2.5

Time (ms) FIG. 7. Displacement versus time predictions for 0.906 kg, 26.9-mm-diameter projectile with f'=36.2 MPa and S= 12.

I000

- 800

V , = 400 II1/s V = 600 ads V , = 800 rids

.... ----

600

%

400

'w,

%''1 0

Time (ms) FIG. 8. Velocity versus time predictions for 0.906 kg, 26.9-mm-diameter projectile with f;=36.2 MPa and $=12.

Displacement as a function of time is given by

z_

naZNp

,n/ L

LW;J

cos[tan -

V']-na2(sf' Np)il2(t-t')

_1 m

}]

+4a,

4a<z<P.

(14)

Lt, ) "JJ

Thus, rigid-body m o t i o n equations are given by (5a-c) for the crater region, 0 < z < 4a, and (12), (13), and (14) for the tunnel region, 4a<z<P. Figures 7, 8 and 9 s h o w the rigid-body m o t i o n predictions for the 0.906 kg projectile (shown in Fig. lc) at striking velocities of ~ = 4 0 0 , 600, and 800 m/s penetrating into a f ' c = 36 M P a target. Equation (13) predicts m a x i m u m rigid-body decelerations at t = tz or

404

4O000

5-I?

%

M.J. FORRESTAL et al.

V = 400 m/s .... ~ ~ V = 600 m/s V

=

/h"~.

800 nVs

3oooo 2oooo

-". C:_-:

--. _..__..,_

_ _

I 10000 I I

!

0 -_1

0.5

1.5

2.5

Time (ms) FIG. 9. Deceleration versus time predictions for 0.906 kg, 26.9-mm-diameter projectile with f'c=36.2 MPa and S= 12.

of 31,000, 36,000, 42,000 g (1 O =9.81 m/s 2) for striking velocities of 400, 600, and 800 m/s. Forrestal and Luk [5] measured rigid body decelerations with 23 kg projectiles launched into soil targets at a striking velocity of 280 m/s. For these tests, peak decelerations were about 1000-1200 g. The much larger peak decelerations predicted by Eqn (13) results from a more resistant target (concrete rather than soil), larger striking velocities, and a projectile with less mass (23 kg for the soil target and 0.9 kg for the concrete target). While current accelerometers t can record up to 200,000 g under some transient loading conditions, penetration tests require an onboard recorder and accelerometers that must be structurally mounted within the projectile. Equation (13) and the numerical results shown in Fig. 8 predict rigid body decelerations, whereas the accelerometer measures the rigid-body motion and transient structural response. Therefore, the measured decelerations would be larger than the rigid-body decelerations predicted in our model. As discussed in Forrestal and Luk [-4], estimates for rigid-body deceleration are obtained by filtering the deceleration-time data.

z=4a

CONCLUSIONS We present a dimensionally consistent empirical equation for the penetration depth of ogive-nose projectiles penetrating concrete targets. This equation has a single, dimensionless empirical constant S that multiplies unconfined compressive strength f'c- The empirical constant S depends only on the unconfined compressive strength of the concrete target and is independent of the projectile parameters and striking velocity. We note that the penetration equation is limited to normal impact and rigid projectiles (nondeforming nose). Most of the penetration data base is limited to V~< 800 m/s, and for V~< 800 m/s, the nose remained undeformed. In addition, we present equations for the rigid-body projectile motion. Predictions for deceleration as a function of time can assist in the design of projectiles with onboard recorders that attempt to measure deceleration-time for penetration into concrete targets.

Acknowledgements--This

work was sponsored by the Joint DoD/DOE Munitions TechnologyDevelopment Program and the U.S. ArmyCorps of Engineers under the Hardened Structures Research Program.

*Endevco 7270A-200K;EndevcoCorp., 30700 Rancho Viejo Road, San Juan Capistrano,CA, 92675.

An empirical equation for penetration depth of projectiles REFERENCES 1. 2. 3. 4. 5.

405

J.A. CANFIELD and I. (3. CLATOR, Development of a scaling law and techniques to investigate penetration in concrete. NWL Report No. 2057, U.S. Naval Weapons Laboratory, Dahlgren, VA (1966). S.J. BROWN,Energy release protection for pressurized systems. Part II. Review of studies into impact/terminal ballistics. Appl. Mech. Rev. 39 (1986). M.J. FORRESTAL,N. S. BRARand V. K. LUK, Penetration of strain-hardening targets with rigid spherical-nose rods. J. appl. Mech. 58, 7-10 (1991). M.J. FORRESTAL, V. K. LUK, Z. ROSENBERGand N. S. BRAR, Penetration of 7075-T651 aluminum targets with ogival-nose rods. Int. J. Solids Struct. 29, 1729-1736 (1992). M.J. FORRESTAL and V. K. Lug, Penetration into soil targets. Int. J. Impact Engng 12, 427-444 (1992).

Das könnte Ihnen auch gefallen

- Fourier Restriction for Hypersurfaces in Three Dimensions and Newton Polyhedra (AM-194)Von EverandFourier Restriction for Hypersurfaces in Three Dimensions and Newton Polyhedra (AM-194)Noch keine Bewertungen

- An Empirical Equation For Penetration Depth of Ogive-Nose PDFDokument11 SeitenAn Empirical Equation For Penetration Depth of Ogive-Nose PDFamarNoch keine Bewertungen

- Review The Double-Torsion Testing Technique For Determination of Fracture Toughness and Slow Crack Growth Behavior of Materials: A ReviewDokument12 SeitenReview The Double-Torsion Testing Technique For Determination of Fracture Toughness and Slow Crack Growth Behavior of Materials: A ReviewYudy SIrNoch keine Bewertungen

- 1 s2.0 S0734743X02001082 MainDokument19 Seiten1 s2.0 S0734743X02001082 Main안진호 / 학생 / 건설환경공학부Noch keine Bewertungen

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionVon EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNoch keine Bewertungen

- Penetration Into Ductile Metal Targets With Rigid Spherical-Nose RodsDokument12 SeitenPenetration Into Ductile Metal Targets With Rigid Spherical-Nose Rodsamar100% (1)

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryVon EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryNoch keine Bewertungen

- 1 s2.0 S0143974X05000763 Main PDFDokument22 Seiten1 s2.0 S0143974X05000763 Main PDFMilmxmenNoch keine Bewertungen

- Tables of Coefficients for the Analysis of Triple Angular Correlations of Gamma-Rays from Aligned NucleiVon EverandTables of Coefficients for the Analysis of Triple Angular Correlations of Gamma-Rays from Aligned NucleiNoch keine Bewertungen

- Da DN Test5Dokument8 SeitenDa DN Test5Anjan GhoshNoch keine Bewertungen

- Pergamon: Int. J. Impact Enyno Vol. 16, No. 5/6, Pp. 801-831, 1995Dokument31 SeitenPergamon: Int. J. Impact Enyno Vol. 16, No. 5/6, Pp. 801-831, 1995apmapNoch keine Bewertungen

- Penetration Into Soil TargetsDokument18 SeitenPenetration Into Soil TargetsamarNoch keine Bewertungen

- Average Stress Strain Relations For ConcDokument10 SeitenAverage Stress Strain Relations For ConcKorrapati Pratyusha 19PHD0497Noch keine Bewertungen

- 23 - HuDokument11 Seiten23 - HuDjordjeDjNoch keine Bewertungen

- Correlation of Post-Installed by Adhesive Pullout Test To Estimate In-Place Concrete StrengthDokument4 SeitenCorrelation of Post-Installed by Adhesive Pullout Test To Estimate In-Place Concrete Strengthfandhiejavanov2009Noch keine Bewertungen

- Plastic Hinge Length of Reinforced Concrete ColumnsDokument11 SeitenPlastic Hinge Length of Reinforced Concrete ColumnsSiavash BayeganNoch keine Bewertungen

- Lab Report 4Dokument13 SeitenLab Report 4vigneshwarimahamuniNoch keine Bewertungen

- Talzat Zacharia PDFDokument16 SeitenTalzat Zacharia PDFArun KumarNoch keine Bewertungen

- CheckongDokument25 SeitenCheckongMaajith MarzookNoch keine Bewertungen

- Mirza Et Al. - 1996 - The Effect of Stress Triaxiality and Strain-Rate On The Fracture Characteristics of Ductile MetalsDokument9 SeitenMirza Et Al. - 1996 - The Effect of Stress Triaxiality and Strain-Rate On The Fracture Characteristics of Ductile MetalsGuilherme DonatoNoch keine Bewertungen

- Uncorrected ProofDokument8 SeitenUncorrected ProofMuthu KumarNoch keine Bewertungen

- Crack Control at End Faces of Inverted T' Bent Caps: by Ronnie R. H. Zhu, Thomas T. C. Hsu, and John VogelDokument32 SeitenCrack Control at End Faces of Inverted T' Bent Caps: by Ronnie R. H. Zhu, Thomas T. C. Hsu, and John VogelKysuXDNoch keine Bewertungen

- Journal of Babylon UniversityDokument14 SeitenJournal of Babylon UniversityMUNIRAJNoch keine Bewertungen

- Materials: The Present SP Tests For Determining The Transition Temperature T On "U" Notch Disc SpecimensDokument7 SeitenMaterials: The Present SP Tests For Determining The Transition Temperature T On "U" Notch Disc SpecimensFajar Sri Lestari PangukirNoch keine Bewertungen

- A Simple Method To Determine Ductile Fracture Strain in A Tensile Test of Plane Specimen'SDokument5 SeitenA Simple Method To Determine Ductile Fracture Strain in A Tensile Test of Plane Specimen'SksNoch keine Bewertungen

- Limit AnalysisDokument15 SeitenLimit AnalysisNadim527Noch keine Bewertungen

- 3144Dokument10 Seiten3144Mona AwadNoch keine Bewertungen

- Critical Buckling EquationDokument18 SeitenCritical Buckling Equationxsi666Noch keine Bewertungen

- A Contribution To The Analysis of The Behaviour of Plate Girders Subjected To Patch LoadingDokument11 SeitenA Contribution To The Analysis of The Behaviour of Plate Girders Subjected To Patch LoadingGogyNoch keine Bewertungen

- CUM7-Remarks To The Direct Strength Method - LindnerDokument14 SeitenCUM7-Remarks To The Direct Strength Method - LindnerAMOKE SHABHARI S K RNoch keine Bewertungen

- Experimental Verification of The New Ultimate Strength Equation of Spherical Pressure HullsDokument8 SeitenExperimental Verification of The New Ultimate Strength Equation of Spherical Pressure HullsYoyok SetyoNoch keine Bewertungen

- 2018 Rock Socket Side Shear Ayithi-RyanDokument31 Seiten2018 Rock Socket Side Shear Ayithi-RyanVetriselvan Arumugam100% (1)

- Fe-Modeling of Fibre Reinforced Concrete Slabs Subjected To Blast LoadDokument7 SeitenFe-Modeling of Fibre Reinforced Concrete Slabs Subjected To Blast Loadনীল জোছনাNoch keine Bewertungen

- Pipe Vibration and Pressure Detection - Bruel - KjaerDokument12 SeitenPipe Vibration and Pressure Detection - Bruel - Kjaervarunsuri8Noch keine Bewertungen

- Chapter 4 - Defect Characterization and ImagingDokument34 SeitenChapter 4 - Defect Characterization and ImagingcwcarusoNoch keine Bewertungen

- A Simple Theory of Static and Dynamic HardnessDokument29 SeitenA Simple Theory of Static and Dynamic HardnessAli AlavianNoch keine Bewertungen

- Molecular Spectroscopy Exam, Second, First Semester Makeup 20092010Dokument3 SeitenMolecular Spectroscopy Exam, Second, First Semester Makeup 20092010DrHamdy KhameesNoch keine Bewertungen

- Armare Fibre MusmarCES5!8!2013Dokument13 SeitenArmare Fibre MusmarCES5!8!2013Girdan BogdanNoch keine Bewertungen

- Free Vibration Analysis of FGM Sandwich Beam RestingDokument39 SeitenFree Vibration Analysis of FGM Sandwich Beam RestingLaksh ManNoch keine Bewertungen

- The Crack Tip Strain Field of AISI 4340: Experimental MeasurementsDokument9 SeitenThe Crack Tip Strain Field of AISI 4340: Experimental Measurementsfrederico wlassakNoch keine Bewertungen

- Estimation of Fatigue Stress Concentration Factor in The Region of Elastic-Plastic StrainDokument6 SeitenEstimation of Fatigue Stress Concentration Factor in The Region of Elastic-Plastic Strain777894292Noch keine Bewertungen

- Micromechanics of Crack Bridging in Fibre-Reinforced ConcreteDokument9 SeitenMicromechanics of Crack Bridging in Fibre-Reinforced ConcreteTran Tuan KietNoch keine Bewertungen

- Material Mass (KG/M) Portland Cement Water Fly Ash (Unclassified) 19 MM Stone (Granite) 13 MM Stone (Granite) Crusher Sand (Granite) Filler SandDokument24 SeitenMaterial Mass (KG/M) Portland Cement Water Fly Ash (Unclassified) 19 MM Stone (Granite) 13 MM Stone (Granite) Crusher Sand (Granite) Filler Sanddisha847Noch keine Bewertungen

- N. A. Alang, N. A. Razak, K.A.Safie', and A. SulaimanDokument9 SeitenN. A. Alang, N. A. Razak, K.A.Safie', and A. SulaimanOskar CorderoNoch keine Bewertungen

- Strength and Stiffness Eduction OF Arge Otched Eams: by Joseph F. MurphyDokument12 SeitenStrength and Stiffness Eduction OF Arge Otched Eams: by Joseph F. MurphyLynx101Noch keine Bewertungen

- Lecture 11-In-Situ Shear StrengthDokument34 SeitenLecture 11-In-Situ Shear Strengthujosec6138Noch keine Bewertungen

- Criteria For Crack Extension in Cylindrical Pressure VesselsDokument24 SeitenCriteria For Crack Extension in Cylindrical Pressure VesselsNelson AlvarezNoch keine Bewertungen

- Singh Investigation Blast Damage Underground StabilityDokument7 SeitenSingh Investigation Blast Damage Underground StabilityllllcesarllllNoch keine Bewertungen

- Diseño y Detalles End PlateDokument10 SeitenDiseño y Detalles End PlateCesar CeronNoch keine Bewertungen

- Comparison of Blast Furnace Raceway Size With TheoryDokument7 SeitenComparison of Blast Furnace Raceway Size With TheoryZainab PeerbuxNoch keine Bewertungen

- A 1018788611620-2Dokument15 SeitenA 1018788611620-2liufei3190Noch keine Bewertungen

- Tofd 1 PDFDokument8 SeitenTofd 1 PDFLuis QuinoNoch keine Bewertungen

- Strain Gauges and Their MeasurementDokument22 SeitenStrain Gauges and Their Measurement200110039Noch keine Bewertungen

- Si3N4 VNUJ 2022Dokument10 SeitenSi3N4 VNUJ 2022Vinh LeNoch keine Bewertungen

- Evaluation of Undrained Shear Strength of Clay Li2018Dokument6 SeitenEvaluation of Undrained Shear Strength of Clay Li2018Juan P MSNoch keine Bewertungen

- A Calculation Method of Cracking Moment For The High Strength Concrete Beams Under Pure TorsionDokument15 SeitenA Calculation Method of Cracking Moment For The High Strength Concrete Beams Under Pure Torsion9886013865aNoch keine Bewertungen

- Back Analysis of Measured Displacements of Tunnels: TakeuchiDokument8 SeitenBack Analysis of Measured Displacements of Tunnels: TakeuchieltunelNoch keine Bewertungen

- Safety Assessment of Austenitic Steel Nuclear Power Plant Pipelines Against Stress Corrosion Cracking in The Presence of Hybrid UncertaintiesDokument7 SeitenSafety Assessment of Austenitic Steel Nuclear Power Plant Pipelines Against Stress Corrosion Cracking in The Presence of Hybrid UncertaintiesanoopsercNoch keine Bewertungen

- Stainless Steel: Presented By, Dr. Pragati Jain 1 YearDokument68 SeitenStainless Steel: Presented By, Dr. Pragati Jain 1 YearSneha JoshiNoch keine Bewertungen

- App 3.3 Scaffolding Measurement 20200512 FINALDokument15 SeitenApp 3.3 Scaffolding Measurement 20200512 FINALharshkumar patelNoch keine Bewertungen

- Uses of The Components of Crude Oil As FuelsDokument6 SeitenUses of The Components of Crude Oil As FuelsPearl LawrenceNoch keine Bewertungen

- APP157 CoP For Site Supervision 2009 202109Dokument92 SeitenAPP157 CoP For Site Supervision 2009 202109Alex LeungNoch keine Bewertungen

- BME (Steel)Dokument8 SeitenBME (Steel)Mohil JainNoch keine Bewertungen

- Review of C++ Programming: Sheng-Fang HuangDokument49 SeitenReview of C++ Programming: Sheng-Fang HuangIfat NixNoch keine Bewertungen

- Crisfield - Vol1 - NonLinear Finite Element Analysis of Solids and Structures EssentialsDokument360 SeitenCrisfield - Vol1 - NonLinear Finite Element Analysis of Solids and Structures EssentialsAnonymous eCD5ZRNoch keine Bewertungen

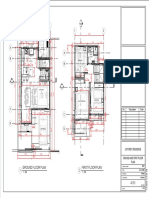

- Floor Plans & ElevationsDokument6 SeitenFloor Plans & Elevationsbryan cardonaNoch keine Bewertungen

- Properties of Building Materials and Their Importance in ConstructionDokument5 SeitenProperties of Building Materials and Their Importance in ConstructionDaisy Jane LulabNoch keine Bewertungen

- Build A 10 Ton Hydraulic PressDokument10 SeitenBuild A 10 Ton Hydraulic PressManuel SterlingNoch keine Bewertungen

- Computer Laboratory Maintenance Plan and ScheduleDokument5 SeitenComputer Laboratory Maintenance Plan and ScheduleJm Valiente100% (3)

- Molinos VerticalesDokument172 SeitenMolinos VerticalesLeonardo RodriguezNoch keine Bewertungen

- Wrights Mushroom ColumnDokument33 SeitenWrights Mushroom ColumnKeithy GandhiNoch keine Bewertungen

- CE 411 Lecture 03 - Moment AreaDokument27 SeitenCE 411 Lecture 03 - Moment AreaNophiNoch keine Bewertungen

- 5 6176700143207711706Dokument198 Seiten5 6176700143207711706abc defNoch keine Bewertungen

- Elvax 460Dokument3 SeitenElvax 460ingindjorimaNoch keine Bewertungen

- Overview On Sourcing: Oracle Fusion: 21D UpdatesDokument24 SeitenOverview On Sourcing: Oracle Fusion: 21D UpdatesMathi VathaniNoch keine Bewertungen

- 2ND 3RD Typical Floor Plan PDFDokument1 Seite2ND 3RD Typical Floor Plan PDFSamuel ZaraNoch keine Bewertungen

- SECTION 1213, 1214, 1215: Report By: Elibado T. MaureenDokument19 SeitenSECTION 1213, 1214, 1215: Report By: Elibado T. MaureenJohnFred CativoNoch keine Bewertungen

- Ex Delta Ex Delta - Dia: OVAL CorporationDokument8 SeitenEx Delta Ex Delta - Dia: OVAL CorporationDaniela GuajardoNoch keine Bewertungen

- Introduction Compression TestDokument7 SeitenIntroduction Compression TestEr Dinesh TambeNoch keine Bewertungen

- Battery Power Management For Portable Devices PDFDokument259 SeitenBattery Power Management For Portable Devices PDFsarikaNoch keine Bewertungen

- Photosynthesis LabDokument3 SeitenPhotosynthesis Labapi-276121304Noch keine Bewertungen

- Water System PQDokument46 SeitenWater System PQasit_mNoch keine Bewertungen

- Hyundai Robex 220LC-9A SpecificationsDokument14 SeitenHyundai Robex 220LC-9A SpecificationsKundan DhurveNoch keine Bewertungen

- Fundamentals of Fluid Mechanics (5th Edition) - Munson, OkiishiDokument818 SeitenFundamentals of Fluid Mechanics (5th Edition) - Munson, OkiishiMohit Verma85% (20)

- Session PlanDokument11 SeitenSession PlanMat Domdom Sansano100% (1)

- Transfer Action in Sap HRDokument3 SeitenTransfer Action in Sap HRKarthi MrvkNoch keine Bewertungen

- Ecg Signal Thesis1Dokument74 SeitenEcg Signal Thesis1McSudul HasanNoch keine Bewertungen

- 200 Series Service Manual FLX200 & SCR200Dokument39 Seiten200 Series Service Manual FLX200 & SCR200Carlos Gomez100% (3)

- Bulk Material Handling: Practical Guidance for Mechanical EngineersVon EverandBulk Material Handling: Practical Guidance for Mechanical EngineersBewertung: 5 von 5 Sternen5/5 (1)

- Basic Digital Signal Processing: Butterworths Basic SeriesVon EverandBasic Digital Signal Processing: Butterworths Basic SeriesBewertung: 5 von 5 Sternen5/5 (1)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedVon EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedBewertung: 5 von 5 Sternen5/5 (1)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionVon EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionBewertung: 4.5 von 5 Sternen4.5/5 (3)

- The Laws of Thermodynamics: A Very Short IntroductionVon EverandThe Laws of Thermodynamics: A Very Short IntroductionBewertung: 4.5 von 5 Sternen4.5/5 (10)

- Mechanical Vibrations and Condition MonitoringVon EverandMechanical Vibrations and Condition MonitoringBewertung: 5 von 5 Sternen5/5 (1)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AVon EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANoch keine Bewertungen

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisVon EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisBewertung: 4 von 5 Sternen4/5 (2)

- Airplane Flying Handbook: FAA-H-8083-3C (2024)Von EverandAirplane Flying Handbook: FAA-H-8083-3C (2024)Bewertung: 4 von 5 Sternen4/5 (12)

- Machinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionVon EverandMachinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionNoch keine Bewertungen

- Pilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CVon EverandPilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CNoch keine Bewertungen

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseVon EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseBewertung: 4.5 von 5 Sternen4.5/5 (51)

- Cyber-Physical Systems: Foundations, Principles and ApplicationsVon EverandCyber-Physical Systems: Foundations, Principles and ApplicationsHoubing H. SongNoch keine Bewertungen

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideVon Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideBewertung: 3.5 von 5 Sternen3.5/5 (7)

- Electrical (Generator and Electrical Plant): Modern Power Station PracticeVon EverandElectrical (Generator and Electrical Plant): Modern Power Station PracticeBewertung: 4 von 5 Sternen4/5 (9)

- Laminar Flow Forced Convection in Ducts: A Source Book for Compact Heat Exchanger Analytical DataVon EverandLaminar Flow Forced Convection in Ducts: A Source Book for Compact Heat Exchanger Analytical DataNoch keine Bewertungen

- The Galactic Federation: Discovering the Unknown Can Be Stranger Than FictionVon EverandThe Galactic Federation: Discovering the Unknown Can Be Stranger Than FictionNoch keine Bewertungen

- Practical Hydraulic Systems: Operation and Troubleshooting for Engineers and TechniciansVon EverandPractical Hydraulic Systems: Operation and Troubleshooting for Engineers and TechniciansBewertung: 4 von 5 Sternen4/5 (8)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsVon EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Safety Theory and Control Technology of High-Speed Train OperationVon EverandSafety Theory and Control Technology of High-Speed Train OperationBewertung: 5 von 5 Sternen5/5 (2)

- Chasing the Demon: A Secret History of the Quest for the Sound Barrier, and the Band of American Aces Who Conquered ItVon EverandChasing the Demon: A Secret History of the Quest for the Sound Barrier, and the Band of American Aces Who Conquered ItBewertung: 4 von 5 Sternen4/5 (25)

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideVon EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideBewertung: 4 von 5 Sternen4/5 (8)

- Gas Turbines: A Handbook of Air, Land and Sea ApplicationsVon EverandGas Turbines: A Handbook of Air, Land and Sea ApplicationsBewertung: 4 von 5 Sternen4/5 (9)