Beruflich Dokumente

Kultur Dokumente

Centrifugal Pump Test Rig

Hochgeladen von

Vaidish SumariaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Centrifugal Pump Test Rig

Hochgeladen von

Vaidish SumariaCopyright:

Verfügbare Formate

Experiment No- 12 CENTRIFUGAL PUMP TEST RIG

1.0 OB ECTI!E"

To obtain the efficiency of a centrifugal pump under varying speed.

2.0 T#EOR$"

Centrifugal pump is so named because the pressure head is generated by centrifugal action. The impeller is made up of a number of curved vanes, which are supported on both sides by plates known as shrouds. It rotates inside a casing or volute. Flow enters the pump through the centre or eye of the impeller. Energy is given to the liquid as the blades of the impeller transport it outwards in a radial direction. The volute is usually shaped in the form of a spiral to form a gradual increase in flow area so that the velocity energy at e it from the impeller is converted to additional pressure energy. The centrifugal pump is initially primed where in the suction pipe, casing of the pump and the portion of the delivery pipe up to the delivery valve are completely filled with the liquid to be pumped. !ith the delivery valve closed, the impeller is made to rotate. "s a result a forced vorte is developed which imparts a centrifugal head to the liquid. #imultaneously the angular momentum is changed resulting in an increase of the liquid pressure. !hen the delivery valve is opened the liquid is forced to flow in an outward radial direction thereby leaving the vanes of the impeller at the outer circumference with high velocity and pressure. The high pressure of the liquid leaving the impeller enables the liquid to rise to a high level. This action is a continuous process because the eye of the impeller is continuously supplied with replacement liquid from the pump as a result of the pressure gradient in the suction pipe $a partial vacuum e ists at the eye of the impeller and the liquid in the sump is at atmospheric pressure%. The high absolute velocity at the outlet of the vanes is converted to useful pressure energy by shaping the casing such that the liquid flows through a gradually e panding passage.

NOTE& In the supplied apparatus, a self priming pump does not require priming. In summary, it may be stated that a centrifugal pump lifts the liquid to a higher level as a result of a modification of the hydraulic gradient caused by centrifugal action and change in angular momentum. This is an contrast to a positive displacement pump where in lifting action is due to pushing in a confined space. It may also be noted that the action of a centrifugal pump vis'('vis a positive displacement pump is that its discharge capacity is much greater, it can be used to pump highly viscous liquids also, it can be operated at high speeds with less danger of separation and cavitations, and its maintenance requirement are low. )owever, it cannot built'up pressure as high as those that can be built up by reciprocating pumps. The performance of a pump at a fi ed* variable speed may be represented as follows&

+ets,

Inlet pressure, m .ischarge pressure, m Flow rate, m *sec .atum )ead, m

0

, p, p/ , 1 , 2/

$)ence datum is the distance of the centre of the pressure gauge connected in the delivery line from the flange.% Total head across pump ) , $p/' p-% 3 2/ m For obtaining the out put of the motor $input of the pump% attached to the pump, a swinging arm field dynamometer is provided. Torque , $load arm distance% Input power p , $/4 5g )1 speed in r.p.s T% watts watts !ater power po ,

$!here 5 is the mass density of the liquid being pumped%.

Efficiency 67

waterpower 8-99 inputpower

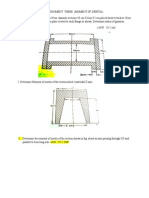

%.0 APPARATUS"

The apparatus consists of a pump connected with a ..C. motor. The suction pipe is provided with a vacuum gauge for measurement of suction head. !hile at the discharge side a pressure gauge is fitted for measurement of the delivery head. " variable speed motor drive is provided. " tachometer is provided for the measurement of the revolution of pump. " swinging arm field dynamometer is connected on motor for measurement of load. " collecting tank is used to find the actual discharge through the pump.

&.0

SUGGESTE' E(PERIMENTAL PROCE'URE"

distance of the spring from the centre of the shaft.

Step 1& :ote down the area of collecting tank, position of delivery pressure gauge $2 /% and arm Step 2" ;riming the pump'set before starting. ;riming means taking the air present in the suction and pressure pipes, volute casing by filling them with water. Ensure to close the aircock * priming adaptor as the air bubbles cease appearing and continuous stream of water come from aircock* priming adaptor. :<TE& In the supplied apparatus, a self priming pump is used so the pump does not require priming. Step %& The speed control on the motor is set to a value and at the same time the flow control valve was ad=usted to give the ma imum possible discharge. Step && Conditions were allowed to steady before the rate of discharge 1, suction head, discharge head, load on the motor and r.p.s. value were recorded. Step )" The flow rate is reduced in stages and the above procedure is repeated.

).0 SAMPLE 'ATA S#EET"

;osition of delivery pressure gauge $.atum head%, 2/, m "rm distance, m 5g "rea of collecting tank AaB m/ , 9.-> , 9.-9 , ?@-9 :*m 0 ,

*i+ O,-er./tion T/,0e" Cun :o .ischarge Deasurement ;ump speed $r.p.m% #uction )ead ;$'mm)g% Initial h- $cm% / 0 *i+ C/0120/tion T/,0e" Cun :o .ischarge measurement Initial h-$m% Final h/$m% Time $sec% .isch' arge 1 $m0*sec% ;ump #peed $r.p.s% #uction )ead ' ;meter .eli' Fery )ead ;/ meter Total )ead $)% meter +oad $:% Torque $T% :'m !ater ;ower ;o $watt% 5g )1 Input ;ower ; $watt% Effi' ciency 67 Final h/ $cm Time $sec% .elivery )ead ;/ $EgF*cm/ % +oad $kg% .atum )ead $2% cm

3.0 RESULTS" The efficiency of Centrifugal pump ,

Das könnte Ihnen auch gefallen

- Force and Vortex ExperimentDokument11 SeitenForce and Vortex ExperimentPauSomerhalderNoch keine Bewertungen

- Flow Meter Procedure: Rotameter, Venturi, OrificeDokument3 SeitenFlow Meter Procedure: Rotameter, Venturi, OrificeZafirah Zaidi100% (1)

- Theory and Introduction Multi Pump Test RigDokument6 SeitenTheory and Introduction Multi Pump Test RigIkhwhanif KhalidNoch keine Bewertungen

- Lab3E8 - Series and Parallel PumpDokument8 SeitenLab3E8 - Series and Parallel PumpRaied Basam0% (1)

- Hydrostatic forces on immersed plane surfacesDokument9 SeitenHydrostatic forces on immersed plane surfacesEssam Ahmed Abd MeguidNoch keine Bewertungen

- Calibration of Bourdon Pressure Gage PDFDokument3 SeitenCalibration of Bourdon Pressure Gage PDFMohammed Cardoza100% (1)

- Hydraulic Bench Parts DemoDokument4 SeitenHydraulic Bench Parts DemoAliya A KhanNoch keine Bewertungen

- Series and Parallel PumpsDokument8 SeitenSeries and Parallel PumpsLanyoong67% (3)

- Hydrostatic Force On A Plane Surface-8Dokument2 SeitenHydrostatic Force On A Plane Surface-8Fahad AreebNoch keine Bewertungen

- Parts of Hydraulic Bench MachineDokument2 SeitenParts of Hydraulic Bench MachineAamir Abbas100% (3)

- Me Lab. Report 2Dokument12 SeitenMe Lab. Report 2Henry Datangel100% (1)

- Experiment No. 1 Performance Test of Centrifugal PumpDokument24 SeitenExperiment No. 1 Performance Test of Centrifugal PumpAli Requiso MahmudNoch keine Bewertungen

- Lab7-Phelton Turbine Experiment-UpdatedDokument7 SeitenLab7-Phelton Turbine Experiment-Updatedtomtoms92Noch keine Bewertungen

- Centrifugal Pump Test RigDokument4 SeitenCentrifugal Pump Test RigSameer Tamboli100% (1)

- Determination of Coefficient of Discharge of A Venturi MeterDokument1 SeiteDetermination of Coefficient of Discharge of A Venturi MeterJoffer Gallamaso50% (2)

- Flow Demonstration ExperimentDokument5 SeitenFlow Demonstration ExperimentVictoria SooknananNoch keine Bewertungen

- Energy Losses in Bends and FittingsDokument11 SeitenEnergy Losses in Bends and FittingsQuenneBelocura100% (1)

- Flow Through an Orifice - Calculating Discharge, Velocity & Contraction CoefficientsDokument6 SeitenFlow Through an Orifice - Calculating Discharge, Velocity & Contraction Coefficientshozipek559950% (2)

- Orifice Jet Flow Experiment GuideDokument3 SeitenOrifice Jet Flow Experiment GuideshaneshaneshaneshaneNoch keine Bewertungen

- FinalPaperTO VERIFY THE MOMENTUM EQUATION BY IMPACT OF JET APPRATUS ON FLAT PLATE 191283Dokument4 SeitenFinalPaperTO VERIFY THE MOMENTUM EQUATION BY IMPACT OF JET APPRATUS ON FLAT PLATE 191283Katy PerryNoch keine Bewertungen

- Pipe Friction ApparatusDokument6 SeitenPipe Friction ApparatusShubham MauryaNoch keine Bewertungen

- Impact of JetDokument5 SeitenImpact of Jetميسرة33% (3)

- Pitot Tube Lab ManualDokument7 SeitenPitot Tube Lab ManualUmAr Malick50% (2)

- Pelton Turbine CharacteristicsDokument10 SeitenPelton Turbine CharacteristicsViknesh MjNoch keine Bewertungen

- CI Engine Lab ReportDokument7 SeitenCI Engine Lab ReportMichael Adrian100% (4)

- Reciprocating Pump PPT L-2 T-1Dokument16 SeitenReciprocating Pump PPT L-2 T-1Ashmi AshiqNoch keine Bewertungen

- Slump Test Determines Concrete WorkabilityDokument3 SeitenSlump Test Determines Concrete WorkabilityKevin P MendozaNoch keine Bewertungen

- PolyLab Engineering Equipment Manual: Losses in Pipe Fittings and Friction ApparatusDokument5 SeitenPolyLab Engineering Equipment Manual: Losses in Pipe Fittings and Friction Apparatussamurai_jackleNoch keine Bewertungen

- Pelton TurbineDokument4 SeitenPelton TurbineHenDricky Magosi100% (1)

- LAB SHEET For Pelton Wheel 21 Sept 2011Dokument3 SeitenLAB SHEET For Pelton Wheel 21 Sept 2011Mohd FazliNoch keine Bewertungen

- Chapter 5 Boundary Layer Flow On A Flat PlateDokument44 SeitenChapter 5 Boundary Layer Flow On A Flat Plateazini amizaNoch keine Bewertungen

- Fluid Flow Measurement Lab: ObjectDokument9 SeitenFluid Flow Measurement Lab: ObjectAboodNoch keine Bewertungen

- Experimental Methods LabDokument6 SeitenExperimental Methods LabIbraheem OlugbadeNoch keine Bewertungen

- Pitot Tube (Velocity Profile)Dokument17 SeitenPitot Tube (Velocity Profile)saleemdbg88% (8)

- Experiment 3Dokument3 SeitenExperiment 3MaisarahNoch keine Bewertungen

- Experiment no. 4 Hydrostatic Force on Submerged and Semi ʹ submerged Rectangular Area 1. bjectiveDokument6 SeitenExperiment no. 4 Hydrostatic Force on Submerged and Semi ʹ submerged Rectangular Area 1. bjectiveGien Lim100% (1)

- Conclusion & Recomendation Thermo Exp 4Dokument2 SeitenConclusion & Recomendation Thermo Exp 4Zoltar JRNoch keine Bewertungen

- Relative Equilibrium of LiquidsDokument18 SeitenRelative Equilibrium of LiquidsIrene Grace BatalaoNoch keine Bewertungen

- How Jet Angles Affect Fluid ForcesDokument11 SeitenHow Jet Angles Affect Fluid Forcesjoshx12Noch keine Bewertungen

- Final ReportDokument36 SeitenFinal ReportKen Denver MaglinteNoch keine Bewertungen

- Calculate Metacentric Height of a Ship ModelDokument4 SeitenCalculate Metacentric Height of a Ship ModelmitulkindNoch keine Bewertungen

- Lab # 5 Plunger Pump: ObjectiveDokument6 SeitenLab # 5 Plunger Pump: ObjectiveNioNoch keine Bewertungen

- Slump Test of Fresh Concrete (ASTM C143/C143M-05a) & (BS 1881: PART 102:83)Dokument17 SeitenSlump Test of Fresh Concrete (ASTM C143/C143M-05a) & (BS 1881: PART 102:83)Zahim Harki100% (1)

- Relative Equilibrium of FluidsDokument3 SeitenRelative Equilibrium of FluidsMike Mor'z25% (4)

- Transport Phenomena 3Dokument19 SeitenTransport Phenomena 3Kaify PeshmergaNoch keine Bewertungen

- Experiment 3 Hydraulics LabDokument12 SeitenExperiment 3 Hydraulics LabMatt NashrudinNoch keine Bewertungen

- Coefficient of Discharge of Weirs Notch TrapezoidalDokument16 SeitenCoefficient of Discharge of Weirs Notch TrapezoidalMuhammad FarhanNoch keine Bewertungen

- Experiment1 Orifice and Jet Flow Group1 A03Dokument6 SeitenExperiment1 Orifice and Jet Flow Group1 A03Francis Aeron PabalanNoch keine Bewertungen

- Experiment No. 1 Hydraulic RamDokument13 SeitenExperiment No. 1 Hydraulic RamAlex Luminarias67% (6)

- Tutorial 03 - Static Forces On SurfacesDokument2 SeitenTutorial 03 - Static Forces On SurfacesafzalNoch keine Bewertungen

- Pitot Tube Exper.Dokument4 SeitenPitot Tube Exper.AbdulrazzaqAL-Maliky100% (1)

- Expt 2 Performance of A Steam PlantDokument8 SeitenExpt 2 Performance of A Steam PlantAzim YusoffNoch keine Bewertungen

- Manning's Roughness Coefficient (N)Dokument11 SeitenManning's Roughness Coefficient (N)Khurram MumtazNoch keine Bewertungen

- Metacentric HeightDokument4 SeitenMetacentric Heightkriap95Noch keine Bewertungen

- Experiment 3 Air Compressor PDFDokument9 SeitenExperiment 3 Air Compressor PDFah qian100% (1)

- Hydraulic Machines LaboratoryDokument27 SeitenHydraulic Machines LaboratoryAnonymous f1UCK4Noch keine Bewertungen

- Exp 8 TM - Centrifugal Pump Trial 09.10.23Dokument7 SeitenExp 8 TM - Centrifugal Pump Trial 09.10.23deepakNoch keine Bewertungen

- Centrifugal Pump Complete Lab ReportDokument23 SeitenCentrifugal Pump Complete Lab Reportriz48577% (61)

- Experiment - 2: AIM: To Study The Characteristics of Pelton Turbine and Plot GraphsDokument8 SeitenExperiment - 2: AIM: To Study The Characteristics of Pelton Turbine and Plot GraphsNishant JainNoch keine Bewertungen

- Constant Speed Centrifugal PumpDokument5 SeitenConstant Speed Centrifugal PumpZia AhmedNoch keine Bewertungen

- Generative and Reinforcement Learning Physics Workshop ApplicationDokument1 SeiteGenerative and Reinforcement Learning Physics Workshop ApplicationVaidish SumariaNoch keine Bewertungen

- 09 Jun 00Dokument29 Seiten09 Jun 00Vaidish SumariaNoch keine Bewertungen

- Mass transfer effects in porous catalystsDokument11 SeitenMass transfer effects in porous catalystsVaidish SumariaNoch keine Bewertungen

- Cheat SheetDokument1 SeiteCheat SheetVaidish SumariaNoch keine Bewertungen

- MajorhdahDokument8 SeitenMajorhdahVaidish SumariaNoch keine Bewertungen

- ChE 299 Winter 2019 SyllabusDokument1 SeiteChE 299 Winter 2019 SyllabusVaidish SumariaNoch keine Bewertungen

- OptimizationDokument2 SeitenOptimizationVaidish SumariaNoch keine Bewertungen

- Serial NumberDokument1 SeiteSerial NumberVaidish SumariaNoch keine Bewertungen

- WDokument1 SeiteWVaidish SumariaNoch keine Bewertungen

- Table of ContentsDokument6 SeitenTable of ContentsVaidish SumariaNoch keine Bewertungen

- Reactions ExtentDokument8 SeitenReactions ExtentVaidish SumariaNoch keine Bewertungen

- QwertyDokument1 SeiteQwertyVaidish SumariaNoch keine Bewertungen

- FenomenosDokument6 SeitenFenomenosenriqueg_53Noch keine Bewertungen

- RequirementsDokument1 SeiteRequirementsVaidish SumariaNoch keine Bewertungen

- Edriveassgnsem 7Dokument3 SeitenEdriveassgnsem 7Vaidish SumariaNoch keine Bewertungen

- IAS Fellowship FormDokument2 SeitenIAS Fellowship FormVaidish SumariaNoch keine Bewertungen

- Qwerty 3Dokument1 SeiteQwerty 3Vaidish SumariaNoch keine Bewertungen

- SsssssssssssssDokument1 SeiteSsssssssssssssVaidish SumariaNoch keine Bewertungen

- Read MeDokument1 SeiteRead MeNateNoch keine Bewertungen

- Placement LetterDokument1 SeitePlacement LetterVaidish SumariaNoch keine Bewertungen

- Mat.T Manuals OrientationDokument24 SeitenMat.T Manuals OrientationVaidish SumariaNoch keine Bewertungen

- Types of RefineriesDokument2 SeitenTypes of RefineriesVaidish SumariaNoch keine Bewertungen

- Resume FormatDokument2 SeitenResume FormatSiddhant SharmaNoch keine Bewertungen

- Course Plan PDU Jan - June 2015Dokument14 SeitenCourse Plan PDU Jan - June 2015Vaidish SumariaNoch keine Bewertungen

- Edited Paper For SchemconDokument9 SeitenEdited Paper For SchemconVaidish SumariaNoch keine Bewertungen

- AdsorptionDokument19 SeitenAdsorptionArun DubeyNoch keine Bewertungen

- Assignment 0Dokument1 SeiteAssignment 0Vaidish SumariaNoch keine Bewertungen

- Assignment FourDokument3 SeitenAssignment FourVaidish SumariaNoch keine Bewertungen

- P&IDsDokument4 SeitenP&IDsRamadhan PrasetyaNoch keine Bewertungen

- Johnson RPM Chart Evinrude E-Tec RPM Chart Mercury 4-Stroke RPM ChartDokument2 SeitenJohnson RPM Chart Evinrude E-Tec RPM Chart Mercury 4-Stroke RPM ChartUlf NymanNoch keine Bewertungen

- 2010 Final Exam (Answers)Dokument10 Seiten2010 Final Exam (Answers)T FNoch keine Bewertungen

- Anti Climbers FlyerDokument2 SeitenAnti Climbers Flyeredark2009Noch keine Bewertungen

- C6713 Lab ManualDokument51 SeitenC6713 Lab Manualsmganorkar100% (1)

- Manifest Merger Debug ReportDokument14 SeitenManifest Merger Debug ReportRam PankhaniyaNoch keine Bewertungen

- Bubble Sort: For (K 0 K X (K + 1) ) Swaparay (X, K, K + 1)Dokument7 SeitenBubble Sort: For (K 0 K X (K + 1) ) Swaparay (X, K, K + 1)Vikas PuniaNoch keine Bewertungen

- Unsaturated Polyester Resins: Chemistry and Technology: Piotr Penczek (U) Piotr Czub Jan PielichowskiDokument2 SeitenUnsaturated Polyester Resins: Chemistry and Technology: Piotr Penczek (U) Piotr Czub Jan Pielichowskiae0011979Noch keine Bewertungen

- Insulation Resistance TestDokument7 SeitenInsulation Resistance Testcarlos vidalNoch keine Bewertungen

- Mass Transfer in Industrial ApplicationsDokument1 SeiteMass Transfer in Industrial ApplicationsMPD19I001 VITHISHA MNoch keine Bewertungen

- Prediction On Miss Mamta Banerjee Honorable CM of West Bengal Much Much Before Result and Election by Indranil RayDokument24 SeitenPrediction On Miss Mamta Banerjee Honorable CM of West Bengal Much Much Before Result and Election by Indranil RayIndranil RayNoch keine Bewertungen

- Muhammad Zahrandhika Bastian-3Dokument2 SeitenMuhammad Zahrandhika Bastian-3dhika zahrandhikaNoch keine Bewertungen

- CSAT 2019 Spe3D Duguid - Andrew PDFDokument111 SeitenCSAT 2019 Spe3D Duguid - Andrew PDFdocturboNoch keine Bewertungen

- Business Conclave - Concept DesignDokument3 SeitenBusiness Conclave - Concept DesignSajal GuptaNoch keine Bewertungen

- Lind 18e Chap005Dokument35 SeitenLind 18e Chap005MELLYANA JIENoch keine Bewertungen

- 1st Periodic Test - Math 9Dokument2 Seiten1st Periodic Test - Math 9Anna Rose Godes AntioquiaNoch keine Bewertungen

- Systems ClassDokument53 SeitenSystems ClassBhetariya PareshNoch keine Bewertungen

- 5100 Series Gas Analyzer: Product Data SheetDokument2 Seiten5100 Series Gas Analyzer: Product Data SheetSai KamalaNoch keine Bewertungen

- INCaDokument47 SeitenINCaMehdi SoltaniNoch keine Bewertungen

- 2017 09Dokument164 Seiten2017 09sowabar100% (1)

- Math IGCSE 2019 PapersDokument13 SeitenMath IGCSE 2019 PapersCraft CityNoch keine Bewertungen

- Hydraulic Accumulator - Test and Charge: Cerrar SIS Pantalla AnteriorDokument9 SeitenHydraulic Accumulator - Test and Charge: Cerrar SIS Pantalla AnteriorHomer Yoel Nieto Mendoza100% (1)

- Order Details for Order #10105Dokument2 SeitenOrder Details for Order #10105Mohamed HarbNoch keine Bewertungen

- MTBF and MTTR For Metal-Enclosed Capacitor Banks and Harmonic Filter SystemsDokument4 SeitenMTBF and MTTR For Metal-Enclosed Capacitor Banks and Harmonic Filter SystemsbansalrNoch keine Bewertungen

- Fractal ForestsDokument50 SeitenFractal ForestsWell Fournier0% (1)

- DSP Lab - ScilabDokument17 SeitenDSP Lab - ScilabSai Nikshipth MaddhugaruNoch keine Bewertungen

- Three Theories of TruthDokument1 SeiteThree Theories of TruthDn AngelNoch keine Bewertungen

- Hyponymy and Hypernymy: Jump To Navigationjump To SearchDokument8 SeitenHyponymy and Hypernymy: Jump To Navigationjump To SearchSteven HamNoch keine Bewertungen

- DLTSoul DrinkersDokument7 SeitenDLTSoul DrinkersIgnacio Burón García100% (1)

- Shs Core Subjects MelcsDokument63 SeitenShs Core Subjects MelcsRoldan Merjudio100% (1)

- EXS Series Product Specification.20180405.01Dokument1 SeiteEXS Series Product Specification.20180405.01Alex Araujo AlvaradoNoch keine Bewertungen