Beruflich Dokumente

Kultur Dokumente

2/2-Way Angle Seat Valve, Manually Operated, For Media Up To +180 °C

Hochgeladen von

Amaya FábianOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

2/2-Way Angle Seat Valve, Manually Operated, For Media Up To +180 °C

Hochgeladen von

Amaya FábianCopyright:

Verfügbare Formate

2000/2702

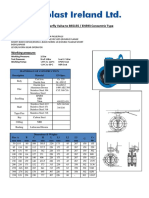

2/2-way Angle Seat Valve, manually

operated, for media up to +180 C

Position indication

Adjustable flow rates

Stainless steel valve body

Compact industrial design with long service life

Type 2000/2702 can be combined with...

Excellent seat tightness due to PTFE soft sealing

Type 8034

Type 8035

Type 8311

Type 8314

Type 8400

Flow Indicator

Flow Transmitter

Pressure Transmitter

with display

Pressure Transmitter

Temperature Transmitter

with display

Manually-operated angle-seat valve of the type

series 2000/2702 are delivered as standard

with threaded or weld end port connection.

Type 2000 with manual actuator without

position indicator is used only for On/Off

function. Type 2702 with manual actuator and

position indicator is designed with a parabolic

trim and therefore it can be used to control a

dened ow.

Technical data

Flow direction below the seat (for gases and uids)

Port size

DN15-50

Body material

Typ 2000 weldend acc. to

EN ISO 1127/150 4200 &

DIN 11850 S2

Stainless steel 316L

Stainless steel 1.4581

Actuator material

PPS

Seal material (Type 2000)

PTFE

Seal material (Type 2702)

PTFE or stainless steel 1.4571

Medium

Neutral gases, water, alcohols, oils,fuels, salt solutions, lye,

organic solvents, steam

Viscosity

Max. 600 mm2/s

Packing gland

PTFE V-rings (silicone grease)

Nominal pressure

PN 16 (DN 15-25)

PN 10 (DN 32-50)

Temperatures

Fluid

Ambient

-10 to +180 C (max. +130 C for PTFE/St.st.

Sealing recommended

-10 to +60 C

Flow direction

Type 2000

Type 2702

any ow direction

below seat

Installation

As required

Port connections

Type 2000/2702

Optional

Options

G threaded port,

weld end acc. EN ISO 1127/ISO 4200,

weld end acc. DIN 11850 series 2

NPT, Rc threaded port,

Weld end acc. BS 4825, ASME, SMS 3008

Handwheel with locking against unauthorised or

unintensional changing of the valve postion

www.burkert.com

p. 1/6

2000/2702

Materials - Flow rates

Type 2000

11

10

Valve body:

Weld end acc. to

EN ISO 1127/150 4200 &

DIN 11850 S2

8

7

6

2

3

4

5

6

7

8

9

10

11

5

4

3

2

1

Type 2000

Seal:

Pin:

Swivel plate:

Spindle:

Wiper:

Nipple:

V-Seals:

Tube:

Torque support:

Manual actuator:

316 L

1.4581

Kv-value

PTFE

1.4404

1.4404

1.4404

PTFE

1.4404

PTFE

1.4404

PPS

PPS

Kvs [m3/h]

4.5

10

20

28

42

55

DN

15

20

25

32

40

50

(without position indicator)

Type 2702

11

10

1

2

3

4

5

6

7

8

9

10

11

9

8

7

6

5

4

3

2

Type 2702

Shows version with

PTFE-seal

Valve body:

Seal:

Pin:

Parabolic trim:

Spindle:

Wiper:

Nipple:

V-Seals:

Tube:

Torque support:

Manual actuator:

(with position indicator)

Kv-values

2702

316 L

PTFE (not applicable for 316 L seat sealing version)

1.4310

Kvs-value

1.4571

DN

Kvs

1.4404

[m3/h]

PTFE

15

4.5

1.4404

20

9

PTFE

25

15

1.4404

32

23

PPS

40

33

PPS

50

52

Port size [mm]

15

20

25

32

40

50

Stroke [mm]

Kv [m3/h]

Stroke [m3/h]

Kv [m3/h]

Stroke [mm]

Kv [m3/h]

Stroke [mm]

Kv [m3/h]

Stroke [mm]

Kv [m3/h]

Stroke [mm]

Kv [m3/h]

Min.Stroke

[mm]

12

18

20

20

24

26

Stroke [%]

5

0.6

0.23

0.9

0.3

1.0

0.39

1.0

0.55

1.3

0.65

1.3

1

10

1.2

0.24

1.8

0.33

2.0

0.41

2.0

0.65

2.0

0.85

2.6

1.3

Indication

20

2.4

0.26

3.6

0.42

4.0

0.60

4.0

0.95

5.2

1.5

5.2

2

30

3.6

0.35

5.4

0.7

6.0

1.25

6.0

1.5

7.8

5

7.8

5

40

4.8

0.7

7.2

2.85

8.0

4.5

8.0

4

10.4

14

10.4

16

50

6.0

1.85

9.0

5.3

10.0

8.5

10.0

9.3

13

20

13

27

60

7.2

2.9

10.8

6.6

12.0

10.5

12.0

13.8

15.6

25

15.6

34

70

8.4

3.5

12.6

7.5

14.0

12.2

14.0

16.5

18.2

27

18.2

41

80

9.6

4

14.4

8.2

16.0

13.5

16.0

18.8

20.8

30

20.8

45

90

10.8

4.3

16.2

8.6

18.0

14.2

18.0

21

23.4

32.5

23.4

49

100

12.0

4.5

18.0

9

20.0

15

20.0

23

24

33

26

53

Flow characteristics

Kv/Kvs [%]

The value of the position indication is a distance in [mm], in general

the actual stroke (distance between valve-seat and seat-seal in mm).

The digit after the vertical line represents 1/10 mm. Per revolution of the

handwheel, the vertical position of the

valve will change exactly 1.5 mm.

For tuning of a well-dened ow rate,

please take the chart with the ow rate

and the stroke.

100

90

80

70

60

50

40

30

20

10

0

10

20

30

40

50

60

70

80

90 100

Hub [%]

p. 2/6

2000/2702

Item no.

Weight

[kg]

Seal

material

Max.

operating

pressure

[bar]

[mm]

[inch]

Port Size

Kvs value

water

[m3/h]

Ordering chart for valves (other versions on request)

Type 2000 body with G threaded port (without position indicator)

Type 2000

Seat sealing PTFE

Any ow direction

15

1/2"

4.5

0-16

PTFE

1.2

219 720

20

3/4"

10

0-16

PTFE

1.25

219 721

25

1"

20

0-16

PTFE

1.58

219 722

32

1 1/4"

28

0-10

PTFE

2.13

219 723

40

1 1/2"

42

0-10

PTFE

2.5

219 724

50

2"

55

0-10

PTFE

3.72

166 080

Type 2000 body with weld end acc. EN ISO 1127/ISO 4200 (without position indicator)

15

1/2"

4.5

0-16

PTFE

1.2

166 016

20

3/4"

10

0-16

PTFE

1.25

166 019

25

1"

20

0-16

PTFE

1.58

166 072

32

1 1/4"

28

0-10

PTFE

2.13

166 075

40

1 1/2"

42

0-10

PTFE

2.5

166 078

50

2"

55

0-10

PTFE

3.72

166 081

1/2"

4.5

0-16

PTFE

1.2

166 017

20

3/4"

10

0-16

PTFE

1.25

166 020

25

1"

20

0-16

PTFE

1.58

166 073

32

1 1/4"

28

0-10

PTFE

2.13

166 076

40

1 1/2"

42

0-10

PTFE

2.5

166 079

50

2"

55

0-10

PTFE

3.72

166 082

Kvs value

water

[m3/h]

Max.

operating

pressure

[bar]

Item no.

15

1/2"

4.5

0-16

PTFE

1.2

219 725

20

3/4"

9.0

0-16

PTFE

1.25

219 727

25

1"

15

0-16

PTFE

1.58

219 729

32

1 1/4"

23

0-10

PTFE

2.13

219 731

40

1 1/2"

33

0-10

PTFE

2.5

219 733

50

2"

53

0-10

PTFE

3.72

166 111

[mm]

Weight

[kg]

Port Size

Seal

material

15

[inch]

Type 2000 body with weld end acc. DIN 11850 series 2 (without position indicator)

Type 2702 body with G threaded port (with position indicator)

Type 2702

Seat sealing PTFE,

parabolic plug

Flow direction

below seat

Type 2702 body with weld end acc. EN ISO 1127/ISO 4200 (with position indicator)

15

1/2"

4.5

0-16

PTFE

1.2

166 097

20

3/4"

9.0

0-16

PTFE

1.25

166 100

25

1"

15

0-16

PTFE

1.58

166 103

32

1 1/4"

23

0-10

PTFE

2.13

166 106

40

1 1/2"

33

0-10

PTFE

2.5

166 109

50

2"

53

0-10

PTFE

3.72

166 112

Type 2702 body with weld end acc. DIN 11850 series 2 (with position indicator)

15

1/2"

4.5

0-16

PTFE

1.2

166 098

20

3/4"

9.0

0-16

PTFE

1.25

166 101

25

1"

15

0-16

PTFE

1.58

166 104

32

1 1/4"

23

0-10

PTFE

2.13

166 107

40

1 1/2"

33

0-10

PTFE

2.5

166 110

50

2"

53

0-10

PTFE

3.72

166 113

p. 3/6

2000/2702

Weight

[kg]

Item no.

4.5

0-16

1.4571

1.2

219 726

3/4"

9.0

0-16

1.4571

1.3

219 728

25

1"

15

0-16

1.4571

1.6

219 730

32

1 1/4"

23

0-10

1.4571

2.1

219 732

40

1 1/2"

33

0-10

1.4571

2.5

219 734

50

2"

53

0-10

1.4571

3.7

166 129

Max.

operating

pressure

[bar]

1/2"

20

[inch]

15

[mm]

Seal

material

(parabolic

trim)

Port Size

Kvs value

water [m3/h]

Ordering chart for valves (other versions on request)

Type 2702 body with G threaded port (with position indicator)

Type 2702

Seat sealing

stainless steel

parabolic plug

Flow direction

below seat

Type 2702 body with weld end acc. EN ISO 1127/ISO 4200 (with position indicator)

15

1/2"

4.5

0-16

1.4571

1.2

166 115

20

3/4"

9.0

0-16

1.4571

1.3

166 118

25

1"

15

0-16

1.4571

1.6

166 121

32

1 1/4"

23

0-10

1.4571

2.1

166 124

40

1 1/2"

33

0-10

1.4571

2.5

166 127

50

2"

53

0-10

1.4571

3.7

166 130

Type 2702 body with weld end acc. DIN 11850 series 2 (with position indicator)

15

1/2"

4.5

0-16

1.4571

1.2

166 116

20

3/4"

9.0

0-16

1.4571

1.3

166 119

25

1"

15

0-16

1.4571

1.6

166 122

32

1 1/4"

23

0-10

1.4571

2.1

166 125

40

1 1/2"

33

0-10

1.4571

2.5

166 128

50

2"

53

0-10

1.4571

3.7

166 131

The manual actuator of Type 2000 and 2702 can also be combined with different globe valve bodies (on request)

Type 2012

without position indicator

with on/off plug

Weld end

Thread

Type 2712

with position indicator

with parabolic plug

Flange

TriClamp

Customized

p. 4/6

2000/2702

Dimensions [mm]

Type 2000

Weld end

45

45

H 1

H 1

86

86

Threaded Port

Class 150

PN 25

C 0,5

C 0,5

A 0,5

All threaded ports G thread

H

D

153.6 G 1/2

NPT thread

A

65

B

178

20

75

180

152.9

25

90

188

158.8

32

110

201

165.0 G 1 1/4

20

40

120

211

175.6 G 1 1/2

22

50

150 239.1 194.1

C 0,5

O 1

B 1

All

bodies

orice

[mm]

15

DN25 PN16 1.4581

Rc thread

All weld end

bodies

EN ISO 1127/

ISO 4200

D

NPT 1/2

G 3/4

16

NPT 3/4

14.0

Rc 3/4

14.5

115 190.5 151.5

26.9

1.6

23

1.5

G1

18

NPT 1

16.8

Rc 1

16.8

130 198.0 155.0

33.7

29

1.5 10

NPT 1 1/4 17.3

Rc 1 1/4

19.1

145 210.0

42.4

35

1.5

NPT 1 1/2 17.3

Rc 1 1/2

19.1

160 218.2 169.2

48.3

41

1.5 10

Rc 2

23.4

175 235.6 185.6

60.3

2.6

12

53

1.5 10

24

NPT 2

17.6

C

M

O

H

D

S

C

13.2 100 186.2 152.2 21.3 1.6

5

DIN 11850 S2

C

14

G2

C

D

13.7 Rc 1/2

M 0,5

165

D

19

S

C

1.5 6

6

6

Other valve bodies on request

p. 5/6

2000/2702

Dimensions [mm]

Type 2702

Weld end

45

45

H 1

H2

86

86

Threaded ports

DN 25

PN 25

C 0,5

C0.5

C0.5

C 0,5

A 0,5

M 0. 5

B 1

O 2

All bodies

orice

[mm]

15

All threaded ports

G thread

NPT thread

A

65

B

178

H

154

D

G 1/2

C

14

D

NPT 1/2

C

13.7

D

Rc 1/2

C

13.2

20

25

75

90

180

188

153

159

G 3/4

G1

16

18

NPT 3/4

NPT 1

14.0

16.8

Rc 3/4

Rc 1

14.5

16.8

32

40

50

110

120

150

201

211

239.5

165

176

194.5

G 1 1/4

G 1 1/2

G2

20

22

24

NPT 1 1/4

NPT 1 1/2

NPT 2

17.3

17.3

17.6

Rc 1 1/4

Rc 1 1/2

Rc 2

19.1

19.1

23.4

All bodies EN ISO 1127/ISO 4200 and DIN 11850 R2

orices

EN ISO 1127/ISO 4200

[mm]

Rc thread

BS 4825 Part 1, ASME, SMS 3008

DIN 11850 S2

BS 4825 Part 1 ASME

SMS 3008

1.2

12.7

1.65

12

15

100

192.5 158.5

21.3

1.6

20

19

1.5

20

135 204.5 158.5 38

12.7

20

115

197.0

26.9

1.6

25

23

1.5

20

145

38

19.05

1.2

19.05 1.65

18

25

130

202.2 159.5

33.7

30

29

1.5

26

152 210.5 159.5 38

25.4

1.65

25.4

25

1.2

32

145

210.0

170

42.4

26

35

1.5

26

40

160

223.0

173

48.3

30

41

1.5

26

182

233

173

38

38.1

1.65

38.1

1.65

38

1.2

50

175

240.5 190.5

60.3

2.6

35

53

1.5

38

210 254.5 190.5 45

50.8

1.65

50.8

1.65

51

1.2

158

210

158

1.65

Other valve bodies on request

To nd your nearest Burkert facility, click on the orange box J

In case of special application conditions,

please consult for advice

www.burkert.com

Subject to alterations

Christian Brkert GmbH & Co. KG

1307/4_EU-en_00891654

p. 6/6

Das könnte Ihnen auch gefallen

- MPVN BrochureDokument32 SeitenMPVN Brochurefernando_naciamentNoch keine Bewertungen

- High Pressure Needle ValvesDokument11 SeitenHigh Pressure Needle ValvesNilesh MistryNoch keine Bewertungen

- Pressfit 316 Stainless Steel Pipe SystemDokument12 SeitenPressfit 316 Stainless Steel Pipe SystemFaull JackmanNoch keine Bewertungen

- Valves 2/2 E290: Pressure Operated Bronze or Stainless Steel Body Threaded Ports, 3/8 To 2 1/2Dokument4 SeitenValves 2/2 E290: Pressure Operated Bronze or Stainless Steel Body Threaded Ports, 3/8 To 2 1/2Velpuri RameshBabuNoch keine Bewertungen

- SVL488 Stainless Steel Safety Valve For Clean Service Applications-Technical InformationDokument5 SeitenSVL488 Stainless Steel Safety Valve For Clean Service Applications-Technical Informationhippong niswantoroNoch keine Bewertungen

- AMRI ISORIA 16 Type Series Booklet DataDokument20 SeitenAMRI ISORIA 16 Type Series Booklet Datarudiskw456Noch keine Bewertungen

- Uniworld: Series Pneumatic ValvesDokument2 SeitenUniworld: Series Pneumatic ValvesSyarif Mutsaqqif100% (1)

- ValvulaDokument8 SeitenValvulaJosé Gasset Del ValleNoch keine Bewertungen

- AMRI ISORIA Broad Market Type Series Booklet DataDokument12 SeitenAMRI ISORIA Broad Market Type Series Booklet Datarudiskw456Noch keine Bewertungen

- Catalogo ASCODokument4 SeitenCatalogo ASCOIkaro MatosNoch keine Bewertungen

- Sez 6 ENGDokument20 SeitenSez 6 ENGGumersindo MelambesNoch keine Bewertungen

- Next Generation: Ultragrip Reducing CouplingsDokument1 SeiteNext Generation: Ultragrip Reducing CouplingsblindjaxxNoch keine Bewertungen

- Sensor Nivel Murphy LS200Dokument3 SeitenSensor Nivel Murphy LS200Sergio PluchinskyNoch keine Bewertungen

- Mallard LevelInstrumentationDokument24 SeitenMallard LevelInstrumentationYasmine ياسمينNoch keine Bewertungen

- Vann Air ValveDokument4 SeitenVann Air ValveDedeLesmanaNoch keine Bewertungen

- Valvula Bola Sarco m40Dokument3 SeitenValvula Bola Sarco m40radacoNoch keine Bewertungen

- 1service Manual 2004Dokument35 Seiten1service Manual 2004Matias VidalNoch keine Bewertungen

- 2WS21ENDokument8 Seiten2WS21ENcibocrisNoch keine Bewertungen

- Mallard LevelInstrumentationDokument24 SeitenMallard LevelInstrumentationtechdocuNoch keine Bewertungen

- v101 v102 Butterfly ValvesDokument6 Seitenv101 v102 Butterfly Valvesapi-18982376Noch keine Bewertungen

- 06 SCT Extended PDFDokument40 Seiten06 SCT Extended PDFSlobodan Antic100% (2)

- Product Data SheetsDokument107 SeitenProduct Data SheetsTree100% (1)

- Descote 2100BDokument4 SeitenDescote 2100BarrikanNoch keine Bewertungen

- Fisher D4 Product BulletinDokument12 SeitenFisher D4 Product BulletindocrafiNoch keine Bewertungen

- Catalogue Solenoid ValveDokument6 SeitenCatalogue Solenoid ValveshrikantbelekarNoch keine Bewertungen

- Tip 3241-7 PozicionatorDokument8 SeitenTip 3241-7 PozicionatorEmir DelicNoch keine Bewertungen

- Parafusos PT SemblexDokument10 SeitenParafusos PT SemblexSBonderNoch keine Bewertungen

- rc33026 D12-UscDokument7 Seitenrc33026 D12-Usceww08Noch keine Bewertungen

- PVH Sight Glass Data SheetDokument11 SeitenPVH Sight Glass Data SheetANIKET PATILNoch keine Bewertungen

- Data Sheet Liquidring Pump: Series L-Bv5 - Range 2BV5 110 CompressorDokument4 SeitenData Sheet Liquidring Pump: Series L-Bv5 - Range 2BV5 110 Compressortutuli1990Noch keine Bewertungen

- Válvulas Bola SegmentadaDokument12 SeitenVálvulas Bola SegmentadarehynaldoNoch keine Bewertungen

- Rosemount 1195 Integral Orifice Primary Element: Product Data SheetDokument18 SeitenRosemount 1195 Integral Orifice Primary Element: Product Data Sheetابزار دقیقNoch keine Bewertungen

- V9271 Fivalco 2902eDokument6 SeitenV9271 Fivalco 2902eharenas7Noch keine Bewertungen

- Control Valve System: PN 16 / 40 DN 15 - 150 ApplicationDokument0 SeitenControl Valve System: PN 16 / 40 DN 15 - 150 Applicationcico_ctNoch keine Bewertungen

- Guth VSR Modulating ValvesDokument8 SeitenGuth VSR Modulating ValvesRaul Guevara TorresNoch keine Bewertungen

- KSB Valvula Diafragma SISTO10Dokument4 SeitenKSB Valvula Diafragma SISTO10Sarah PerezNoch keine Bewertungen

- Catálogo Válvula DirecionalDokument20 SeitenCatálogo Válvula DirecionalcristianoclemNoch keine Bewertungen

- STEEL Filters: Durable High Quality Steel Filters For Wide Range of Filtration ApplicationsDokument14 SeitenSTEEL Filters: Durable High Quality Steel Filters For Wide Range of Filtration ApplicationsJos AcadNoch keine Bewertungen

- Ball Valves: For SteamDokument8 SeitenBall Valves: For SteamcontorrresjulianNoch keine Bewertungen

- ARO Flo 1500 SeriesDokument11 SeitenARO Flo 1500 SeriesEliasNoch keine Bewertungen

- Butterfly Valves EgeplastDokument4 SeitenButterfly Valves EgeplastdsyashankaNoch keine Bewertungen

- Preview 92103Dokument4 SeitenPreview 92103Almir RodriguesNoch keine Bewertungen

- Unique Single Seat Valve-Simply UniqueDokument8 SeitenUnique Single Seat Valve-Simply UniquelggomezupbNoch keine Bewertungen

- Pumpe Za Septičkudw-Dw-VoxDokument12 SeitenPumpe Za Septičkudw-Dw-VoxMiha GlighaNoch keine Bewertungen

- Pneumatic PosisionerDokument10 SeitenPneumatic Posisionerwong_arifNoch keine Bewertungen

- Top Guide Control ValveDokument32 SeitenTop Guide Control Valveachari_swapnilNoch keine Bewertungen

- Valvulas de Bola - JAMESBURYDokument4 SeitenValvulas de Bola - JAMESBURYcasv9Noch keine Bewertungen

- Service SpecificationDokument95 SeitenService SpecificationLoc TruongNoch keine Bewertungen

- 93 Camry SERVICE SPECIFICATIONS - STANDARD BOLTDokument72 Seiten93 Camry SERVICE SPECIFICATIONS - STANDARD BOLTdgc513Noch keine Bewertungen

- Valve0114 PDFDokument14 SeitenValve0114 PDFbinhjukiNoch keine Bewertungen

- Sensor SITRANS MAG 5100W Datasheet PDFDokument9 SeitenSensor SITRANS MAG 5100W Datasheet PDFdavidcevs89Noch keine Bewertungen

- Suction Strainer Type SUS (Polyamide End Cap) : Flow CharacteristicsDokument2 SeitenSuction Strainer Type SUS (Polyamide End Cap) : Flow CharacteristicsZMCONTROLNoch keine Bewertungen

- Inline Filter RFLD Inline Filter RFLD Inline Filter RFLD Inline Filter RFLD Inline Filter RFLDDokument11 SeitenInline Filter RFLD Inline Filter RFLD Inline Filter RFLD Inline Filter RFLD Inline Filter RFLDAllan ArraisNoch keine Bewertungen

- FoxPro V723 e - 09.99Dokument0 SeitenFoxPro V723 e - 09.99cico_ctNoch keine Bewertungen

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryVon EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNoch keine Bewertungen

- Working Guide to Drilling Equipment and OperationsVon EverandWorking Guide to Drilling Equipment and OperationsBewertung: 5 von 5 Sternen5/5 (9)

- How to prepare Welding Procedures for Oil & Gas PipelinesVon EverandHow to prepare Welding Procedures for Oil & Gas PipelinesBewertung: 5 von 5 Sternen5/5 (1)

- LayoutDokument4 SeitenLayoutAmaya FábianNoch keine Bewertungen

- SRS10ADokument14 SeitenSRS10AAmaya FábianNoch keine Bewertungen

- Valve Terminals - Automation's Best AssetDokument24 SeitenValve Terminals - Automation's Best AssetAmaya FábianNoch keine Bewertungen

- fp93 CDokument8 Seitenfp93 CAmaya FábianNoch keine Bewertungen

- SRS10ADokument14 SeitenSRS10AAmaya FábianNoch keine Bewertungen

- Science TunnelDokument1 SeiteScience TunnelAmaya FábianNoch keine Bewertungen

- Reaction Engineering CHEG 443: Ch.2. Conversion and Reactor SizingDokument36 SeitenReaction Engineering CHEG 443: Ch.2. Conversion and Reactor Sizing100053191Noch keine Bewertungen

- Impulse MomentumDokument18 SeitenImpulse MomentumJulius CodillaNoch keine Bewertungen

- Bone CementDokument31 SeitenBone CementSivaprasath Jaganathan100% (1)

- Group1 Lab1b ReportDokument13 SeitenGroup1 Lab1b ReportMark Allen FacunNoch keine Bewertungen

- BCS 012Dokument92 SeitenBCS 012RishabhNoch keine Bewertungen

- CBSE Class 12 Physics Worksheet - ElectrostatisticsDokument3 SeitenCBSE Class 12 Physics Worksheet - ElectrostatisticsSanjukthNoch keine Bewertungen

- Controllability, Observability, Pole: AllocationDokument14 SeitenControllability, Observability, Pole: AllocationSanchez Resendiz BonifacioNoch keine Bewertungen

- 2.mean Value TheoremsDokument29 Seiten2.mean Value TheoremsPratyush SrivastavaNoch keine Bewertungen

- CT Analyzer User Manual ESPDokument178 SeitenCT Analyzer User Manual ESPmendezhanda100% (1)

- Numerical Analysis of The Capacity of Suction Caisson Anchors Considering Soil-Caisson Interface CharacteristicsDokument106 SeitenNumerical Analysis of The Capacity of Suction Caisson Anchors Considering Soil-Caisson Interface CharacteristicsDang Quang Minh0% (1)

- Unit V R2019Dokument46 SeitenUnit V R2019Gayathri RadhaNoch keine Bewertungen

- (DOC) EXACTLY HOW THE UNIVERSE IS CONSTRUCTED - Docx - MIKE EMERY - Academia - EduDokument3 Seiten(DOC) EXACTLY HOW THE UNIVERSE IS CONSTRUCTED - Docx - MIKE EMERY - Academia - EduStellaEstelNoch keine Bewertungen

- T-Retaining Wall Design To AS5100.3 Rev BDokument7 SeitenT-Retaining Wall Design To AS5100.3 Rev BKevin FarriesNoch keine Bewertungen

- Matigo Mocks Uace Phy 2 GuideDokument22 SeitenMatigo Mocks Uace Phy 2 Guidebuuleivan8Noch keine Bewertungen

- PDF WH1604A TMI CT WinstarDokument26 SeitenPDF WH1604A TMI CT WinstarСергейNoch keine Bewertungen

- CHE145 Gomez, TerradoDokument42 SeitenCHE145 Gomez, TerradoRicky JayNoch keine Bewertungen

- Nptel Internship Progress Presentation at Iisc Bangalore: Different Methodologies Opted For Site Characterization"Dokument11 SeitenNptel Internship Progress Presentation at Iisc Bangalore: Different Methodologies Opted For Site Characterization"Aditya Kumar AnshuNoch keine Bewertungen

- Fulham Induction LuminariesDokument44 SeitenFulham Induction LuminariesAJ BradyNoch keine Bewertungen

- ATOMEX Europe 2011: Sigma Group A.SDokument35 SeitenATOMEX Europe 2011: Sigma Group A.StomognNoch keine Bewertungen

- Lesson 1 Measuring DistanceDokument20 SeitenLesson 1 Measuring DistanceKarl EliezerNoch keine Bewertungen

- Mutriku OWC Plant PDFDokument11 SeitenMutriku OWC Plant PDFLeoPérezNoch keine Bewertungen

- Jet Engine IntegrationDokument8 SeitenJet Engine IntegrationZeeshan100% (1)

- StarWalk Manual enDokument17 SeitenStarWalk Manual enspectraattackNoch keine Bewertungen

- Assignment 1 MAT283Dokument2 SeitenAssignment 1 MAT283meiofaunaNoch keine Bewertungen

- CH4 - Jan 2014Dokument15 SeitenCH4 - Jan 2014Kieran RichardsNoch keine Bewertungen

- IJCER (WWW - Ijceronline.com) International Journal of Computational Engineering ResearchDokument6 SeitenIJCER (WWW - Ijceronline.com) International Journal of Computational Engineering ResearchInternational Journal of computational Engineering research (IJCER)Noch keine Bewertungen

- Sample 7580Dokument11 SeitenSample 7580SagarKasarla0% (1)

- Panasonic TX L32C10P 10PS Chassis GLP24Dokument38 SeitenPanasonic TX L32C10P 10PS Chassis GLP24yacosNoch keine Bewertungen

- FP 700 EngineeringDokument8 SeitenFP 700 EngineeringCarlos Alberto VargasNoch keine Bewertungen

- Density of Rocks Lab WorksheetDokument6 SeitenDensity of Rocks Lab Worksheetadaglio001100% (1)