Beruflich Dokumente

Kultur Dokumente

TT3000 - 5000 Bulk Installation Instructions H55553 - 4 - 96

Hochgeladen von

JC InquillayOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

TT3000 - 5000 Bulk Installation Instructions H55553 - 4 - 96

Hochgeladen von

JC InquillayCopyright:

Verfügbare Formate

Installation Instructions

R

General Information

These instructions detail techniques used to install TT3000 or TT5000 bulk sensing cable into double-containment pipe. Installation is made from pull point (access tee) to pull point. Two people, the feeder and the puller, are needed to complete the installation. They must be able to communicate at all times during the installation. Two-way radios may be required. These instructions assume that 1/4-inch or 3/8-inch hollow braid pull rope has been installed according to the TraceTek Double Containment Installation Guide (LIT-138). To ensure that the pipe is cable ready, see the TraceTek Products Selection Guide (H54783), Section 2. After the cable has been installed, use the connector installation instructions included in connector kits for TT3000 and TT5000 sensing cables (TT-3000-CK-MC-xxx or TT-5000-CK-MC-xxx). For more information call (800) 553-1737.

TraceTek TT3000 and TT5000 Series Bulk Sensing Cable

Tools and Materials Needed Ohmmeter (20 MW range or greater)

Kellems grip (TT-KELLEM-GRIP) Reel mounting stand (to allow reel to spin and pay off sensing cable; see page 3) Two lengths of 3/4-inch electrical conduit bent to a gentle sweep. These must be longer than the highest riser (the vertical pipe section at access tees), flared slightly, and deburred at both ends (see Step 4 on page 3). Electrical tape

In addition, for installing TT5000 series sensing cables:

TT-ULTRATORCH flameless heating tool or appropriate heat gun Pliers (to crimp heat-shrinkable tubing) Masking tape

General Notes

Do

Store the sensing cable in its original container in a clean, dry area prior to installation. Schedule sensing cable installation after pipe is assembled and pressure tested. Install alarm module first, then install sensing cable from the module outward. Clean the area where the cable will be installed, to remove debris and sources of contamination. Install sensing cable before burying pipe. Provide as built drawings to facilitate completion of a system map. Replace TT5000 sensing cable once it has contacted a solvent or fuel.

Dont

Drag the cable through contaminants (such as pipe dope, PVC cement, alcohol, oil, dirt). Use damaged or contaminated sensing cable. Solder or weld near the cable without protecting it from heat, flux, and splatter. Use pulling lubricants to install TraceTek cables. Drop tools, or sharp or heavy objects onto the cable. Pull sensing cable with excessive force (more than 50 pounds /20 kg for TT5000, more than 75 pounds/30 kg for TT3000). Pull bulk TT5000 sensing cable without sealing its end. Place TT5000 sensing cable where it is subject to pinching or temperatures above 60C (140F). Leave TT5000 sensing cable installed under tension. Use adhesive tapes or clamping devices to permanently secure the sensing cable. Allow cable ends to become wet, dirty, or contaminated.

Sensing Cable Installation in Double-Containment Piping

Bulk sensing cable

Pull rope

Check that preinstallation requirements have been met before installing sensing cable in double-containment pipe:

1. The pipe annulus is clean and dry and has been pressure-tested. 2. A continuous length of 1/4-inch to 3/8-inch (6-mm to 9.5-mm) hollow braid polypropylene or nylon rope has been installed from access to access of the containment piping as a pull rope. 3. The pull rope moves freely through the pipe (for example, it is not knotted, pinched, or glued to the pipe).

Installation Instructions for TT3000 and TT5000 Series Bulk Sensing Cable

Installation Steps

1. Prepare the sensing cable prior to installation.

For TT5000 sensing cable: Ensure that the end of the cable is sealed with heat-shrink tubing (as it was when supplied from the factory). If the cable end is not sealed: 1. Trim the end of the cable as necessary to remove any irregularities. 2. Apply a single layer of masking tape 3/4 inch (19 mm) from the end of the cable. 3. Push the fluoropolymer braid back and clip it off back to the masking tape (see illustration at right). Take care not to damage the black cable jacket; if jacket is damaged, trim the end off and begin again. 4. Slide one of the heat-shrinkable tubes (catalog no. DWP125-1/4, supplied with the bulk reel) over the cable and past the masking tape. Remove the masking tape, then position the tube so that 3/8 inch (9.5 mm) of the tubing extends beyond the end of the cable. 5. Using a Raychem heat gun or Ultratorch, shrink the tube down to bond to the sensing cable. Begin at the end over the cable braid. Apply heat long enough to fully recover the tubing, but not so long as to melt the braid; do not apply heat directly on the braid, and if braid is damaged, begin again. In the middle of the tube, continue heating for 10 to 15 seconds after the tubing has shrunk, to ensure adhesive in the tubing bonds to the cable jacket. Shrink the entire tube, finishing at the end off the cable. 6. While the tubing end is still hot, use pliers to crimp and seal the end, as shown. 7. Let the tubing and cable end cool a minute or two before proceeding with insertion into the Kellems grip. For TT3000 sensing cable: 1. Prepare the cable and perform resistance measurement to confirm the cable is clean and dry. Locate and expose the cable end from the inside of the reel (not the end to be pulled). Expose 1 to 2 inches (25 to 50 mm) of the two black wires by prying them out of the cable. Strip 1/2 inch (12 mm) of the black material to expose the copper wire. Note: The black material is conductive; it is not insulation. Use an ohmmeter to measure the resistance between the two black wires; attach the ohmmeter leads to the exposed copper. For a clean, dry cable, the resistance should be greater than 20 MW. If the resistance is less than 20 MW, check to see if there is moisture or contamination on the cable. If the problem causing a low-resistance reading cannot be located, the sensing cable may be damaged. Contact Raychem for help. 2. While TT3000 cable is being installed in double-containment pipe, it must be monitored with an ohmmeter to alert the feeder if moisture is encountered. Clip the ohmmeter to the two black wires and tape it to the outside of the cable reel flange (see illustration). 3. Wrap a small amount of electrical tape tightly around cable end to be pulled; this makes it easier to insert in the Kellems grip.

TT3000 sensing cable

To ohmmeter

Note: Drawings are not to scale

Masking tape 3/4 in (19 mm)

3/8 in (9.5 mm)

Secure the ohmmeter to the reel flange.

0.000

Electrical tape

Installation Instructions for TT3000 and TT5000 Series Bulk Sensing Cable

Installation Steps (continued)

Note: Begin cable installation at the end of the pipe closest to the TraceTek alarm and locating module.

2. Attach Kellems grip to sensing cable.

1. Make sure the end of the sensing cable has been properly prepared (end of TT5000 sensing cable should be sealed with heat-shrink tubing; end of TT3000 should be wrapped tightly with electrical tape). 2. Insert the end of the cable as far as possible into the cage end of the Kellems grip. 3. Tightly wrap electrical tape over 1 in (25 mm) of the Kellems grip and 1 in (25 mm) of the exposed sensing cable to make a smooth transition.

2 in (50 mm) Tape over here.

Sensing cable

Make sure end has been prepared

3. Attach pull rope to Kellems grip.

1. To ensure the end of the pull rope is compact and has no loose strands, tightly wrap the tip with electrical tape. 2. Feed the end of the pull rope through one of the sections of sweep conduit, curved end first (see illustration).

Curved, flared and deburred conduit From pipe

To reel

3. Open the braid 18 in (450 mm) from the end of the pull rope. A pencil or screwdriver can be used.

Open rope braid to access hollow core.

18 in (450 mm)

Compress rope lengthwise to balloon section 18" (450 mm) from end.

4. Pass the rope end through the looped end of the Kellems grip and insert 6 in (150 mm) through the braid opening and into the hollow core of the rope. Tightly wrap tape over the end of the rope and back 2 in (50 mm) toward the loop (see illustration).

Tape here 2 in (50 mm) 6 in (150 mm) Insert end into hollow core. Pass rope end through looped end of Kellems grip.

4. Prepare to pull sensing cable into pipe.

1. Insert the curved end of the conduit section into the access tee down to the level of the primary pipe. Use the conduit to guide the pull rope and sensing cable into the pipe; position it to avoid sharp bends, abrasion, and snags.

Conduit prevents snags and stress to cable at 90 bends

Access point

2. Mount the cable reel onto a payoff stand; insert a piece of pipe through the reel flange holes and support it with two chairs or some other appropriate means (see illustration). The reel must be free to turn.

Two methods for paying off cable

Installation Instructions for TT3000 and TT5000 Series Bulk Sensing Cable

Installation Steps (continued)

4. Prepare to pull sensing cable into pipe (continued).

3. Prepare to Pull from Next Access Point Take the second piece of sweep conduit to the next access point of the containment pipe. Identify the correct pull rope. If there is more than one section of pull rope at this access point, the person to feed cable can lightly tug the rope from the sensing cable end to identify the correct rope. Important: Be careful not to lose the rope into the access point. It can be time-consuming and expensive to recover a pull rope lost into the pipe. If the pull rope has been installed as one continuous length (that is, looped but not cut at each access tee), it must be cut at the access tee. Important: After cutting, secure the end not attached to the sensing cable. At the access point, pass the installed pull rope through the conduit, curved end first. Insert the curved end of the conduit into the access tee down to the level of the primary pipe. Use the conduit section to guide the pull rope and sensing cable out of the pipe; position it to avoid sharp bends, abrasion, and snags.

Conduit prevents snags and stress to cable at 90 bends Access point

5. Pull sensing cable into containment pipe.

1. Hold the conduit in position while pulling the cable. Begin to pull the rope and cable from the second access point. The person feeding the cable must be able to communicate problems (such as snags or twisted cable) to the person pulling, before the sensing cable is subjected to excessive stress. TT5000 sensing cable must not be pulled with force greater than 50 pounds or the cable may be damaged. When installing TT3000 sensing cable, use the ohmmeter on the payoff reel to monitor the cable condition during pulling. If the ohmmeter measures a resistance less than 20 MW between the sensing wires, it indicates the sensing cable has encountered water or contaminant. If this happens, stop pulling at once. Carefully remove the sensing cable; maintain a light tension on the pull rope as the cable is pulled out, because the Kellems grip is not designed for tension in this direction. Dry or clean pipe before reinstalling sensing cable. Be sure to secure the ends of the pull rope. 2. Finish by pulling the cable through the conduit beyond the top of the access point riser. Leave at least 12 in (30 mm) of extra cable for installation of connectors.

TT3000 sensing cable Secure the ohmmeter to the reel flange

To pipe

0.000

6. Check the sensing cable condition.

Important: TT5000 sensing cable is sensitive to pressure from such things as pinches or tight corners. After pulling, make sure the cable has adequate clearance and is not left under tension. For TT3000 sensing cable, use the ohmmeter on the payoff reel to confirm that the cable is clean and dry. If the ohmmeter measures a resistance of less than 20 MW between the sensing wires, corrective action will be required. If TT5000 sensing cable has been installed, first prepare the cable for testing. Remove the Kellems grip, and then cut off and discard the section of cable that was in the Kellems grip. Slit and remove 3/4 in (19 mm) of outer braid and black jacket. Unbraid the two black wires, and strip 1/2 in (12 mm) of the black material to expose their copper wire.

Installation Instructions for TT3000 and TT5000 Series Bulk Sensing Cable

Installation Steps (continued)

6. Check the sensing cable condition (continued).

Slit an additional 1/2 in (12 mm) of outer braid and black jacket. Flare the jacket so that it does not touch either black wire (see illustration). Use an ohmmeter to check that the cable has not been damaged or left in an alarm condition. Measure the resistance between each black wire and the black (conductive) jacket. Measure the resistance between the two black wires. In all cases the resistance should be greater than 20 MW. If the measured resistance is less than 20 MW: Confirm that the black wires at either end of the cable are not touching the black jacket. If they touch the jacket, move them away from the jacket and retest. Confirm that the cable is not pinched by the reel flange or other object. If the cable is pinched, correct the problem and retest. If the measured resistance is still below 20 MW, it may indicate the cable is bent or crimped (which simulates a leak), or the cable has been tripped by exposure to a hydrocarbon (such as oil or adhesive), or the jacket has been damaged and allowed water to enter the braided inner construction. A TraceTek Portable Test Box (TT-PTB-1000) may be used to determine the location of the problem; contact your Raychem representative for further information. In any case, determine the cause of the problem and address it.

TT5000 sensing cable Do not let the jacket touch the black wires

To Ohmmeter

7. Complete the installation process.

If the results of the cable test are satisfactory and the sensing cable will be left in the pipe: Remove the conduit sections used to guide the cable during installation. Before cutting the cable at the feeder end, make sure that at least 12 in (300 mm) of sensing cable (not including the Kellems grip) is above each riser to allow for connector installation. Cut off and discard the section of cable that was in the Kellems grip. (Note: For TT5000 cable, this should have been done in the previous step, when preparing for cable testing). If possible, install connectors on ends of sensing cable immediately after pulling, following instructions supplied with the connector kits. Important: Water must not be permitted to enter the end of TT5000 cable. If not installing connectors on TT5000 cable, be sure to seal the end with heat-shrinkable tubing, as described in Step 1 on page 2. For connectors not mated to another sensing cable, attach an end termination to prevent water ingress. Secure the end of cable so it is not lost into the pipe. At the end of the day or if the job is interrupted by bad weather, seal all access points to keep moisture and contaminants out of the pipe.

Seal access points Secure end of cable

Installation Instructions for TT3000 and TT5000 Series Bulk Sensing Cable

R

Belgium NV Raychem SA Diestsesteenweg 692 3010 Kessel-Lo Tel (32) 16/351-800 Fax (32) 16/351-797 Korea Raychem Korea Limited 831-45 Yeuksam-Dong Kangnam-Ku Seoul 135 Tel (82) 2/557-7752 Fax (82) 2/558-5765 United Kingdom Raychem Ltd. Faraday Road Dorcan, Wiltshire SN3 5HH Tel (44) 1793/572-663 Fax (44) 1793/572-629 United States Raychem Corporation 300 Constitution Drive Menlo Park, CA 94025-1164 Tel (800) 553-1737 Fax (415) 361-3215

1996 Raychem Corporation Printed in USA H55553 P/N221149 4/96

TraceTek is a trademark of Raychem Corporation.

Das könnte Ihnen auch gefallen

- Ifm Product Innovations PDFDokument109 SeitenIfm Product Innovations PDFJC InquillayNoch keine Bewertungen

- Abb FusesDokument124 SeitenAbb FusesJC InquillayNoch keine Bewertungen

- Article Selecting Sensors For Safety Instrumented Systems en 5462144Dokument7 SeitenArticle Selecting Sensors For Safety Instrumented Systems en 5462144JC InquillayNoch keine Bewertungen

- SHB 4200Dokument1 SeiteSHB 4200JC InquillayNoch keine Bewertungen

- APISingapore2012 Christian Skaug PDFDokument23 SeitenAPISingapore2012 Christian Skaug PDFJC InquillayNoch keine Bewertungen

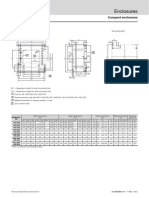

- Enclosures: Compact Enclosures Plastic Enclosures KSDokument2 SeitenEnclosures: Compact Enclosures Plastic Enclosures KSJC InquillayNoch keine Bewertungen

- Logo JciDokument1 SeiteLogo JciJC InquillayNoch keine Bewertungen

- Butterfly Valve Flowseal H.P.Dokument5 SeitenButterfly Valve Flowseal H.P.JC InquillayNoch keine Bewertungen

- NFS2 3030 SpecificationDokument26 SeitenNFS2 3030 SpecificationJC InquillayNoch keine Bewertungen

- Butterfly Valve Flowseal H.P.Dokument5 SeitenButterfly Valve Flowseal H.P.JC InquillayNoch keine Bewertungen

- Operating Instructions Exd Iib PDFDokument12 SeitenOperating Instructions Exd Iib PDFJC InquillayNoch keine Bewertungen

- Crouse HindsDokument6 SeitenCrouse HindsJC InquillayNoch keine Bewertungen

- NFS2 3030 SpecificationDokument26 SeitenNFS2 3030 SpecificationJC InquillayNoch keine Bewertungen

- MariposaDokument1 SeiteMariposaJC InquillayNoch keine Bewertungen

- Ice 157Dokument188 SeitenIce 157JC InquillayNoch keine Bewertungen

- Emerson Series 600t Series 600Dokument168 SeitenEmerson Series 600t Series 600JC InquillayNoch keine Bewertungen

- 3 246Dokument16 Seiten3 246JC InquillayNoch keine Bewertungen

- Enclosures: Compact Enclosures Plastic Enclosures KSDokument2 SeitenEnclosures: Compact Enclosures Plastic Enclosures KSJC InquillayNoch keine Bewertungen

- Homework 4 Answer: Page 12 of Student Book: Due Date: Thursday 15Dokument2 SeitenHomework 4 Answer: Page 12 of Student Book: Due Date: Thursday 15JC InquillayNoch keine Bewertungen

- 4C DSD Cover and Device Sub-Assemblies: Manual Motor StartersDokument3 Seiten4C DSD Cover and Device Sub-Assemblies: Manual Motor StartersJC InquillayNoch keine Bewertungen

- Imprimir Dia de La PrimaveraDokument1 SeiteImprimir Dia de La PrimaveraJC InquillayNoch keine Bewertungen

- Mario Vargas Llosa: Conversacion en La Catedral, La Fiesta Del Chivo, El Sueño Del Celta. 3.-The Nobel Prize inDokument1 SeiteMario Vargas Llosa: Conversacion en La Catedral, La Fiesta Del Chivo, El Sueño Del Celta. 3.-The Nobel Prize inJC InquillayNoch keine Bewertungen

- RedesDokument24 SeitenRedesJC InquillayNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Interpretations of The IMO Gas Code: International Association of Classification SocietiesDokument53 SeitenInterpretations of The IMO Gas Code: International Association of Classification SocietiesAlkaNoch keine Bewertungen

- HW 5, 448Dokument16 SeitenHW 5, 448pdrogos02100% (1)

- Us 20060145019Dokument11 SeitenUs 20060145019Raymond100% (4)

- 1 Routing Tables ExplainedDokument8 Seiten1 Routing Tables ExplainedallandonaldNoch keine Bewertungen

- AC 23-8B Flight Test Guide App 1Dokument22 SeitenAC 23-8B Flight Test Guide App 1Ladislao PazmanyNoch keine Bewertungen

- Notepad++ Shortcut Keys ListDokument1 SeiteNotepad++ Shortcut Keys ListWillieNoch keine Bewertungen

- Tutorial 4 JawapanDokument6 SeitenTutorial 4 JawapanlimNoch keine Bewertungen

- Lehmann Et Al 2013 PDFDokument13 SeitenLehmann Et Al 2013 PDFJack HamiltonNoch keine Bewertungen

- 3Dokument8 Seiten3K@mR@N D@uD P@nHw@RNoch keine Bewertungen

- Introduction To Revit Structure FamiliesDokument12 SeitenIntroduction To Revit Structure FamiliesLobsang Matos100% (1)

- Oxygen Flak Combustion MethodDokument2 SeitenOxygen Flak Combustion MethodSandip Firke100% (2)

- Iconnect v3.1 User ManualDokument105 SeitenIconnect v3.1 User Manualcjamiz2006Noch keine Bewertungen

- Running Concurrent WorkflowsDokument10 SeitenRunning Concurrent WorkflowsyprajuNoch keine Bewertungen

- Surge Arresters: Selection, Application and Testing: Pass YouDokument30 SeitenSurge Arresters: Selection, Application and Testing: Pass YouOoi Ban JuanNoch keine Bewertungen

- Siemens Profiset 3030 enDokument11 SeitenSiemens Profiset 3030 enBoasu FlorinNoch keine Bewertungen

- Module One 4 BAKERY INGREDIENTSDokument46 SeitenModule One 4 BAKERY INGREDIENTSIhsan BadshaNoch keine Bewertungen

- Poly MobilDokument49 SeitenPoly MobilPham Thanh HUng0% (1)

- Activities InterventionDokument2 SeitenActivities InterventionDonabel Villasaya CariosNoch keine Bewertungen

- KPS Alignment Procedure & FormulaDokument4 SeitenKPS Alignment Procedure & FormulaWidhyatmika RestuNoch keine Bewertungen

- Complex Numbers SpreadsheetDokument2 SeitenComplex Numbers SpreadsheetrodwellheadNoch keine Bewertungen

- A330 FCOM Vol III PDFDokument1.137 SeitenA330 FCOM Vol III PDFGraham Waterfield100% (1)

- BMorioka-Jet Grouting Methods Used To Improve The Constructability of Trenchless ProjectsDokument13 SeitenBMorioka-Jet Grouting Methods Used To Improve The Constructability of Trenchless ProjectsVictor Ernesto Arana VasquezNoch keine Bewertungen

- Boakye Danquah Mphil Analytical Chemistry PG 1: THE 'Heart'' of Electronic Noses ' Chemosensors''Dokument21 SeitenBoakye Danquah Mphil Analytical Chemistry PG 1: THE 'Heart'' of Electronic Noses ' Chemosensors''Alexander Appiah-KubiNoch keine Bewertungen

- REVIEW TASK 1 - Capitalization, Punctuation, Fragments, Run-On Sentences and Subject & Verb Agreement Review (-1Dokument2 SeitenREVIEW TASK 1 - Capitalization, Punctuation, Fragments, Run-On Sentences and Subject & Verb Agreement Review (-1Johao DoradoNoch keine Bewertungen

- Testing & Maintenance of Rotating Machines Type Tests, Routine Tests & Special Tests of 1 & 3 Phase Induction MotorsDokument12 SeitenTesting & Maintenance of Rotating Machines Type Tests, Routine Tests & Special Tests of 1 & 3 Phase Induction MotorsPKNoch keine Bewertungen

- Sapmm - Spro .Path SettingsDokument2 SeitenSapmm - Spro .Path SettingsVijay AnandNoch keine Bewertungen

- Structural ReliabilityDokument8 SeitenStructural ReliabilityDeepak SolankiNoch keine Bewertungen

- Info Sphere Information Analyzer - Methodology and Best PracticesDokument127 SeitenInfo Sphere Information Analyzer - Methodology and Best PracticesRoshava KratunaNoch keine Bewertungen

- Shortcuts For Ellipses and HyperBolaDokument3 SeitenShortcuts For Ellipses and HyperBolaChristian Simon D. SOLINAPNoch keine Bewertungen

- A Simple Favor 2018 720p BluRay x264 - (YTS AM) mp4Dokument2 SeitenA Simple Favor 2018 720p BluRay x264 - (YTS AM) mp4Dewi SartikaNoch keine Bewertungen