Beruflich Dokumente

Kultur Dokumente

Textilr Industry Scenerio

Hochgeladen von

sivapathasekaranCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Textilr Industry Scenerio

Hochgeladen von

sivapathasekaranCopyright:

Verfügbare Formate

Textile Industry OverviewTextile Industry is one of the largest and oldest industries in India.

It has a significant role inIndia as it fulfils the essential and basic need of people. Textile Industry in India stands atunique place and has maintained a sustainable growth over the years. This is a self-reliant andindependent industry and has great diversification and versatility. Textile Industry in Indiaprovides great contribution for the development of economy. It is the second largest textileindustry in the world after China. It provides ample employment opportunities to peoplebelonging to all classes. After agriculture this industry provides employment to maximumnumber of people in India employing ! million people.Textile Industry represents the rich culture" tradition" heritage # economic well-being ofcountry with diversified range and versatility. At the same time industry is competitiveenough to fulfill different demand patterns of domestic and global mar$ets. Indian TextileIndustry plays vital role in countrys economic development and contributes %&' to industrialproduction in the country. Textile Industry contributes around &' of ()*" +' of excisecollections" %,' of employment in industrial sector" and %-' share in country.s export.Indian Textile Industry is valued at /0 1 - bn. The development of Indian Textile Industrystarted in %+,!. This was the year" for the first time Textile sector was considered as animportant industry and a separate policy was formulated for sector.s development. In the year2333" 4ational Textile *olicy was announced.5ith further development Textile Industry came out of 6uota 7egime of Import 7estrictionsunder the 8ulti 9iber Arrangement :89A;. This development came on %st <anuary 233!under the 5orld Trade Organi=ation :5TO; Agreement on Textiles and Clothing. >ecause ofthe elimination of quota restrictions" most of the developing countries now can develop thepotential mar$et at both domestic and international level. These countries can develop theindustry expertise and can have competitive advantage through implementing newtechnology" more s$illed labor will improved distribution channel" cost effective operationand production with greater value addition in each step of value chain. 8oreover it will helpfor 9oreign )irect Investment in industry that will create great opportunity to strengthen thesector. 0ome of the strengths of Indian Textile Industry are large and potential domestic andinternational mar$et" large pool of s$illed and cheap labor" well-established industry"promising export potential etc. 2. ?I0TO7@ O9 TABTICA4o one $nows when exactly the spinning and weaving of textile began. It has been said thatpeople $new how to weave even 2D333 years ago. This was even before humans were able todomesticate

animals. The oldest actual fragment of cloth found was in southern Tur$ey.*eople used fibers found in nature and hand processes to ma$e fibers into cloth. Aven thoughhigh technology was not available" s$illed weavers created a wide variety of fabrics. )yeingof fabrics was done to satisfy the universal human need for beauty.5ithin time" more complex social and political organi=ation of people evolved. 5ith thegrowth of cities and nations" improvements in technology came into place and there was asubstantial development in the international trade" both of which involved textiles.Chinese textile was considered to be the most significant in international trade. ?istorianshave claimed that sil$ from China has reached ancient (reece and 7ome along a trade routecalled the 0il$ 7oad in the latter part of the second century >.C. and Agypt in %333 >.C. The7omans also imported cotton from nearby Agypt and from India. Archeologists have foundfacilities for dyeing and finishing cotton fabrics in settlements throughout the 7oman world.)uring the middle ages" the production and trading of the plant called Ewoad." an importantsource of dye" was a highly developed industry. )uring the fifteenth century" Trade 9airs insouthern 9rance provided a place for the active exchange of wools from Angland and sil$sfrom the 8iddle Aast. The economic activities surrounding these events gave rise to the firstinternational ban$ing arrangements. Aven the discovery of America was a result of the desireof Auropeans to find a faster route not only to the spices but also to the textiles of the Orient.Textile trade quic$ly too$ root in America" as colonists sold native dyes such as indigo andcochineal to Aurope and bought cottons from India. Although advances were being made inthe technology of textile production" the manufacture of cloth in 5estern Aurope in %D33 wasstill essentially a hand process. @arns were spun on a spinning wheel and fabrics were wovenby handoperated looms.A maFor reorgani=ation of manufacturing of a variety of goods occurred during the latter halfof the %D33s in 5estern Aurope. These changes" $nown as the Industrial E7evolution." alterednot only technology" but also social" economic" and cultural life. The production of textileswas the first area to undergo industriali=ation during the seventeenth and eighteenth centuriesas the result of an economic crisis. (ood quality textile products" produced inexpensively inIndia and the 9ar Aast" were gradually replacing Auropean goods in the international mar$et. . In >ritain" it became imperative that some means be found to increase domestic production"to lower costs" and to improve the quality of textiles. The solution was found in thesubstitution of machine or nonhuman power for hand

processes and human power.8any important inventions" most importantly spinning machines" automatic looms" and thecotton gin" improved the output and quality of fabrics. These inventions provided thetechnological base for the industriali=ation of the textile industry. Aach invention improvedone step of the process. 9or example" an improvement that increased the speed of spinningmeant that looms were needed that consumed yarn more rapidly. 8ore rapid yarn productionrequired greater quantities of fiber. The growth of the textile industry was further hastened bythe use of machines that were driven first by waterpower" then by steam" and finally byelectricity. The textile industry was fully mechani=ed by the early part of the nineteenthcentury. The next maFor developments in the field were to ta$e place in the chemistEslaboratory. Axperimentation with the synthesis of dyestuffs in the laboratory rather than fromnatural plant materials led to the development and use of synthetic dyes in the latter half ofthe nineteenth century. Other experiments proved that certain natural materials could bedissolved in chemical solvents and re-formed into fibrous form. >y %+%3" the first plant formanufacturing rayon had been established in the /nited 0tates.The manufacture of rayon mar$ed the beginning of the manufactured textile fibers industry.0ince that time" enormous advances have been made in the technology for every field in thetextile industry. Today" the textile industry utili=es a complex technology based on scientificprocesses and vast economic organi=ations.5ith the application of advanced technology to the textile field" textile use has expandedfrom the traditional areas of clothing and home furnishings into the fields of construction"medicine" aerospace" sporting goods" and industry. These applications have been madepossible by the ability of textile scientists to utili=e textile fibers" yarns" and fabrics forspecific uses. At the same time that textile technology is ma$ing strides in new directions" thefabrics that consumers buy for clothing and household use also benefit from the developmentof new fibers" new methods of yarn and fabric construction" and new finishes for existingfibers and fabrics.Today" a huge international industrial complex encompasses the production of fiber"spinning of yarns" fabrication of cloth" dyeing" finishing" printing" and manufacture of goodsfor purchase. Consumers purchase many different products made of textiles. The story of the &. Fourney that these products ma$e as they progress from fiber to yarn to fabric to finishedproduct is not Fust the story of spinning yarns" weaving or $nitting fabric" or constructing theend product. It is also the story of a complex networ$

of interrelated industries.?I0TO7@ O9 I4)IA4 TABTICA I4)/0T7@The history of textiles in India dates bac$ to nearly five thousand years to the days of the?arappan civili=ation. Avidences that India has been trading sil$ in return for spices from the2nd century have been found. This shows that textiles are an industry which has existed forcenturies in our country. 7ecently there has been a si=eable increase in the demand for Indiantextiles in the mar$et. India is fast emerging as a competitor to China in textile exports. The(overnment of India has also reali=ed this fact and lowered the customs duty and reduced therestrictions on the imported textile machinery. The intention of the governmentEs move is toenable the Indian producers to compete in the world mar$et with high quality products. Theresults of the governmentEs move can be visible as Indian companies li$e Arvind 8ills"8afatlal" (rasimG 7eliance Industries have become prominent players in the world. TheIndian textile industry is the second largest in the world-second only to China. The othercompeting countries are Horea and Taiwan. Indian Textile constitutes !' of the totalexports of our country.The history of apparel and textiles in India dates bac$ to the use of mordant dyes and printingbloc$s around 333 >C. The foundations of the Indias textile trade with other countriesstarted as early as the second century >C. A hoard of bloc$ printed and resist-dyed fabrics"primarily of (uFarati origin" discovered in the tombs of 9ostat" Agypt" are the proof of largescale Indian export of cotton textiles to the Agypt in medieval periods.)uring the % th century" Indian sil$ was used as barter for spices from the western countries.Towards the end of the %Dth century" the >ritish Aast India Company had begun exports ofIndian sil$s and several other cotton fabrics to other economies. These included the famousfine 8uslin cloth of >engal" Orissa and >ihar. *ainted and printed cottons or chint= waswidely practiced between India" <ava" China and the *hilippines" long before the arrival of theAuropeans.India Textile Industry is one of the largest textile industries in the world. Today" Indianeconomy is largely dependent on textile manufacturing and exports. India earns around 2D'of the foreign exchange from exports of textiles. 9urther" India Textile Industry contributes !. about %&' of the total industrial production of India. 9urthermore" its contribution to thegross domestic product of India is around ' and the numbers are steadily increasing. IndiaTextile Industry involves around ! million wor$ers directly and it accounts for 2%' of thetotal employment generated in the economy.Indian Textile Industry 8ar$etIndia Textile Industry is one of the leading textile industries in the world. Though waspredominantly

unorgani=ed industry even a few years bac$" but the scenario started changingafter the economic liberali=ation of Indian economy in %++%. The opening up of economygave the much-needed thrust to the Indian textile industry" which has now successfullybecome one of the largest in the world. India textile industry largely depends upon the textile manufacturing and export. It alsoplays a maFor role in the economy of the country. India earns about 2D' of its total foreignexchange through textile exports. 9urther" the textile industry of India also contributes nearly%&' of the total industrial production of the country. It also contributes around ' to the()* of the country. India textile industry is also the largest in the country in terms ofemployment generation. It not only generates Fobs in its own industry" but also opens upscopes for the other ancillary sectors. India textile industry currently generates employmentto more than ! million people. It is also estimated that" the industry will generate %! millionnew Fobs by the year 23%!India is a traditional textile -producing country with textiles in general" and cotton inparticular" being maFor industries for the country. India is among the world.s top producers ofyarns and fabrics" and the export quality of its products is ever increasing. Textile Industry isone of the largest and oldest industries in India. Textile Industry in India is a selfreliant andindependent industry and has great diversification and versatility. The textile industry can bebroadly classified into two categories" the organi=ed mill sector and the unorgani=eddecentrali=ed sector.The organi=ed sector of the textile industry represents the mills. It could be a spinning mill ora composite mill. Composite mill is one where the spinning" weaving and processingfacilities are carried out under one roof. The decentrali=ed sector is engaged mainly in theweaving activity" which ma$es it heavily dependent on the organi=ed sector for their yarnrequirements. This decentrali=ed sector is comprised of the three maFor segments vi=." power -. loom" handloom and hosiery. In addition to the above" there are readymade garments" $hadias well as carpet manufacturing units in the decentrali=ed sector.The Indian Textile Industry has an overwhelming presence in the economic life of thecountry. It is the second largest textile industry in the world after China. Apart fromproviding one of the basic necessities of life i.e. cloth" the textile industry contributes about%&' to the countrys industrial output and about %D' to export earnings. After agriculturethis industry provides employment to maximum number of people in India employing !million people. >esides" another !3 million people are engaged in allied activities. India is thelargest producer of <ute" the 2nd largest producer of 0il$" the rd largest

producer of Cottonand Cellulosic 9ibersI@arn and !th largest producer of 0ynthetic 9ibersI@arn.The main obFective of the textile policy 23%% is to provide cloth of acceptable quality atreasonable prices for the vast maFority of the population of the country" to increasinglycontribute to the provision of sustainable employment and the economic growth of the nationGand to compete with confidence for an increasing share of the global mar$et. Indias textileindustry is considered a pioneer in the industry" as the industriali=ation of India in other areasis managed by funds generated by the textile machinery industry. ?owever" since thebeginning of liberali=ation in %++2 to %+D3" the industry tends to protect domestic producersof cotton with a clear obFective continuous erosion of its prosperity.*rospectConsidering the continual capital investments in the textile industry" the (ovt. of India mayextend the Technology /pgradation 9und 0cheme :T/90; by the end of the %%th 9ive @ear*lan :till 23%%-23%2;" in order to support the industry. Indian textile industry is massivelyinvesting to meet the targeted output of 1,!bn by the end of 23%3" aiming exports of 1!3bn.There is huge development foreseen in Indian textile exports from the 1%Dbn attained in233!-3- to 1!3bn by 233+-%3. The estimation for the exports in the current financial year isabout 1%+bn. There is substantial potential in Indian exports of technical textiles and hometextiles" as most Auropean companies want to set up facilities near-by the emerging mar$ets"such as China and India.The global demand for apparel and woven textiles is li$ely to grow by 2! percent by year23%3 to over !mn tons" and Asia will be responsible for ,! percent output of this growth.The woven products output will also rise in Central and 0outhern American countries" D. however" at a reasonable speed. On the other hand" in maFor developed countries" the outputof woven products will remain stable. 5eaving process is conducted to ma$e fabrics for abroad range of clothing assortment" including shirts" Feans" sportswear" s$irts" dresses"protective clothing etc." and also used in non-apparel uses li$e technical" automotive" medicaletc.It is been forecasted that the woven textile and apparel mar$ets will sustain their growth fromcurrent till 23%3. The imports of apparel and textiles will rise from developed economies li$ethe /0A and the western countries of Aurope and <apan" along with some newly emergedeconomies" such as 0outh Horea and Taiwan. Certainly" import growth has been witnessedvertical rise in the previous year.Apparel is the most preferred and important of all the other applications. 5oven fabrics arewidely used in apparel assortments" including innerwear" outerwear" nightwear andunderwear" as well as in speciali=ed apparels li$e protective clothing and

sportswear. ?ometextile also contributes considerably in woven fabric in products assortments li$e curtains"furnishing fabrics" carpets" table cloths etc.0pecial $ind of woven fabrics are utili=ed in medical as well as industrial applications. Themedical applications include adhesives" dressing bandages" plasters etc.The Indian Industry foresees huge demand for industrial woven products for medical andautomotive applications. )emand for woven fabrics is anticipated to be rise vertically in thesector of home textiles.4on woven sector has great future in terms of global demand" thus maFor facilities of cottonyarn are currently concentrating Fust on home textiles. It is mandatory" that the pea$management of the cotton yarn manufacturers analy=e the future prospect and growing graphof demand for non woven products.Anticipating massive growth in medical and automobile sectors" these sectors assuressubstantial demand for non woven facilities in India. Albeit" home textiles also will lurehigher demand" there are specific demands for home textile facilities also.The Dth 9ive @ear *lan has huge consideration on agricultural growth that also includescotton textile industry" resulting a prosperous future forecast for the textile industry in India.Indian cotton yarn manufacturers should rush forward for Foint ventures and integrated plans ,. for establishing processing and weaving facilities in home textiles and technical textiles inorder to meet export target of 1!3bn" and a total textile production of 1,!bn by 233+-23%3. Axpectations are high" prospects are bright" but capitalising on the new emergingopportunities will be a challenge for textile companies. 0ome prerequisites to be included inthe globally competing textile industry areJ Imbibing global best practices Adopting rapidly changing technologies and efficient processes Innovation 4etwor$ing and better supply chain management Ability to lin$ up to global value chains.The Indian textiles industry has established its supremacy in cotton based products" especiallyin the readymade garments and home furnishings segment. These two segments will be the$ey drivers of growth for Indian textiles. 7eadymade garment exports were worth /01 , bnin 9@3- and will cross /01 %- bn by the end of 23%3" assuming a conservative growth of%!' per annum. According to estimates" investments in textiles are expected to touch /01 %bn by 23%3.The readymade garment segment will be the principal driver of growth even in the domesticindustry. The changing preferences of Indian consumers -- from buying cloth to readymadegarments -- have prompted several companies to move up the value chain into the finishedproducts segment.0trategic Initiatives>usiness integration -- especially forward integration -- by the larger

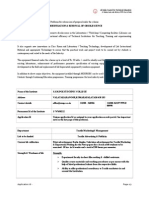

textile companies hasbeen prominent among Indian companies. 0everal companies that are engaged in fabricmanufacturing are now $een to enter the readymade garments space. A recent entrant is0iyaram" which launched its readymade garments range in 4ov 3-" following suit with othermaFors li$e Century Textiles and 7aymond.8ost of the large textile companies have opted for an inorganic growth strategy to scale upoperations. Acquisition is the most logical step towards integrating operations and buildingthe value chain. )omestic acquisitions are on the rise" while acquiring foreign assets is yet togain traction. 0ome recent domestic acquisitions that have been executed in 233- include +. H0C # Industries. acquisition of )eccan Cooperative" and Ambattur Clothing ta$ing overCelebrity 9ashions. Another growing phenomenon observed among Indian textile companiesis the setting up of manufacturing facilities in strategic regions outside India" where they canavail of duty concessions and reduce export lead-time. Kodiac and Ambattur Clothing haveset up facilities in the (ulf region to cut down on export delivery schedules to the Auropeanand /0 mar$ets. 7aymond has set up a unit in >angladesh to avail of the =ero duty access tothe A/.This trend is seen primarily among the large domestic players" who are trying to achievesi=able scales in order to win orders from the large retailers in the /0 and A/. (lobalretailers prefer largesi=ed companies that can scale up capacities consistently" $eep up withdelivery schedules and meet their growing demand. They have clear preferences forcompanies with integrated design" process and manufacturing facilities.An interesting commonality in countries with successful garment exports is that they have amuch lower level of sub-contracting than India. A study during the %++3s found that apparelfirms 9uture Outloo$ BBBIII in India subcontracted D&' of their output" as compared toonly %%' in ?ong Hong" %,' in China" 23' in Thailand" 2,' in 0outh Horea and -' inTaiwan. Consequently" these countries have a wider base of exports and have done very wellin the mar$et for large volumes of uniform products.9oreign Acquisitions by Indian Textile Companies *eriod Acquirer Acquired Company Cicense Of E?ealthtex. Hidswear 8ay 3% Arvind 8ills >rand Of Lf Corpn :/0A; <un 3% Ambattur Clothing Colour *lus :/H; 7egency Texteis *ortuguesa 0ep 3% 7aymond.s Cimitada :*ortugal; 0ep 3 <indal *olyester 7exor (roup :9rance; )ec 3& <CT Ctd C4CT 8alaysia :0ynegal;

%3. 8ay 3! 7eliance (roup ICI *a$istan Ctd :*a$istan; 0hirting Company Cocated In <un 3! Kodiac Clothing Alqo=e Industrial Area :)ubai; )ec 3! (?CC )an 7iver :/0A; Ammetre Tintolavanderie 8ay 3- 8alwa Industries Industrial :Italy; 8ay 3- 8alwa Industries Third )imension Apparels :Italy; <ul 3- 5elspun India C?T ?olding :/H; Tash$ent-To.yetpa Te$stil Ctd <ul 30pentex Industries :/=be$; <ul 3- (?CC 7osebys :/H;The exports mar$et will remain favourable for India till 233," when quota restrictions onChina end. *ost 233," competition will become tougher. This will be the phase in whichIndian textile companies will come under tremendous pricing pressures and tighter productdelivery schedules. 4evertheless" the value-added segments of readymade garments" homefurnishings and made-ups will continue to grow.Implications for 08AsThe new business dynamics have varying undertones across the value chain. The segmentthat is li$ely to be hit is weaving. The 08As in the *owerloom and handloom sector will facesignificant churn in the future. 0pinning mills that account for +!' of the yarn and fibreproduction" will move up the value chain into weaving. This will erode the viability of thehitherto protected *owerloom and handloom operators numbering over &33"333" who haveremained insulated from competitive forces so far. A possible remedy could be for theseweavers to align with bigger players or integrate operations that would ensure off-ta$e oftheir products. %%. The fragmented industry structure has in the past been beneficial in generating employment"but will be difficult to sustain in a globally competitive environment. 9or fabricmanufacturers in the unorganised segment" this will mean inefficient units losing outeventually" while the more efficient and dynamic ones aligning with manufacturers or buyers.9or readymade garment 08As" rising demand and preference for ready-to-wear outfits in thedomestic mar$et will sustain a large number of units in this sector. This will be the mostthriving segment in the industry and 08As will play a $ey role.India.s $ey assets include a large and low-cost labour force" si=able supply of fabric"sufficiency in raw material and spinning capacities. On the basis of these strengths" India willbecome a maFor outsourcing hub for foreign manufacturers and retailers" with compositemills and large integrated firms being their preferred partners. It will thus be essential for08As to align with these firms" which can ensure a mar$et for their products and new orders.5ea$nesses of the Indian textile industry include fragmentation of the industry" lengthydelivery times" delays in customs clearance and high transportation and input costs. To tac$lethese factors" the (overnment will have to play a $ey role. Infrastructure

development"reforms in labour laws and significant policy support will be essential.Textile 0ectors in IndiaJThe 8an-8ade 9iber I @arn and *owerloom 0ectorJ This part of industry includes fiberand filament yarn manufacturing units. The *ower looms sector is decentrali=ed and plays avital role in Indian Textiles Industry. It produces large variety of cloths to fulfill differentneeds of the mar$et. It is the largest manufacturer of fabric and produces a wide variety ofcloth. The sector contributes around -2' of the total cloth production in the country andprovides ample employment opportunities to &.,- million people.The Cotton 0ectorJ Cotton is one of the maFor sources of employment and contributes inexport in promising manner. This sector provides huge employment opportunities to around!3 million people related activities li$e Cultivation" Trade" and *rocessing. India.s Cottonsector is second largest producer of cotton products in the world.The ?andloom 0ectorJ The handloom sector plays a very important role in the country.seconomy. It is the second largest sector in terms of employment" next only to agriculture.This sector accounts for about % ' of the total cloth produced in the country :excludingwool" sil$ and Hhadi;. %2. The 5oolen 0ectorJ The 5oolen Textile sector is an Organi=ed and )ecentrali=ed 0ector.The maFor part of the industry is rural based. India is the Dth largest producer of wool" andhas %.,' share in total world production. The share of apparel grade is !'" carpet grade is,!'" and coarse grade is %3' of the total production of raw wool. The Industry is highlydependent on import of raw wool material" due to inadequate production.The <ute 0ectorJ <ute 0ector plays very important role in Indian Textile Industry. <ute iscalled (olden fiber and after cotton it is the cheapest fiber available. Indian <ute Industry isthe largest producer of raw Fute and Fute products in the world. India is the second largestexporter of Fute goods in world.The 0ericulture and 0il$ 0ectorJ The 0il$ industry has a unique position in India" and playsimportant role in Textile Industry and Axport. India is the 2nd largest producer of sil$ inworld and contributes %,' of the total world raw sil$ production. In India 0il$ is availablewith varieties such as" 8ulberry" Ari" Tasar" and 8uga. 0ericulture plays vital role in cottageindustry in the country. It is the most labor-intensive sector that combines both Agricultureand Industry.The ?andicraft 0ectorJ The Indian handicrafts industry is highly labor intensive" cottagebased and decentrali=ed industry. It plays a significant # important role in the country.seconomy. It provides employment to a vast segment of craft persons in rural # semi urbanareas and generates substantial foreign exchange for the

country" while preserving its culturalheritage.0tructure of IndiaMs Cotton Textile Industry/nli$e other maFor textile-producing countries" India.s textile industry is comprised mostly ofsmall-scale" non-integrated spinning" weaving" finishing" and apparel-ma$ing enterprises.This unique industry structure is primarily a legacy of government policies that havepromoted labor intensive" small-scale operations and discriminated against larger scale firmsJ Cotton farming and harvestingJ Cotton is grown in tropical as well as sub tropical area in India. 8ostly the cotton grown in India is from dry lands and crops mostly depend on the irrigation systems available and not only on the rain water. (inningJ (inning is the process where cotton fiber is separated from the cotton seed. The first step in the ginning process is when the cotton is vacuumed into tubes that carry it to a dryer to reduce moisture and improve the fiber quality. Then it runs % . through cleaning equipment to remove leaf trash" stic$s and other foreign matter.(inning is accomplished by one of two methods. Cotton varieties with shorter stapleor fiber length are ginned with saw gins. This process involves the use of circularsaws that grip the fibers and pull them through narrow slots. The seeds are too large topass through these openings" resulting in the fibers being pulled away from the seed.Cong fiber cottons must be ginned in a roller gin because saw gins can damage theirdelicate fibers.Oil millJ in the operation the oil is extracted from the cotton seeds that are comingfrom the ginning process. The cotton seeds coming from the ginning unit are thenpassed through the pressing unit and crude cotton oil is produced. The pressed cottonseed oil ca$e is supplied as the cattle feed. The crude is further modified as the bio-diesel which could be used as the one of the energy source. The refined cotton oil isalso used as the edible oil but it is proved to be unfit for the human health.0pinningJ 0pinning is the process of converting cotton or manmade fiber into yarn tobe used for weaving and $nitting. Cargely due to deregulation beginning in the mid-%+,3s" spinning is the most consolidated and technically efficient sector in India.stextile industry. Average plant si=e remains small" however" and technology outdated"relative to other maFor producers. In 2332I3 " India.s spinning sector consisted ofabout %"%&- small-scale independent firms and %"!++ larger scale independent units.5eaving and HnittingJ 5eaving and $nitting converts cotton" manmade" or blendedyarn into woven or $nitted fabrics. India.s weaving and $nitting sector remains highlyfragmented" small scale" and labor-intensive. This sector consists of about .+ millionhandlooms" ,3"333 N*owerloom enterprises that operate about %.D million looms"and Fust % D"333 looms in the various composite mills.

N*ower looms are smallfirms" with an average loom capacity of four to five owned by independententrepreneurs or weavers. 8odern shuttle less looms account for less than % percent ofloom capacity.9abric 9inishingJ 9abric finishing :also referred to as processing;" which includesdyeing" printing" and other cloth preparation prior to the manufacture of clothing" isalso dominated by a large number of independent" small scale enterprises. Overall"about 2" 33 processors are operating in India" including about 2"%33 independent unitsand 233 units that are integrated with spinning" weaving" or $nitting units. %&. ClothingJ Apparel is produced by about DD"333 small-scale units classified as domestic manufacturers" manufacturer exporters" and fabricators :subcontractors;. Composite 8illsJ 7elatively large-scale mills that integrate spinning" weaving and" sometimes" fabric finishing are common in other maFor textile-producing countries. In India" however" these types of mills now account for about only percent of output in the textile sector. About 2D- composite mills are now operating in India" most owned by the public sector and many deemed financially Nsic$.India textile industry is one of the leading in the world. Currently it is estimated to be around/01 !2 billion and is also proFected to be around /01 %%! billion by the year 23%2. Thecurrent domestic mar$et of textile in India is expected to be increased to /01 -3 billion by23%2 from the current /01 &.- billion. The textile export of the country was around /01%+.%& billion in 233--3D" which saw a stiff rise to reach /01 22.% in 233D3,. The share ofexports is also expected to increase from &' to D' within 23%2. 9ollowing are area"production and productivity of cotton in India during the last six decadesJ Area in la$h *roduction in la$h bales of %D3 @ield $gs per@ear hectares $gs hectare%+!3-!% !-.&, 3.-2 +2%+-3--% D-.D, !-.&% %2&%+D3-D% D-.3! &D.- %3-%+,3-,% D,.2& D,.-3 %D3%++3-+% D&. + %%D.33 2-D2333-3% ,!.D- %&3.33 2D,233%-32 ,D. 3 %!,.33 3, %!. 2332-3 D-.-D % -.33 32233 -3& D-. 3 %D+.33 ++233&-3! ,D.,- 2& .33 &D3233!-3- ,-.DD 2&&.33 &D,233--3D +%.&& 2,3.33 !2%233D-3, +&. + %!.33 !-D233,-3+ + .D 2+3.33 !2-Though during the year 233,-3+" the industry had to face adverse agro-climatic conditions" itsucceeded in producing 2+3 la$hs bales of cotton comparing to %! la$hs bales last year" yetmanaged to retain its position as worlds second highest cotton producer.Aconomic issues*rices of CottonThe 8inimum 0upport *rices of Hapas :0eed cotton; for fair average quality announced forthe cotton season 233!- 233- :Oct O 0ept;" was fixed at last year.s level :233&-3!; i.e.7s.%D-3I- per quintal for medium staple variety

:9-&%&I<- &I?- DDD;. The support price for?-& :Cong staple variety; has been fixed at 7s.%+,3I - per quintal" an increase of 7s.23I- perquintal over support price of 233&-3!. The 80* fixed for 9-&%&I?-DDDI<- & variety of $apaswill be applicable only to 7aFasthan. The price of this variety" grown in ?aryana and *unFabhas been fixed $eeping in view the respective quality differential" vis-Pvis 7aFasthan"obtaining in these 0tates. The Cotton Corporation of India Ctd. :CCI; undertoo$ massive80* operations throughout 233&-3! in all the cotton growing states" and procured $apasequivalent to lint cotton of 2D.!2 la$hs bales. In 233&-3!" due to favourable seasonalconditions" there was a sharp rise in productivity" which pea$ed to a record &- Hg.CintIhectare" as compared to ++ $g. I lint per hectare during 233 -3&" the cultivated areaincreased to ,+.23 la$hs hectares in 233&-3!" as compared to D-. 3 la$hs hectares in 233 -3&" %-. and the production touched 2& la$h bales in 233&-3!" as compared to %D+.33 la$h bales in233 -3&.*resent 0cenarioTextile Industry is offering one of the most basic requirements of community and it possessimportanceG preserve continued growth for developing quality of life. 9rom themanufacturing of raw materials to the delivery of end products" it has gain it.s $ind ofposition" as a self-dependent sector and with considerable value-addition at every stage ofdealingG it is a $ey input to the country.s economy.Today the textiles and clothing industry engages an important position in India.s economy.>eing the maFor foreign exchange earner having about !' in its torso" contributing to about 3 ' of India.s exports and %&' of industrial productions" expecting above -' ()* in233!" and it considered as the second largest vital sector of employment initiator afteragriculture sector./nder the 5orld Trade Organi=ation :5TO; Agreement on Textiles and Clothing" the textilequota scheme of quantitative import limitations under the multi-fiber arrangement :89A;came to an end on %st <anuary" 233!" hence developing countries li$e India will flourish inthe new competitive atmosphere and as a result" the Indian textile industry will have astronger place in both their export and domestic mar$ets.All along with its usual yarn and fabrics" at present India is exporting more than %33 garmentproduct range. 8any worlds. leading brands li$e Tommy ?ilfiger" (ap" Ci= Claibome" *oloetc are sourcing products from India.5ith huge investments" persistence innovations" latest product mix and planned mar$eting"today" India has come out as a flourishing outsourcing centre for textiles and apparel industryto meet the global requirement of the manufacturing fibers and yarns products. In a view ofthe rising rapport with maFor global brands" dismantling of quota system from 233! erawould hit upon

India as a main global outsourcing hub.Competitive advantage # possible growth in 0ynthetic Textiles 0ector India.s synthetictextile sector is relatively modern and has a high growth potential which will help India tocoming out as a maFor outsourcing hub. 5ith a compounded annual growth rate of more than22' the exports of 889 textiles have stretched out to a level of /0 1%.-2 billion in 2332-3 starting from small exports in %+!&. The export growth in 2332-3 matches up to the %D. preceding year was in the harmony of 3 percent" and the 889 textile sector is the onlysector where the performance has exceeds by the target fixed for this year by /0 1 %%!million.Indian synthetic textiles are more and more accomplishing new mar$ets along with $eepingthe mar$et share in the existing mar$ets. At present Indian synthetic textile exports aretargeting more than %D! countries worldwide" where 8iddle Aast accounted for over 2percent of our exports and the share of the extremely quality conscious in Auropean /nion"approximately 2 percent.Over the years" the Indian 889 textile sector has built-up an export baseG and the share of889 textile exports in the total Indian textile export has also been raised" the share movedup from %3. ,' in 2333-3% to %%.&-' in 233%-32 and more to about %&' in 2332-3 .At present Indian exports of synthetic textiles to /0A are rising at more than +3' yearly. Ithas also been observed that export growth will be stri$ing for maFor 889 textile items afterdismantling of quota system from 233!.9urthermore" Indonesia" Horea.s export of synthetic textiles are turning down compared toprevious year. 8anufacturing capacity of Horea has declined by more than 3' in thepolyester filament sector in 2332 and in 233 and it is expected to turn down further more"which will end with a turn down in their exports of polyester filament fabrics. )ue to anti-dumping duty on the polyester filament fabrics obtained from Taiwan and Horea" countriesli$e >ra=il" gaining of more opportunity for India will exists as a larger synthetic fabricsexporter.In the world" synthetic textile trade.s share of India is also seeing increasing. The exportshare of Indian synthetic textiles in worldwide increased from 3.%%' in %+D% to %.%2' in%++% and more to about ' in 2332. This suggests the rising performance of Indian synthetictextile items in the worldwide mar$et.0till there is an opportunity to explore new mar$et segments li$e Catin America and Africaall along with maintaining the share in the established mar$ets li$e Auropean /nion and/0A. At this stage an annual growth expected to %!' for synthetic textiles and exports areexpected to touch /01 2.! billion in 233!-3! and /01 &. billion in 233+-%3.05OT analysis of the textile industry

Average cotton yarn spinning cost at Axcept spinning" all other segments are /01 2.! per $g. 5hich is lower than all predominantly in decentrali=ed sector. the countries including China The rigid labour lawsJ proving a bottlenec$ Cow wagesJ rate at 3.D! /01 per operator particularly to the garment sector. Carge hour as compared to /01 % of China and seasonal orders cannot be ta$en because the /01 of Tur$ey labour strength cannot be reduced during the /nique strength in traditional handlooms slac$ season. and handicrafts Inadequate capacity of the domestic textile 9lexible production system machinery manufacturing sector. )iverse design base >ig demand and supply gap in the training facilities in textile sector. Infrastructural bottlenec$s in terms of power" utility" road transport etc.Amployment (enerationThe textile sector itself has the potential to create %.2 crore employment opportunity over thenext five years. The government would continue to encourage growth within the textilesindustry as it holds huge potential for employment and exports.Textile 0ector ContributionJAccording to the Annual 7eport 233+-%3 of the 8inistry of Textiles" the Indian textileindustry contributes about %& per cent to industrial production" & per cent to the countrysgross domestic product :()*; and %D per cent to the country.s export earnings. It providesdirect employment to over ! million people and is the second largest provider ofemployment after agriculture. According to the 8inistry of Textiles" the cumulative 9ifth largest producer of man-made percentage of total looms as against fibre and yarn world average of %- percent and China" Lertical and hori=ontal integrated textile *a$istan and Indonesia %! percent" + value chain percent and %3 percent respectively. 0trong presence in entire textile value ?ighly fragmented and technology chain from raw material to finished goods bac$ward textile processing sector (lobally competitive spinning industry ?ighly fragmented garment industry 2 percent of shuttle less looms as Third largest producer of cotton processing %,. 0trengths 5ea$nesses 0trong and diverse raw material base 0tructural wea$nesses in weaving and %+. production of cloth during April.3+-8arch.%3 increased by ,. per cent as compared to the corresponding period of the previous year. Total textile exports increased to /01 %,.- billion during April.3+- <anuary.%3" from /01 %D.D billion during the corresponding period of the previous year" registering an increase of &.+! per cent in rupee terms. 9urther" the share oftextile exports in total exports has increased to %2. - per cent during April.3+<anuary.%3"according to the 8inistry of Textiles. As per the Index of Industrial

*roduction :II*; datareleased by the Central 0tatistical Organi=ation :C0O;" cotton textiles have registered agrowth of !.! per cent during April-8arch 233+-%3" wool" sil$ and man-made fibre textileshave registered a growth of ,.2 per cent and textile products including wearing apparel haveregistered a growth of ,.! per cent.Technical Textile 0egmentJAccording to the 8inistry of Textiles" technical textiles are an important part of the textileindustry. The 5or$ing (roup for the Aleventh 9ive @ear *lan has estimated the mar$et si=eof technical textiles to increase from /01 !.2+ billion in 233--3D to /01%3.billion in 23%%-%2" without any regulatory framewor$ and to /01 %!.%- billion with regulatory framewor$.The 0cheme for (rowth and )evelopment of Technical Textiles aims to promote indigenousmanufacture of technical textile to leverage global opportunities and cater to the domesticdemand.Current 0tatusThe textile industry holds significant status in the India. Textile industry provides one of themost fundamental necessities of the people. It is an independent industry" from the basicrequirement of raw materials to the final products" with huge value-addition at every stage ofprocessing.Today textile sector accounts for nearly %&' of the total industrial output. Indian fabric is indemand with its ethnic" earthly colored and many textures. The textile sector accounts about 3' in the total export. This conveys that it holds potential if one is ready to innovate.The textile industry is the largest industry in terms of employment economy" expected togenerate %2 million new Fobs by 23%3. It generates massive potential for employment in thesectors from agricultural to industrial. Amployment opportunities are created when cotton iscultivated. It does not need any exclusive (overnment support even at present to go further. 23. Only thing needed is to give some directions to organi=e people to get enough share of theprofit to spearhead development.0egmentsTextile industry is constituted of the following segments 7eadymade (arments Cotton Textiles including ?andlooms :8illmade I *owerloomI ?andloom; 8an-made Textiles 0il$ Textiles 5oollen Textiles ?andicrafts including Carpets Coir <uteThe cottage industry with handlooms" with the cheapest of threads" produces average dressmaterial" which costs only about 233 I47 featuring fine floral and other patterns. It is notnecessary to add any design to it. The women of the house spin the thread" and weave a piecein about a wee$.It is an established fact that small and irregular apparel production can be profitable byproviding affordable casual wear and leisure garments varieties.4ow" one may as$" where from the economy and the large profit comes in if the lowest endof the chain does not get paid with minimum per day labour charge. It is an irony of course.5hat people

at the upper stratum of the chain do is" to apply this fabric into a design withsome imagination and earn in millions. The straight - yards simple saree" drape in with ablouse with embroideries and bead wor$" then it becomes a designerQRs ensemble. 9or anaverage person" it can be a slant cut while giving it a shape" which can double the profit.8aybe" the 3 ' credit that the industry is ta$ing for its contribution to Indian economy asgood as -3 ' this way. Though it is an industry" it has to innovate to prosper. It has all theingredients to go ahead.Textile exports are targeted to reach 1!3 billion by 23%3" 12! billion of which will go to the/0. Other mar$ets include /AA" /H" (ermany" 9rance" Italy" 7ussia" Canada" >angladeshand <apan. The name of these countries with their bac$ground can give thousands of insights 2%. to a thin$ing mind. The slant cut that will be producing a readymade garment will sell at aprice of -33 Indian rupees" ma$ing the value addition to be profitable by 33 '.Currently" because of the lifting up of the import restrictions of the multi-fibre arrangement:89A; since %st <anuary" 233! under the 5orld Trade Organi=ation :5TO; Agreement onTextiles and Clothing" the mar$et has become competitiveG on closer loo$ however" it soundsan opportunity because better material will be possible with the traditional inputs so faravailable with the Indian mar$et.At present" the textile industry is undergoing a substantial re-orientation towards other thenclothing segments of textile sector" which is commonly called as technical textiles. It ismoving vertically with an average growing rate of nearly two times of textiles for clothingapplications and now account for more than half of the total textile output. The processes inma$ing technical textiles require costly machinery and s$illed wor$ers.The application that comes under technical textiles are filtration" bed sheets and abrasivematerials" healthcare upholstery and furniture" bloodabsorbing materials and thermalprotection" adhesive tape" seatbelts" and other speciali=ed application and products.0trengths India enFoys benefit of having plentiful resources of raw materials. It is one of the largest producers of cotton yarn around the globe" and also there are good resources of fibres li$e polyester" sil$" viscose etc. There is wide range of cotton fibre available" and has a rapidly developing synthetic fibre industry. India has great competitiveness in spinning sector and has presence in almost all processes of the value chain. Availability of highly trained manpower in both" management and technical. The country has a huge advantage due to lower wage rates. >ecause of low labor rates the manufacturing cost in textile automatically comes down to very reasonable rates. The installed capacity of spindles in India contributes for 2&' share of the

world" and it is one of the biggest exporters of yarns in the global mar$et. ?aving modern functions and favourable fiscal policies" it accounts about 2!' of the world trade in cotton yarn. 22. The apparel industry is largest foreign exchange earning sector" contributing %2' of the countrys total exports. The garment industry is very diverse in si=e" manufacturing facility" type of apparel produced" quantity and quality of output" cost" requirement for fabric etc. It comprises suppliers of ready-made garments for both" domestic or export mar$ets.5ea$ness8assive 9ragmentationJA maFor loop-hole in Indian textile industry is its huge fragmentation in industry structure"which is led by small scale companies. )espite the government policies" which made thisdeformation" have been gradually removed now" but their impact will be seen for some timemore. 0ince most of the companies are small in si=e" the examples of industry leadership arevery few" which can be inspirational model for the rest of the industry.The industry veterans portrays the present productivity of factories at half to as low as one-third of levels" which might be attained. In many cases" smaller companies do not have thefiscal resources to enhance technology or invest in the high-end engineering of processes.The s$illed labor is cheap in absolute termsG however" most of this benefit is lost by smallcompanies.The uneven supply base also leads barriers in attaining integration between the lin$s insupply chain. This issue creates uncontrollable" unreliable and inconsistent performance.*olitical and (overnment )iversityJThe reservation of production for very small companies that was imposed with an intention tohelp out small scale companies across the country" led substantial fragmentation that distortedthe competitiveness of industry. ?owever" most of the sectors now have been de-reserved"and maFor entrepreneurs and corporate are putting-in huge amount of money in establishingbig facilities or in expansion of their existing plants.0econdly" the foreign investment was $ept out of textile and apparel production. 4ow" the(overnment has gradually eliminated these restrictions" by bringing down import duties oncapital equipment" offering foreign investors to set up manufacturing facilities in India. Inrecent years" India has provided a global manufacturing platform to other multi-national 2 . companies that manufactures other than textile productsG it can certainly provide a base fortextiles and apparel companies.)espite some motivating step ta$en by the government" other problems still sustains li$evarious taxes and excise imbalances due to diversification into ! states and /nionTerritories.

?owever" an outline of LAT is being implemented in place of all other taxdiversifications" which will clear these imbalances once it is imposed fully.Cabour CawsJIn India" labour laws are still found to be relatively unfavorable to the trades" with companieshaving not more than ideal model to follow a hire and fire policy. Aven the companies haveoften bro$en their business down into small units to avoid any trouble created by labourunioni=ation.In past few years" there has been movement gradually towards reforming labour laws" and itis anticipated that this movement will uphold the environment more favourable.)istant (eographic CocationJThere are some high-level disadvantages for India due to its geographic location. 9or theforeign companies" it has a global logistics disadvantage due the shipping cost is higher andalso ta$es much more time comparing to some other manufacturing countries li$e 8exico"Tur$ey" China etc. The inbound freight traffic has been also low" which affects cost ofshipping - though" movement of containers are not at reasonable costs.Cac$ of trade membershipsJIndia is serious lac$ing in trade pact memberships" which leads to restricted access to theother maFor mar$ets. This issue made others to impose quota and duty" which put scissors onthe sourcing quantities from India.OpportunitiesIt is anticipated that Indias textile industry is li$ely to do much better. 0ince the consumptionof domestic fibre is low" the growth in domestic consumption in tandem is anticipated with()* of - to , ' and this would support the growth of the local textile mar$et at about - to D' a year. 2&. India can also grab opportunities in the export mar$et. The industry has the potential ofattaining 1 &bn export earnings by the year 23%3. The regulatory polices is helping out toenhance infrastructures of apparel par$s" 0peciali=ed textile par$s" A*Ks and AO/s.The (overnment support has ensured fast consumption of clothing as well as of fibre. Asingle rate will now be prevalent throughout the country.The Indian manufacturers and suppliers are improving design s$ills" which include differentfabrics according to different mar$ets. Indian fashion industry and fashion designers aremar$ing their name at international platform. Indian sil$ industry that is $nown for its fineand exclusive brocades" is also adding massive strength to the textile industry.The industry is being moderni=ed via an exclusive scheme" which has set aside 1!bn forinvestment in improvisation of machinery. International brands" such as Cevis" 5al-8art" <C*enny" (ap" 8ar$s # 0pencer and other industry giants are sourcing more and more fabricsand garments from India. Alone 5al-8art had purchased products worth 1233mn last yearand plans to increase buying up to

1 bn in the coming year. The clothing giant from Aurope"(A* is also sourcing from India.AnticipationAs a result of various initiatives ta$en by the government" there has been new investment of7s.!3"333 crore in the textile industry in the last five years. 4ine textile maFors invested7s.2"-33 crore and plan to invest another 7s.-"&33 crore. 9urther" Indias cotton productionincreased by !D' over the last five yearsG and million additional spindles and 3"333shuttle-less looms were installed.9orecast till 23%3 for textiles by the government along with the industry and Axport*romotion Councils is to attain double the ()*" and the export is li$ely attain 1,!bn. Theindustry is anticipated to generate %2mn new Fobs in various sectors.7ecent TrendsThe mood in the Indian textile industry given the phase-out of the quota regime of the 8ulti-9ibre Arrangement :89A; is upbeat with new investment flowing in and increased orders forthe industry as a result of which capacities are fully boo$ed up to April 233!. As a result ofvarious initiatives ta$en by the government" there has been new investment of 7s.!33 billionin the textile industry in the last five years. 4ine textile maFors invested 7s.2- billion and 2!. plan to invest another 7s.-& billion. 9urther" Indias cotton production increased by !D' overthe last five yearsG and million additional spindles and 3"333 shuttles-less looms wereinstalled.The industry expects investment of 7s.%"&33 billion in this sector in the post-89A phase. ALision 23%2 for textiles formulated by the government after intensive interaction with theindustry and Axport *romotion Councils to capitalise on the upbeat mood aims to increaseIndias share in worlds textile trade from the current &' to ,' by 23%2 and to achieve exportvalue of /0 1 !3 billion by 23%2 Lision 23%2 for textiles envisages growth in Indian textileeconomy from the current /0 1 D billion to 1 ,! billion by 23%2G creation of %2 million newFobs in the textile sectorG and modernisation and consolidation for creating a globallycompetitive textile industry. The textile industry is undergoing a maFor reorientation towardsnonclothing applications of textiles" $nown as technical textiles" which are growing roughlyat twice rate of textiles for clothing applications and now account for more than half of totaltextile production. The processes involved in producing technical textiles require expensiveequipments and s$illed wor$ers and are" for the moment" concentrated in developedcountries. Technical textiles have many applications including bed sheetsG filtration andabrasive materialsG furniture and healthcare upholsteryG thermal protection and blood-absorbing materialsG seatbeltsG adhesive tape" and multiple other speciali=ed products andapplications.

To enable 0mall To equip the textile industry to withstand the pressures of import penetration" and maintain dominance of the growing domestic mar$et. To secure a D percent share in global textile trade by the end of the Aleventh 9ive @ear *lan. To ensure the growth of the Indian textile industry at %percent per annum in value terms" to /01 %%! billion" by the end of the Aleventh 9ive @ear *lan. To build world class" state-of-the-art" manufacturing capacities and achieve a predominant global standing in manufacture and export of textiles and clothing. 2-. Lision 0tatement for textile industry:233D-23%2; # 8edium Anterprises :08As; to achieve competitiveness to face the global scenario with confidence. To provide a conducive policy environment which will encourage innovation" augment 72D. # To establish the Indian textiles industry as a producer of internationally competitive value added products.) efforts" and enhance productivity through the upgradation of technology" manufacturing processes and the development of human resources. 2,. 9uture of Textile Industry in IndiaThe textile industry in India is one of the flourishing sectors of Indian economy. It contributesmore than % ' to industrial output" %-.- ' to export revenues and &' to the nation.s ()*.In the year 23%3" the industry is estimated to produce %2 million Fobs with an investment of/01 - billion in the fields of textiles equipments and structure" and garment manufacturingby the end of 23%!./nion 8inistry of Textiles certified Apparel Axport *romotion Council :AA*C; has ta$en theresponsibility to motivate the foreign investors to invest in Indian Textile industry byexhibiting it massive unexplored domestic mar$et. It has also formulated and endorsed themotto of Ncome" invest" produce and sell in India. /nder this the ministry has decided tosend it representatives to (ermany" 0wit=erland" 9rance" Italy and /0. The obFective is totrigger the foreign investment towards instituting textile units in India by offering numerousallowances to global investor li$e low-priced wor$force and intellectual right fortification.The government of India has also ta$en few initiatives to promote the textile industry bypermitting %33' 9oreign )irect Investment in the mar$et. Owing to the upright and straightincorporated textiles price chain" the Indian textile industry symboli=es a strong existence inthe complete value chain from raw commodities to finished products. The 0ynthetic and7ayon Textile Axport *romotion Council :07TA*C; has ta$en all the required steps to meetthe target of doubling the synthetic textile exports in

India to /01 -.2 billion by sei=ing &'of mar$et share by 9@ 23%%-%2.(lobal Textile 8ar$et OverviewThe global textile mar$et value is estimated to be /01 &.!3 trillion during the year 233,. It isobserved that clothing accounted for about -3' of the mar$et" while textile accounted for thebalance &3'. The global textile industry grew at an estimated average annual rate of about2.!' during 2333-233,. The global slowdown has also affected Textile industry adversely.The global fibre demand has decreased by one percent in 233,. It is also observed that theglobal textile and clothing industry can be broadly divided into 4atural 9ibre and 8anmade9ibre industry. The 4atural 9ibre industry includes Cotton" 5ool" 0il$ and <uteG while themanmade 9ibre Industry includes *olyamides" *olyester" *olyethylene" Liscose and Acrylic.(lobal 9ibre 0cenario 2+. The global fibre demand in 233 was -&% Cacs 8T. The demand for fibre grew at a CA(7of !.3!' to reach an estimated ,3D.!3 Cacs 8T during 233,. It is noted that during the sameperiod" demand for natural fibre grew at a CA(7 of &.-!'" while the demand for manmadefibre grew at CA(7 of !. ,'.*9@ )emand in IndiaThe domestic demand for *9@ stood at %3%&D!! Tons during the year 233 . The demand for*9@ grew at CA(7 of &.2%' to reach an estimated %2,,!2 Tons by the years 233,.*9@ industry" as we $now" had faced difficult mar$et conditions during the years %+++-2332due to excess capacity over demand which lead to cut throat unhealthy competition causingsubstantial erosion in profitability of these companies. ?owever" as now new capacities cameup during this period" the gap between supply and demand got gradually bridged up and *O@manufacturing unitsIcompanies are doing reasonably well since beginning of 2332 and areexpected to do much better during the next few years in view of the sustained demandgrowth.As per detailed survey conducted by C7I0I49AC the domestic *olyester industry is li$elyto witness robust demand growth and higher profit margins in the next five years due to thefollowing positive factors favouring *olyester Industry. *rice Competitiveness of *olyesterJ vi=-a-vi= other substitutes li$e cotton" sil$ and woollen yarns. Axcise duty reduction to encourage demandJ Axcise duty on *O@ has been progressively reduced over the previous few years to %-' and is expected to be reduced further which will further increase the price competitiveness of *O@. Increase of *9@ in non-appeal segmentsJ In India" fibre is mostly used for textile applications i.e. + ' and only D' for nonapparel applications li$e home textiles" automotive an industrial segments as against !+' worldwide. The demand of non- apparel segment is expected to

grow S 23' p.a. as *olyester offers high tenacity an strength which is most suitable for such applications. Cower per capita consumptionJ The average per capita consumption :*CC; of fabric in India is much lower than in its neighbouring countries. India has a huge potential mar$et" given that its *CC is as low as %.& $g as compared China :! $gs;" *a$istan : 3. $gs; and Indonesia :! $gs;. India has the advantage of a large an growing domestic mar$et" and a good ()* growth. 7apid urbani=ationJ higher spend on clothingJ In India" out of the total population" about D3' is rural. >ehaviour patterns suggest that most of the fabric demand in this segment is need-based. The urban demand" on the other hand" is also driven by fashion trends and favours more sophisticated textiles" and variety in designs and colours. The average urban spend on apparel is higher than rural spend. ?owever" over the years" the clothing pattern in India has shifted. 8ens clothing consumption has moved from the traditional cotton based wear to synthetic fabrics. Cotton dhotis are giving way to trousers :mostly made of polyester or polyester blends;. Ci$ewise" women are moving from cotton saris to synthetic sarisIdresses. Cevy of Anti-dumping duty on import of *O@ to lower threats of import leading to availability of better contribution to domestic manufacturers. 7apid additions in downstream processing facilities leading to incremental demand. 8anufacturing of manmade fibres globally is getting shifted mainly to China and India. As Chinas domestic consumption almost matches its production" India will be able to increase its presence in the International mar$et.Heeping in view the strong fundamentals mentioned above" C7I0I49AC has proFected the*O@ industry grew at a healthy D.,' Compounded Annual (rowth 7ate :CA(7;.7aising concern over Indias share in the /0 imports of technical textiles and nonwovenfabric which is way behind China" industry body 9icci today said domestic industry needsresearch and development :7#); support.TIndias share in the /0 imports of special purpose fabric :technical textiles; and nonwovenfabrics was merely 2.- per cent and %.2 per cent" respectively in 233+ compared to Chinasshare of %! per cent and %2 per cent"T a 9icci study said.India needs to strengthen its capabilities to tap this growing mar$et as technology-intensiveproducts are the future" it said.The study said there is a need to formulate a comprehensive research and development:7#); policy for the Indian textile industry. The chamber has submitted itsrecommendations to the 8inistry of Textiles in this regard. The study pointed out that only a

%. small portion of revenue of the Indian textile industry is derived by innovative or technologyintensive products. TThe policy should aim at increasing the countrys share of advancetechnology-based products and high value-added items in global mar$et to seven per cent innext five years from less than two percent currently.The chamber has also recommended setting-up of a 4ational Textiles 7esearch Council withseed money of 7s 3 crore and an annual grant of 7s %3 crore. The council could be the apexbody for underta$ing and providing direction to research in textiles in the country" the studysaid.9icci said that the policy should provide a special focus on eco-friendly textiles that wouldhelp in reducing carbon footprint. T)evelopment of eco-friendly and sustainable lin$ages is$ey to competitiveness. Also" the competitive edge for Indian textile industry will come fromadoption of new and advance materials with functional properties :li$e anti-microbial fabricsfor patients dress; in the textiles sector"T it said.(overnment Initiative for Textile IndustryJAccording to the 8inistry of Textiles" investment under the Technology /pgradation 9und0chemes :T/90; has been increasing steadily. )uring the year 233+-%3" %,+- applicationshave been sanctioned at a proFect cost of /01 !.2 billion. The cumulative progress as on)ecember %" 233+" includes 2D"&DD applications sanctioned" which has triggered investmentof /01 &!.! billion and amount sanctioned under T/90 is /01 %,.+ billion of which /01%-.& billion has been disbursed so far till the end of April" 23%3.8oreover" in 8ay 23%3" the 8inistry of Textiles informed a parliamentary panel that itproposes to allocate /01 D,!.2 million for the moderni=ation of the textile industry.The 0cheme for Integrated Textile *ar$ :0IT*; was approved in <uly 233! to facilitate settingup of textiles par$s with world class infrastructure facilities. &3 textiles par$ proFects havebeen sanctioned under the 0IT*. According to the 8inister of 0tate for Textiles" *anabaa$aCa$shmi" under the 0IT*" a cumulative expenditure of /01 23&. million has been incurredagainst allocation of /01 223.D million in the last three years.In the /nion >udget 23%3-%% presented in 9ebruary 23%3" the 9inance 8inister made thefollowing announcements to benefit the textile industryJ 2. The central plan outlay for the industry has been enhanced to /01 %.3 billion. Of this /01 !2%.& million is for T/90" /01 D- million for 0IT*" /01 ,3.2 million for handlooms" /0 1 -+. million for handicrafts and /01 +,.& million for sericulture. Allocation for textiles and Fute industry is /01 D% .& million. The total allocation for village and small enterprises sector which include handicrafts and handlooms is /01 2%3. million. /01 %.! million has

been provided for development of mega clusters in handlooms" handicrafts and powerloom sectors. Customs duty at & per cent for import of readymade garments for retail sales has been withdrawn. The micro small medium enterprises in textiles sector have been given full CA4LAT credit on capital goods in one installment in the year of receipt of such goods and the facility of payment of excise duty in quarterly basis.InvestmentsAccording to the 8inister for Textiles" 8r )ayanidhi 8aran" around /01 !. ! billion offoreign investment is expected to be made in India in the textile sector over the next fiveyears.The textiles industry has attracted foreign direct investment :9)I; worth /01 ,%D.2- millionbetween April 2333 and 8arch 23%3" according to data released by the )epartment ofIndustrial *olicy and *romotion. 0 Humars 4ationwide has formed a Foint venture :<L; with )onna Haran International to design" produce and distribute the entire range of )H4@ menswear apparel across the world except <apan for %3 years. The new venture will invest /01 2! million for expansion of )onna Haran.s menswear brand and expects to record sales of about /01 %&3 million in the next three years. The Andhra *radesh government has allocated over %333 acres of land for the >randix India Apparel City :>IAC; in the state.s special economic =one :0AK;" which was inaugurated in 8ay 23%3. The apparel city is expected to attract an investment of /01 %.2 billion :around 7s !"&33 crore;. *rivate equity firms T*( and >ain Capital have pic$ed up sta$es in children apparel retailer Cilliput Hidswear for /01 2D million and /01 -3.D million respectively. . Italian sportswear ma$er Cotto is planning to invest /01 %3 million over the next five years to capture D per cent of India.s branded sports apparel and equipment mar$et. The brand" which started its stand-alone retail chain in India in 233," has % stand- alone stores across the country and plans to open 233 more such stores by 23%!.5orlds leading lingerie brand" (ermany-based" Triumph International" plans to invest over/01 2%D million in India to open %2 more flagship outlets and 3 additional A*0 :Axclusive*artner 0tores; during 23%3.(overnment policies relating to textile industries in IndiaThe Indian textile industry is one of the largest industries in the world. The 8inistry ofTextiles in India has formulated numerous policies and schemes for the development of thetextile industry in India. 0ome of them are detailed in the following sections.4ational Textile *olicyThe 4ational Textile *olicy was formulated $eeping in mind the following obFectivesJ )evelopment of the textile sector in India in order to nurture and maintain its position in the global arena as the leading manufacturer and exporter of clothing. 8aintenance of a

leading position in the domestic mar$et by doing away with import penetration. InFecting competitive spirit by the liberalisation of stringent controls. Ancouraging 9oreign )irect Investment as well as research and development in this sector. 0tressing on the diversification of production and its /pgradation ta$ing into consideration the environmental concerns. )evelopment of a firm multi-fibre base along with the s$ill of the weavers and the craftsmen.0uch goals are set to meet the following targetsJ The si=e of textile and apparel exports must reach a level of /0 1!3 billion by the year 23%3. The Technology /pgradation 9und 0cheme should be implemented in a strict manner. &. The garments industry should be removed from the list of the small scale industry sector. The handloom industry should be boosted and encouraged to enter into foreign ventures so as to compete globally. The 4ational Textile *olicy has also formulated rules pertaining to certain specific sectors. 0ome of the most important items in the agenda happen to be the availability and productivity along with the quality of the raw materials. 0pecial care is also ta$en to curb the fluctuating price of raw materials. 0teps have also been ta$en to raise sil$ to the international standard.*reamble To comprehend the purpose of textile industry that is to provide one the most basic needs of the people and promote its sustained growth to improve the quality of life. To ac$nowledge textile industry as a self-reliant industry" from producing raw materials to delivery of finished productsG and its maFor contribution to the economy of the country. To understand its immense potentiality for creating employment opportunities in significant sectors li$e agriculture" industry" organi=ed sector" decentrali=ed sector" urban areas and rural areas" specifically for women and deprived. To recogni=e the Textile *olicy of %+,!" this boosted the annual growth rate of cloth production by D.% '" export of textile by % . 2' and per capita availability of fabrics by .-'. To analy=e the issues and problems of textile industry and the guidelines provided by the expert committee set up for this specific purpose. To give a different specification to the obFectives and thrust areas of textile industry. To produce good quality cloth for fulfilling the demands of the people with reasonable prices. To maintain a competitive global mar$etThrust areas(overnment of India is trying to promote textile industry by giving emphasis on several areasof textile" which are as belowJ Innovative mar$eting strategies !. )iversification of product Anhancement of textile oriented technology 6uality awareness Intensifying raw materials (rowth of productivity Increase

in exports 9inancing arrangements Creating employment opportunities ?uman 7esource )evelopmentAfforts(overnment of India has set some targets to intensify and promote textile industry. Tomateriali=e these targets" efforts are being made" which are as followsJ Textile and apparel exports will reach the /0 1 D3 billion mar$ by 23%! All manufacturing segments of textile industry will come under T/90 : Technology /pgradation 9und 0cheme; Increase the quality and productivity of cotton. The target is to increase !3' productivity and maintain the quality to international standards Astablish the Technology 8ission on Fute with an obFective to increase cotton productivity of the country Ancourage private organi=ation to provide financial support for the textile industry *romote private sectors for establishing a world class textile industry Ancourage handloom industry for producing value added items Ancourage private sectors to set up a world class textile industry comprising various textile processing units in different parts of India 7egenerate functions of the T7A :Textile 7esearch Associations; to stress on research wor$s.(overnment policy on cotton and man-made fiber -. One of the principal targets of the government policy is to enhance the quality and productionof cotton and man-made fiber. 8inistry of Agriculture" 8inistry of Textiles" cotton growingstates are primarily responsible for implementing this target.Other thrust areas %. Information TechnologyJ Information technology plays a significant role behind the development of textile industry in India. IT :Information Technology; can promote to establish a sound commercial networ$ for the textile industry to prosper. 2. ?uman 7esource )evelopmentJ Affective utili=ation of human resource can strengthen this textile industry to a large extent. (overnment of India has adopted some effective policies to properly utili=e the manpower of the country in favour of the textile industry. . 9inancing arrangementJ (overnment of India is also trying to encourage talented Indian designers and technologists to wor$ for Indian textile industry and accordingly government is setting up venture capital fund in collaboration with financial establishments.Acts0ome of the maFor acts relating to textile industry include Central 0il$ >oard Act" %+&, The Textiles Committee Act" %+- The ?andlooms Act" %+,! Cotton Control Order" %+,The Textile /nderta$ings Act" %++!(overnment of India is earnestly trying to provide all the relevant facilities for the textileindustry to utili=e its full potential and achieve the target. The textile industry is presentlyexperiencing an average annual growth rate of +-%3' and is expected to grow at a rate of%-' in value"

which will eventually reach the target of /0 1 %%! billion by 23%2. Theclothing and apparel sector are expected to grow at a rate of 2% 't in value terms. D. Tariff policyIndia # /0 have reached on an Agreement for reciprocal mar$et access commitments forTextiles and Apparel with the negotiation of the 5TO Agreement on Textile # Clothing. Itprovides elimination of 6uota system of Textiles # Apparel from %st <anuary 233!./nder Indo-/0 Agreement of %st <anuary %++!" India agreed to reduce tariffs on Textile #apparel and remove all the restrictions on these products.9rom %st April 2333" (overnment of India reduced tariffs on 8anmade 9ibers # 9ilament @arns from !' to 23' Cotton @arn from 2!' to 23' 0pun" >lended" and 5oolen @arn from &3' to 23 'India agreed to bind its tariffs on 2-! textile # apparel products :Textured @arns of 4ylon #*olyester" 9ilament 9abrics" 0portswear" and ?ome Textiles.;Apparel products are free from Axcise )uties # various Taxes.(rey 9abrics and certain Cotton @arns are exempt from basic Axcise )uty.Customs duty on *olyester 9ilament @arns is reduced from %3' to D.!'. )uty on other9ilament yarns will be remain at %3'.Customs duty on *olyester 0taple fibers is reduced from %3' to D.!'. )uty on other 8an8ade 0taple fibers will be remain at %3'.Customs duty on 7aw 8aterials such as )8T" *TA and 8A( reduced from %3' to D.!'.9or 0mall 0cale Industries there is 9ull Axemption Cimit being increased from 7s.% crore to7s.%.!3 crores.8ost of the products fall under ?0 code -% and -2 carry an import duty of !-., ' whichincludes 3' basic duty" %-' additional duty and & per cent special additional duty.Axcise duty on 4ylon Chips has been reduced from %-' to %2'.Optional excise duty on 4ylon 9ish 4et 9abrics is increased from ,' to %2'. ,. Axcise )uty Axemption on specified Textile 8achinery Items is withdrawn and ,' Axcise)uty is imposed.C0T rate reduced from &' to ' with effect from April %" 233D.7emoval of surcharge on income tax on all firms and companies with a taxable income of7s.% crore or less.Import CicensingJIndia has liberali=ed its Import regime for Textiles and apparel" but some of the part is stilllimited for mar$et access. Currently" there is no import restriction for yarns # fabrics items.Apparel # 8ade-up textiles goods require a 0pecial Import Cicense :0IC;. (ovt. revisedAxim *olicy on %st 8arch %+++ by eliminating Import Cicensing 7equirements for ,+&consumer goods" agriculture products and textiles. On 2,th )ecember %+++ India and /ssigned an Agreement for the elimination of import restrictions of %"&2+ agriculture" textiles"consumer goods