Beruflich Dokumente

Kultur Dokumente

PJ4 CSO Handout

Hochgeladen von

XARA62Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

PJ4 CSO Handout

Hochgeladen von

XARA62Copyright:

Verfügbare Formate

STORM SEWAGE OVERFLOW CHAMBERS Functions of storm sewage overflow: The primary function of a storm sewage overflow is to limit

the flow to the sewer downstream and to the treatment works, for economic reasons. Given the economic necessity to overflow storm sewage, the overflow chamber has the equally important function of controlling the polluting load which the overflowed storm sewage carries to the watercourse. These two functions are essentially in conflict and the design of overflow chambers must be based on an acceptable compromise. It is estimated that there are around 30,000 CSOs of which currently 15-20% are thought to be unsatisfactory. All CSOs have to have a consent to discharge approved by the Environment Agency. Retained flow Formula A Originally retained flows were multiples of dry weather flow DWF, usually 6 times DWF. Currently the discharge setting is determined in consultation with the EA to take account of the location of the CSO. Formula A is sometimes used which to some extent takes account of the nature of the effluent when deciding the setting at which the dilute sewage is discharged to the receiving watercourse. Formula A Flow = DWF + 1360 P + 2 E Dry Weather Flow = P G + I + E litres/day

DWF is the average daily flowrate in dry weather in litres/day including infiltration and industrial effluent where: P is the population, G is their daily water consumption, I is the infiltration and E is the industrial effluent. Pollutant loads in sewage 1) Substances in solution 2) Substances in suspension 3) Floating solids 4) Heavy solids An efficient overflow chamber has to deal with all four sources of pollution: Dilution and separation are the processes normally used. (1) and (2) in the list above are difficult to remove therefore the overflow setting (ie the point at which the overflow starts to discharge to a nearby watercourse) is such that they are adequately diluted before they are discharged from the sewage system. (3) and (4) are dealt with by separation by the use of tranquil (stilling) areas within the CSO structure, or increasingly mechanically raked screens. Location of Storm Sewage Overflows within the sewage system It is generally considered that a storm sewage overflow should not be installed on a sewer designed to carry less that 75 litres/sec. Where is necessary to connect a foul sewer, serving an area drained by separate systems of sewers for foul and surface water, to a combined sewage system, the connection should be made to a flow for treatment sewer, downstream of any overflow on the system, where reasonably practicable.

It is considered desirable that the combined sewers serving drainage sub-areas should be overflowed before discharging to the trunk sewer serving the catchment. Such a system will result in the maximum use of natural watercourses for the conveyance of storm water, and the minimum size trunk sewer carrying flows for treatment only. This should result in the spreading of the pollutant load. Contrary to this approach some water companies have moved to an approach based on large well designed CSO structures which effectively represent a point source of pollutant loading, as opposed to a dispersed load throughout the catchment. The CSO structure should be located so that it is easily accessed for maintenance. Receiving watercourses should have sufficient base flow to further dilute the overflow discharge and the CSO outlet basin should be designed so as to prevent scour of the river bed. Constituent parts of a CSO 1) Control device The quantity of flow passed forward for treatment from the overflow will be determined by a control device within the chamber. The hydraulic setting for the control will be that agreed with the EA This control device will generally consist of one of the following, which should normally have an opening of 200mm diameter or larger: i) ii) iii) iv) Throttle pipe Orifice plate Hydrobrake Adjustable Penstock

2) Means of overflow The storm flow in excess of the agreed retention flow needs to be ejected safely and in a controlled manner from the chamber. This will normally consist of one of the following: i) ii) iii) iv) Transverse weir Side weir Peripheral weir Syphon

3) Means of storage To allow the separation of heavy and floating solids and encourage their retention within the CSO chamber a tranquil/storage area should be provided. This will normally take the form of one of the following: i) ii) iii) iv) Stilling Pond Oversized upstream pipes Online tank Offline tank

4) Means of retaining floating/heavy solids An efficient CSO must have a high solids retention capability so as to minimise the risk of gross pollution. This will normally involve one or all of the following; i) ii) iii) iv) Scum boards or baffle plates Sloped benching Dry weather flow channel Mechanically raked screens

It is desirable that mechanically raked screens are provided to screen the overflowed storm system sewage prior to discharge to the watercourse. The design of the chamber should include an automatic means of returning the screening to the flow for treatment. Use of fine screens or micro strainers may be considered for sensitive locations. In the US disinfection of CSO discharges is sometimes used. Besides meeting hydraulic and pollution control criteria new overflow structures should normally be designed for a life well in excess of 50 years, have a chamber that is self cleansing with minimal risk of blockage, and has easy and safe access. An effective storm sewage overflow structure should, therefore, satisfy the following objectives: (i) It should not come into operation until the prescribed flow is being passed to treatment (ii) There should not be a significant increase in the flow to treatment whilst the overflow is operating. (iii) The maximum practical amount of polluting material should be passed to treatment. (iv) It should be fully automatic. (v) The design should avoid any complication likely to lead to unreliable performance. (vi) The chamber should be self cleansing with minimal risk of blockage (vii) It should have minimum maintenance requirements. (viii) It should allow safe access. (viiii) Construction cost should be kept to a minimum

TYPES OF OVERFLOW i) High sided weir ii) Stilling pond iii) Vortex i) High Sided Weir This type of overflow was a development from the earlier low sided weir flow. It was recognised that a deeper flow in the chamber and lower velocities were essential to gain effective control of the flow. Flow control devices designed specifically for this purpose were located within the overflow chamber in order to achieve the required flow.

ii)

Stilling Pond

The stilling pond was developed by Sharpe and Kirkbride and was particularly important as it was designed to separate gross solids, both floating and settling, from the flow. Thus reducing visual pollution to the watercourse. As stilling pond overflows are generally large structures they have the added value of storage, thus reducing the volume of frequency of spill to the watercourse.

iii)

Vortex Overflow

The vortex type overflow is a fairly modern type of overflow that has been developed over the past decade. Under normal conditions, flow passes through the centre of the vortex and away through the contamination pipe. When storm conditions occur, the centre of the vortex chamber fills, producing a vortex flow motion and dragging gross solids down into the continuation pipe. Any flows that overtop the weir wall should already have had any gross solids settled out. Following tests carried out on the vortex overflows, it has been shown that the vortex is practically self cleansing and not prone to blockage.

Das könnte Ihnen auch gefallen

- Overland FlowDokument74 SeitenOverland Flowsatria11Noch keine Bewertungen

- 6300 L20 InvertedSiphonsDokument0 Seiten6300 L20 InvertedSiphonschakfarmerNoch keine Bewertungen

- Appendix 9.B 9.B.1 Inverted Siphon: Sag CulvertsDokument21 SeitenAppendix 9.B 9.B.1 Inverted Siphon: Sag CulvertsJulia DiazNoch keine Bewertungen

- CSO Design Guide Version3Dokument23 SeitenCSO Design Guide Version3XARA62Noch keine Bewertungen

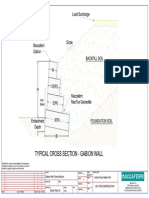

- 2007 - Gabion WallsDokument4 Seiten2007 - Gabion WallsXARA62Noch keine Bewertungen

- Epa Water Treatment Manual PreliminaryDokument111 SeitenEpa Water Treatment Manual PreliminaryTony GallacherNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- 22ba093 - Souvick SahaDokument12 Seiten22ba093 - Souvick SahaSouvickNoch keine Bewertungen

- Ligutan V CA (Full Text)Dokument15 SeitenLigutan V CA (Full Text)Yaz CarlomanNoch keine Bewertungen

- Module - No. 7 CGP G12. - Name of AuthorsDokument77 SeitenModule - No. 7 CGP G12. - Name of AuthorsJericson San Jose100% (1)

- Experience Certificate For English TeacherDokument2 SeitenExperience Certificate For English TeacherShaher Alburaihy86% (7)

- BrochureDokument10 SeitenBrochureSaurabh SahaiNoch keine Bewertungen

- Hazing in The PhilippinesDokument24 SeitenHazing in The PhilippinesEdz Votefornoymar Del Rosario100% (2)

- Femi-1020315836-The Life Styles Hotel Surabaya-HOTEL - STANDALONE-1Dokument2 SeitenFemi-1020315836-The Life Styles Hotel Surabaya-HOTEL - STANDALONE-1Deka AdeNoch keine Bewertungen

- Professional Cloud Architect Journey PDFDokument1 SeiteProfessional Cloud Architect Journey PDFPraphulla RayalaNoch keine Bewertungen

- Case Digest - LawDokument11 SeitenCase Digest - Lawjonjie.jumamil.23Noch keine Bewertungen

- Division of Pagadian City Zamboanga Del Sur National High SchooolDokument3 SeitenDivision of Pagadian City Zamboanga Del Sur National High SchooolMyra KadatuanNoch keine Bewertungen

- FDDokument17 SeitenFDYash BhatnagarNoch keine Bewertungen

- Specpro 4Dokument12 SeitenSpecpro 4Venice SantibañezNoch keine Bewertungen

- Bang e Dara PDFDokument274 SeitenBang e Dara PDFAtta ur Rehman100% (1)

- Market Conduct Guidelines Philippine Life Insurance Association June 2009Dokument28 SeitenMarket Conduct Guidelines Philippine Life Insurance Association June 2009Roselle Perez-BariuanNoch keine Bewertungen

- Hon. William Ruto's Speech at The Jubilee Manifesto LaunchDokument10 SeitenHon. William Ruto's Speech at The Jubilee Manifesto LaunchH.E. President Uhuru KenyattaNoch keine Bewertungen

- Ephesians 5.32-33Dokument2 SeitenEphesians 5.32-33Blaine RogersNoch keine Bewertungen

- TWG 2019 Inception Reports forERG 20190717 PDFDokument95 SeitenTWG 2019 Inception Reports forERG 20190717 PDFGuillaume GuyNoch keine Bewertungen

- Aac04 2017Dokument153 SeitenAac04 2017Panneer SelvamNoch keine Bewertungen

- Managing Transaction ExposureDokument34 SeitenManaging Transaction Exposureg00028007Noch keine Bewertungen

- (Group 2) Cearts 1 - Philippine Popular CultureDokument3 Seiten(Group 2) Cearts 1 - Philippine Popular Culturerandom aestheticNoch keine Bewertungen

- Auditing Unit - 5 by Anitha RDokument16 SeitenAuditing Unit - 5 by Anitha RAnitha RNoch keine Bewertungen

- Drugs: Use, Abuse and Addiction - Lesson Plan (Grades 9 & 10)Dokument23 SeitenDrugs: Use, Abuse and Addiction - Lesson Plan (Grades 9 & 10)Dimple Lasala ElandagNoch keine Bewertungen

- Transformation of Green Areas in Urban Landscape of Lucknow: Need For Holistic Intervention With Respect To River GomtiDokument10 SeitenTransformation of Green Areas in Urban Landscape of Lucknow: Need For Holistic Intervention With Respect To River GomtiASHUTOSH SINGHNoch keine Bewertungen

- 雅思口语常用高效表达句型 PDFDokument3 Seiten雅思口语常用高效表达句型 PDFJing AnneNoch keine Bewertungen

- Criticism On Commonly Studied Novels PDFDokument412 SeitenCriticism On Commonly Studied Novels PDFIosif SandoruNoch keine Bewertungen

- 08 - Case Law-Unknown Case Law ListDokument28 Seiten08 - Case Law-Unknown Case Law ListNausheen100% (1)

- Animal AkanDokument96 SeitenAnimal AkanSah Ara SAnkh Sanu-tNoch keine Bewertungen

- Obsa Ahmed Research 2013Dokument55 SeitenObsa Ahmed Research 2013Ebsa AdemeNoch keine Bewertungen

- Questionnaire DellDokument15 SeitenQuestionnaire Dellkumarrohit352100% (2)

- Internship ReportDokument44 SeitenInternship ReportRAihan AhmedNoch keine Bewertungen