Beruflich Dokumente

Kultur Dokumente

Undercutting and Backfilling

Hochgeladen von

Mohan ManickamCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Undercutting and Backfilling

Hochgeladen von

Mohan ManickamCopyright:

Verfügbare Formate

Technical Paper

What successful Cost Estimators know. . . . and you should, too.

>>>>>>> AN ESTIMATORS GUIDE TO POLICIES, >>>>>>>>>>> PROCEDURES, AND STRATEGIES

ESTIMATE THE COST OF

UNDERCUTTING & BACKFILLING UNSTABLE SUBGRADE SOILS

submitted by Brian P. Stumph CPE

Brian P. Stumph is a senior estimator with W.G. Yates & Sons Construction, an ENR Top 50 general contractor serving primarily the southeastern United States. Brian holds a B.S. in Construction Engineering Technology from the University of Southern Mississippi. He has worked in the construction industry for over fteen years as an estimator, project manager and owner of Earth Specialties Construction, LLC. His primary area of estimating expertise is heavy/civil construction.

1) Introduction A. Main CSI Division B. Specific Sub-Division Code and Name C. Brief Description of Subject Matter 2) Types and Methods of Measurement 3) Factors Affecting TakeOff and Pricing A. Small Quantities vs. Large Quantities B. Geographic Locations C. Seasonal Effect on Work 4) Overview of Labor, Material, Equipment, and Indirect Costs 5) Special Risk and Considerations 6) Ratios and Analysis 7) Miscellaneous Pertinent Information 8) Sample Sketch 9) Sample TakeOff and Pricing

www.aspenational.org

ESTIMATE THE COST OF: Undercutting and Backfilling Unstable Subgrade Soils

INTRODUCTION

Whether required by the project specifications, or needed due to unforeseen site conditions, the undercutting and backfilling of unstable soils is a common sitework activity. This paper will show an estimator how to quantify volumes of undercut / backfill excavation and how to estimate the cost of labor, materials, and equipment needed to perform the work.

A. Main CSI Division:

Construction Specifications Institute 2004 Master Format Division 31 Earthwork

tions that will usually be addressed in a projects plans, specifications, and geotechnical reports. The designing engineer will sometimes specify areas and depth of undercut and replacement that needs to occur. The engineer may require a certain strata of soil be removed to a certain depth and have the contractor rely on the geotechnical report information to make the determination to what extent the undercut and backfill should occur. Items four and five, above, are situations that occur during construction and usually are estimated as a change condition. The need to remove and replace unstable soils on a construction project is a typical activity regardless of project size.

change between compacted and loose will vary depending on material type. Granular soils, such as sand, will swell less when excavated than clay soils. The estimator should consult the project geotechnical report or consult a geotechnical engineer to help determine the appropriate swell factor. Historical cost data is also a good source for help in determining swell factors. The estimator should determine if the cost estimate should be based on compacted quantities or loose quantities. A companys cost tracking system, historical cost data, how disposal fees are paid, how the backfill material is purchased, as well as an owners pricing requirements will help the estimator make this determination. Under most circumstances, it is recommended that the estimator stay consistent with his estimating approach once the decision to estimate the item as compacted measure or loose measure has been established. Often undercutting and backfilling unit prices are required to be submitted with a project bid or as a change order for unforeseen site conditions. Care should be taken to make sure the basis of the cost estimate is the same as the owners request.

B. CSI Subdivision:

Construction Specification Institute 2004 Master Format 31 23 13 Subgrade Preparation 31 23 16 Excavation 31 23 23 Fill

TYPES AND METHODS OF MEASURMENTS

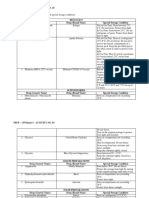

Undercutting and backfilling volumes are measured in cubic yards. The estimator should be very specific in stating the manner by which the cubic yard cost was estimated when expressing a cubic yard volume of earthwork. A cubic yard measurement in earthwork can have several different meanings. Unlike concrete estimating where a cubic yard is simply length x width x depth divided by twenty seven, earthwork expands on the simple cubic yardage equation. The earthwork estimator must understand the difference between loose cubic yardage and compacted cubic yardage. Quantity surveys are done in compacted cubic yardage. Quantities can be derived by using the average end area method of computation. To estimate quantities using the average end area method, the estimator should divide the area to be undercut into a grid. The smaller the grid, the more accurate the estimate. Once the grid area is determined, the existing elevations and the proposed elevations should be compared to determine the depth of excavation at each corner of the grid. The resulting depths should then be averaged. The average depth is then multiplied by the area of the grid and divided by twenty seven to determine the cubic yard volume. When undercutting is specified to be done in a prescribed area, the grid area may be substituted with the footprint of the area to be undercut. (See example takeoff sheets). The resulting cubic yardage is compacted or in place cubic yardage. The estimator should review project bid documents to determine if compacted or loose measure is the appropriate pricing approach. Often unit prices for the undercut are requested by the truck load or loose vehicle measure. To determine loose quantities, the compacted quantity is adjusted by a swell factor. The amount of volume

C. Description:

What is undercutting and backfilling of unstable soils? Unstable soils are soils encountered on a site that do not provide a suitable base to properly support new structures or pavement. Undercutting is the removal of existing soils. Backfilling is the replacing of the soil removed during undercutting process. Undercutting and backfilling are usually performed in conjunction with each other. The work is performed with heavy equipment such as hydraulic excavators, bulldozers and dump trucks. The need to undercut can occur for various reasons. Some of the more common reasons that precipitate the need for undercutting and backfilling are: 1. The in situ soils may have high moisture content; therefore, the soil will not provide a stable foundation for construction. 2. The in situ soil may be composed of highly expansive clays that are unstable due to the potential for volume change. 3. The designing engineer may want to replace low bearing capacity soils underneath foundations with soils that will have higher bearing capacity. 4. Otherwise stable soils become weak and unstable due to poor drainage and damage caused by construction equipment; a result of poor site management. 5. Prolonged wet conditions may cause soils to become unstable, thus causing a need to replace the wet soil with stable material. Above items one, two, and three, are condi-

FACTORS AFFECTING TAKEOFF AND PRICING

A. Small Quantities vs. Large Quantities

Typically large quantities will have a lower unit cost than small quantity projects. Large quantities allow the contractor to utilize labor and equipment at optimum productivity. Indirect costs become less of a percentage of total cost on large quantity projects than on small quantity projects.

B. Geographic Location

The need to remove and replace unstable soils is not unique to any one region. The distance from the project site to the undercut soil disposal area as well as the distance from the replacement soil site to the undercut site are important factors when determining cost. The cost of hauling material is determined by the distance from the project site and the time needed to haul the material. Generally, the shorter the distance, the lower the haul cost. The estimator should also consider the travel time when determining haul cost. In some cases, a slightly longer haul distance may have a lower cost than a shorter haul distance due to the travel time.

10

November 2009

Estimating Today

C. Seasonal Effect on Work

Weather will have an effect on the undercutting and backfilling operation. Since undercutting and backfilling go together, seasonal weather patterns influence each part of the operation equally. Undercutting will be affected if there is no way to access disposal areas or the material becomes too wet to haul. The backfilling will be even more affected. During wet periods, the areas where the backfill material is obtained will become wet and saturated causing the soil to have a high moisture content. Wet soils will not reach required compaction and produce a suitable fill. Conversely, during dry seasons, backfill soils may become to dry and will need to be hydrated in order to meet compaction requirements. Temperature will also affect the effort required to properly compact the backfill. Undercutting may be limited during the winter months because specifications do not allow the material to be placed while the ground is frozen. It is helpful for the estimator to review historical weather data in order to understand the weather may potentially impact the project.

wage rate surveys are a source of wage rate information. As a rule of thumb, excavator and bulldozer operators are paid higher wages than compactor, tractor and truck operators. Common laborers will be the lowest paid workers. The estimate should also include the cost of federal taxes, state taxes, workers compensation insurance, general liability insurance and any fringe benefits. The estimator should review the specifications, and understand the Davis Bacon wage requirements when estimating for federal projects.

ing the hourly equipment rate times the travel time. Divide this total by the volume capacity of the truck. For example: the hourly rate of a truck is sixty dollars ($60.00), travel time is thirty minutes (.5 hrs.) and the trucks volume capacity is twenty cubic yards (loose vehicle measure =20 CY LVM). The cubic yard haul cost would be as follows: $60.00 x .5 hrs 20 CY LVM = $1.50 per CY LVM

B. Overview of Material

The estimator should evaluate both the material taken from the undercut, and the material needed for backfilling to determine the cost for either disposing of the existing material (in the case of an undercut) or purchasing suitable material (in the case of a backfill). Material produced from the undercut should be evaluated to determine if it will be acceptable for use elsewhere onsite. If the material will not meet the specification for use elsewhere on the site, or if there is not sufficient area available for onsite disposal, it must be removed to an offsite location. Usually, the contractor must pay a disposal fee to deposit the excess material to an offsite location. The cost of disposing of the undercut material should be included in the cost estimate. The disposal fee will be based on either a cross-section measure or loose vehicle measure. The estimator should understand the method of measurement that will be used to determine disposal fees. The estimator should include the cost of the labor and equipment needed in his estimate if the contractor is required to spread or stockpile the undercut material in lieu of paying a disposal fee. If the material from undercut is to remain onsite, the cost of labor and equipment needed to spread the material onsite should be accounted for in the estimate. Required backfill material may come from either onsite or offsite sources. Project specifications will dictate the type of material required for backfill. The supplier of the material will normally set the basis for determining how quantities for payment will be measured. Material for backfill will either be sold by truck load (loose vehicle measure), weight, or by cross-section measure. The material supplier will either deliver the material to the site or will require the contractor to arrange for delivery. To estimate a delivery rate, the estimator needs to know the volume capacity of the truck hauling the material, the trucks hourly equipment rate (including operators labor rate), and the distance/travel time to and from the site. The cost per yard can be determined by multiply-

The haul rate per load will be: 20 CY LVM x $1.50 per CY LVM = $30.00 per load.

C. Overview of Equipment

The basic equipment needed to perform undercutting and backfilling is an excavator, bulldozer, hauling unit (scraper, off-road truck, or highway truck) and compactors. The estimator should also consider if equipment will be needed to maintain haul routes onsite or sweep and clean public roadways. Often a tractor and disk will be needed to help dry and condition the backfill material. The number and size of the equipment will be determined by the desired production rate. Historical cost data and manufacturers data for a machines productivity is a good source of information for estimating the productivity of a piece of equipment. Invaluable sources for information on equipment productivity are field supervisors and operators. Since field personnel are using the machines daily, they will usually have a good perspective regarding what equipment is best suited for a particular project. The estimator should consider the production capacity of the equipment and pair/group the equipment to maximize productivity. For example, the cost of a bulldozer capable of spreading 40 loads of dirt per hour should not be paired with an excavator capable of making only 5 loads per hour. This lack of efficiency will result in a skewed estimate unit cost that may not accurately reflect the actual cost to perform the work. Equipment cost used in an estimate will typically come from a companys equipment rate sheet. If rental equipment is to be used the vendor can help the estimator establish an hourly rate that can be used in the estimate. When using rented equipment, the estimator should not overlook the cost of fuel and maintenance that will be required.

OVERVIEW OF LABOR, MATERIAL, EQUIPMENT, AND INDIRECT COSTs

A. Overview of Labor

The labor needed for undercutting and backfilling is largely determined by the number of pieces of equipment needed to perform the task. Each piece of equipment will require an operator. In addition to number of equipment operators required, the estimator should consider the following : 1. Will the task require additional personnel for traffic control on roads or streets? 2. Will labor be needed to check grade or cross section the area? 3. How much labor is needed for cleanup? 4. Will labor be needed to document load counts or receive load tickets? 5. Will labor be needed to route haul vehicles around the site? The productivity of equipment and the rate at which backfill material can be delivered to the site will determine production rates of labor. The estimator should determine appropriate base wage rates for each labor classification once the labor requirements are determined. Wages paid to current employees, historical cost data and local

www.aspenational.org

11

ESTIMATE THE COST OF: Undercutting and Backfilling Unstable Subgrade Soils

D. Overview of Indirect Cost

In addition to the direct cost of labor, the indirect cost of material and equipment should be accounted for in the estimate. The primary indirect cost incurred will be as follows: 1. 2. 3. Crew Forman. The cost of the forman can either be part of the over all project general conditions or as part of the crew cost associated with doing the work. Mobilization Cost. The estimator should determine how to allocate mobilization cost. If the undercutting and backfilling is part of the mass excavation on the project, and the equipment used will be utilized for other items of work, then mobilization cost for the equipment may not contribute significantly to the unit price. However, if a small quantity of undercutting and backfilling is required after equipment is demobilized, the mobilization cost to perform the work will become a significant cost item. Accounting for mobilization should be done at some level of the estimate. Surveying Cost. If the work is to be cross-sectioned to determine quantities for payment, then the cost of the field measurements and calculations should be included.

SPECIAL RISK CONSIDERATIONS

Any earthmoving operation will have an impact on the environment; therefore, the estimator should be certain to account for the cost of environmental controls in the estimate. Silt control will be the primary environmental issue associated with undercutting and backfilling. At the start of a project, silt fences and other erosion control measures are usually installed on the site. Usually the existing erosion control measures are sufficient to accommodate any undercutting and backfilling operation. The estimator must include the cost for proper erosion control measures, if needed, in the undercut material disposal area. These areas should have erosion control measures installed that meet all applicable local requirements. Another environmental concern is the tracking of dirt and debris onto public roadways when hauling dirt on and off the site. Roadway cleanup cost should be included in the estimate. The estimator should always consider and include the cost of safety measures in the estimate. The presence of underground utilities is a safety and production concern. In areas where there are utilities present, production rates may need to be lowered to allow time for underground utility location. In some cases, it may be appropriate to increase/adjust the number of workers in the estimate if the crew is required to locate the utilities before excavation. The cost of barricades and sloping the sides of an excavation, if needed, should also be included in the estimate.

backfilling that is required, and the cost of performing the work. Being physically present on the site allows the estimator to correlate site plans and geotechnical reports with the actual conditions. This correlation will help the estimator understand the terrain and how it affects access to and movement around the project site. The estimator should drive the proposed haul routes before completing the estimate. Driving the routes will enable the estimator to verify haul time/distance. The estimator should always check his estimate for accuracy. When checking the accuracy of an estimate requiring undercutting and backfilling, the estimator should be mindful of the following: 1. Usually the cost of undercutting will be less than the cost of backfilling. 2. The labor cost should be less than the equipment cost. 3. Converting a compacted quantity estimate to a loose measure quantity estimate will increase the quantity while decreasing the unit cost.

MISCELLANOUS PERTINENT INFORMATION

The estimator should always verify that the backfill material source has appropriate environmental permits. The contractor can face penalties for purchasing materials from nonpermitted locations. Likewise, care should be taken when choosing disposal areas for the undercut material. Disposing of material on sites that do not have appropriate permits can result in fines and penalties for the contractor(s).

Other indirect cost will be for items such as small tools, safety supplies, and temporary facilities. The estimator should keep in mind that the indirect cost for the work can be very significant for small quantity projects. On very small quantity project the indirect cost could be more than the direct cost.

RATIOS AND ANAYLSIS

A site visit by the estimator is invaluable when determining the amount of undercutting and

12

November 2009

Estimating Today

www.aspenational.org

13

ESTIMATE THE COST OF: Undercutting and Backfilling Unstable Subgrade Soils

14

November 2009

Estimating Today

www.aspenational.org

15

ESTIMATE THE COST OF: Undercutting and Backfilling Unstable Subgrade Soils

16

November 2009

Estimating Today

www.aspenational.org

17

Das könnte Ihnen auch gefallen

- Chapter 7 - Site WorkDokument43 SeitenChapter 7 - Site WorkMekuannint DemekeNoch keine Bewertungen

- RiskBasedConstructionCostEstimating 2 PDFDokument286 SeitenRiskBasedConstructionCostEstimating 2 PDFthiruNoch keine Bewertungen

- Critical Structures Construction Issues: Self Study CourseDokument43 SeitenCritical Structures Construction Issues: Self Study CourseEliNoch keine Bewertungen

- Concrete Construction: Estimate The Cost ofDokument12 SeitenConcrete Construction: Estimate The Cost ofYay B. GicoNoch keine Bewertungen

- Coastal Flood Risk Reduction: The Netherlands and the U.S. Upper Texas CoastVon EverandCoastal Flood Risk Reduction: The Netherlands and the U.S. Upper Texas CoastSamuel BrodyNoch keine Bewertungen

- REGIONAL TRANSPORTATION DISTRICT Standard Drawings PDFDokument96 SeitenREGIONAL TRANSPORTATION DISTRICT Standard Drawings PDFİlker Yılmaz TürkerNoch keine Bewertungen

- Construction Contract Administration Manual PDFDokument214 SeitenConstruction Contract Administration Manual PDFcomandoNoch keine Bewertungen

- Estimating Labor Unit Data For Concrete ConstructionDokument13 SeitenEstimating Labor Unit Data For Concrete ConstructionsoparlNoch keine Bewertungen

- 2012 National Construction EstimatorDokument765 Seiten2012 National Construction EstimatorMiguel DeLa Cruz SilveraNoch keine Bewertungen

- Civil Design GuideDokument322 SeitenCivil Design GuideSubramanian RajendranNoch keine Bewertungen

- Practical Guide To Cost Estimating by AASHTO PDFDokument215 SeitenPractical Guide To Cost Estimating by AASHTO PDFMahyarDavamiNoch keine Bewertungen

- Private Water CrossingDokument18 SeitenPrivate Water CrossingPunithan PunithanNoch keine Bewertungen

- Cost EstimationDokument76 SeitenCost EstimationsoxalNoch keine Bewertungen

- P120-Project Estimating Requirements GSA 2007Dokument92 SeitenP120-Project Estimating Requirements GSA 2007Adrian Calin JurubescuNoch keine Bewertungen

- EarthworksDokument145 SeitenEarthworksLillian Gonzales100% (1)

- Enhanced Resource Planning - Rafael DavilaDokument53 SeitenEnhanced Resource Planning - Rafael DavilaBogdanloeNoch keine Bewertungen

- DS13 8Dokument186 SeitenDS13 8Subhash SharmaNoch keine Bewertungen

- Cost Estimating Manual For Projects 1686373084Dokument72 SeitenCost Estimating Manual For Projects 1686373084Nurul Fikri100% (2)

- Guideline EarthworkDokument110 SeitenGuideline EarthworkAhmad ZuwairisyazwanNoch keine Bewertungen

- Utilities Performance NSW Reference Rates ManualDokument77 SeitenUtilities Performance NSW Reference Rates Manualscrane@Noch keine Bewertungen

- Contract Change Order No. 12 RedactedDokument12 SeitenContract Change Order No. 12 RedactedL. A. PatersonNoch keine Bewertungen

- Pricing The Job-Mark-Up, Overhead & ProfitDokument6 SeitenPricing The Job-Mark-Up, Overhead & Profitbeq97009Noch keine Bewertungen

- Construction Submittal and Shop Drawing LiabilityDokument7 SeitenConstruction Submittal and Shop Drawing LiabilityKhue NguyenNoch keine Bewertungen

- RE Progress ReportingDokument19 SeitenRE Progress ReportingHedi ZarkounaNoch keine Bewertungen

- As NZS 2419-1-1994 Fire Hydrant Installations Part 1 System Design Installation and CommissioningDokument66 SeitenAs NZS 2419-1-1994 Fire Hydrant Installations Part 1 System Design Installation and CommissioningdavidNoch keine Bewertungen

- Jamir, Dewan R. EMGT Field Project Part 1Dokument116 SeitenJamir, Dewan R. EMGT Field Project Part 1fucker66Noch keine Bewertungen

- Pr-Rs Means FyDokument2 SeitenPr-Rs Means FyhasanplanningNoch keine Bewertungen

- c3d Content Us Ohio Doc 2014Dokument252 Seitenc3d Content Us Ohio Doc 2014Reynaldo CastilloNoch keine Bewertungen

- HISD Design GuidelinesDokument551 SeitenHISD Design GuidelinesCarl CrowNoch keine Bewertungen

- NCHRP RPT 574Dokument290 SeitenNCHRP RPT 574Shabbir1989Noch keine Bewertungen

- Lecture 7 Project Planning BasicsDokument22 SeitenLecture 7 Project Planning Basicsraobabar21100% (1)

- Cost EstimatingDokument36 SeitenCost EstimatingVisal ChengNoch keine Bewertungen

- FTA LRT Capital Cost Study Final Report 101003Dokument309 SeitenFTA LRT Capital Cost Study Final Report 101003gsa666Noch keine Bewertungen

- Global SCANDokument187 SeitenGlobal SCANLuis GonzalezNoch keine Bewertungen

- Cost Estimation TechniquesDokument26 SeitenCost Estimation TechniquesKentDemeterioNoch keine Bewertungen

- VD V013 ZPM Pro 1507Dokument105 SeitenVD V013 ZPM Pro 1507abdulNoch keine Bewertungen

- Reinforcement AccessoriesDokument18 SeitenReinforcement Accessorieseltorro-tNoch keine Bewertungen

- Roof Drainage PDFDokument68 SeitenRoof Drainage PDFFrancisco BonillaNoch keine Bewertungen

- Procedures Concerning Construction Contracts and Close Out of ProjectsDokument16 SeitenProcedures Concerning Construction Contracts and Close Out of ProjectsJuan AlayoNoch keine Bewertungen

- The Analysis and Valuation of Disruption (Derek Nelson)Dokument42 SeitenThe Analysis and Valuation of Disruption (Derek Nelson)moentaseerNoch keine Bewertungen

- Cost Estimate Guide PDFDokument177 SeitenCost Estimate Guide PDFNoirchevalNoch keine Bewertungen

- TechnicalProposal Volumes1and2Dokument498 SeitenTechnicalProposal Volumes1and2M Refaat FathNoch keine Bewertungen

- 1-5 Construction Management Cost Est EquipDokument25 Seiten1-5 Construction Management Cost Est EquipVũ Thị Hà TrangNoch keine Bewertungen

- Construction Cost EngineeringDokument23 SeitenConstruction Cost Engineeringmatthew cometaNoch keine Bewertungen

- Civil Works Cost EngineeringDokument44 SeitenCivil Works Cost EngineeringMrityunjay MallikNoch keine Bewertungen

- Specs For Highway and Bridge ConstructionDokument629 SeitenSpecs For Highway and Bridge ConstructionmsohaibazizNoch keine Bewertungen

- Wortham DelaysDokument44 SeitenWortham DelaysAjaya KumarNoch keine Bewertungen

- Design Services Contract Between Design-Builder and ConsultantDokument28 SeitenDesign Services Contract Between Design-Builder and ConsultantYinka OdegbamiNoch keine Bewertungen

- AASHTO Section 15 ManualDokument34 SeitenAASHTO Section 15 ManualChristine HermawanNoch keine Bewertungen

- Designexample01 Three Span COntinuous Straight I-GirderDokument171 SeitenDesignexample01 Three Span COntinuous Straight I-GirderJohn Archie Dela CruzNoch keine Bewertungen

- CostEstimatingHandbook 2-3-11Dokument161 SeitenCostEstimatingHandbook 2-3-11yasyboyNoch keine Bewertungen

- Labor Requirements For Construction M Aterials: Par T Il-Concrete Masonry UnitsDokument22 SeitenLabor Requirements For Construction M Aterials: Par T Il-Concrete Masonry UnitsMohammed AffrozeNoch keine Bewertungen

- Study On Scope of Cost Estimating For ProjectsDokument52 SeitenStudy On Scope of Cost Estimating For ProjectsShrikant ShuklaNoch keine Bewertungen

- 2020 - NDOT Standard Plans PDFDokument389 Seiten2020 - NDOT Standard Plans PDFChunyu ZhangNoch keine Bewertungen

- Guidelines For Estimation of Construction Time For Road and Bridge Works 2021Dokument11 SeitenGuidelines For Estimation of Construction Time For Road and Bridge Works 2021Sang Rawal100% (1)

- Draft Bridge Aesthetics Sourcebook March09Dokument72 SeitenDraft Bridge Aesthetics Sourcebook March09Nguyễn Định TríNoch keine Bewertungen

- 2015 April TPDokument21 Seiten2015 April TPPercy CasaniNoch keine Bewertungen

- Bridge Construction: How To Estimate The Cost ofDokument7 SeitenBridge Construction: How To Estimate The Cost ofluis_enrique_cvNoch keine Bewertungen

- Soil Investigation and Foundation DesignVon EverandSoil Investigation and Foundation DesignBewertung: 4.5 von 5 Sternen4.5/5 (9)

- GI ParagraphsDokument36 SeitenGI ParagraphsGolam MasudNoch keine Bewertungen

- Study Skills2016 Registration FormDokument2 SeitenStudy Skills2016 Registration FormMohan ManickamNoch keine Bewertungen

- லஞ்ச ஒழிப்புத்துறையினரின் தொடர்பு எண்கள் PDFDokument10 Seitenலஞ்ச ஒழிப்புத்துறையினரின் தொடர்பு எண்கள் PDFMohan ManickamNoch keine Bewertungen

- AsceDokument1 SeiteAsceMohan ManickamNoch keine Bewertungen

- CH 11 - Column Bases and Anchorage Into Concrete Aug 2011Dokument33 SeitenCH 11 - Column Bases and Anchorage Into Concrete Aug 2011Stephanie DavisNoch keine Bewertungen

- AUH Winter Camp 2016 Registration FormDokument2 SeitenAUH Winter Camp 2016 Registration FormMohan ManickamNoch keine Bewertungen

- Manual For Design and Detailing of RCCDokument340 SeitenManual For Design and Detailing of RCCimranmehfoozNoch keine Bewertungen

- Aggregates For ConcreteDokument1 SeiteAggregates For ConcreteMohan ManickamNoch keine Bewertungen

- Application Form For Community CertificateDokument1 SeiteApplication Form For Community CertificateN Rakesh100% (1)

- Is 2911 1 1 2010 PDFDokument26 SeitenIs 2911 1 1 2010 PDFAnupamPanjaNoch keine Bewertungen

- Teng ChartDokument1 SeiteTeng ChartMohan ManickamNoch keine Bewertungen

- Reference For Co-Efficient of Modulus VariationDokument1 SeiteReference For Co-Efficient of Modulus VariationMohan ManickamNoch keine Bewertungen

- Civil Engineering: EG380 Colorado State University Dr. Robert N. MeroneyDokument15 SeitenCivil Engineering: EG380 Colorado State University Dr. Robert N. MeroneyMohan ManickamNoch keine Bewertungen

- Pile Foundation DesignDokument82 SeitenPile Foundation Designcuongnguyen89% (28)

- Structural Engineering FormulasDokument120 SeitenStructural Engineering FormulasAnonymous PjmE9RJcgh100% (2)

- Bearing Capacity Canadian F MDokument8 SeitenBearing Capacity Canadian F MMohan ManickamNoch keine Bewertungen

- Reinforced ConcreteDokument13 SeitenReinforced ConcreteRenukadevi Rpt17% (18)

- Structural Engineering 2Dokument31 SeitenStructural Engineering 2sm_jdsNoch keine Bewertungen

- Cement ConsumptionDokument4 SeitenCement ConsumptionKapil Verma100% (11)

- Chapter 8Dokument44 SeitenChapter 8Mohan ManickamNoch keine Bewertungen

- Arch324 w09 Lecture Unit4Dokument24 SeitenArch324 w09 Lecture Unit4Mohan ManickamNoch keine Bewertungen

- Week2 Rectangularandsectionanalysisinbendingandshear 111203094640 Phpapp01Dokument38 SeitenWeek2 Rectangularandsectionanalysisinbendingandshear 111203094640 Phpapp01Mohan ManickamNoch keine Bewertungen

- Column Design - As Per BS CodeDokument16 SeitenColumn Design - As Per BS CodeMohan ManickamNoch keine Bewertungen

- 10 - Reinforced Concrete DesignDokument26 Seiten10 - Reinforced Concrete DesignEssuconNoch keine Bewertungen

- Sample Specification For Pile Integrity Testing by The Low Strain Impact MethodDokument4 SeitenSample Specification For Pile Integrity Testing by The Low Strain Impact MethodMohan ManickamNoch keine Bewertungen

- Cracking and DeflectionsDokument21 SeitenCracking and DeflectionsDeepakRavindraPrasadNoch keine Bewertungen

- Eth 5467 02Dokument159 SeitenEth 5467 02Mohan ManickamNoch keine Bewertungen

- BS National Structural Concrete Specification For Building ConstructionDokument132 SeitenBS National Structural Concrete Specification For Building ConstructionAmie D MalobagoNoch keine Bewertungen

- The Modular Ratio in Reinforced Concrete Design (Manuscript) - A.KDokument15 SeitenThe Modular Ratio in Reinforced Concrete Design (Manuscript) - A.KMohan ManickamNoch keine Bewertungen

- Eurocode 4Dokument70 SeitenEurocode 4leodegarioporral100% (2)

- 11 Ehe08Dokument7 Seiten11 Ehe08Mohan ManickamNoch keine Bewertungen

- Dig Inn Early Summer MenuDokument2 SeitenDig Inn Early Summer MenuJacqueline CainNoch keine Bewertungen

- Summative Test SolutionsDokument1 SeiteSummative Test SolutionsMarian Anion-GauranoNoch keine Bewertungen

- Oral Airway InsertionDokument3 SeitenOral Airway InsertionSajid HolyNoch keine Bewertungen

- Contact Point ContoursDokument69 SeitenContact Point ContourstarekrabiNoch keine Bewertungen

- Red Winemaking in Cool Climates: Belinda Kemp Karine PedneaultDokument10 SeitenRed Winemaking in Cool Climates: Belinda Kemp Karine Pedneaultgjm126Noch keine Bewertungen

- Concrete and Its PropertiesDokument24 SeitenConcrete and Its PropertiesAmila LiyanaarachchiNoch keine Bewertungen

- Leon County Sheriff'S Office Daily Booking Report 4-Jan-2022 Page 1 of 3Dokument3 SeitenLeon County Sheriff'S Office Daily Booking Report 4-Jan-2022 Page 1 of 3WCTV Digital TeamNoch keine Bewertungen

- Piaget Stages of Cognitive DevelopmentDokument2 SeitenPiaget Stages of Cognitive DevelopmentSeph TorresNoch keine Bewertungen

- 36 Petroland PD Serie DKDokument7 Seiten36 Petroland PD Serie DKBayu RahmansyahNoch keine Bewertungen

- 7B Form GRA Original - Part499 PDFDokument1 Seite7B Form GRA Original - Part499 PDFRicardo SinghNoch keine Bewertungen

- Creative An Inclusive ClassroomDokument3 SeitenCreative An Inclusive Classroommuneeba zafarNoch keine Bewertungen

- November 2013 (v3) QP - Paper 6 CIE Biology IGCSEDokument12 SeitenNovember 2013 (v3) QP - Paper 6 CIE Biology IGCSEAfra AhamedNoch keine Bewertungen

- Reaction Paper On Water PollutionDokument1 SeiteReaction Paper On Water PollutionAztah KivycNoch keine Bewertungen

- "Hiv and Aids Awareness of Junior and Senior High School Students" Part I: Profile of RespondentsDokument1 Seite"Hiv and Aids Awareness of Junior and Senior High School Students" Part I: Profile of RespondentsDahl xxNoch keine Bewertungen

- Time Sheets CraneDokument1 SeiteTime Sheets CraneBillie Davidson100% (1)

- Damasco - Cpi - Activity No. 10Dokument18 SeitenDamasco - Cpi - Activity No. 10LDCU - Damasco, Erge Iris M.Noch keine Bewertungen

- Schools Division of Roxas CityDokument4 SeitenSchools Division of Roxas CityHuge Propalde EstolanoNoch keine Bewertungen

- Hotel ClassificationDokument10 SeitenHotel ClassificationRonelyn Boholst100% (1)

- Texas Steering and Insurance DirectionDokument2 SeitenTexas Steering and Insurance DirectionDonnie WeltyNoch keine Bewertungen

- Ott OTT Ecolog 1000 Water Level LoggerDokument3 SeitenOtt OTT Ecolog 1000 Water Level LoggerNedimZ1Noch keine Bewertungen

- Stress Relieving, Normalising and Annealing: Datasheet For Non-Heat-TreatersDokument2 SeitenStress Relieving, Normalising and Annealing: Datasheet For Non-Heat-TreatersGani PateelNoch keine Bewertungen

- So 2nd Ed Adv Read Extra U4Dokument2 SeitenSo 2nd Ed Adv Read Extra U4hector1817Noch keine Bewertungen

- Osma Osmadrain BG Pim Od107 Feb 2017pdfDokument58 SeitenOsma Osmadrain BG Pim Od107 Feb 2017pdfDeepakkumarNoch keine Bewertungen

- DocumentDokument6 SeitenDocumentGlennford Loreto SuyatNoch keine Bewertungen

- Tropical Fruit CHAPTER-3Dokument32 SeitenTropical Fruit CHAPTER-3Jeylan FekiNoch keine Bewertungen

- Fire BehaviourDokument4 SeitenFire BehaviourFirezky CuNoch keine Bewertungen

- Learnership AgreementDokument10 SeitenLearnership Agreementkarl0% (1)

- Exterior Wall PrimerDokument2 SeitenExterior Wall PrimerAsian PaintsNoch keine Bewertungen

- The Exceeding Sinfulness of Sin - Guy CaskeyDokument402 SeitenThe Exceeding Sinfulness of Sin - Guy Caskeyclaroblanco100% (1)

- Northbrook CollegeDokument10 SeitenNorthbrook CollegeDaniyal AsifNoch keine Bewertungen