Beruflich Dokumente

Kultur Dokumente

What Is Six Sigma

Hochgeladen von

Vishal SharmaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

What Is Six Sigma

Hochgeladen von

Vishal SharmaCopyright:

Verfügbare Formate

Six Sigma?

Silicon Beach Training

Silicon Beach Training 86 Gloucester Road, Brighton, BN1 4AP +44 (0)1273 622272 - info@siliconbeachtraining.co.uk

Follow Silicon Beach Training

What is

What is Six Sigma?

PAGE 1

Contents

What is Six Sigma? Why Six Sigma? The Six Sigma Management System Benefits of Six Sigma DMAIC Model for Process Improvement Define Measure Analyse Improve Control

Six Sigma Belt Levels Six Sigma Black Belt Six Sigma Green Belt Six Sigma Master Black Belt Six Sigma Training Courses Yellow Belt Green Belt Black Belt Master Black Belt

Silicon Beach Training

Silicon Beach Training 86 Gloucester Road, Brighton, BN1 4AP +44 (0)1273 622272 - info@siliconbeachtraining.co.uk

Follow Silicon Beach Training

What is Six Sigma?

PAGE 2

What is Six Sigma?

Six Sigma is a methodology, a statistical analysis tool and a management system designed to streamline business processes by eradicating defects. The implementation of Six Sigma aims to improve and sustain quality, eliminate waste and raise profits. This is achieved by the: Reduction of variations in processes Measuring, analysis, improvement and control of processes Involvement and dedication from the whole organisation including top level

management

Processes are measured and defects recorded; the aim of Six Sigma is to operate processes with less than 3.4 defects per one million opportunities. The implementation of these processes can enable vast savings for the organisation.

Motorola claims that the implementation of Six Sigma has saved the company in excess of 17 billion American dollars.

Silicon Beach Training

Silicon Beach Training 86 Gloucester Road, Brighton, BN1 4AP +44 (0)1273 622272 - info@siliconbeachtraining.co.uk

Follow Silicon Beach Training

What is Six Sigma?

PAGE 3

Originally developed for the manufacturing industry Six Sigma is now applied to the service industry. This means, however that rather than measuring manufacturing processes for defects, organisations need to look to their staff. Streamlining staff performance may cause problems; the human factor needs to be taken into consideration. It may look good on paper to have fewer employees serving more customers, but customer and employee satisfaction may suffer. To improve the Six Sigma system for the service industry, more emphasis is needs to be placed on: Understanding and managing customer needs Adapting business processes to meet those needs Using data analysis to minimise variation in those processes Using the above to quickly improve existing processes using sustainable practices

Why Six Sigma?

Sigma comes from statistics and means the measurement of variance. Mainly Six Sigma is about measuring defects (quality) and production time. There is a statistical scale for measuring this. Six refers to the highest possible score on the scale (0 being the lowest score), this would be a defect score of 0.34% and an on-time score of 99.966% Six Sigma time and quality measurements methodology can be applied to all types of businesses that have customers, including service industries. Six Sigma tools allow companies to assess and measure the quality of their processes and improve delivery to the customer. This can be done incrementally one Sigma level at a time.

Silicon Beach Training

Silicon Beach Training 86 Gloucester Road, Brighton, BN1 4AP +44 (0)1273 622272 - info@siliconbeachtraining.co.uk

Follow Silicon Beach Training

What is Six Sigma?

PAGE 4

The Six Sigma Management System

From experience, large companies such as Motorola have found that the use of metrics (statistics) alone is not enough to sustain improvements over time.

In order to achieve sustainable results the methodology must be linked to the overall company strategy.

This is why it is necessary to implement Six Sigma from the top-down. Those companies making the biggest savings have implemented Six Sigma practices throughout their organisation and fundamentally changed their management approach. These businesses train lots of people and make continuous improvement a way of life. Companies that have not applied Six Sigma throughout the organisation have not achieved the same level of results. In order for Six Sigma to produce maximum benefit: The overall business strategy must be aligned to the implementation of continuous improvement of processes Management teams must be created to govern key projects You must drive the implementation of improvements to achieve the quickest possible results You must monitor continued effort to sustain improvements

Silicon Beach Training

Silicon Beach Training 86 Gloucester Road, Brighton, BN1 4AP +44 (0)1273 622272 - info@siliconbeachtraining.co.uk

Follow Silicon Beach Training

What is Six Sigma?

PAGE 5

Benets of Six Sigma

The key benefits of the Six Sigma Management system are: Process flows are improved Defects are reduced Communication is improved as the whole company works towards the same goals Cycle times are reduced Customer satisfaction improved Staff satisfaction improved Productivity is increased Capacity and output are improved Quality is improved Reliability of products and processes are improved Unit costs decreased Designs improvedTime to market is quicker Better delivery time

Six Sigma enables organisations to become more effective and efcient.

Organisations using the Six Sigma Management System improve their processes, efficiency, products, services and customer experience.

Silicon Beach Training

Silicon Beach Training 86 Gloucester Road, Brighton, BN1 4AP +44 (0)1273 622272 - info@siliconbeachtraining.co.uk

Follow Silicon Beach Training

What is Six Sigma?

PAGE 6

DMAIC Model for Process Improvement

The DMAIC model is the foundation of all Six Sigma projects. DMAIC is an acronym for: Define opportunity Measure performance Analyse opportunity Improve performance Control performance

Define In order to implement the Six Sigma Methodology and Management System it is crucial to define: The Customer who is the customer, what do they want and what are their expectations? This will involve looking at quality control issues and core business processes The project boundaries Where does the process begin and end? The process to be improved Measure In order to apply the Six Sigma Methodology and Management System it is essential that you measure the performance of Core Business Processes. You will need to Develop a plan for the collection of data for the process Gather data to identify types of defects and metrics Compare evidence to customer survey results

Silicon Beach Training

Silicon Beach Training 86 Gloucester Road, Brighton, BN1 4AP +44 (0)1273 622272 - info@siliconbeachtraining.co.uk

Follow Silicon Beach Training

What is Six Sigma?

PAGE 7

Analyse The next step in the DMAIC model is to analyse the data and process map to establish causes of defects and where you can improve: Current performance and goal performance are compared to identify gaps Opportunities for improvements are prioritised Sources of variation are identified Improve Using the data from the implementation of the above it is now possible to improve the process by designing creative solutions to fix and prevent problems. This is achieved by: Using discipline and technology to develop innovative solutions Develop and implement a plan Control Control and sustain improvements over time by: Preventing the instinct to return to the old ways of doing things Developing, documenting and implementing an on-going monitoring plan Integrating the improvements throughout the company through the use of training, staffing and incentives

Silicon Beach Training

Silicon Beach Training 86 Gloucester Road, Brighton, BN1 4AP +44 (0)1273 622272 - info@siliconbeachtraining.co.uk

Follow Silicon Beach Training

What is Six Sigma?

PAGE 8

Six Sigma Belt Levels

The success of the Six Sigma management process is dependent on senior executives, master black belts, black belts, and Six Sigma green belts working together, towards the same aims and understanding and implementing the process throughout the organisation. A senior executive should bring the whole company into alignment and instigate changes necessary for Six Sigmas ultimate success. The most successful Six Sigma projects all share in common clear and committed leadership from top management.

Six Sigma processes initiated at lower levels may show benets but not dramatic and sustainable changes.

Managers who have been trained as Six Sigma Champions have a vital role to play in conducting and implementing Six Sigma projects. Champions will work closely with the executive committee including the assigned Six Sigma black belt and the master black belt.

Six Sigma Black Belt

Six Sigma Black Belts are typically full-time change agents and lead by making improvements to processes across multiple Six Sigma projects. He or she will be in charge of a team of Green Belts and will be mentored by a Master Black Belt.

Silicon Beach Training

Silicon Beach Training 86 Gloucester Road, Brighton, BN1 4AP +44 (0)1273 622272 - info@siliconbeachtraining.co.uk

Follow Silicon Beach Training

What is Six Sigma?

PAGE 9

Six Sigma Green Belt

Six Sigma Green Belts usually work on large projects part-time. In many successful Six Sigma Organisations most of their managers have been trained to Six Sigma Green Belt level. In complicated Six Sigma projects, Green Belts work closely with the project Six Sigma Black Belt to keep the team functioning together and monitor progression through the Six Sigma project. Simpler projects may be led by Six Sigma Green Belts and it is their responsibility to: Create or refine a project charter Discuss the project charter with the project champion Select team members for the project Liaise with the champion, master black belt, black belt, and process Facilitate the team through all phases of the project Schedule meetings Coordinate logistics Analyse data Train team members

Six Sigma Master Black Belt

A Six Sigma Master Black Belt takes a leadership role in the Six Sigma process. They will advise Senior Executives as well as oversee and offer direction for projects led by Six Sigma Black Belts vand Green Belts. A Six Sigma Master Black Belt will have proven success leading Six Sigma projects. It is preferable, although not always possible, for organisations to develop their own Master Black Belts. Learn more about Six Sigma belt levels in this video

Silicon Beach Training

Silicon Beach Training 86 Gloucester Road, Brighton, BN1 4AP +44 (0)1273 622272 - info@siliconbeachtraining.co.uk

Follow Silicon Beach Training

What is Six Sigma?

PAGE 10

Six Sigma Training Courses

One of Six Sigmas strengths is the structure of belts to show level of achievement and capability. In all cases the training should be backed up by real experience on projects and at Six Sigma Black Belt level this is mandatory.

Six Sigma Yellow Belt Training

Six Sigma Yellow Belt Training is for current or future Team Members so they need to understand the key processes and some of the basic tools.

No prerequisites.

Six Sigma Green Belt Training

Six Sigma Green Belt Training is for prospective Team Leaders.

A good understanding of the processes and many of the tools is key. They will understand a number of key statistical techniques but not be an expert in their application. Very intensive 5-day course.

Silicon Beach Training

Silicon Beach Training 86 Gloucester Road, Brighton, BN1 4AP +44 (0)1273 622272 - info@siliconbeachtraining.co.uk

Follow Silicon Beach Training

What is Six Sigma?

PAGE 11

Six Sigma Black Belt Training

Six Sigma Black Belt Training is for those who are leading or supporting Six Sigma projects on a continuous basis.

May provide internal training for Green Belts. A thorough understanding of Six Sigma processes and a wide range of statistical and process improvement tools is needed.

Six Sigma Master Black Belt Training

This is an executive level position that is advising the board on the development and implementation of Six Sigma across the organisation.

Master Black Belts will also be managing the Black Belts, in some cases they will also train the Black Belts, they will have a lot of management expertise in addition to their expertise in all aspects of Lean Six Sigma.

Silicon Beach Training

Silicon Beach Training 86 Gloucester Road, Brighton, BN1 4AP +44 (0)1273 622272 - info@siliconbeachtraining.co.uk

Follow Silicon Beach Training

What is Six Sigma?

PAGE 12

Thanks for reading.

If youd like to book Six Sigma Training here at Silicon Beach, contact us on 01273 622272 Dont forget to share this eBook with anybody you think would be interested.

Please get in touch with any additional comments or to discuss your training requirements. Web: www.siliconbeachtraining.co.uk Phone: 01273 622272 Facebook: facebook.com/siliconbeach Twitter: @sbttraining

Silicon Beach Training

Silicon Beach Training 86 Gloucester Road, Brighton, BN1 4AP +44 (0)1273 622272 - info@siliconbeachtraining.co.uk

Follow Silicon Beach Training

Das könnte Ihnen auch gefallen

- Sample: TÜV SÜD Certified Lean Six Sigma Black Belt CertificationDokument14 SeitenSample: TÜV SÜD Certified Lean Six Sigma Black Belt CertificationAlpha Excellence consultingNoch keine Bewertungen

- The Six Sigma Way Team Fieldbook: An Implementation Guide for Process Improvement TeamsVon EverandThe Six Sigma Way Team Fieldbook: An Implementation Guide for Process Improvement TeamsBewertung: 3.5 von 5 Sternen3.5/5 (5)

- Problem 1 (15 Marks) Select Only ONE of The Answers. Each Correct Answer Has 1 Mark. Write Your Answer On The Exam BookletDokument7 SeitenProblem 1 (15 Marks) Select Only ONE of The Answers. Each Correct Answer Has 1 Mark. Write Your Answer On The Exam BookletKeyvan HajjarizadehNoch keine Bewertungen

- IASSC LeanSixSigma BoK GreenBeltDokument8 SeitenIASSC LeanSixSigma BoK GreenBeltBilal Salameh100% (1)

- Six Sigma BB Sample Questions PDFDokument2 SeitenSix Sigma BB Sample Questions PDFnaacha457Noch keine Bewertungen

- Six Sigma Black Belt Exam ReviewDokument1 SeiteSix Sigma Black Belt Exam Reviewhans_106Noch keine Bewertungen

- LSSA Green Belt ISQI Sample Paper Question Booklet v1.1Dokument30 SeitenLSSA Green Belt ISQI Sample Paper Question Booklet v1.1Khatija KamNoch keine Bewertungen

- Integrated Management Systems: QMS, EMS, OHSMS, FSMS including Aerospace, Service, Semiconductor/Electronics, Automotive, and FoodVon EverandIntegrated Management Systems: QMS, EMS, OHSMS, FSMS including Aerospace, Service, Semiconductor/Electronics, Automotive, and FoodNoch keine Bewertungen

- Business Process Reengineering Using Six Sigma: Abella, Vanessa Balanag, Julie Anne Mojal-Amarillo, Mary Leonite MGT 201Dokument79 SeitenBusiness Process Reengineering Using Six Sigma: Abella, Vanessa Balanag, Julie Anne Mojal-Amarillo, Mary Leonite MGT 201Weng Torres AllonNoch keine Bewertungen

- Sex SigmaDokument6 SeitenSex SigmabinjibrilNoch keine Bewertungen

- The Asq Certified Six Sigma Black BeltDokument16 SeitenThe Asq Certified Six Sigma Black BeltJohn Jerome ThompsonNoch keine Bewertungen

- Book For CSSBBDokument1 SeiteBook For CSSBBJahidul IslamNoch keine Bewertungen

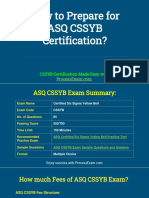

- How To Prepare For Asq Cssyb Certification?Dokument14 SeitenHow To Prepare For Asq Cssyb Certification?mastere ticNoch keine Bewertungen

- A Sample Filled in CSSBB Affidavit: Page 1 of 1Dokument1 SeiteA Sample Filled in CSSBB Affidavit: Page 1 of 1Sourodweep MittraNoch keine Bewertungen

- Exam Questions CSSBB: Certified Six Sigma Black BeltDokument22 SeitenExam Questions CSSBB: Certified Six Sigma Black BeltBassem BouzraraNoch keine Bewertungen

- Asq Black BookDokument15 SeitenAsq Black Bookafreen timberwallaNoch keine Bewertungen

- American Society For Quality Answers Questions PDFDokument4 SeitenAmerican Society For Quality Answers Questions PDFbmn_testNoch keine Bewertungen

- CSSYBDokument8 SeitenCSSYBdarwin_huaNoch keine Bewertungen

- Referance SSGBDokument3 SeitenReferance SSGBJahidul IslamNoch keine Bewertungen

- Lesson - 6.5 - Course End - Exam TipsDokument6 SeitenLesson - 6.5 - Course End - Exam TipsMichele BolettieriNoch keine Bewertungen

- FEIGENBAUM + Ishikawa + TaguchiDokument7 SeitenFEIGENBAUM + Ishikawa + Taguchiaulia rakhmawatiNoch keine Bewertungen

- 6 SigmaDokument5 Seiten6 SigmajaisonguruNoch keine Bewertungen

- IASSC Lean Six Sigma Black Belt Study GuideDokument9 SeitenIASSC Lean Six Sigma Black Belt Study GuideAli AteeqNoch keine Bewertungen

- Process Improvement Simplified: A How-to-Book for Success in any OrganizationVon EverandProcess Improvement Simplified: A How-to-Book for Success in any OrganizationNoch keine Bewertungen

- School of Mechanical and Materials Engineering: Assignment-1Dokument5 SeitenSchool of Mechanical and Materials Engineering: Assignment-1Ismail HussainNoch keine Bewertungen

- ASQ PracticeTest CSSGB v2021-06-02 by Lyanna 86qDokument34 SeitenASQ PracticeTest CSSGB v2021-06-02 by Lyanna 86qSyed Danish AlamNoch keine Bewertungen

- Six SigmaDokument13 SeitenSix Sigmashafvan_786Noch keine Bewertungen

- Lean BOKDokument6 SeitenLean BOKumeshjmangroliyaNoch keine Bewertungen

- CSSBB Certification Guide and How To Cra PDFDokument23 SeitenCSSBB Certification Guide and How To Cra PDFAnonymous kIrNuhNoch keine Bewertungen

- Six Sigma Proposal (1.1)Dokument40 SeitenSix Sigma Proposal (1.1)Joni Pablo100% (1)

- Kim H. Pries-Six Sigma For The New Millennium - A CSSBB Guidebook, Second Edition-ASQ Quality Press (2009)Dokument456 SeitenKim H. Pries-Six Sigma For The New Millennium - A CSSBB Guidebook, Second Edition-ASQ Quality Press (2009)Elvis Sikora100% (1)

- Looking For Real Exam Questions For IT Certification Exams!Dokument11 SeitenLooking For Real Exam Questions For IT Certification Exams!Kabala UsmanNoch keine Bewertungen

- Six Sigma: Advanced Tools for Black Belts and Master Black BeltsVon EverandSix Sigma: Advanced Tools for Black Belts and Master Black BeltsNoch keine Bewertungen

- DMAIC Six Sigma Guide 3MDokument162 SeitenDMAIC Six Sigma Guide 3MArturo Naranjo Naranjo100% (1)

- Lean Six Sigma - Black BeltDokument7 SeitenLean Six Sigma - Black BeltCarlos Delgado NietoNoch keine Bewertungen

- Lean Six Sigma PreparationDokument12 SeitenLean Six Sigma Preparationlipsy25Noch keine Bewertungen

- Six SigmaDokument18 SeitenSix SigmarajeeevaNoch keine Bewertungen

- Fish Bone Diagram: Yellow Belt RefresherDokument33 SeitenFish Bone Diagram: Yellow Belt RefresherSnehasish PadhyNoch keine Bewertungen

- Lean Six Sigma Green BeltDokument5 SeitenLean Six Sigma Green BeltMadhavaKrishna0% (1)

- Improving Bank Call Centre Operations Using Six Sigma: Rahul GautamDokument8 SeitenImproving Bank Call Centre Operations Using Six Sigma: Rahul Gautamsajeeby100% (1)

- Evaluation of Field DataDokument84 SeitenEvaluation of Field DatajcesarcerriNoch keine Bewertungen

- IASSC Green Belt Body of KnowledgeDokument5 SeitenIASSC Green Belt Body of KnowledgeBilal Salameh50% (2)

- A Fictitious Six Sigma Green Belt Part IDokument19 SeitenA Fictitious Six Sigma Green Belt Part IhalilpashaNoch keine Bewertungen

- Quality 4.0Dokument14 SeitenQuality 4.0kishore100% (2)

- 2006-09 Tutorial ASQ BoKDokument45 Seiten2006-09 Tutorial ASQ BoKRaghavendra NarayanaswamyNoch keine Bewertungen

- How To Prepare For ASQ CSSBB Certified S PDFDokument5 SeitenHow To Prepare For ASQ CSSBB Certified S PDFsunilkhairnar38Noch keine Bewertungen

- Lean Six Sigma 1616096074Dokument100 SeitenLean Six Sigma 1616096074Hany Rashad DawoodNoch keine Bewertungen

- GE Six SigmaDokument6 SeitenGE Six Sigmaimran27pk100% (2)

- Lean Six SigmaDokument24 SeitenLean Six SigmaArvind Jha100% (1)

- Referance SSBBDokument4 SeitenReferance SSBBJahidul IslamNoch keine Bewertungen

- Introduction To Six Sigma - EnglishDokument18 SeitenIntroduction To Six Sigma - Englishnitin98325100% (3)

- Six Sigma Quality Improvement at BD CompanyDokument10 SeitenSix Sigma Quality Improvement at BD CompanyJLuisCarterNoch keine Bewertungen

- Six Sigma Quality Engineering: Week 2 Introduction To Six Sigma Macro Model of Six Sigma ManagementDokument29 SeitenSix Sigma Quality Engineering: Week 2 Introduction To Six Sigma Macro Model of Six Sigma Managementkr_padmavathiNoch keine Bewertungen

- Six Sigma Training MaterialDokument88 SeitenSix Sigma Training MaterialManoj ToppoNoch keine Bewertungen

- Six Sigma - Lean Manufacturing and Six Sigma Definitions PDFDokument3 SeitenSix Sigma - Lean Manufacturing and Six Sigma Definitions PDFsanjaigNoch keine Bewertungen

- Is It Right For You? Six Sigma Black Belt Certification - CSSBBDokument4 SeitenIs It Right For You? Six Sigma Black Belt Certification - CSSBBJahidul IslamNoch keine Bewertungen

- SIX SIGMA Black Belt ProjectDokument44 SeitenSIX SIGMA Black Belt ProjectMark AinsworthNoch keine Bewertungen

- ASQ Certkey CSSBB v2019!02!24 by Charlotte 125qDokument63 SeitenASQ Certkey CSSBB v2019!02!24 by Charlotte 125qSyed Danish AlamNoch keine Bewertungen

- DBOutput ORISERDokument51 SeitenDBOutput ORISERVishal SharmaNoch keine Bewertungen

- DBOutput RISERDokument51 SeitenDBOutput RISERVishal SharmaNoch keine Bewertungen

- Dboutput CrossDokument17 SeitenDboutput CrossVishal SharmaNoch keine Bewertungen

- Astm A 714 (1999) PDFDokument8 SeitenAstm A 714 (1999) PDFnisha_khanNoch keine Bewertungen

- Is 1239 Part 1-2004 Mild Steel Tubes, Tubulars and Other Wrought Steel Fittings - SpecificationDokument12 SeitenIs 1239 Part 1-2004 Mild Steel Tubes, Tubulars and Other Wrought Steel Fittings - SpecificationSaravanan KcNoch keine Bewertungen

- SAM Project Description PDFDokument2 SeitenSAM Project Description PDFVishal SharmaNoch keine Bewertungen

- Product Release Latest Update: Aveva Pdms 12.1.Sp4 Full Release 52150Dokument2 SeitenProduct Release Latest Update: Aveva Pdms 12.1.Sp4 Full Release 52150Alan LeonNoch keine Bewertungen

- DBOutputDokument109 SeitenDBOutputVishal SharmaNoch keine Bewertungen

- ch09Dokument14 Seitench09CallGRNoch keine Bewertungen

- Install PDMS1214 2. Install Plant12.1.SP4.14 3. Copy 4 Patches in Install Folder and Run 4. Enjoy WWW - Downloadly.irDokument1 SeiteInstall PDMS1214 2. Install Plant12.1.SP4.14 3. Copy 4 Patches in Install Folder and Run 4. Enjoy WWW - Downloadly.irVishal SharmaNoch keine Bewertungen

- DBOutputDokument109 SeitenDBOutputVishal SharmaNoch keine Bewertungen

- Annexure DDokument1 SeiteAnnexure DVishal SharmaNoch keine Bewertungen

- TiresDokument3 SeitenTiresVishal SharmaNoch keine Bewertungen

- Rulebook BAJA SAE INDIA 2013 Rev 0Dokument46 SeitenRulebook BAJA SAE INDIA 2013 Rev 0Arnab Animesh DasNoch keine Bewertungen

- IB Econ IA GuidanceDokument11 SeitenIB Econ IA GuidanceKavin RukNoch keine Bewertungen

- Etech11 - 12 - Q1mod2 - Online Safety - Eljim - Ramos - Bgo - v1Dokument26 SeitenEtech11 - 12 - Q1mod2 - Online Safety - Eljim - Ramos - Bgo - v1Grace ManuelNoch keine Bewertungen

- Children's Day 2021 ProgrammeDokument6 SeitenChildren's Day 2021 ProgrammeHimani KaushikNoch keine Bewertungen

- RSO UpdatesDokument17 SeitenRSO UpdatesKenny AbellanosaNoch keine Bewertungen

- Science Week 678Dokument2 SeitenScience Week 678Creative ImpressionsNoch keine Bewertungen

- How Are You Judged in Cyberspace?: Task #5 Quiz On Analyzing StatementsDokument1 SeiteHow Are You Judged in Cyberspace?: Task #5 Quiz On Analyzing StatementsopawbunaNoch keine Bewertungen

- Sankalp SPL Practice Test Result For Batch Sankalp820lotheld On 07 June 2019 PDFDokument7 SeitenSankalp SPL Practice Test Result For Batch Sankalp820lotheld On 07 June 2019 PDFLakshay GuptaNoch keine Bewertungen

- Developing The WHO Disability Assessment Schedule 2.0 PDFDokument9 SeitenDeveloping The WHO Disability Assessment Schedule 2.0 PDFcora4eva5699Noch keine Bewertungen

- Practical Research 11 TQDokument6 SeitenPractical Research 11 TQsandungankevenNoch keine Bewertungen

- To Be or Not To BeDokument10 SeitenTo Be or Not To BeJethro EncarnadoNoch keine Bewertungen

- Episode-4 Management of The Learning EnvironmentDokument4 SeitenEpisode-4 Management of The Learning EnvironmentJohn FordNoch keine Bewertungen

- PDFDokument1.952 SeitenPDFSaszet RékaNoch keine Bewertungen

- Icke - Frank Ankersmit's Narrative Substance A Legacy To Historians (Rethinking History)Dokument19 SeitenIcke - Frank Ankersmit's Narrative Substance A Legacy To Historians (Rethinking History)Alfonso_RoqueNoch keine Bewertungen

- Hairdressing and Beauty Therapy - Course ProspectusDokument24 SeitenHairdressing and Beauty Therapy - Course ProspectusNHCollege0% (1)

- Global History of Child EduDokument92 SeitenGlobal History of Child EduNashwaNoch keine Bewertungen

- DiassDokument33 SeitenDiassOlive AsuncionNoch keine Bewertungen

- Mailman PetitionDokument9 SeitenMailman PetitionColumbia Daily SpectatorNoch keine Bewertungen

- Certificate Course On CSR: Reliance Industries LimitedDokument3 SeitenCertificate Course On CSR: Reliance Industries LimitedHaritha K. PrahladNoch keine Bewertungen

- English 31Dokument5 SeitenEnglish 31Sybil ZiaNoch keine Bewertungen

- Film Review RubricDokument2 SeitenFilm Review RubricTorres Ken Robin Delda100% (1)

- Subodh Public School: Learners 4Dokument9 SeitenSubodh Public School: Learners 4Shresth GourNoch keine Bewertungen

- BUILDING A NEW ORDER - George S. CountsDokument26 SeitenBUILDING A NEW ORDER - George S. CountsMarie-Catherine P. DelopereNoch keine Bewertungen

- Business English Practice PDFDokument3 SeitenBusiness English Practice PDFMutiara FaradinaNoch keine Bewertungen

- HRM in Knowledge EconomyDokument13 SeitenHRM in Knowledge EconomyTayyab Ahmed Chughtai100% (1)

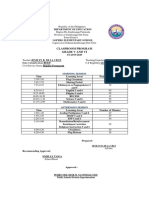

- Classroom Program JenDokument1 SeiteClassroom Program JenjenilynNoch keine Bewertungen

- Daily Lesson Log APPLIED SUBJECT - GAS - Philippine Politics & GovernanceDokument5 SeitenDaily Lesson Log APPLIED SUBJECT - GAS - Philippine Politics & GovernanceHannae pascuaNoch keine Bewertungen

- Portfolio Ready Acpa NaspaDokument10 SeitenPortfolio Ready Acpa Naspaapi-448323503Noch keine Bewertungen

- UT Dallas Syllabus For Socs3405.502.10f Taught by Heja Kim (Heja)Dokument4 SeitenUT Dallas Syllabus For Socs3405.502.10f Taught by Heja Kim (Heja)UT Dallas Provost's Technology GroupNoch keine Bewertungen

- Customer Service Manager ResumeDokument2 SeitenCustomer Service Manager ResumerkriyasNoch keine Bewertungen

- School ViolenceDokument10 SeitenSchool ViolenceCường Nguyễn QuốcNoch keine Bewertungen