Beruflich Dokumente

Kultur Dokumente

Report9 24

Hochgeladen von

Alejandra Ale AleOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Report9 24

Hochgeladen von

Alejandra Ale AleCopyright:

Verfügbare Formate

Date: 9/24/2013 Arango

Report #: 4 Prepared By: Alejandra

Project Title: Highway Energy Harnessing System Energy harnessing system to integrate into the highway system and capture thermal energy. Team Members: Andrew Lyon, Zack Hixon, Torus Washington, Alejandra Arango 1. Major activities for this week were mainly look at the needs that we have already discussed and classify them into super groups according to similarities. 2. The main problem was determining if a need could belong to two super groups but we were able to overcome this problem by going through the slides. 3. We planned to go over the metrics and do some research on it. 4. Team dynamics are going well, we all always come to agreements, We always work together to put all our different ideas and make it a good strong one that will make our project successful.

User Needs Alejandra Arango, Zack Hixon, Torus Washington, Andrew Lyon Repairs are easy to access (Functionality) (Hygiene) Negligible additional road construction time (Compatibility) (Affordability)

Energy return is substantial (Affordability) (Functionality) Investment cost is reasonable (Affordability) Lifespan is comparable to current infrastructure (Durability) System is in modules (segmented) (Compatibility) (Usability) Easily retrofitted for future improvements (Compatibility) (Hygiene) Safe Conditions Driver Safety Installation Safety Easily converted for residential usage (Compatibility) (Novelty) Installation supplies are easily transported (Compatibility) (Affordability) Cost effective (Affordability) Green (good for environment, low ecological impact) (Functionality) (Safety) Safety (Safety) Appearance (Aesthetics) Climate resistance (Durability) Interchangeable components (Hygiene) (Compatibility)

Compatible with government transportation standards (Compatibility) (Usability) Safe structure configuration (avoid collisions/accidents) (Safety) Durability Preliminary Metrics

Climate resistance If the internal temperature exceeds 70C (158F), the long term durability of some concretes can be affected by delayed ettringite formation (DEF). DEF is rare and only certain concretes can be affected. When DEF occurs, the concrete paste expands and cracks the concrete with detrimental results, which may not be evident for many years. Additionally, while the interior can be quite hot, the surface can be relatively cool. The resulting large temperature difference results in large thermal stresses which can cause cracking of the surface. Historically, limiting the temperature difference between the interior and surface so that it is less than 20C (35F) has been found to prevent or minimize thermal cracking. Certain concretes are more tolerant of thermal cracking than others, and these concretes can withstand a higher temperature difference without thermally cracking. You must ensure that the maximum temperature in the concrete will not exceed 70C (158F). In placements over about 1.80 m (6 ft) thick, the maximum temperature is the sum of the installed concrete temperature plus the temperature rise of the concrete. The temperature rise can be measured or estimated. If the maximum temperature of the concrete is predicted to exceed 70C (158F), the concrete can be precooled by using chilled batch water, substituting ice for a portion of the batch water, or by liquid nitrogen injection into the fresh concrete. If significant precooling is required, internal cooling pipes can be used to reduce the amount of precooling.

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Frank - Emilys ScarsDokument13 SeitenFrank - Emilys ScarsAlejandra Ale AleNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- SynthesisDokument5 SeitenSynthesisAlejandra Ale AleNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Polypropylene TGA 4022 Lab 06sep13 Group 1Dokument1 SeitePolypropylene TGA 4022 Lab 06sep13 Group 1Alejandra Ale AleNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Polypropylene DSC 4022 Lab 06sep13 Group 1Dokument1 SeitePolypropylene DSC 4022 Lab 06sep13 Group 1Alejandra Ale AleNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Arh 2002 PaperDokument3 SeitenArh 2002 PaperAlejandra Ale AleNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Frank - Emilys ScarsDokument13 SeitenFrank - Emilys ScarsAlejandra Ale AleNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Possible Points Points Earned: MSE 3002 Previous ExamDokument4 SeitenPossible Points Points Earned: MSE 3002 Previous ExamAlejandra Ale AleNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- GaddafiDokument5 SeitenGaddafiAlejandra Ale AleNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Intralox in Catalog PDFDokument346 SeitenIntralox in Catalog PDFMohammad Bataineh67% (3)

- Lec. 13. Shell & Tube HX-Designing-FA21Dokument18 SeitenLec. 13. Shell & Tube HX-Designing-FA21HAMMAD ALINoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Rolling (Bulk Deformation Process)Dokument27 SeitenRolling (Bulk Deformation Process)Kazal ArefinNoch keine Bewertungen

- 2 - Compressibility of SoilsDokument34 Seiten2 - Compressibility of SoilsKatherine Shayne YeeNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Build Up RateDokument4 SeitenBuild Up RateLai Chungyi100% (2)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Why Are Risers Not As Useful in Die Casting As They Are in Sand Casting?Dokument3 SeitenWhy Are Risers Not As Useful in Die Casting As They Are in Sand Casting?Sq GohNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Comparison of Different Cooling Tower by TechnologyDokument1 SeiteComparison of Different Cooling Tower by TechnologyANIMESH JAINNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Planning Revised TirurDokument8 SeitenPlanning Revised TirurBHAVANA SURESHNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

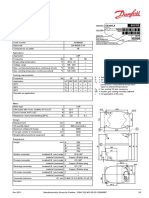

- Gs26Clx LBP Compressor R404A/R507 220-240V 50Hz: GeneralDokument2 SeitenGs26Clx LBP Compressor R404A/R507 220-240V 50Hz: GeneralmustafaNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Use of Paraloid B72 As An AdhesiveDokument9 SeitenThe Use of Paraloid B72 As An AdhesivetindaljuNoch keine Bewertungen

- BDK ValveDokument12 SeitenBDK ValvevinaypNoch keine Bewertungen

- How Plants Reduce Noise Levels Indoors - AmbiusDokument4 SeitenHow Plants Reduce Noise Levels Indoors - AmbiusSakshi SahuNoch keine Bewertungen

- Heat Transfer Chapter 1 ProblemsDokument8 SeitenHeat Transfer Chapter 1 ProblemsVon A. Damirez0% (1)

- FS 2004 A - Rev-7Dokument78 SeitenFS 2004 A - Rev-7Maffone NumerounoNoch keine Bewertungen

- FormingPotential EN PDFDokument28 SeitenFormingPotential EN PDFNhan LeNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Advantages and Disadvantages Each MaterialDokument25 SeitenAdvantages and Disadvantages Each MaterialPewe WulandariNoch keine Bewertungen

- Basalt Fiber PDFDokument2 SeitenBasalt Fiber PDFsalvepramod99Noch keine Bewertungen

- Mill Test Certificate: Run Date 12/07/2018 OR0019M - JAZ User ID E1037Dokument1 SeiteMill Test Certificate: Run Date 12/07/2018 OR0019M - JAZ User ID E1037yugandhar100% (2)

- DBR PDFDokument7 SeitenDBR PDFrajeev shahNoch keine Bewertungen

- IPS Pipe Data Chart for Iron Pipe Size DimensionsDokument2 SeitenIPS Pipe Data Chart for Iron Pipe Size DimensionsJoãoNoch keine Bewertungen

- Improving Bearing Capacity of SoilDokument3 SeitenImproving Bearing Capacity of SoilJustin MusopoleNoch keine Bewertungen

- Fatigue Crack Growth Behavior of 4340 Steels: P. K. Liaw and T. R. LeaxDokument18 SeitenFatigue Crack Growth Behavior of 4340 Steels: P. K. Liaw and T. R. LeaxSWAPNIL PATILNoch keine Bewertungen

- Castrol BulletinDokument1 SeiteCastrol BulletinHarrier ESNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Highway Materials & Mix Design Ppt. MMHDokument35 SeitenHighway Materials & Mix Design Ppt. MMHMd Mehedi HasnatNoch keine Bewertungen

- Aisi 200 SeriesDokument19 SeitenAisi 200 Seriessgupta_192494Noch keine Bewertungen

- Sequential Load Analysis For Tall BuildingsDokument10 SeitenSequential Load Analysis For Tall BuildingsharisleeNoch keine Bewertungen

- Wall Mounted PDFDokument5 SeitenWall Mounted PDFAhmed AzadNoch keine Bewertungen

- Snap-Action Microswitches - Standard Metal M9/C9: CharacteristicsDokument3 SeitenSnap-Action Microswitches - Standard Metal M9/C9: CharacteristicsAlexanderNoch keine Bewertungen

- Tunnel KilnDokument4 SeitenTunnel KilnSatria PurwantoNoch keine Bewertungen

- Doha Clinic-Revised (7 Months)Dokument4 SeitenDoha Clinic-Revised (7 Months)DU A NENoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)