Beruflich Dokumente

Kultur Dokumente

Air Quality

Hochgeladen von

Richard MarbunOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Air Quality

Hochgeladen von

Richard MarbunCopyright:

Verfügbare Formate

Air Quality Guide

The Importance of Air Quality

Air Quality

Atmospheric

Compressed to 7 bar(g)

The act of compressing atmospheric air to 7 bar(g) creates an 800% increase in the concentration of contaminants.

What Influences Your Compressed Air Quality? Dirt, moisture and oil are everywhere. But they shouldnt be in your compressed air supply. Dust, dirt, pollen, microorganisms, smoke, exhaust emissions and other particulates Moisture in the form of water vapor Oil, unburned hydrocarbons from the ambient air and compressor coolant carryover Caustic gases such as sulfur oxides, nitrogen oxides and chlorine compounds

2 Air Quality

General Manufacturing Assembly Conveying Air Tool Use

Advanced Pneumatics Instrument Quality Food Grade

The Results of Contaminated Compressed Air The problems created by contaminated compressed air in your system can range from annoyance to wreaking havoc on your equipment and your end products. Premature wearing and scoring of surfaces Rust and corrosion in tools, piping and equipment Damaged instruments Spoiled paint surfaces Increased scrap rate Unsafe or unpleasant work environment

ISO 8573.1 Air Quality Classes Maintaining air quality is so important that the International Standards Organization (ISO) developed six compressed air quality classes, as defined by ISO 8573.1. To determine which industry classification you require, ask yourself these simple questions: Does compressed air quality affect my production process and the quality of my end products?

Air Quality 3

Will poor compressed air quality decrease my productivity, cost savings and product quality standards? What internal and external ambient conditions affect the quality of my compressed air produced by my system?

Removing Particulate Contamination

Air Quality

For sensitive or critical applications, more than one set of filters may be required at the point-of-use.

Always precede fine filters with a coarser grade.

The first filter removes larger particulates.

The second filter removes smaller particulates.

Contaminants Can Destroy a Compressed Air System Think of it as a mini dust storm at 125 psig. The particulates scattered almost invisibly throughout the ambient air become a concentrated force for damage and destruction of your air-operated tools, equipment and instruments. Systems are damaged and products are spoiled.

4 Air Quality

Scoring and uneven wear patterns ruin tools and instruments. Volatile, hazardous compounds are produced. Production shuts down; productivity and quality suffer.

General Manufacturing Assembly Conveying Air Tool Use

Advanced Pneumatics Instrument Quality Food Grade

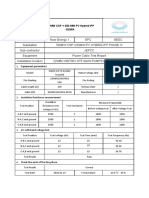

Compressed Air Quality ISO 8573.1 Class SOLID PARTICLES

(Maximum number of particles per m3) 0.1-0.5 micron 0.5-1.0 micron 1.0-5.0 micron

Water

Pressure Dewpoint (F)

Oil

Solids & Vapor (mg/m3)

1 2 3 4 5 6

100 100,000

1 1,000 10,000

0 10 500 1,000 20,000

-94.0 -40.0 -4.0 37.4 44.6 50.0

.01 0.1 1.0 5.0

Dual Filters Eliminate Dirt and Problems Eliminating the sandblast effect of particulates in your compressed air stream gets rid of: Premature wear Scored surfaces Clogged orifices Ruined finishes and instruments

Air Quality 5

Removing Moisture

Air Quality

Relative Humidity (%) vs. Ambient Air Temperature (F)

100 90

ISO Class 6 PDP (50.0F) ISO Class 5 PDP (44.6F) ISO Class 4 PDP (37.4F)

RELATIVE HUMIDITY (%)

80 70 60 50 40 30 20 10 0 50 60 70 77F 80 90

100

110

120

AMBIENT AIR TEMPERATURE (F)

Why Is Relative Humidity Important? ISO classifies a constant pressure dewpoint (PDP) at a specific ambient air temperature (77F). As illustrated in the graph, when PDP is held constant (represented by the color curves) and ambient air temperature changes, the relative humidity (Rh) will increase or decrease.

6 Air Quality

When a constant Rh is maintained, your air systems performance will be consistent and reliable.

General Manufacturing Assembly Conveying Air Tool Use

Advanced Pneumatics Instrument Quality Food Grade

ISO 8573.1 Air Quality Classes

Class

Solid Particle

(Maximum number of particles per m3) 0.1-0.5 micron 0.5-1.0 micron 1.0-5.0 micron

WATER

Pressure Dewpoint (F)

Oil

Solids & Vapor (mg/m3)

1 2 3 4 5 6

100 100,000

1 1,000 10,000

0 10 500 1,000 20,000

-94.0 -40.0 -4.0 37.4 44.6 50.0

.01 0.1 1.0 5.0

The Effects of Moisture Contamination Rust and corrosion in the air system piping Inadequate air tool lubrication Damage to labeling, packaging and the finished goods Productivity losses throughout your operation Refrigerated air dryers are capable of maintaining less than 50% Rh in most industrial plant ambient environments. Processes that require ultra-dry air (ISO Class 1, 2 or 3) will need an advanced solution using nonrefrigerated dryer technology.

Air Quality 7

Removing Oil

Air Quality

For sensitive or critical applications, more than one set of filters may be required at the point-of-use.

Always precede fine filters with a coarser grade. The first filter removes large oil droplets. The second filter removes fine oil droplets. The third filter removes oil vapors, providing odor-free air.

Oil in Compressed Air Affects Products and the Work Environment Oil, unburned hydrocarbons and compressor coolant become highly concentrated during compression. These contaminants enter the air flow as entrained droplets and will pass through the compressed air system into the production process unless they are removed. The built-in air/oil separator on all rotary screw air compressors will remove a portion of the oil, but this is not sufficient for most applications. Oil contamination will cause batch spoilage, poor quality in finished goods, unwanted coloring in finished goods and a messy or hazardous work environment.

8 Air Quality

General Manufacturing Assembly Conveying Air Tool Use

Advanced Pneumatics Instrument Quality Food Grade

Compressed Air Quality ISO 8573.1

Class

Solid Particle

(Maximum number of particles per m3) 0.1-0.5 micron 0.5-1.0 micron 1.0-5.0 micron

Water

Pressure Dewpoint (F)

OIL

Solids & Vapor (mg/m3)

1 2 3 4 5 6

100 100,000

1 1,000 10,000

0 10 500 1,000 20,000

-94.0 -40.0 -4.0 37.4 44.6 50.0

.01 0.1 1.0 5.0

Proper Filtration Removes Unwanted Oil from the Air Stream Removing oil from the compressed air stream provides some real benefits. Longer air tool life Ensures high quality of finished goods No unwanted odors Safer workplace Totally oil-free compressed air can only be achieved by installing an oil-free air compressor. However, particulate filtration and moisture removal are still necessary.

Air Quality 9

IR Industry Classifications

Air Quality

Class

Description

Applications Instrumentation, process, oil and gas, chemical, electronics

Efficient removal of solid IN1 Instrument Grade Air: particulates and oil. ISO Class 1 pressure dewpoint (PDP) will ISO Class 1-1-1 be maintained.

IN1 Odor-Free Instrument Grade Air: ISO Class 1-1-1, odor-free

Efficient removal of solid particulates and oil, and oil vapor. ISO Class 1 PDP will be maintained.

Pharmaceutical, food and beverage, clean rooms

Efficient removal of solid IN2 Instrument Grade Air: particulates and oil. ISO Class 2 PDP will be maintained. ISO Class 1-2-1

Instrumentation, process, oil and gas, chemical, electronics

IN2 Odor-Free Instrument Grade Air: ISO Class 1-2-1, odor-free

Efficient removal of solid particulates and oil, and oil vapor. ISO Class 2 PDP will be maintained.

Pharmaceutical, food and beverage, clean rooms

IG4 Industrial Grade Air: ISO Class 1-4-1

Efficient removal of solid particulates and oil. ISO Class 4 PDP or a 30% (or less) relative humidity (Rh) will be maintained. Efficient removal of solid particulates and oil, and oil vapor. ISO Class 4 PDP or a 30% (or less) Rh will be maintained.

General manufacturing, metal stamping, air tool use, forging, assembly, painting and finishing

IG4 Odor-Free Industrial Grade Air: ISO Class 1-4-1, odor-free

Food and beverage, raw material mixing

IG6 Industrial Grade Air: ISO Class 1-6-1

Efficient removal of solid particulates and oil. ISO Class 6 PDP or a 50% (or less) Rh will be maintained.

Sand blasting, home use, construction

Ingersoll Rand Audit Portfolio

IS

Intellisurvey Automated compressor audit

IS

Customer Needs

FS

Detailed air profile Identify fast-track savings opportunities Feasibility Study Analysis by walking around Interview operations, finance, management Identify potential opportunities from a supply-side audit or full-system audit

SA

EFFICIENCY EFFICIENCY

FS

PRODUCTIVITY PRODUCTIVITY

FA

RELIABILITY RELIABILITY

Supply-Side Audit Differentials, signals and set point management

SA

Starting Points

Pressure-drop management yields significant energy savings Air-quality management results in significant productivity improvements

FA

Full-System Audit All audit components previously identified, plus... An exact match of optimal demand-side requirements to minimum compressed

AirCare Advantage

Flexible Maintenance Programs and Constant Quality With an understanding of your industry classification requirements, Ingersoll Rand can provide the optimal air treatment equipment for your system. And with Ingersoll Rands AirCare extended warranty and preventive maintenance program, youll continue to enjoy reduced costs and increased productivity. The drivetrain or full-package warranty can be extended for six years.

air consumption

Certified professional technicians will perform routine inspections and diagnostic service. An all-inclusive fluid analysis program monitors compressor lubricants for early detection of problems. Vibration analysis and trending can pinpoint an impending component replacement.

Air Quality 11

Ingersoll Rand Industrial Technologies provides products, services and solutions that enhance our customers energy efficiency, productivity and operations. Our diverse and innovative products range from complete compressed air systems, tools and pumps to material and fluid handling systems and environmentally friendly microturbines. We also enhance productivity through solutions created by Club Car, the global leader in golf and utility vehicles for businesses and individuals. www.ingersollrand.com www.clubcar.com Distributed by:

Ingersoll Rand compressors are not designed, intended or approved for breathing air applications. Ingersoll Rand does not approve specialized equipment for breathing air applications and assumes no responsibility or liability for compressors used for breathing air service. Nothing contained on these pages is intended to extend any warranty or representation, expressed or implied, regarding the product described herein. Any such warranties or other terms and conditions of sale of products shall be in accordance with Ingersoll Rands standard terms and conditions of sale for such products, which are available upon request. Product improvement is a continuing goal at Ingersoll Rand. Designs and specifications are subject to change without notice or obligation.

2007 Ingersoll-Rand Company CCN-38450110

Das könnte Ihnen auch gefallen

- BakerHughes BN Orbit60 Brochure-050421-WEBDokument13 SeitenBakerHughes BN Orbit60 Brochure-050421-WEBRichard MarbunNoch keine Bewertungen

- Orbit 60Dokument31 SeitenOrbit 60Richard MarbunNoch keine Bewertungen

- 4 5947533744993738326 PDFDokument18 Seiten4 5947533744993738326 PDFRichard MarbunNoch keine Bewertungen

- Air QualityDokument12 SeitenAir QualityRichard MarbunNoch keine Bewertungen

- Transfer Vessel AnimationDokument1 SeiteTransfer Vessel AnimationRichard MarbunNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5782)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- 3906 Qep Dec11Dokument88 Seiten3906 Qep Dec11ronfrendNoch keine Bewertungen

- Science and Technology Yearly 2023 VisionDokument182 SeitenScience and Technology Yearly 2023 Visionmukeshsgf5Noch keine Bewertungen

- Whirlpool Triturador GC2000PE dimension-guide-4211597-D-WHDokument1 SeiteWhirlpool Triturador GC2000PE dimension-guide-4211597-D-WHAlexis MayerNoch keine Bewertungen

- Run-Up Test: FI-37240 Linnavuori, Nokia FinlandDokument4 SeitenRun-Up Test: FI-37240 Linnavuori, Nokia FinlandGaston SosaNoch keine Bewertungen

- HEC Pakistan Syllabus For B.S. & M.S.physics 2005Dokument75 SeitenHEC Pakistan Syllabus For B.S. & M.S.physics 2005Jehan Zaib Ali Khan100% (2)

- Energy Revision Summary Key PointsDokument8 SeitenEnergy Revision Summary Key PointsyuhNoch keine Bewertungen

- Vortex Care & SafetyDokument37 SeitenVortex Care & SafetyRodel FadroganeNoch keine Bewertungen

- JSW Energy Ltd Performance Test of Unit 4 in Nozzle and Throttle ModesDokument6 SeitenJSW Energy Ltd Performance Test of Unit 4 in Nozzle and Throttle ModesAnkur DasNoch keine Bewertungen

- York On Nine EtherDokument4 SeitenYork On Nine EtherLaron Clark100% (8)

- 3-Stresses in TrackDokument49 Seiten3-Stresses in Trackarpit_089Noch keine Bewertungen

- Everest Group RFP Questionnaire For ESG AttributesDokument7 SeitenEverest Group RFP Questionnaire For ESG AttributesAbhijeet ShindeNoch keine Bewertungen

- "Electrons in Atoms": Chemistry Atlantic Bilingual School Christian Campbell MDDokument75 Seiten"Electrons in Atoms": Chemistry Atlantic Bilingual School Christian Campbell MDusmcdoc113597Noch keine Bewertungen

- Sac - WacDokument4 SeitenSac - WacAdyasa ChoudhuryNoch keine Bewertungen

- Molar Mass of ButaneDokument11 SeitenMolar Mass of ButaneReena0% (1)

- Journal of Molecular Liquids: Mohammad Hatami Maryam Hasanpour, Dengwei JingDokument22 SeitenJournal of Molecular Liquids: Mohammad Hatami Maryam Hasanpour, Dengwei JingSugam KarkiNoch keine Bewertungen

- Horizontal Barriers For Controlling Water ConingDokument8 SeitenHorizontal Barriers For Controlling Water ConingBahman MatouriNoch keine Bewertungen

- RMC Online Washing System Industrial Gas TurbineDokument3 SeitenRMC Online Washing System Industrial Gas TurbinepayamzarNoch keine Bewertungen

- Basic USIT Interpretation - SLB Presentation, 2009Dokument18 SeitenBasic USIT Interpretation - SLB Presentation, 2009alizareiforoushNoch keine Bewertungen

- CEB1061Dokument6 SeitenCEB1061oscar horacio floresNoch keine Bewertungen

- IEEE C57-117 Guide For Reporting Failure Investigation Transformer-ReactorDokument29 SeitenIEEE C57-117 Guide For Reporting Failure Investigation Transformer-ReactorSukant Bhattacharya100% (1)

- Workshop II ManualDokument76 SeitenWorkshop II Manualzelalem walie100% (1)

- M Rizqi WicaksonoDokument8 SeitenM Rizqi WicaksonoIlhamNoch keine Bewertungen

- Energy Conservation and ManagementDokument2 SeitenEnergy Conservation and ManagementkannanchammyNoch keine Bewertungen

- Geothermal Energy NCESDokument71 SeitenGeothermal Energy NCESAdarsh ShuklaNoch keine Bewertungen

- Best Practice Guidelines For PV Cost CalculationDokument72 SeitenBest Practice Guidelines For PV Cost CalculationDoan Anh TuanNoch keine Bewertungen

- HTF Buildigng Cable Hippot Test From VFD To MotorDokument20 SeitenHTF Buildigng Cable Hippot Test From VFD To Motorمحمد ابن علیNoch keine Bewertungen

- Diesel Turbo Dv6ted4 Fap UvodDokument8 SeitenDiesel Turbo Dv6ted4 Fap UvoddearonNoch keine Bewertungen

- PMS Eil PDFDokument132 SeitenPMS Eil PDFAravind Dhudaka100% (1)

- ICAT Diesel EmissionDokument9 SeitenICAT Diesel EmissionValekarNoch keine Bewertungen

- DTC P1B77 High Voltage Precharging Fault - SonataHybrid 2015Dokument12 SeitenDTC P1B77 High Voltage Precharging Fault - SonataHybrid 2015Auto DiagNoch keine Bewertungen