Beruflich Dokumente

Kultur Dokumente

Refrigerant Mixtures As HCFC-22 Alternatives

Hochgeladen von

mani317Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Refrigerant Mixtures As HCFC-22 Alternatives

Hochgeladen von

mani317Copyright:

Verfügbare Formate

Purdue University

Purdue e-Pubs

International Refrigeration and Air Conditioning

Conference

School of Mechanical Engineering

1992

Refrigerant Mixtures as HCFC-22 Alternatives

M. B. Shifet

Du Pont Fluorochemicals

A. Yokozeki

Du Pont Fluorochemicals

D. B. Bivens

Du Pont Fluorochemicals

Follow this and additional works at: htp://docs.lib.purdue.edu/iracc

Tis document has been made available through Purdue e-Pubs, a service of the Purdue University Libraries. Please contact epubs@purdue.edu for

additional information.

Complete proceedings may be acquired in print and on CD-ROM directly from the Ray W. Herrick Laboratories at htps://engineering.purdue.edu/

Herrick/Events/orderlit.html

Shifet, M. B.; Yokozeki, A.; and Bivens, D. B., "Refrigerant Mixtures as HCFC-22 Alternatives" (1992). International Refigeration and

Air Conditioning Conference. Paper 139.

htp://docs.lib.purdue.edu/iracc/139

REFRIGERANT MIXTURES AS HCFC-22 ALTERNATIVES

M. B._ Shiflett, A. 'lokozeki, & D. B, Bivens

ou Pont Fluorochemicals

Wilmington, DE

SUMMARY

A recent international assessment of the atmospheric science

has provided a basis to accelerate the chlorofluorocarbon (CFC)

phase-out. In addition, the assessment provided a basis for

advancing the phase-out schedule for long-lived

hydrochlorofluorocarbons such as chlorodifluoromethane

(HCFC-22). The objective of this study was to identify potential

alternatives to HCFC-22 and evaluate their performance in a

room air conditioner. Computer model simulations of a

theoretical refrigeration cycle suggested that a mixture of

hydrofluorocarbons (HFCs) might perform the same as HCFC-22. The

air conditioner test results indicate that mixtures may be used

as alternatives to HCFC-22.

INTRODUCTION

HCFC-22 has been widely used in the air conditioning

industry especially in residential unitary and central air

conditioning systems for many years. In the United States

approximately 5 million room air conditioners are sold each year,

and most of them are used _for residential /1/

Because HCFC-22 has been readily available, low cost, and

less harmful to the environment than CFCs, it has become the

alternative of choice for many new applications. For example,

HCFC-22 is currently being used for some commercial and transport

refrigeration applications which traditionally used R-502, new -

design industrial chillers which traditionally used CFC-11, and

some stationary medium temperature applications which -

traditionally used CFC-12.

Recently, scientific information has indicated that ozone is

being depleted over latitude bands that encompass the United

States at faster rates than anticipated. /2/ This finding has

increased concern over the potential long-term effects of certain

long-lived HCFcs (such as HCFC-22) on atmospheric ozone

concentrations.

Based on this new information, ou Pont Company

Fluorochemicals announced intentions to discontinue sale of

HCFC-22 for all but service applications by January 1, 2005 and

for all applications by January 1, 2020.

Because HCFC-22 is used in a large variety of applications,

more than one alternative may be needed to provide optimum

performance for all applications. This study will focus on

identifying possible HFC alternatives to HCFC-22 for use in

residential cooling applications.

35

REFRIGERANT ALTERNATIVES CYCLE PERFORMANCE

A search was conducted to identify nonflammable compounds or

mixtures which provided the same refrigeration capacity and

enerqy efficiency as HCFC-22 at the ARI air conditioning and heat

pump rating points. /3/ No single nonflammable compound was

identified which provided the same theoretical capacity and

energy efficiency as HCFC-22 (see figure I): HFC-134a was the

only nonflammable refrigerant which offered a similar energy

efficiency with about a 35' lower refrigeration capacity based on

the same compressor displacement. Several HFC mixtures have been

proposed as HCFC-22 alternatives based on model calculations (see

figure II). /4/

1.4

1.2

0.8

0.6

0.4

0.2

0

1.4

1.2

0.8

0.6

0.4

0.2

0

HCFC22 HFCt3-4a HFC-125

HFC-32 HFC1-43a HFC152a

0 Capacity Bc.o.P.

Figure I

HCFC-22

HFC32/HFC13-4 HFC32/HFC126 HFC32/HFC162e.

(32wtfo/1!18wt'llol (80wt'llo/40wt'llol (-40wtfo/80wt'llol

D Capacity lli!lm C.O.P.

Figure II'

36

T

A mixture of HFC-32 ana HFC-134a offered the closest match

in theoretical capacity ana energy efficiency compared with

HCFC-22 while having the potential to be nonflammable. The

mixture Of 32 weight% (wt%) HFC-32 and 68 wt% HFC-l34a is a

zeotropic mixture, having a bubble point/dew point temperature

difference of 6 c (11 F) at a pressure of 620 kPa (90 psia).

Many questions have been raised concerning the use of

refrigerant mixtures such as HFC-32/HFC-134a for use in

refrigeration equipment. In order to verify the model

calculations and answer some of these concerns, we decided to

compare the performance of this mixture in a room air conditioner

designed to use HCFC-22.

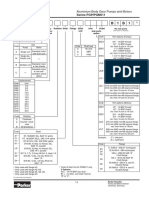

AIR CONDITIONER AND INSTRUMENTATION

The air conditioner was rated by the manufacturer to have a

cooling capacity of 4787 kcal/hr (19000 btufhr). The unit was

equipped with a rotary compressor, accumulator, and the

and condenser each had three circuits.

The air conditioner was set up in an environmentally

controlled chamber so that the dry and wet bulb temperatures

could be held constant and/or adjusted during the

experiments. /S/ The temperatures were varied over a wide

operating range in order to study the effects on performance.

The air conditioner was not modified except to accommodate

for the instrumentation necessary to take measurements. A

schematic of the instrumentation is provided in Figure III.

T

-.....

..oE---

T

MASS FLOW

M(TER.

Figure III

37

I

I

I

I

I

___.... AIR-FlOW

*' SAMPLE PORT

T THERMOCOUPLE

. p PRESSURE TRANSDUCER

T

several thermocouples and pressure transducers were

installed for making measurements around the cycle. Using these

measurements with our thermodynamic model allowed us to calculate

the enthalpy at each point. A coriolis type mass flow meter was

installed in the liquid line before the capillary tubes and

several sample ports were added for liquid and vapor phase

samples. These samples were later run on a gas chromatograph

(GC) to check mixture composition.

A power meter was used to measure the volts and amperes

drawn by the air conditioner. The power meter software

calculated the watts drawn and applied a power factor to adjust

for any distorted waveforms. The refrigeration capacity was

calculated by taking the enthalpy difference across the

evaporator times the mass flow rate. The energy efficiency ratio

(E.E.R.) was calculated by dividing the refrigeration capacity by

the total energy consumption. A data acquisition system was used

to process the measurements.

The rotary compressor was charged with naphthenic mineral

oil. The HFC refrigerants have little to no miscibility with

mineral oil, but the oil was not changed in order to eliminate

effects of different lubricants. Also, we wanted to determine if

the air conditioner could operate during the test period with an

immiscible refrigerant/lubricant combination.

TEST_PROCEOURES

The first set of experiments were conducted to verify our

measuring techniques. The system was evacuated with a two-stage

vacuum pump and charged with 1100 grams of HCFC-22 (recommended

nameplate charge size) . The mass flow rate and capacity

measurements were compared with the performance curves provided

by the compressor manufacturer (see figures IV and V). The

measurements agreed within +/- 4t for mass flow and +/- St for

capacity. This small difference was probably due to the oil

circulation through the mass flow meter. Based on this close

agreement we had confidence in our measurement techniques and

began evaluating the mixtures.

*

130

125

120 *

115

110

105

1 0 0 ~ ~ ~ ~ ~ ~ ~ ~ ~

100 105 110 115 120 125 130 135 140

Measured Mass Flow Rate (kg/hr)

Figure IV

38

Compressor Rating (kcal/hr)

5600.--------------------------

5400

5200

5000

4800

4600

* *

*

*

'!C

*

4 4 0 0 ~ ~ ~ ~ ~ ~ ~ ~

4400

4600 4800 5000 5200 5400

5600

Measured Capacity (kcal/hr)

Figure v

The air conditioner was operated over a range of indoor and

outdoor conditions and the steady-state performance measured at

each condition.

To ensure there were no slow leaks which might alter

performance measurements or change the mixture composition, the

HCFC-22 charge was recovered in a cylinder cooled in a dry

icejacetone bath. The charge was weighed and over 98% was

recovered.

A mixture of 32 wt' HFC-32 and 68 wt% HFC-134a was prepared

in the lab by weight and composition checked with a gas

chromatograph. The mixture was charged into the air conditioner

liquid phase by inverting the cylinder which had a vapor only

valve. The material was charged through the sample port at the

inlet to the accumulator (see figure III). In order to determine

the optimum charge size the mixture was added in small increments

and the refrigeration capacity and E.E.R. plotted as a function

of charge size. The optimum charge size for the HFC-32/HFC-134a

mixture was 943 grams.

The air conditioner was operated at the same conditions as

HCFC-22 and steady-state performance measured at each condition.

To determine if the mixture composition changes around the cycle

during operation, several samples were taken while the air

conditioner was running. The refrigerant charge was recovered

using the same method and the composition analyzed.

PERFORMANCE RESULTS

Figure VI provides a comparison of the experimental

measurements between HCFC-22 and the HFC-32/HFC-134a mixture.

HCFC-22 and HFC-32/HFC-134a had an average capacity of 4938

and 4888 kcalfhr (19600 and 19400 btujhr), respectively. HCFC-22

and HFC-32/HFC-134a both had an average E.E.R. of 3.0

(10.5 btujhr/W). The average deviation in the capacity

measurement was +/- 100 kcaljhr (400 btujhr) and the E.E.R.

deviation was +/- o.os (0.2 btujhrfW).

39

The compressor discharge line temperature was measured

10.2 em (4 inches) from the compressor shell. The

HFC-32/HFC-134a mixture had an average compressor discharge line

temperature of about 9 c (16 F) lower than HCFC-22. The

compression ratios for HCFC-22 and HFC-32fHFC-134a were 2.79 and

2,89, respectively.

The evaporator and condenser inlet and outlet pressures were

measured and the overall pressure drop for both refrigerants

calculated. The HFC-32/HFC-134a mixture had about the same

percent pressure drop as HCFC-22 (3,8\ versus 3,9\ in the

evaporator and 6.8\ versus 6.4\ in the condenser). The average

evaporating and condensing temperatures were calculated by using

the average pressures. Both HCFC-22 and HFC-32/HFC-134a had the

same average evaporating and condensing temperatures of

9 C (48 F) and 48 C (118 F), respectively.

The mass flow rate for the HFC-32/HFC-134a mixture was about

10\.lower than HCFC-22 because the suction gas density is about

lOt lower (22.6 kgfmJ (1.41 lb/ft3) at 18.3 C (65 F) and 627 kPa

(90.9 psia) versus 25.5 kg/m3 (1.59 lb/ftJ) at 18.3 c (65 F) and

642 kPa (93.1 psia), respectively). The overall power

consumption for the HFC-32/HFC-134a mixture was also slightly

lower than HCFC-22.

HCFC22

HFC32/HFC134a

CPIllly kcal/hr, (Biu/hd

4938 (19600)

4888 ( 19400)

e.e.R.

W/W, (BIU/hr/W)

3.0 (10.5)

3.0 (10.5)

Comp.

Dlacharge Temp. C,

(F)

96 (205)

87 (189)

Evap. Inlet Pre

kPa, (psla)

667 (96.8)

661 (94.4)

Outlet Pre a kPa, (psia)

6<l2 (93.1)

627 (90.9)

Cond. Inlet Pree kPa, (psia)

1890 (274.1)

1686

(273.4)

Outlet Prea k Pa,

(psia)

1772 (257.0)

1761

(255.4)

Comprenion Aatlo

2.79

2.89

Mau Flow kg/hr, (lb/hr)

114.2 (251.6)

102.7 (226.1)

Power Consumption Walls

1864

1666

Figure VI

Figure VII and VIII are graphs of the evaporator and

condenser temperature profiles. The temperature glide in the

two-phase region can be seen with the HFC-32/HFC-134a mixture.

The exact temperature glides were difficult to determine

trom the limited number of thermocouples; however, the values

seem to be near the calculated values of about 6 C (11 F) in the

condenser and 5.5 c (10 F) in the evaporator.

40

25

20

Distance along Evaporator

-- HCFC-22 --+- HFC-32/HFC-134a

Figure VII

Condenser Temperature (C)

80

70

\

60

50

'

Distance along Condenser

- - HCFC-22 -+- HFC-321HFC-134a

Figure VII!

several refrigerant samples were taken while the air

conditioner was in operation. The first set of samples were from the liquid line just before the mass flow meter with no refrigerant flashing in the accumulator (inactive). The second set of samples were taken at a low ambient condition with

refrigerant flashing in the accumulator (active) . We compared these samples with the initial refrigerant charged and within the accuracy of the Gc method (+/- 0.3 wt%) did not see any

composition changes in the. liquid line samples (see figure IX).

Therefore, liquid in the accumulator (internal volume of 722 cc) had no effect on the circulating liquid composition.

41

Sample

Initial Charge

Accumulator Inactive

LiQuid Line

Accumulator Active

LiQuid Line

Mixture Composition (wt%)

HFC-32 HFC-134a

32.2 67.8

32.1

67.9

32.2

67.8

Figure IX

FLAMMABILITY TESTING AND VAPOR/LIQUID MEASUREMENTS

The flammable limits for HFC-32 in HFC-l34a were measured

according to the ASTM 681 E test method. /6/ The liquid and

vapor compositions for mixtures of HFC-32/HFC-l34a were

calculated at various temperatures to ensure that the flammable

component HFC-32 did not exceed the flammability limit.

The maximum nonflammable HFC-32 concentration in HFC-l34a at

atmospheric pressure was about 56 wt% at room temperature and

about 52 wt% at 80 c (176 F). The vapor composition of a

cylinder containing 30 wt% HFC-32 and 70 wt% HFC-134a was

calculated over a range of temperatures between -25 C (-13 F) and

40 C (104 F). The vapor composition was also calculated for a

mixture containing 25 wt% HFC-32 and 75 wt% HFC-134a.

Composition (Weight%)

6 0 r ~ ~

Room Temperature Flammability limit

55

80 C Flammability Limit

50 r---

--

-----

45

---

---

4 0 ~ ~ ~

-25

0

Temperature (C)

HFC-32 Vapor Cone. - - HFC-32 Vapor Cone.

30 wt'\ 32 I 70 wt'\ HFC-134a 25 wl'\ 32 1 75 wtor. HFC-134a

Figure X

42

40

FiqQre X shows that at room temperature and above a mixture

of 30 wtt HFCJ2 and 70 wtt HFC-134a crosses t h e ~ S C

flammability boundary. At a temperature of about 20 c (-4 F)

the same mixture crosses the room temperature boundary. A

mixture containing 25 wtt HFC32 and 75 wtt HFC-134a remained

below both flammability boundaries. Therefore, mixtures of

HFC32 and HFC-134a which contain in excess of 25 wtt HFC-32 in

the liquid phase may have a flammable vapor space under certain

conditions.

Using the refrigeration cycle model, a mixture of 25 wt%

HFC-32 and 75 wtt HFC-134a would have a capacity about 9% lower

than HCFC22 with the same energy efficiency. The lower capacity

could be increased to HCFC22 capacity mechanically by increasing

the compressor displacement or chemically by adding HFCl25. A

ternary mixture of 30 wtt HFCJ2, 10 wtt HFC-125, and 60 wtt

HFC-134a should provide the same capacity and energy efficiency

as HCFC-22 based on model calculations. Adding small amounts of

HFC-125 allows more HFC-32 to be added to HFC-134a because it

lowers the HFC-32 concentration in the vapor space and acts as a

better flammability suppressant. The ternary mixture remains

below the flammability limits over the range of temperatures

studied.

CONCLUSIONS

The objective of this study was to identify alternatives to

HCFC-22 and evaluate their performance in a room air conditioner.

A mixture of 32 wtt HFC-32 and 68.wt% HFC-l34a provided the

same performance as HCFC-22 in a unmodified room air conditioner.

The tests verified the cycle calculations which showed the

mixture should have the same capacity, energy efficiency, and

about a 9 c lower compressor discharge temperature compared with

HCFC-22.

The tests proved that no major equipment changes may be

necessary in order to switch from HCFC-22 to a zeotropic mixture

such as HFC-32/HFC134a in certain applications such as room air

conditioners. The air conditioner operated with an immiscible

refrigerant/lubricant combination with no apparent effects on

performance for almost 1000 hours; however, polyol ester

lubricants may be required for long-term acceptable compressor

durability.

Refrigerant samples taken before and after operation suggest

that zeotropic mixtures such as HFC-32/HFC-134a can be charged

and recovered with no measurable composition changes. Also, no

composition changes were detected during operation from samples

taken at the liquid line.

Flammability tests and vaporjliquid composition measurements

show that mixtures of HFC-32/HFC-134a which contain in excess of

25 wtt HFC-32 may be flammable under certain conditions.

A mixture of 25 wt\ HFC-32 and 75 wt% HFC-l34a would have

about a 9% lower capacity with the same energy efficiency as

HCFC-22. The lower capacity could be increased to HCFC-22'

capacity by increasing the compressor displacement or by adding

HFC-125. A ternary mixture of 30 wt% HFC-32, 10 wtt HFC-125, and

60 wt\ HFC-134a may provide the same capacity and energy

efficiency as HCFC-22, while remaining below the flammability

limits over the range of temperatures studied.

43

Based on cycle calculations and tests results, these

mixtures as well as HFC-134a were nominated to the ARI task force

which is investigating potential HCFC-22 alternatives. /7/ The

next step is to verify the performance of the ternary and

test the mixtures in other applications such as unitary heat

pumps.

ACI{NOWLEDGMENTS

We would to give a special thanks to several other

members who contributed to this project: M.H. Bland, L. Bracale,

K.M. Henschen, J,A. Gehrig, R.R. Parkell, o.M. Patron, R.W.

Martin, and J.T. Nicholas. We would also like to thank

W.O. Roberts and J.F. Shilling for allowing us to use the

environmental chamber and finally D.L. Klug and S.C. Gidumal for

their s1.1pport.

REFeRENCES

1. Stoecker, W.F. and Jones, J.W., "Refrigeration and Air

Conditioning", 2nd Edition, 1982

1

pg 4.

2. Scientific Assessment of ozone Depletion: 1991 Executive

Summary, World Meteorological Organization, United Nations

Environment Programme, National Aerona1.1tics and Space

Administration, National Oceanic and Atmospheric

Administration, and United Kingdom Department of Environment,

October 1991.

J, Air-conditioning and Refrigeration Institute (ARI)

standard, 210/240-89,

4. Bivens, O.B., "Choosing Alternative Fluids for Air

Conditioning", 1991 CFC Conference, Baltimore, MD, 12/4/91.

5. Association of Home Appliance Manufacturers Standards

(AHAM RAC-1, July 1990).

6. The American Society for Testing and Materials, (ASTM)

1

Standard Test Method for Concentration Limits of

Flammability of Chemicals, Designation E681-85.

7, Bivens, O.B. and Klug, O.L, "HCFC-22 Alternatives -

OuPont Company Nominations", ARI Test Program, 2/4/92.

44

Das könnte Ihnen auch gefallen

- Co2 CompressorDokument9 SeitenCo2 CompressorManthanNoch keine Bewertungen

- R32 - R125 - R161 Mixture For R407CDokument4 SeitenR32 - R125 - R161 Mixture For R407CClaudia MadalinaNoch keine Bewertungen

- Refrigerant PerformanceDokument8 SeitenRefrigerant PerformanceJulius ApigoNoch keine Bewertungen

- Energetic Analysis of Single Stage Lithium Bromide Water Absorption Refrigeration SystemDokument8 SeitenEnergetic Analysis of Single Stage Lithium Bromide Water Absorption Refrigeration SystemMalayPatelNoch keine Bewertungen

- Natural Gas Purification (Water Absorption Only)Dokument18 SeitenNatural Gas Purification (Water Absorption Only)austingoewertNoch keine Bewertungen

- Comparisons and Theoretical Analysis of R32 and R134A Refrigerants in A Vapour Compression Heat Pump Water Heating DONE2Dokument9 SeitenComparisons and Theoretical Analysis of R32 and R134A Refrigerants in A Vapour Compression Heat Pump Water Heating DONE2Marclauryn Adewale100% (1)

- Effect of Sub Cooling and Superheating On Vapour Compression Refrigeration Systems Using R-22 Alternative RefrigerantsDokument11 SeitenEffect of Sub Cooling and Superheating On Vapour Compression Refrigeration Systems Using R-22 Alternative RefrigerantsMalayPatelNoch keine Bewertungen

- HFODokument10 SeitenHFOMuhammad HishamNoch keine Bewertungen

- Geo Thermal Heat ExchangerDokument11 SeitenGeo Thermal Heat Exchangernalinsingla95Noch keine Bewertungen

- Ie 500084 WDokument13 SeitenIe 500084 WAngela Paul PeterNoch keine Bewertungen

- البحث الثانيDokument15 Seitenالبحث الثانيBahaa SalehNoch keine Bewertungen

- Thermal Performance of Three Stage Cascade Vapour Compression Refrigeration Systems Using New HFO in High and Intermediate Temperature Cycle and R32Dokument15 SeitenThermal Performance of Three Stage Cascade Vapour Compression Refrigeration Systems Using New HFO in High and Intermediate Temperature Cycle and R32Ijrei JournalNoch keine Bewertungen

- EXPERIMENTAL ANALYSISzube2011Dokument16 SeitenEXPERIMENTAL ANALYSISzube2011yodit girmaNoch keine Bewertungen

- Accepted Manuscript: Applied Thermal EngineeringDokument32 SeitenAccepted Manuscript: Applied Thermal EngineeringPriamdanduNoch keine Bewertungen

- TEWI AutomobilesDokument15 SeitenTEWI Automobilesmirali74Noch keine Bewertungen

- Efficiency Increase in Carbon Dioxide Refrigeration Technology With Parallel CompressionDokument10 SeitenEfficiency Increase in Carbon Dioxide Refrigeration Technology With Parallel CompressionIvana MacedoNoch keine Bewertungen

- Co2 Heat Pump SystemsDokument7 SeitenCo2 Heat Pump SystemsAmine Yahiaoui100% (1)

- Sum Ant RanDokument26 SeitenSum Ant RanSanju KumarNoch keine Bewertungen

- 10 11648 J Ijepe 20150403 15Dokument10 Seiten10 11648 J Ijepe 20150403 15Jose AndresNoch keine Bewertungen

- Refrigerants 410a 407cDokument8 SeitenRefrigerants 410a 407cAnonymous rYwUkpNoch keine Bewertungen

- Pac Ihx Sur RefoidirDokument24 SeitenPac Ihx Sur RefoidirfredNoch keine Bewertungen

- Adiabatic Capillary Tube Test Data For HFC-134aDokument10 SeitenAdiabatic Capillary Tube Test Data For HFC-134aAhmed AlrubeayNoch keine Bewertungen

- Methods For Improving Thermal Performances of Vapour Compression Refrigeration Systems Using Ecofriendly Refrigerant in The ExpanderDokument13 SeitenMethods For Improving Thermal Performances of Vapour Compression Refrigeration Systems Using Ecofriendly Refrigerant in The ExpanderIjrei JournalNoch keine Bewertungen

- Comparative Experimental Study of An Open Piston Compressor Working With R1234, R134, R290Dokument8 SeitenComparative Experimental Study of An Open Piston Compressor Working With R1234, R134, R290Giorgio Intenz DangerNoch keine Bewertungen

- Ijesrt: A Performance of A Window Air Conditioner Using Alternative Refrigerants R22 AND R410ADokument7 SeitenIjesrt: A Performance of A Window Air Conditioner Using Alternative Refrigerants R22 AND R410AThi DamNoch keine Bewertungen

- Refrigeration Cycle and Compressor Performance For Various Low GWDokument9 SeitenRefrigeration Cycle and Compressor Performance For Various Low GWAritz CalvoNoch keine Bewertungen

- Madhu Jhariya, Et AlDokument7 SeitenMadhu Jhariya, Et Almd junuNoch keine Bewertungen

- 2016-Performance Analysis of An Ejector Enhanced Refrigeration Cycle WithDokument29 Seiten2016-Performance Analysis of An Ejector Enhanced Refrigeration Cycle WithVictor PerezNoch keine Bewertungen

- BERK DAĞLARAŞTI Design of V-C Refrigeration Sys. For Ship Patent SearchingDokument5 SeitenBERK DAĞLARAŞTI Design of V-C Refrigeration Sys. For Ship Patent Searchingberkdaglarasti009Noch keine Bewertungen

- A Thorough Examination and Evaluation of CO2 Heat Recovery Heaters QotybaDokument10 SeitenA Thorough Examination and Evaluation of CO2 Heat Recovery Heaters QotybaHazim MohammedNoch keine Bewertungen

- Disproportionation Resistant Alloy Development For Hydride Hydrogen CompressionDokument5 SeitenDisproportionation Resistant Alloy Development For Hydride Hydrogen CompressionMilton BidoneNoch keine Bewertungen

- 07 Chapter 2Dokument36 Seiten07 Chapter 2DevNoch keine Bewertungen

- Process Design and Simulation: Submission Deadline: TBCDokument24 SeitenProcess Design and Simulation: Submission Deadline: TBCBrajesh ChandraNoch keine Bewertungen

- Design, Construction and Testing of An Air-Cycle Refrigeration System For Road TransportDokument8 SeitenDesign, Construction and Testing of An Air-Cycle Refrigeration System For Road TransportRafael Andres Albuja Del ValleNoch keine Bewertungen

- 39 Model of LPG Refrigerator A Literature Review PDFDokument4 Seiten39 Model of LPG Refrigerator A Literature Review PDFIJAERS JOURNALNoch keine Bewertungen

- Performance Assessment of HFC Group Refrigerants in Window Air Conditioning SystemDokument5 SeitenPerformance Assessment of HFC Group Refrigerants in Window Air Conditioning SystemAdi PriyantoNoch keine Bewertungen

- Evaporative Cooling Comfort in Small Cabin Space VehiclesDokument24 SeitenEvaporative Cooling Comfort in Small Cabin Space VehiclesShiv Kumar KushwahaNoch keine Bewertungen

- Residential and Commercial Air Conditioning and Heating: Coordinating Lead Authors Lead AuthorsDokument26 SeitenResidential and Commercial Air Conditioning and Heating: Coordinating Lead Authors Lead AuthorsAshok KumarNoch keine Bewertungen

- J.apenergy.2008.08.019) Cheng Yang Zeliang Yang Ruixian Cai - Analytical Method For Evaluation of Gas Turbine Inlet Air Cooling in Combined CyclDokument9 SeitenJ.apenergy.2008.08.019) Cheng Yang Zeliang Yang Ruixian Cai - Analytical Method For Evaluation of Gas Turbine Inlet Air Cooling in Combined CyclidigitiNoch keine Bewertungen

- Sarkar 2010Dokument8 SeitenSarkar 2010Bounty MaNoch keine Bewertungen

- Air ConditioningDokument26 SeitenAir Conditioningsamuel kaluNoch keine Bewertungen

- eArt-Air Conditioning Systems With Desiccant Wheel For Italian ClimatesDokument21 SeiteneArt-Air Conditioning Systems With Desiccant Wheel For Italian ClimatesJurizal Julian LuthanNoch keine Bewertungen

- Critique of The Design and Operation of Sustainable Air-Cooled Chillers in Commercial BuildingsDokument26 SeitenCritique of The Design and Operation of Sustainable Air-Cooled Chillers in Commercial BuildingsKailas NimbalkarNoch keine Bewertungen

- Royand MandalDokument5 SeitenRoyand MandalLekane nelsonNoch keine Bewertungen

- Simulation of Fluid Catalytic CrackerDokument62 SeitenSimulation of Fluid Catalytic CrackerAhmed Ali100% (1)

- Compact HEDokument8 SeitenCompact HEShailesh LohareNoch keine Bewertungen

- Thermo Prject 2-1Dokument20 SeitenThermo Prject 2-1Syed AhmerNoch keine Bewertungen

- Experimental Performance Evaluation of Vapour Compression Refrigeration System Without Nano ParticlesDokument7 SeitenExperimental Performance Evaluation of Vapour Compression Refrigeration System Without Nano ParticlesIjrei JournalNoch keine Bewertungen

- COPs OF R718 IN COMPARISIONDokument7 SeitenCOPs OF R718 IN COMPARISIONThanhNoch keine Bewertungen

- Transcritical Co2 Refrigeration - PDFDokument11 SeitenTranscritical Co2 Refrigeration - PDFHector Fabian Hernandez Algarra100% (1)

- Methanation of CO2 Storage of Renewable Energy in A Gas Distribution SystemDokument6 SeitenMethanation of CO2 Storage of Renewable Energy in A Gas Distribution SystemzirimiaNoch keine Bewertungen

- Barta - Et - Al - 2018 - Experimental Analysis and Design Improvements On Combined Viper Expansion Work Recovery Turbine and Flow Phase Separation Device in R410ADokument10 SeitenBarta - Et - Al - 2018 - Experimental Analysis and Design Improvements On Combined Viper Expansion Work Recovery Turbine and Flow Phase Separation Device in R410AAmmarNoch keine Bewertungen

- Modelling of CO 2 Acetone Fluid Mixture ThermodynaDokument14 SeitenModelling of CO 2 Acetone Fluid Mixture ThermodynaTHUEZNoch keine Bewertungen

- Biomass Gasifier CalculationDokument10 SeitenBiomass Gasifier CalculationH.J.Prabhu100% (4)

- Planning and Scheduling Operations Theoretical Knowledge BDokument186 SeitenPlanning and Scheduling Operations Theoretical Knowledge BPanagiwtis M.Noch keine Bewertungen

- بحثي المنشور بمؤتمر الاردنDokument13 Seitenبحثي المنشور بمؤتمر الاردنShurooq TaibNoch keine Bewertungen

- Proposal 1Dokument8 SeitenProposal 1Akram NahriNoch keine Bewertungen

- 1D SimulationDokument24 Seiten1D SimulationAkram GhanemNoch keine Bewertungen

- Ejectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsVon EverandEjectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsNoch keine Bewertungen

- PFMEA - MachiningDokument14 SeitenPFMEA - Machiningmani317100% (1)

- Standard Wire Gauge (SWG) Conversion To MetricDokument1 SeiteStandard Wire Gauge (SWG) Conversion To Metricmani317Noch keine Bewertungen

- Osmose Plan PDFDokument20 SeitenOsmose Plan PDFmani317Noch keine Bewertungen

- Darwin Platform OverviewDokument36 SeitenDarwin Platform Overviewmani317100% (2)

- OSM Plan PresentationDokument20 SeitenOSM Plan Presentationmani317Noch keine Bewertungen

- Global: ROC Registered CompanyDokument8 SeitenGlobal: ROC Registered Companymani317Noch keine Bewertungen

- 4M SheetDokument1 Seite4M Sheetmani317Noch keine Bewertungen

- Delphi Supplier Quality Fmea Severity RankingsDokument3 SeitenDelphi Supplier Quality Fmea Severity Rankingsmani317Noch keine Bewertungen

- How To Make Gantt Chart in ExcelDokument22 SeitenHow To Make Gantt Chart in Excelmani317Noch keine Bewertungen

- Yearly CalenderDokument5 SeitenYearly Calendermani317Noch keine Bewertungen

- FMEA Ranking PDFDokument3 SeitenFMEA Ranking PDFmani317Noch keine Bewertungen

- Afsov MX & TRX PDFDokument2 SeitenAfsov MX & TRX PDFmani317Noch keine Bewertungen

- PFMEA Severity RankingDokument3 SeitenPFMEA Severity Rankingmani317Noch keine Bewertungen

- Thread & FastenerDokument35 SeitenThread & Fastenermani317Noch keine Bewertungen

- Bput Mtech Thermal 2010Dokument24 SeitenBput Mtech Thermal 2010mani317Noch keine Bewertungen

- Service Manual: PhilipsDokument39 SeitenService Manual: PhilipsRogerio E. SantoNoch keine Bewertungen

- Topic 6 ESD & EMI Considerations Electrostatic Sensitive Devices (M4.2, 5.12 &5.14) - 1Dokument49 SeitenTopic 6 ESD & EMI Considerations Electrostatic Sensitive Devices (M4.2, 5.12 &5.14) - 1BeaglelalahahaNoch keine Bewertungen

- " " Reach: Ordering InformationDokument8 Seiten" " Reach: Ordering InformationTrong TranNoch keine Bewertungen

- Comfort and Performance Your Customers DemandDokument18 SeitenComfort and Performance Your Customers Demandgizex2013Noch keine Bewertungen

- Computer Networking: A Top-Down Approach Featuring The InternetDokument27 SeitenComputer Networking: A Top-Down Approach Featuring The InternetmssacNoch keine Bewertungen

- VXN150 Vixion Fuel Tank PDFDokument3 SeitenVXN150 Vixion Fuel Tank PDFHarris Jum'aniandaNoch keine Bewertungen

- Gordon NovelDokument50 SeitenGordon NovelNic Hotep100% (2)

- 4 Rec. ITU-R BS.775-3: Reference Loudspeaker Arrangement With Loudspeakers L/C/R and LS/RSDokument3 Seiten4 Rec. ITU-R BS.775-3: Reference Loudspeaker Arrangement With Loudspeakers L/C/R and LS/RSPaulo PiresNoch keine Bewertungen

- 4 and 6 Pole MotorDokument6 Seiten4 and 6 Pole Motorarajamani78100% (1)

- Jacky Smith Resume Project ManagerDokument1 SeiteJacky Smith Resume Project ManagerGrey GrayNoch keine Bewertungen

- Islamic Law - WaterDokument12 SeitenIslamic Law - WaterAnum FaheemNoch keine Bewertungen

- A Sample of Wet Soil Has A Volume of 0Dokument8 SeitenA Sample of Wet Soil Has A Volume of 0eph0% (1)

- Coastal DefenceDokument112 SeitenCoastal DefenceMorvin BudhanNoch keine Bewertungen

- PORTFOLIO: OFFICE WORK (20/06/2022-20/12/2022) Harleen KlairDokument34 SeitenPORTFOLIO: OFFICE WORK (20/06/2022-20/12/2022) Harleen KlairHarleen KlairNoch keine Bewertungen

- CLS 747 200Dokument158 SeitenCLS 747 200Rodrigo Adam100% (8)

- Solar Module CellDokument4 SeitenSolar Module CellVinod BabhaleNoch keine Bewertungen

- Jamesbury Polymer and Elastomer Selection GuideDokument20 SeitenJamesbury Polymer and Elastomer Selection Guidesheldon1jay100% (1)

- Web 2.0: Dynamic Web PagesDokument12 SeitenWeb 2.0: Dynamic Web PagesAra PantaleonNoch keine Bewertungen

- BSR NH Circle Jaipur 2016Dokument103 SeitenBSR NH Circle Jaipur 2016vikash kumar50% (4)

- Tutorial - 05 - Excavation Settle 3DDokument13 SeitenTutorial - 05 - Excavation Settle 3DAlejandro Camargo SanabriaNoch keine Bewertungen

- Gathering Network RequirementsDokument30 SeitenGathering Network RequirementsAmin ZangetsuNoch keine Bewertungen

- PG 511 B 1 B 1: Ordering Code Series PGP/PGM511Dokument7 SeitenPG 511 B 1 B 1: Ordering Code Series PGP/PGM511Four SticksNoch keine Bewertungen

- Sewer Connection Application Guidance PDFDokument7 SeitenSewer Connection Application Guidance PDFSamuel FuentesNoch keine Bewertungen

- Internship Report May 2016Dokument11 SeitenInternship Report May 2016Rupini RagaviahNoch keine Bewertungen

- Preview ISO+749-1977 PDFDokument3 SeitenPreview ISO+749-1977 PDFLiana GaniNoch keine Bewertungen

- Pro TrekDokument4 SeitenPro TrekTri WidodoNoch keine Bewertungen

- Acceleration GrpahDokument14 SeitenAcceleration GrpahRAFAEL TORRESNoch keine Bewertungen

- High Integrity Aluminum (GENERAL)Dokument140 SeitenHigh Integrity Aluminum (GENERAL)Kmilo Giraldo100% (3)

- 007-013558-001 SAS PCE SPE With Support For HSM PSE2 Integration Feature Documentation RevCDokument43 Seiten007-013558-001 SAS PCE SPE With Support For HSM PSE2 Integration Feature Documentation RevCpietoeNoch keine Bewertungen

- Korantin PPDokument4 SeitenKorantin PPteddy garfieldNoch keine Bewertungen