Beruflich Dokumente

Kultur Dokumente

SAIC-D-2022 Rev 2

Hochgeladen von

ரமேஷ் பாலக்காடுCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

SAIC-D-2022 Rev 2

Hochgeladen von

ரமேஷ் பாலக்காடுCopyright:

Verfügbare Formate

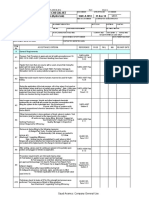

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - December 2005)

Rev 2 SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Verification of Non-Material Requirements for Vessels and Trays

PROJECT TITLE

31-Dec-05 DATE APPROVED QR NUMBER

SAIC-D-2022

WBS / BI / JO NUMBER

1-Dec-06

MECH-

CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) LAYOUT DRAWING NUMBER SCHEDULED INSPECTION DATE & TIME SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO INSPECTION LEVEL

EQUIPMENT DESCRIPTION REV. NO. PURCHASE ORDER NUMBER

EQPT CODE

SYSTEM ID.

PLANT NO.

EC / PMCC / MCC NO. QUANTITY INSP. MH's SPENT TRAVEL TIME

ACTUAL INSPECTION DATE & TIME SAUDI ARAMCO ACTIVITY NUMBER CONTRACTOR INSPECTION LEVEL

SAUDI ARAMCO USE ONLY

WORK PERMIT REQUIRED?

ITEM No. A

ACCEPTANCE CRITERIA Non-material Requirements for Pressure Vessels (NMR-7919-1) Non-material requirements per NMR-7919-1 were available on site for equipment verification : a. Certified drawings, literature, photographs, etc. b. Maintenance Manuals, Installation Instructions, c. Test Certs (for details see below) Pressure vessel is designed to ASME Sec VIII Div. 1 or Div. 2 Vessel manufacturer has prepared drawings which indicate the ultrasonic thickness of the vessel shell section, heads and nozzles. (NOTE: An adequate number of readings were taken to represent the actual thickness of the components .) Nominal thickness of shells and heads shall not be less than the following: (Put check mark on the applicable vessel material) a) 6 mm -for carbon steel materials b) 5 mm - for low chrome alloy steel materials All materials must be clearly identified and provided with legible original or certified true copies of Mill Test Certificates. Lack of adequate identification and certification shall be cause for rejection. (NOTE: Verification of Inspection records is required ) Alloy materials were alloy-verified by the Vessel Manufacturer and test reports verified to comply with SAES-A-206. (NOTE: Use applicable checklist items on SAIC-L-2010 for verification of compliance. ) Heat-treatment of formed components. (Put check mark on the applicable condition) Heads and other double-curvature components with nominal thickness exceeding 50 mm. Heads and other double-curvature components made of P-No. 3, 4, 5, 9A or 9B materials. Any hot-formed component Heat treatment Reports/Certificate of vessel per Table UHT-56 of ASME Sec VIII, Div 1(attached), and for vessels in the following service conditions: (Put check mark on the applicable condition) a) All caustic soda (NaOH) solutions, including conditions where caustic carryover may occur. b) All monoethanolamine (MEA) solutions (all temperatures). c) All diglycol amine (DGA) solutions above 138C design temperature. d) All rich amino diisopropanol (ADIP) solutions above 90C design temperature. e) All lean ADIP solutions above 60C design temperature. f) Boiler deaerator service (i.e., ambient temperature vacuum deaerators are exempt). g) Hydrogen service for P-No. 3, 4, and 5A/B/C base materials.

REFERENCE

PASS

FAIL

N/A

RE-INSP DATE

A1

32-SAMSS-004, Section 20

A2

32-SAMSS-004, Par. 7.1.1 32-SAMSS-004, Par. 20.3

A3

A4

32-SAMSS-004, Par. 7.9.2

A5

32-SAMSS-004, Par. 12.1.4

A6

32-SAMSS-004, Par. 12.1.6

A7

04-SAMSS-004, Par.13.2.14.1

A8

SAES-W-010 Par. 13.1 & 13.3

Page 1 of 5

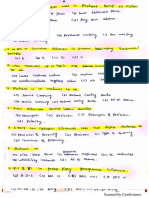

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - December 2005)

Rev 2 SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Verification of Non-Mat'l Reqmts for Vessels and Trays

PROJECT TITLE

31-Dec-05 DATE APPROVED QR NUMBER

SAIC-D-2022

WBS / BI / JO NUMBER

1-Dec-06

MECH-

CONTRACTOR / SUBCONTRACTOR

ITEM No.

ACCEPTANCE CRITERIA Hardness testing reports on production welds for the following applications: (Put check mark on the applicable condition) a) For all materials in sour service. b) For vessels PWHTed for service. c) Vessels of P-No. 4 or 5 material.

REFERENCE

PASS

FAIL

N/A

RE-INSP DATE

A9

SAES-W-010 Par. 14.1

A10

All required NDE for final acceptance of vessel, prior to pressure testing, shall be performed after completion of all welding & repairs. In 32-SAMSS-004, vessels requiring PWHT, all NDE for final acceptance shall be performed Par. 14.1.3 after the final PWHT. Magnetic Particle Examination MT & PT A) Permanent magnetic yokes are not permitted. B) Prods are not permitted for use on air-hardenable materials, materials 32-SAMSS-004, that require impact testing, and on the fluid side of pressured Par.14.4 components for vessels in wet sour service. Magnetic particle examination or liquid penetrant examination per the applicable Code shall be performed on the surfaces of hot formed and reheat treated parts. MT& PT 32-SAMSS-004, Par.14.1.5

A11

A12

A13

Except for non-Ferro magnetic materials, wet fluorescent magnetic particle examination using an AC yoke is required for the following: a) All internal welds and areas where temporary welds have been removed for vessels in wet sour, caustic, amine, de-aeration and MT & PT hydrogen services. 32-SAMSS-004, b) All internal and external welds and areas where temporary welds have Par. 14.4.3 been removed when the nominal thickness of pressured components is 25 mm and thicker. c) Vessel support attachment fillet welds. In thick Wall Vessel (MPT) A) All edges prepared for welding and all openings shall be MPT examined in accordance with the applicable Code. B) Forgings shall be examined on all surfaces, utilizing wet fluorescent magnetic particle method after final machining. All defects shall be removed & repaired by welding per SAES-W-010. Exception: For welding edges, liquid penetrant exam is acceptable C) All welds, including areas where temporary welds have been removed, are to be wet fluorescent magnetic particle examined. Magnetic particle examination is required for the weld-up of skirt to vessel joints (Para. 10.2.10) after each 6 mm depth weld deposit. For non-Ferro magnetic mat'ls, liquid penetrant exam shall be used. Radiographic Exams follows Table 4 (Attachment 1) and: Butt welds in forged skirt-to-head junction ring, conforming to ASME SEC VIII D2, Figure AD-912-1 (k), shall be 100% Radiograped See Attachment 1 for Table 4 Notes & UT interface with RT Where it is not possible to meet the 20 mm (toe to toe) spacing rule for butt weld encroachment (nozzle, repad, structural attachment): A) If the nozzle is installed onto or encroaching on a butt weld in the vessel wall: 1) RT the butt weld in the vessel wall for a length equal to 3 x diam. of the opening with the center of the opening at mid-length. 2) Where a repad is required, the butt weld shall be ground flush and RT'd, prior to the installation of the reinforcing pad. B) Where attachment weld (repad or structural component) will either intersect or encroach on a butt-weld in vessel: 1) Butt weld is RT'd for a length equal to projection of intersecting or encroaching segment of attachment weld plus 50 mm on either side 2) Perform magnetic particle examination on the vessel side of the joint attaching the reinforcing pad or structural component.

A13

MT & PT 32-SAMSS-004, Par. 14.4.4

A14

MT & PT 32-SAMSS-004, Par. 14.4.5 RT EXAMS 04-SAMSS-004, Par.14.2.3 & Table 4 Notes

A15

A16

RT EXAMS 04-SAMSS-004, Par. 14.2.4

Page 2 of 5

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - December 2005)

Rev 2 SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Verification of Non-Mat'l Reqmts for Vessels and Trays

PROJECT TITLE

31-Dec-05 DATE APPROVED QR NUMBER

SAIC-D-2022

WBS / BI / JO NUMBER

1-Dec-06

MECH-

CONTRACTOR / SUBCONTRACTOR

ITEM No.

ACCEPTANCE CRITERIA Ultrasonic Examination follows Table 5 (Attachment 1) and: Ultrasonic examination is required for thick wall vessels as follows: Plates and Welds a) All plates, including plate-like forgings, such as shell rings shall be ultrasonically examined by the Vessel Manufacturer in accordance with ASME SA-435. b) All pressure retaining welds and vessel support attachment fullpenetration welds shall be 100% UT examined after final PWHT. Pressure Test Reports Paints and Coating Reports and Quality Control Records The following Test/Inspection Reports were available and verified for Cladded/overlayed Vessels: a) Chemical Composition of final Weld overlay Surface (Par.6.3) b) Ferrite measurement (between 3 & 10FN) for austenitic SS c) Liquid Penetrant testing of final layer-100% of overlay weld. Non-material Requirements for Column Trays (NMR-7919-2) Data or information on Vessel design data sheets for trays (SA-9524-2ENG) was verified for validity, consistency & completeness. Certified drawings of shop details, installation drawings and installation instructions are included in the shipment. Alloy materials were alloy-verified by Vessel Manufacturer and test reports verified to comply with SAES-A-206. Use SAIC-L-2010

REFERENCE

PASS

FAIL

N/A

RE-INSP DATE

A14

UT EXAMS 04-SAMSS-004, Par. 14.3

A15 A16

04-SAMSS-004, Par. 16.3 SAES-H-100, Par. 9.2

A17

SAES-W-014, Sec. 6

B B1 B2 B3

SAES-C-001, Par. 5.1 32-SAMSS-020, Par. 14.2.7 32-SAMSS-004, Par. 12.1.6

REMARKS: ATTACHMENTS: 1 - 32-SAMSS-004 Tables 4 & 5 for RT & UT Requirements for Vessels REFERENCE DOCUMENTS: 1. SAES-A-005, Safety Instruction Sheet (28 February 2005) 2. SAES-A-206, Positive Material Identification, (29 December, 2004) 3. SAES-D-001, Design Criteria for Pressure Vessels (30 March 2005) 4. SAES-W-010 (30 June, 2002), Welding Requirements for Pressure Vessels 5. SAES-W-014 (30 June, 2002) Weld Overlays and Welding of Clad Materials 6. 32-SAMSS-004 (30 March, 2005), Manufacture of Pressure Vessels 7. 32-SAMSS-020 (30 March, 2005), Manufacture of Trays and Packing 8. SAIC-L-2010, (Saudi Aramco Inspection Checklist)-Positive Material Identification (PMI) of Alloy Components, Rev. 2

Contractor / Third-Party

Construction Representative*

Work is Complete and Ready for Inspection: Name, Initials and Date: Name, Initials and Date:

Saudi Aramco

PMT Representative

T&I Witnessed QC Record Reviewed Work Verified

QC Inspector

Performed Inspection Name, Initials and Date: Work / Rework May Proceed

PID Representative

T&I Witnessed Name, Initials and Date: QC Record Reviewed Work Verified

QC Supervisor

Quality Record Approved: Name, Sign and Date: *Person Responsible for Completion of Quality Work / Test

Proponent and Others

Name, Organization, Initials and Date: T&I Witnessed QC Record Reviewed Work Verified

Y = YES

N = NO F = FAILED

Page 3 of 5

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 2 (Standards Cutoff - December 2005)

REV 2 SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Verification of Non-Mat'l Reqmts for Vessels and Trays

31-Dec-05 DATE APPROVED QR NUMBER

SAIC-D-2022

1-Dec-06

MECH-

ATTACHMENT 1 - 32-SAMSS-004 Tables 4 & 5 for RT & UT of Vessels

ATTACHMENT 1 - 32-SAMSS-004 Tables 4 & 5 for RT & UT of Vessels

Das könnte Ihnen auch gefallen

- Saudi Aramco Piping ChecklistDokument3 SeitenSaudi Aramco Piping ChecklistphilipyapNoch keine Bewertungen

- SAIC-A-2013 Rev 0Dokument2 SeitenSAIC-A-2013 Rev 0philipyapNoch keine Bewertungen

- SAIC-D-2012 Rev 2Dokument4 SeitenSAIC-D-2012 Rev 2ரமேஷ் பாலக்காடுNoch keine Bewertungen

- Three-Phase Motor Current Unbalance CausesDokument3 SeitenThree-Phase Motor Current Unbalance CausesjoabaarNoch keine Bewertungen

- Vedic Maths TutorialDokument12 SeitenVedic Maths TutorialNitin Jain100% (15)

- SAIC-L-2136 Rev 0Dokument3 SeitenSAIC-L-2136 Rev 0philipyapNoch keine Bewertungen

- SAIC-D-2007 Rev 2Dokument4 SeitenSAIC-D-2007 Rev 2ரமேஷ் பாலக்காடுNoch keine Bewertungen

- SAUDI ARAMCO PRESSURE VESSEL INSPECTION CHECKLISTDokument2 SeitenSAUDI ARAMCO PRESSURE VESSEL INSPECTION CHECKLISTnisha_khanNoch keine Bewertungen

- Volvo Xc70 (08-) - 2011 Supplement Volvo v70 (08-), Xc70 (08-) & s80 (07-) Wiring DiagramDokument21 SeitenVolvo Xc70 (08-) - 2011 Supplement Volvo v70 (08-), Xc70 (08-) & s80 (07-) Wiring Diagramsen tilNoch keine Bewertungen

- SATR-L-2001 Rev. 5Dokument10 SeitenSATR-L-2001 Rev. 5Neelam AhmadNoch keine Bewertungen

- 07 DiagnosticsDokument132 Seiten07 DiagnosticsJosué Soldera100% (2)

- Saudi Aramco Inspection Checklist: Nitrogen and Pearlite Application On BAHE Frame SAIC-E-2011 15-Nov-17 MechDokument1 SeiteSaudi Aramco Inspection Checklist: Nitrogen and Pearlite Application On BAHE Frame SAIC-E-2011 15-Nov-17 MechmominNoch keine Bewertungen

- SAIC-L-2038 Rev 7 - Final Inspection For Release of Fabricated PipinDokument2 SeitenSAIC-L-2038 Rev 7 - Final Inspection For Release of Fabricated PipinLipika GayenNoch keine Bewertungen

- SAIC-D-2006 Rev 2Dokument2 SeitenSAIC-D-2006 Rev 2ரமேஷ் பாலக்காடுNoch keine Bewertungen

- SAIC-D-2006 Rev 2Dokument2 SeitenSAIC-D-2006 Rev 2ரமேஷ் பாலக்காடுNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Installation of Fire Water Isolation Valves SAIC-L-2056 25-May-05 MechDokument2 SeitenSaudi Aramco Inspection Checklist: Installation of Fire Water Isolation Valves SAIC-L-2056 25-May-05 MechphilipyapNoch keine Bewertungen

- Saudi Aramco Storage ChecklistDokument4 SeitenSaudi Aramco Storage Checklistரமேஷ் பாலக்காடுNoch keine Bewertungen

- SAIC-A-2003 Rev 7 Review of Test Package PreparationDokument7 SeitenSAIC-A-2003 Rev 7 Review of Test Package PreparationPrince JoseNoch keine Bewertungen

- Saudi Aramco Inspection ChecklistDokument13 SeitenSaudi Aramco Inspection ChecklistAli AhmedNoch keine Bewertungen

- Saudi Aramco Test ReportDokument7 SeitenSaudi Aramco Test ReportziaNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 31-Dec-14 MechDokument4 SeitenSaudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 31-Dec-14 MechpravinNoch keine Bewertungen

- Em - 1110 2 2610Dokument652 SeitenEm - 1110 2 2610David LeviNoch keine Bewertungen

- Saudi Aramco Inspection ChecklistDokument3 SeitenSaudi Aramco Inspection ChecklistAbdul HannanNoch keine Bewertungen

- Duties of A Welding Inspector 1Dokument12 SeitenDuties of A Welding Inspector 1ரமேஷ் பாலக்காடுNoch keine Bewertungen

- Saic L 2008 PDFDokument4 SeitenSaic L 2008 PDFHesham HelalNoch keine Bewertungen

- BS 6399 PDFDokument22 SeitenBS 6399 PDFTeoh ChunliNoch keine Bewertungen

- Codes Standards and SpecificationsDokument15 SeitenCodes Standards and Specificationsரமேஷ் பாலக்காடுNoch keine Bewertungen

- Saudi Aramco Test ReportDokument2 SeitenSaudi Aramco Test ReportEswari AnandNoch keine Bewertungen

- SAIC-A-2008 Rev 0Dokument3 SeitenSAIC-A-2008 Rev 0Kristine Caye DatarioNoch keine Bewertungen

- Materials System SpecificationDokument7 SeitenMaterials System Specificationaanouar77Noch keine Bewertungen

- Saudi Aramco flange inspection procedureDokument13 SeitenSaudi Aramco flange inspection procedurebiplabpal2009Noch keine Bewertungen

- Saudi Aramco Inspection ChecklistDokument23 SeitenSaudi Aramco Inspection ChecklistjahaanNoch keine Bewertungen

- 1 SATIP-E-004-01 H Exc Installation-Shell and Tube-Rev1Dokument2 Seiten1 SATIP-E-004-01 H Exc Installation-Shell and Tube-Rev1Anonymous S9qBDVkyNoch keine Bewertungen

- Welding Processes ModuleDokument27 SeitenWelding Processes Moduleரமேஷ் பாலக்காடு100% (1)

- Saudi Aramco Inspection ChecklistDokument2 SeitenSaudi Aramco Inspection ChecklistJoni Carino SuniNoch keine Bewertungen

- SAIC-D-2023 Rev 2Dokument2 SeitenSAIC-D-2023 Rev 2ரமேஷ் பாலக்காடுNoch keine Bewertungen

- SAIC-D-2023 Rev 2Dokument2 SeitenSAIC-D-2023 Rev 2ரமேஷ் பாலக்காடுNoch keine Bewertungen

- SAIC-D-2023 Rev 2Dokument2 SeitenSAIC-D-2023 Rev 2ரமேஷ் பாலக்காடுNoch keine Bewertungen

- SAIC-D-2023 Rev 2Dokument2 SeitenSAIC-D-2023 Rev 2ரமேஷ் பாலக்காடுNoch keine Bewertungen

- Saudi Aramco Inspection ChecklistDokument9 SeitenSaudi Aramco Inspection Checklistரமேஷ் பாலக்காடுNoch keine Bewertungen

- SAIC-K-2026 Rev 0Dokument2 SeitenSAIC-K-2026 Rev 0philipyapNoch keine Bewertungen

- SAIC-L-2014 Flange Joint Insp PDFDokument7 SeitenSAIC-L-2014 Flange Joint Insp PDFAnonymous S9qBDVkyNoch keine Bewertungen

- III. Applicable Codes & Standards for Aramco ProjectsDokument5 SeitenIII. Applicable Codes & Standards for Aramco ProjectsZain Ali KidwaiNoch keine Bewertungen

- Receiving Inspection of Pressure VesselsDokument5 SeitenReceiving Inspection of Pressure Vesselsரமேஷ் பாலக்காடுNoch keine Bewertungen

- Procurement 6.1. Material List Requistion and InquiriesDokument3 SeitenProcurement 6.1. Material List Requistion and InquiriesMercy EdemNoch keine Bewertungen

- Validate Welding Power SuppliesDokument4 SeitenValidate Welding Power Suppliesfariboy123Noch keine Bewertungen

- C57 12 24-2000Dokument18 SeitenC57 12 24-2000raza239Noch keine Bewertungen

- Saudi Aramco Reinstatement Procedure ChecklistDokument5 SeitenSaudi Aramco Reinstatement Procedure ChecklistpravinNoch keine Bewertungen

- Method Statement For Static Equipment InstallationDokument20 SeitenMethod Statement For Static Equipment Installationคุณพ่อน้อง บิ๊กบอสNoch keine Bewertungen

- SAIC-E-2001 Rev 2Dokument7 SeitenSAIC-E-2001 Rev 2ரமேஷ் பாலக்காடுNoch keine Bewertungen

- SAES X 500 Cathodic ProtectionDokument8 SeitenSAES X 500 Cathodic ProtectionAbdul Khader HassanNoch keine Bewertungen

- SATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)Dokument2 SeitenSATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)deepa narayanNoch keine Bewertungen

- Merlin Gerin Medium VoltageDokument10 SeitenMerlin Gerin Medium VoltagekjfenNoch keine Bewertungen

- B2020-TDC-VF-009 Vessel Fabrication R0Dokument5 SeitenB2020-TDC-VF-009 Vessel Fabrication R0Ramalingam PrabhakaranNoch keine Bewertungen

- ThesisDokument150 SeitenThesishamad_sdrNoch keine Bewertungen

- Manufacturing Process Capability and Specification LimitsDokument8 SeitenManufacturing Process Capability and Specification LimitsMitul100% (1)

- Saudi Aramco Inspection ChecklistDokument21 SeitenSaudi Aramco Inspection ChecklisthamidjoyiaNoch keine Bewertungen

- QAPCO Interview For Welding Piping NDT InspectorDokument5 SeitenQAPCO Interview For Welding Piping NDT InspectormohamedNoch keine Bewertungen

- Saudi-Arabian-Engineering-Standardssaes-J-001 PDFDokument11 SeitenSaudi-Arabian-Engineering-Standardssaes-J-001 PDFsalasineNoch keine Bewertungen

- Analytics 2023 11 15 020004.ips - CaDokument4.251 SeitenAnalytics 2023 11 15 020004.ips - Cawardegger.cristianNoch keine Bewertungen

- SAIC-W-2015 Rev 7 (NDE Selection)Dokument17 SeitenSAIC-W-2015 Rev 7 (NDE Selection)vijayachiduNoch keine Bewertungen

- Inspection Procedure for Determining Retirement Thickness of PipingDokument6 SeitenInspection Procedure for Determining Retirement Thickness of Pipingmalika_00Noch keine Bewertungen

- Saudi Aramco Hardness Testing Procedure ReviewDokument3 SeitenSaudi Aramco Hardness Testing Procedure ReviewphilipyapNoch keine Bewertungen

- Saudi Aramco Inspection ChecklistDokument3 SeitenSaudi Aramco Inspection ChecklistJoni Carino Suni100% (1)

- Saudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 MechDokument2 SeitenSaudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 Mechsuresh100% (1)

- Saudi Aramco Typical Inspection Plan: Hydrostatic Testing of Pipelines SATIP-A-004-03 30-Nov-17 MechanicalDokument11 SeitenSaudi Aramco Typical Inspection Plan: Hydrostatic Testing of Pipelines SATIP-A-004-03 30-Nov-17 MechanicalRijwan MohammadNoch keine Bewertungen

- Cleaning Gauging Hydrautesting and Chemical CleaningDokument2 SeitenCleaning Gauging Hydrautesting and Chemical CleaningJosephKaren LorzanoIlaganNoch keine Bewertungen

- Inspection Procedure EDRDokument8 SeitenInspection Procedure EDRaamirtec301Noch keine Bewertungen

- Saep 351Dokument24 SeitenSaep 351Raj KumarNoch keine Bewertungen

- Saes A 109Dokument4 SeitenSaes A 109malika_00Noch keine Bewertungen

- Saudi Aramco Inspection Checklist: Inspection of Filling & Pressurization (Hydro Test) SAIC-A-2013 31-Dec-14Dokument10 SeitenSaudi Aramco Inspection Checklist: Inspection of Filling & Pressurization (Hydro Test) SAIC-A-2013 31-Dec-14pravinNoch keine Bewertungen

- SAIC L 2031 (Comments)Dokument2 SeitenSAIC L 2031 (Comments)Anton Thomas PunzalanNoch keine Bewertungen

- Saic RT 2007Dokument9 SeitenSaic RT 2007munnaNoch keine Bewertungen

- Satr W 2012Dokument1 SeiteSatr W 2012Mohammed Hamed BaganNoch keine Bewertungen

- Tech. Spec. For VesselsDokument6 SeitenTech. Spec. For Vesselssanjay421Noch keine Bewertungen

- SAIC-A-2026 Rev 2Dokument5 SeitenSAIC-A-2026 Rev 2ரமேஷ் பாலக்காடுNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Final Insp of Tank Installation (Tanks) SAIC-D-2021 1-Dec-06 MechDokument4 SeitenSaudi Aramco Inspection Checklist: Final Insp of Tank Installation (Tanks) SAIC-D-2021 1-Dec-06 Mechரமேஷ் பாலக்காடுNoch keine Bewertungen

- Technical Specification for Higher Carrying Capacity (HCC) EMU/DMU BogieDokument24 SeitenTechnical Specification for Higher Carrying Capacity (HCC) EMU/DMU BogiePremchand BeuraNoch keine Bewertungen

- Saic D 2022Dokument7 SeitenSaic D 2022sureshNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Structural Re-Instatement Punchlisting SAIC-M-1074 18-May-05 CivilDokument5 SeitenSaudi Aramco Inspection Checklist: Structural Re-Instatement Punchlisting SAIC-M-1074 18-May-05 Civil(*KaT*)Noch keine Bewertungen

- Saudi Computer Exam For QC WeldingDokument4 SeitenSaudi Computer Exam For QC Weldingரமேஷ் பாலக்காடு100% (1)

- Online Reg Certfct PDF PDFDokument2 SeitenOnline Reg Certfct PDF PDFரமேஷ் பாலக்காடுNoch keine Bewertungen

- Air Carbon Arc Gouging: ElectrodeDokument1 SeiteAir Carbon Arc Gouging: Electrodeரமேஷ் பாலக்காடுNoch keine Bewertungen

- SA JER PUAAA SKEC 50 3004 - Packing, Marking and Shipping Inst. - Rev.02Dokument62 SeitenSA JER PUAAA SKEC 50 3004 - Packing, Marking and Shipping Inst. - Rev.02ரமேஷ் பாலக்காடுNoch keine Bewertungen

- Online Reg Certfct PDF PDFDokument2 SeitenOnline Reg Certfct PDF PDFரமேஷ் பாலக்காடுNoch keine Bewertungen

- Gouging 01Dokument2 SeitenGouging 01ரமேஷ் பாலக்காடுNoch keine Bewertungen

- Responabilities of A Welding InspectorDokument13 SeitenResponabilities of A Welding Inspectorரமேஷ் பாலக்காடுNoch keine Bewertungen

- Pew205 Slide ShowDokument23 SeitenPew205 Slide Showரமேஷ் பாலக்காடுNoch keine Bewertungen

- API 510 Examination Sample ItemsDokument3 SeitenAPI 510 Examination Sample ItemsMagira PasaribuNoch keine Bewertungen

- Computer Kerala - 4 Folder LockDokument2 SeitenComputer Kerala - 4 Folder Lockரமேஷ் பாலக்காடுNoch keine Bewertungen

- 0 Wis10 Contents ListDokument1 Seite0 Wis10 Contents ListSangram RoutarayNoch keine Bewertungen

- Computer Kerala - 4 Folder LockDokument2 SeitenComputer Kerala - 4 Folder Lockரமேஷ் பாலக்காடுNoch keine Bewertungen

- Computer Kerala - 4 Folder LockDokument2 SeitenComputer Kerala - 4 Folder Lockரமேஷ் பாலக்காடுNoch keine Bewertungen

- Practical Guide To Pressure Vessel Manufacturing - SUNIL PULLARCOTDokument362 SeitenPractical Guide To Pressure Vessel Manufacturing - SUNIL PULLARCOTrodrigoperezsimoneNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Inspection of Tank Trim Installation SAIC-D-2020 1-Dec-06 MechDokument3 SeitenSaudi Aramco Inspection Checklist: Inspection of Tank Trim Installation SAIC-D-2020 1-Dec-06 Mechரமேஷ் பாலக்காடுNoch keine Bewertungen

- SAIC-E-2002 Rev 2Dokument7 SeitenSAIC-E-2002 Rev 2ரமேஷ் பாலக்காடுNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Final Insp of Tank Installation (Tanks) SAIC-D-2021 1-Dec-06 MechDokument4 SeitenSaudi Aramco Inspection Checklist: Final Insp of Tank Installation (Tanks) SAIC-D-2021 1-Dec-06 Mechரமேஷ் பாலக்காடுNoch keine Bewertungen

- SAIC-F-2007 Rev 2Dokument1 SeiteSAIC-F-2007 Rev 2ரமேஷ் பாலக்காடுNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: SAIC-D-2018 1-Dec-06 Mech-Insp of Under-Tank Leak Detection, Sub-Grade ProtectionDokument1 SeiteSaudi Aramco Inspection Checklist: SAIC-D-2018 1-Dec-06 Mech-Insp of Under-Tank Leak Detection, Sub-Grade Protectionரமேஷ் பாலக்காடுNoch keine Bewertungen

- Title Revision No. Issued Date::: Sm-90 / Sm-500 Specification List 19 28 January 2008Dokument32 SeitenTitle Revision No. Issued Date::: Sm-90 / Sm-500 Specification List 19 28 January 2008john aguirreNoch keine Bewertungen

- WPS - 018Dokument12 SeitenWPS - 018MAT-LIONNoch keine Bewertungen

- TCA 8K Datasheet JUNIPERDokument4 SeitenTCA 8K Datasheet JUNIPERcp_gautamNoch keine Bewertungen

- Altova XMLDokument131 SeitenAltova XMLzeller2010Noch keine Bewertungen

- 6 SQ - MM Standard Feed Through Terminal Blocks: Cat. No. Description Std. PackDokument3 Seiten6 SQ - MM Standard Feed Through Terminal Blocks: Cat. No. Description Std. PackKaran SanghviNoch keine Bewertungen

- CBSE Class 12 Computer Science - Communication and Network ConceptsDokument16 SeitenCBSE Class 12 Computer Science - Communication and Network ConceptsShubham PatelNoch keine Bewertungen

- Dometic RM 7390Dokument30 SeitenDometic RM 7390Zoran Prokic100% (1)

- Technical Line: How The New Revenue Standard Affects Engineering and Construction EntitiesDokument24 SeitenTechnical Line: How The New Revenue Standard Affects Engineering and Construction EntitiesvenkatesanmuraliNoch keine Bewertungen

- International Sxs Ser ManDokument104 SeitenInternational Sxs Ser ManaderlochNoch keine Bewertungen

- Metrology AssignmentDokument24 SeitenMetrology AssignmentKailas Sree ChandranNoch keine Bewertungen

- Bugs 6 EjerciciosDokument33 SeitenBugs 6 EjerciciosmoncaciNoch keine Bewertungen

- Performance PresentationDokument51 SeitenPerformance PresentationSridhar ChandrashekarNoch keine Bewertungen

- GE Series 90-70 Genius I/O Bus Controller DatasheetDokument9 SeitenGE Series 90-70 Genius I/O Bus Controller Datasheetvanselmetti1969Noch keine Bewertungen

- An17808a PDFDokument8 SeitenAn17808a PDFtatingoNoch keine Bewertungen

- Mismatch Defect in ERW Steel Tubes: September 2014Dokument5 SeitenMismatch Defect in ERW Steel Tubes: September 2014Riza KhanNoch keine Bewertungen

- Sign SystemDokument50 SeitenSign SystemluismpgluismpgNoch keine Bewertungen

- Asterisk BrochureDokument7 SeitenAsterisk BrochureOmar WaheedNoch keine Bewertungen

- Guide For Asme Stamp Holders-2001 PDFDokument122 SeitenGuide For Asme Stamp Holders-2001 PDFSandra Viviana Esquivel Benavides75% (4)

- Prepare Active Directory and Domains For Exchange 2013 PDFDokument18 SeitenPrepare Active Directory and Domains For Exchange 2013 PDFAdam DanielNoch keine Bewertungen

- 06-086-098 Weld Ring GasketsDokument13 Seiten06-086-098 Weld Ring GasketsRitesh VishambhariNoch keine Bewertungen