Beruflich Dokumente

Kultur Dokumente

3 Eng Stainless Steel Tube Annealing

Hochgeladen von

Victor HugoOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

3 Eng Stainless Steel Tube Annealing

Hochgeladen von

Victor HugoCopyright:

Verfügbare Formate

On-line heat treatment of austenitic stainless and ferritic steel tubes

Feasibility study concerning the inclusion of a bright annealing equipment for AISI series 3 and 4 stainless steel tubes in a forming line Giorgio Mazzola Massimo Mosca Termomacchine s.r.l. Via Valgioie, 12/4 10040 Rivalta Torino Italy Telephone ++39 011 9008811 Facsimile ++39 011 9034066 E-mail address: giorgiomazzola@termomacchine.com info@termomacchine.com

Solution treatment (austenitic steels series 3) Recrystallization annealing (ferritic steels series 4) Topics of the ASTM specifications What are the results that can be obtained on-line Termomacchine's fully solid state generators Bibliographic references

Solution treatment (austenitic steels series 3) The object of the treatment The heat treatment to make the steel structure uniform provides more intergranulate corrosion strength than in a non-treated material, e specially in correspondence with the welds.

Fig. 1 Tensile stress test To determine material ductility a steel test piece is put through the tensile test (A). Through loading (vertical arrows) the test piece lengthens, and its cross section reduces and it forms necking (B). In the case of steel, which becomes brittle due to cold working, cracking of the test piece follows that will present cutting and sharp edges (C). If the material is put through the solution treatment, the test piece breaks if larger loads are applied; the surface fracture is filamentous (D).

Fig. 2 - AISI steel series 3 structure after gradual elongation due to pulling stress (corresponds to point A of fig. 1).

Fig. 3 AISI series 3 steel structure put through the tensile test (corresponds to point B of figure 1). The progressive horizontal stretch of the crystalline grains that buckle from a plastic point of view and slide one on the other should be noted.

Fig. 4 - AISI steel series 3 steel structure put through a tensile test (corresponds to point B of figure 1 - a different view). The presence of various slip planes induces tension stresses inside the piece that will be work-hardened. The solution treatment is aimed at restoring a structure with small, uniform equi-axial grains. Recrystallization annealing (ferritic steels series 4) The object of the treatment Heat treatment eliminates structural stresses and makes it possible to obtain a pliable and softened material.

Fig. 5 - AISI 430 steel subject to cold working and work-hardened. The base of the figure is 450 micron long. To be noted: the stretched and oriented crystals which are separate from the slip planes.

Fig. 6 - AISI 430 steel recrystallized at 800C, water cooling. Basal side is 100 micron; note the well-formed crystals without preferential orientation. Solution treatment of austenitic steels Recrystallization annealing of ferritic steels List of ASTM reference specifications A 249: Austenitic steel welded tubes for boilers, superheaters, heat exchangers, and capacitors A 268: Weldless tubes and ferritic stainless steel welds for general use A 269: Weldless tubes and austenitic stainless steel welds for general use A 270: Sanitary weldless tubes (for the food industry) and austenitic stainless steel welds A 312: Weldless tubes and austenitic stainless steel welds A 791: Ferritic stainless steel welded tubes not subject to annealing

DIN 17457: Austenitic stainless steel round welded tubes for specific requirements supply technical conditions Solution treatment of austenitic steels Technological parameters Temperature Temperatures range between 950C and 1,200C; in our case the range is between 1,050 to 1,100 C Temperature stabilization Temperature is held for about 3-5 minutes each for 2.5 mm thick material. Temperature is to be as low as possible within the tolerance range: the increase of the temperature and dwell time makes the crystalline grain coarser and lowers the level of tube deformation.

Fig. 7 Comparison between a fine grain structure obtained from heating within the set temperature range and a coarse grain structure with spoilage of the mechanical properties. Cooling Water cooling (for thicknesses of some millimetres) or blown gas (for lower thicknesses where there is risk of deformation) is to be rapid to keep the carbides in solution. Which gas is to be used for cooling? Air Since hot oxidation above 900C is important, air utilization will result in the formation of a scale of oxides; the speed at which of the oxide layer forms is proportional to the oxygen concentration.

Nitrogen Using nitrogen results in the formation of nitrides (their amount increases with increased temperature). Hydrogen This gas makes it possible to obtain bright annealing but it will be necessary to take some safety precautions (474% hydrogen mixture in air is explosive). Recrystallization annealing of ferritic steels Technological parameters Temperature Temperatures range between 750C and 790C (870900C for AISI 409); above 850C it is produced a coarse grain structure is produced and steels become brittle. Temperature stabilization Work temperature is held about 11.5 minute for each millimetre of material thickness. Cooling Water cooling (for thicknesses of some millimetres) or blown gas (for lower thicknesses where there is risk of deformation) is to be rapid to maintain the carbides in solution. Which gas is to be used for cooling? Air Air can be used with the formation of an oxide layer that is easily removed by pickling. Nitrogen In this case temperatures are low; there is no nitride formation. Problems incidental to the on-line treatment (AISI series 3xx) Preliminary If the tube should be produced for forming a solution heated and laser welded strip, the problem of solubilising the carbides precipitated during welding does not subsist: the use of the laser involves fast heating and cooling that avoids structural transformation both in the weld bead and in the contiguous zone.

In any case, it is necessary to eliminate the strain hardening; the specification DIN 17457 calls for heating at a temperature above 1,040C where it would be possible to have the product certified. Problems Graduated heating with a short dwell time at 350450C (stress relief) to partially relieve the material's elastic stresses to prevent the product deformation. The work temperature must be high to offset the s h o r t time at the holding temperature; however, this is not enough to eliminate stresses completely. It is possible to determine the residual stress percentage after treatment by using the LarsonMiller's equation: T (log t + 20) 10 3 = Thermal effect T is the temperature in degree Rankine t is the stay time in hours Reference curves used are available from literature. Example: for AISI 347 holding of 4 at 1,100C implies residual stresses equivalent to 20% Delta Ferrite Presence of delta ferrite in the weld bead in a quantity of 38% (measurable) prevents hot cracks from forming; these form during cooling of the steel to around 980C. The delta ferrite forms during hot forging above 1,100C or during welding of stainless steels such as for example AISI 309 S, 310 S, 314. Considering the steel composition it will be possible to calculate the quantity of delta ferrite that is present using Delong's diagram. The delta ferrite can slowly change into Sigma's phase (FeCr hard and noxious compound) during steel heating due to a long dwell time within the range 540 870C. Sigma will turn again into Delta above 955C. It can be predicated that fast heating to the solution treatment temperature does not allow transformation of the delta ferrite which, after a sufficiently rapid heating, is still present in the austenitic matrix. Problems incidental to the on line treatment (AISI series 4xx)

The observations made about the residual stress for the AISI series 3 apply to ferritic steel annealing as well. In this case, since the temperatures in play are higher than standard (the operation is at 900 C ca), the treatment is still less effective. It is possible but less probable that in the above-stated conditions the phenomenon of precipitation of hard intermetallic compounds (such as Laves' phases, Sigma's phase but not the carbides) occur in the case of highly alloyed ferritic steels (with titanium, molybdenum, niobium). The sole strong point of these precipitates is a better creep strength at a high temperature, yet corrosion strength worsens. As above 1,000C all the undesired phases solubilise, the same solution treatment used for the austenitic steels can also hold for ferritic steels. The crystalline grains have no time to coarsen; there are some risks connected with cooling like for example the introduction of new stresses and a slight hardening effect (only for AISI 430 and 434). What are the results that can be expected from an on-line treatment? Performances that can be obtained from the traditional furnaces are definitely correct; they entail, however, high productions costs because of the various intermediate treatment handling needed. On-line process is, without a doubt, a primary need for tube manufacturers who are constantly searching for new technologies able to help them cut production costs. The biggest problem the producers of on-line installations have to tackle is to hold the process temperature for the necessary time to allow the material transformation. In this direction, Termomacchine has carried out positive tests acting on the tube heating temperature, which is higher than the standard, to shorten the dwell time. Increase in temperature offsets (in large part but not totally) shortening the dwell time according to the law that a rise in temperature of around 20C can halve holding. It cannot be assumed that a considerable heating temperature rise can shorten holding to a minimum because other mechanisms intervene for which solution treatment is partial. Empirical trials allow defining how much carbide has remained and how they reduce ductility and corrosion strength.

It is correct to predicate that the results obtainable on-line are a good compromise in order to reach much lower production costs than those that can be obtained from chamber furnaces; as to quality, it is technically acceptable and well accepted by clients, even though such performances are not, as absolute quality, in line with the ones reachable from the traditional furnaces.

Fig. 8 Comparison between furnace treatment and on-line treatment. The black line shows the treatment called for in literature. The red line illustrates treatments that, because of too long dwell time or a too high temperature, result in coarse grain structures. The blue line is the induction heat treatment: the temperature is higher than that standard, holding is shorter.

Fig. 9 Cooling; the red line shows a wrong treatment. Termomacchine's on-line installation for "Clean Annealing" or "Bright Annealing" of stainless steel tubes series 3 and 4 directly on the production line Phase 1 Heating by electromagnetic induction heating Phase 2 Process temperature stabilization Phase 3 - Cooling

Many-faceted applications Black treatment without controlled atmosphere Clean Annealing treatment with nitrogen only Bright Annealing with nitrogen and hydrogen Stabilization sector with modular furnace Ceramic bushings for tube guide Modular construction Shortened set-up time User-friendliness / easier maintenance operations Cut down on running costs Greater safety factor for operators also considering the small quantity of gaseous mixture circulating Closed loop pyrometric control of the temperatures that characterize the heating cycle Feedback of temperature and power supplied by the heating equipment Ability to certify the technological cycle

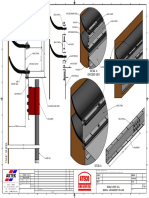

Of a jam

Ceramic Bushing Assembly

Easy exchange

Das könnte Ihnen auch gefallen

- Introduction to Heat Treatment ProcessesDokument10 SeitenIntroduction to Heat Treatment ProcessesAzhar AliNoch keine Bewertungen

- Performance Appraisal Form - Assistant Sales ManagerDokument3 SeitenPerformance Appraisal Form - Assistant Sales ManagerCherry DagamiNoch keine Bewertungen

- Hot Rolled Coil - Drawing & Forming Steel Grades PDFDokument3 SeitenHot Rolled Coil - Drawing & Forming Steel Grades PDFSunitSGalimathNoch keine Bewertungen

- XRD CatalogDokument4 SeitenXRD Catalogkumar.phanindra100% (1)

- Section 2. Visual InspectionDokument5 SeitenSection 2. Visual InspectionblackhawkNoch keine Bewertungen

- Heat-Treatment of High Carbon Steel Wire - PatentingDokument4 SeitenHeat-Treatment of High Carbon Steel Wire - Patentingعزت عبد المنعم100% (1)

- Tol Geom Ansi y 14.5Dokument33 SeitenTol Geom Ansi y 14.5Rebecca TurnerNoch keine Bewertungen

- Effective Auditing of Purchasing & Subtier Supplier Control ProcessesDokument40 SeitenEffective Auditing of Purchasing & Subtier Supplier Control ProcessesJHBernardoNoch keine Bewertungen

- Friction Grip Bolt PDFDokument2 SeitenFriction Grip Bolt PDFboyzesNoch keine Bewertungen

- Nice Label AutomotiveDokument9 SeitenNice Label AutomotiveacalancNoch keine Bewertungen

- The Seven Most Important ISO 9001:2015 Audit QuestionsDokument4 SeitenThe Seven Most Important ISO 9001:2015 Audit QuestionsAmit PaulNoch keine Bewertungen

- Superglaze Aluminum Mig Welding GuideDokument28 SeitenSuperglaze Aluminum Mig Welding Guidetastaman123Noch keine Bewertungen

- Astm A 275 A 275 M para Atualizar Planilha de Normas PDFDokument7 SeitenAstm A 275 A 275 M para Atualizar Planilha de Normas PDFFabio SegattoNoch keine Bewertungen

- AMS 2750E System Accuracy Testing & Temperature Uniformity SurveysDokument2 SeitenAMS 2750E System Accuracy Testing & Temperature Uniformity SurveysMickloSoberanNoch keine Bewertungen

- Measuring and Managing Performance RafDokument17 SeitenMeasuring and Managing Performance RafAya KusumaNoch keine Bewertungen

- SLIVER DEFECTS ON LOW CARBON STEELSDokument5 SeitenSLIVER DEFECTS ON LOW CARBON STEELSVarun MishraNoch keine Bewertungen

- 1.1 Lean SystemDokument21 Seiten1.1 Lean SystemSujoy DattaNoch keine Bewertungen

- Iso 9000Dokument57 SeitenIso 9000vinniieeNoch keine Bewertungen

- White Paper Automated Ultrasonic Inspection of Tube To Tube Sheet WeldsDokument7 SeitenWhite Paper Automated Ultrasonic Inspection of Tube To Tube Sheet WeldsdanemsalNoch keine Bewertungen

- Determining Hardenability of Steel: Standard Test Methods ForDokument26 SeitenDetermining Hardenability of Steel: Standard Test Methods ForJuan Diego Palacio VelasquezNoch keine Bewertungen

- Types, AsDokument23 SeitenTypes, AsAnanthanarayananNoch keine Bewertungen

- Electrodeposited Engineering Chromium Coatings On Ferrous SubstratesDokument5 SeitenElectrodeposited Engineering Chromium Coatings On Ferrous Substratesraulpalma93Noch keine Bewertungen

- A 48 Gray Iron CastingsDokument5 SeitenA 48 Gray Iron Castingswasatiah05Noch keine Bewertungen

- AS - 1252 - High Stregnth BNW For StructuralDokument7 SeitenAS - 1252 - High Stregnth BNW For StructuralDang Thanh Tuan100% (1)

- Impact of Quality Management in The Swedish Construction ProcessDokument143 SeitenImpact of Quality Management in The Swedish Construction ProcessHabeebNoch keine Bewertungen

- Hettich Price List 2019Dokument158 SeitenHettich Price List 2019danielNoch keine Bewertungen

- 177 13 Medical Gas Cylinders Colour CodingDokument9 Seiten177 13 Medical Gas Cylinders Colour CodingMarcelo Ojeda100% (1)

- Threads - NPTF Taper Thread GagingDokument5 SeitenThreads - NPTF Taper Thread GagingTrushantNoch keine Bewertungen

- Eurovent Test StandardsDokument12 SeitenEurovent Test StandardsMiki SinghNoch keine Bewertungen

- Guide To Document ControlDokument2 SeitenGuide To Document ControlAbdurRahmanFNoch keine Bewertungen

- tmpv5fB3M PDFDokument140 Seitentmpv5fB3M PDFtabaquiNoch keine Bewertungen

- Clauses IATF16949 2016Dokument2 SeitenClauses IATF16949 2016Javier BustamanteNoch keine Bewertungen

- The Relationship Between ISO 9000 and Business Performance-Does Registration Really MatterDokument13 SeitenThe Relationship Between ISO 9000 and Business Performance-Does Registration Really MatterThanh NamNoch keine Bewertungen

- Air Leakage in Air Handling Units PDFDokument10 SeitenAir Leakage in Air Handling Units PDFpNoch keine Bewertungen

- Eco Labelling Programme - Iso 14024Dokument7 SeitenEco Labelling Programme - Iso 14024Maureen Grace LebriaNoch keine Bewertungen

- ISO-9000 For Small BusinessDokument6 SeitenISO-9000 For Small Businessapi-37010580% (1)

- Eurolab Handbook Iso Iec 17025 2017Dokument17 SeitenEurolab Handbook Iso Iec 17025 2017Mohammad RehanNoch keine Bewertungen

- Ph-Ec InfoDokument4 SeitenPh-Ec InfoNick ChooNoch keine Bewertungen

- Iecex Bas 13.0069XDokument4 SeitenIecex Bas 13.0069XFrancesco_CNoch keine Bewertungen

- Sampling of High Pressure Hydrogen and Related Fuel Cell Feed GasesDokument5 SeitenSampling of High Pressure Hydrogen and Related Fuel Cell Feed GasesFaiber AndrésNoch keine Bewertungen

- Theories of Selling: AIDAS and Behavioral ApproachesDokument6 SeitenTheories of Selling: AIDAS and Behavioral Approachesdrlov_20037767Noch keine Bewertungen

- Alloy Steel Eyebolts: Standard Specification ForDokument6 SeitenAlloy Steel Eyebolts: Standard Specification Forjuniuni18Noch keine Bewertungen

- Heat Treatment - Self Assessment - CQ 9Dokument12 SeitenHeat Treatment - Self Assessment - CQ 9sunil mathewNoch keine Bewertungen

- Annexure V Documents for Enlistment EnhancementDokument1 SeiteAnnexure V Documents for Enlistment Enhancementbiswasdipankar05Noch keine Bewertungen

- User Guide Orifice Plates, Orifice Flanges, Metering Runs and Venturi TubesDokument12 SeitenUser Guide Orifice Plates, Orifice Flanges, Metering Runs and Venturi Tubesxaaabbb_550464353100% (1)

- Fastenal - Mechanical Properties of Inch FastenersDokument4 SeitenFastenal - Mechanical Properties of Inch FastenersbclarkeoobNoch keine Bewertungen

- NASA Facilities Maintenance ProceduresDokument301 SeitenNASA Facilities Maintenance ProceduresNguyễn Thanh SơnNoch keine Bewertungen

- RBACodeofConduct6.0 EnglishDokument15 SeitenRBACodeofConduct6.0 Englishleo G. BautistaNoch keine Bewertungen

- NT-EHS-SOP04 SOP For Communication - EMSDokument3 SeitenNT-EHS-SOP04 SOP For Communication - EMSSuraj RawatNoch keine Bewertungen

- Conformity Assessment (Management System Certification)Dokument5 SeitenConformity Assessment (Management System Certification)Talal AhmedNoch keine Bewertungen

- Heatstake Guide LinesDokument17 SeitenHeatstake Guide LinesJereRAESNoch keine Bewertungen

- HDT First Article Inspection Policy 01Dokument7 SeitenHDT First Article Inspection Policy 01Srinivasan VenkatNoch keine Bewertungen

- Process AnalysisDokument46 SeitenProcess AnalysisProfessor GowthamNoch keine Bewertungen

- The Marketing Audit Comes of AgeDokument14 SeitenThe Marketing Audit Comes of AgeRaluca NistorNoch keine Bewertungen

- Reliability ImprovementDokument22 SeitenReliability ImprovementJaroslav KurucNoch keine Bewertungen

- RBACodeofConduct7.0 EnglishDokument16 SeitenRBACodeofConduct7.0 EnglishMariaCecilia AnteNoch keine Bewertungen

- Double Wiper SealDokument1 SeiteDouble Wiper SealJoeNoch keine Bewertungen

- Study of Process Parameters of Gravity Die Casting DefectsDokument4 SeitenStudy of Process Parameters of Gravity Die Casting DefectsIAEME PublicationNoch keine Bewertungen

- European Standard EN 30-2-1 1998 A2 PDFDokument4 SeitenEuropean Standard EN 30-2-1 1998 A2 PDFVictor HugoNoch keine Bewertungen

- W10343440 PDFDokument12 SeitenW10343440 PDFVictor HugoNoch keine Bewertungen

- Din en 1561 1997 PDFDokument22 SeitenDin en 1561 1997 PDFVictor HugoNoch keine Bewertungen

- Value Analysis ConceptsDokument24 SeitenValue Analysis ConceptsDMastermindNoch keine Bewertungen

- Corrosion Study of AISI 304, AISI 321 and AISI 430 Stainless Steels in A Tar Sand DigesterDokument9 SeitenCorrosion Study of AISI 304, AISI 321 and AISI 430 Stainless Steels in A Tar Sand DigesterFerRy P. RAziNoch keine Bewertungen

- CFB DomesticDokument8 SeitenCFB DomesticHoang TuyenNoch keine Bewertungen

- Bio Gas Burner 1Dokument21 SeitenBio Gas Burner 1saadullah_siddiqui6076Noch keine Bewertungen

- 316 316L 317L Spec SheetDokument9 Seiten316 316L 317L Spec SheetbluecreteNoch keine Bewertungen

- Application of Multiple Domain Feature Mapping in Design For Cost (DFC) - Ce10Dokument8 SeitenApplication of Multiple Domain Feature Mapping in Design For Cost (DFC) - Ce10Victor HugoNoch keine Bewertungen

- APQP Manual VolvoDokument30 SeitenAPQP Manual VolvoVictor Hugo50% (2)

- ASME & NAFEMS - 2004 - What Is Verification and Validation - SCDokument4 SeitenASME & NAFEMS - 2004 - What Is Verification and Validation - SCjadamiat100% (1)

- Performing Failure Mode and Effects Analysis (FMEADokument54 SeitenPerforming Failure Mode and Effects Analysis (FMEAaakashtrivedi0% (1)

- Bio Gas Burner 1Dokument21 SeitenBio Gas Burner 1saadullah_siddiqui6076Noch keine Bewertungen

- Resistance Heating Wire Iron-Chrome-Aluminum (Fe-Cr-Al) Alloy - KA1Dokument2 SeitenResistance Heating Wire Iron-Chrome-Aluminum (Fe-Cr-Al) Alloy - KA1Victor HugoNoch keine Bewertungen

- 1162950895Dokument175 Seiten1162950895Victor HugoNoch keine Bewertungen

- CFB DomesticDokument8 SeitenCFB DomesticHoang TuyenNoch keine Bewertungen

- Application of Multiple Domain Feature Mapping in Design For Cost (DFC) - Ce10Dokument8 SeitenApplication of Multiple Domain Feature Mapping in Design For Cost (DFC) - Ce10Victor HugoNoch keine Bewertungen

- 1 A 2 3 Appliance Handbook UKDokument0 Seiten1 A 2 3 Appliance Handbook UKVictor HugoNoch keine Bewertungen

- Capitulo 3Dokument88 SeitenCapitulo 3Victor HugoNoch keine Bewertungen

- Integrating Electrical Heating Element Cap IDokument85 SeitenIntegrating Electrical Heating Element Cap IVictor Hugo100% (1)

- Integrating Electrical Heating Element Cap IDokument85 SeitenIntegrating Electrical Heating Element Cap IVictor Hugo100% (1)

- Bio Gas Burner 1Dokument21 SeitenBio Gas Burner 1saadullah_siddiqui6076Noch keine Bewertungen

- XDokument136 SeitenXVictor HugoNoch keine Bewertungen

- Quemadores - Criterios de DiseñoDokument44 SeitenQuemadores - Criterios de DiseñoVictor HugoNoch keine Bewertungen

- 02 2 Chicago 09-58 0059Dokument12 Seiten02 2 Chicago 09-58 0059Victor HugoNoch keine Bewertungen

- Cap 2Dokument17 SeitenCap 2Victor HugoNoch keine Bewertungen

- O-Rings: Back-Up Rings / P SeriesDokument1 SeiteO-Rings: Back-Up Rings / P SeriesRian PratamaNoch keine Bewertungen

- Embuild BrochureDokument38 SeitenEmbuild BrochureKawish TamourNoch keine Bewertungen

- Kingspan Coating Cards UA EN 202203 v1Dokument10 SeitenKingspan Coating Cards UA EN 202203 v1Bruno GuedesNoch keine Bewertungen

- Theory of Indeterminate Structure by Syed Ali Rizwan PDFDokument470 SeitenTheory of Indeterminate Structure by Syed Ali Rizwan PDFZain Ashfaq100% (2)

- Asme B16.9 Int 1993Dokument13 SeitenAsme B16.9 Int 1993SUSEINCANoch keine Bewertungen

- 0701 Mechanical General ProvisionDokument13 Seiten0701 Mechanical General ProvisionHiei ArshavinNoch keine Bewertungen

- 002 - ITP Earthworks - Revision 2.0Dokument12 Seiten002 - ITP Earthworks - Revision 2.0randyNoch keine Bewertungen

- Hardened ConcreteDokument3 SeitenHardened ConcreteEng Aidaruos Abdi MatanNoch keine Bewertungen

- PV-KK Blast Valve - Product FamilyDokument2 SeitenPV-KK Blast Valve - Product FamilyyousufbashaNoch keine Bewertungen

- BRICKS Answer Q & ADokument17 SeitenBRICKS Answer Q & ARajha RajeswaranNoch keine Bewertungen

- Marine Growth Protection SystemDokument21 SeitenMarine Growth Protection Systemwin htikeNoch keine Bewertungen

- 7607 E7018 SUPER OPTIMAL 4.0mm - BNM25913Dokument1 Seite7607 E7018 SUPER OPTIMAL 4.0mm - BNM25913魏利强Noch keine Bewertungen

- Ensure Even Preload with Proper Tightening Tools and SequenceDokument2 SeitenEnsure Even Preload with Proper Tightening Tools and SequenceMachineryengNoch keine Bewertungen

- Parts Book (18001-Up)Dokument650 SeitenParts Book (18001-Up)Helio100% (1)

- FENDER TEAM - Product CatalogueDokument100 SeitenFENDER TEAM - Product CataloguenikifNoch keine Bewertungen

- Elastic critical moment for lateral torsional buckling00.20.4M0.60.81M<0End moments and concentrated load – Factor C1Dokument14 SeitenElastic critical moment for lateral torsional buckling00.20.4M0.60.81M<0End moments and concentrated load – Factor C1Hamati RamiNoch keine Bewertungen

- RatesDokument197 SeitenRatesArea Engineer Civil Sonepur Bazari AreaNoch keine Bewertungen

- Certex Product Catalogue Chapter 001 PDFDokument69 SeitenCertex Product Catalogue Chapter 001 PDFAther AliNoch keine Bewertungen

- Civil Engineering FundamentalsDokument12 SeitenCivil Engineering FundamentalsAthith D100% (1)

- D 6477 - 02 Rdy0nzctmdjbDokument4 SeitenD 6477 - 02 Rdy0nzctmdjbJuan GutierrezNoch keine Bewertungen

- Formina Sanitary Ware Bathtub Shower Tray Sauna Jacuzzi FreestandingDokument156 SeitenFormina Sanitary Ware Bathtub Shower Tray Sauna Jacuzzi FreestandingmahertexNoch keine Bewertungen

- Soft Rock PillarsDokument34 SeitenSoft Rock PillarsvttrlcNoch keine Bewertungen

- Upc 2021Dokument5 SeitenUpc 2021TOP 5Noch keine Bewertungen

- An Introduction to the Benefits of Autoclaved Aerated Concrete (AACDokument7 SeitenAn Introduction to the Benefits of Autoclaved Aerated Concrete (AACRadhika KhandelwalNoch keine Bewertungen

- Hvac DuctDokument28 SeitenHvac DuctAhmed El TayebNoch keine Bewertungen

- Astm D578Dokument10 SeitenAstm D578MaRy Ge50% (2)

- Flygt Bs 2640 MT 226 5 6 KW 7 5 HP Salida 4Dokument2 SeitenFlygt Bs 2640 MT 226 5 6 KW 7 5 HP Salida 4MartinTPNoch keine Bewertungen

- Spraying Tank-Hot Oil Heating (Massenza)Dokument2 SeitenSpraying Tank-Hot Oil Heating (Massenza)jude tallyNoch keine Bewertungen

- CN30-8 (Classification Notes - Strength Analysis of Hull Structures in H...Dokument25 SeitenCN30-8 (Classification Notes - Strength Analysis of Hull Structures in H...Công TuấnNoch keine Bewertungen

- Valvula SolenoideDokument6 SeitenValvula SolenoideArnezNoch keine Bewertungen