Beruflich Dokumente

Kultur Dokumente

Manual de Operacion CellSure Ingles

Hochgeladen von

Qsanac KumbaraCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Manual de Operacion CellSure Ingles

Hochgeladen von

Qsanac KumbaraCopyright:

Verfügbare Formate

CellSure

Installation Guide

Issue: IPN 997-00012-20F

Issue Date: July 2009

Eaton Corporation

Telecommunications Power Solutions

www.Eaton.com/telecompower

DCinfo@Eaton.com

Eaton Corporation disclaims any liability for direct, indirect, incidental, special or consequential damages arising

out of the application or use of any information contained in this document. The foregoing disclaimer applies to

damages or personal injury, property damage, loss of operation, loss of profits, loss of product or loss of time,

whether incurred by the purchaser, the purchasers employees or third party.

Information in this document does not constitute a warranty, representation or guarantee concerning the

suitability or performance of Eaton products. No such warranty, representation or guarantee is expressed or

implied.

Information contained in this document is subject to change without further notice.

Subject to the right to use its equipment, Eaton Corporation does not convey any right, title or interest in its

intellectual property, including, without limitation, its patents, copyrights and know-how.

No part of this document may be reproduced or transmitted in any form, by any means or for any purpose other

than the Purchasers personal use, without the express written permission of Eaton Corporation.

Eaton

, Powerware

, Intergy

TM

, CellSure

TM

, SiteSure

TM

, PowerManagerII

TM

and DCTools

TM

are trade names,

trademarks, and/or service marks of Eaton Corporation or its subsidiaries and affiliates. Unless otherwise noted,

brands, product names, trademarks or registered trademarks are the property of their respective holders.

Copyright 2001-2009 Eaton Corporation. All Rights Reserved.

About This Guide

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

i

About This Guide

Required Software

The Eaton DCTools configuration software is required to install and operate CellSure battery

management systems.

DCTools can be downloaded free from www.powerquality.eaton.com/downloads. It is not

supplied with CellSure systems.

Scope

This guide covers the installation, configuration, operation and maintenance of CellSure

battery management systems with Eaton SC200 system controller, SM45/SM65 supervisory

modules, or in stand-alone mode.

This guide does not cover:

Installation and configuration of other Eaton products. For details, refer to the relevant

guide listed under Related Information on page ii.

Detailed instructions for setting up DCTools/PowerManagerII, except for the

DCTools/PowerManagerII communications settings.

Installation, commissioning and maintenance of batteries. Always consult the battery

manufacturer's relevant instruction manual before installing or servicing the batteries.

Installation of CellSure battery management systems with Eaton SM50 supervisory

modules. For full details see Worldwide Support on page 101.

Audience

This guide is intended for use by:

Installers competent in:

installing and commissioning dc power systems

safe working practices for dc powered equipment

the relevant local electrical safety regulations and wiring standards

Operators and maintenance staff competent in:

operation of dc power systems

safe working practices for dc powered equipment

CellSure Installation Guide

ii

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

Related Information

DCTools Online Help (DCTools is available for free download from:

www.powerquality.eaton.com/downloads)

PowerManagerII Online Help

SiteSure Installation and Configuration Guide IPN 997-00012-19

SM65 Supervisory Module Handbook - IPN 997-00012-35

SM60 Supervisory Module Handbook - IPN 997-00012-27

Access Power Solutions Installation Guide (SM40 Versions) - IPN 997-00012-37

Access Power Solutions Installation Guide (SM45 Versions) - IPN 997-00012-38

SC200 System Controller Operation Handbook - IPN 997-00012-50

Reporting Problems with this Guide

Please use this email address to report any problems you find in this guide:

Eaton DC Product Marketing Communications

EMAIL: DCMarketingNZ@Eaton.com

For Further Information and Technical Assistance

For further information and technical assistance see Worldwide Support on page 101.

Table of Contents

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

iii

Table of Contents

About This Guide

Required Software.....................................................................................................................i

Scope............................................................................................................................................i

Audience.....................................................................................................................................i

Related Information..................................................................................................................ii

Reporting Problems with this Guide .....................................................................................ii

For Further Information and Technical Assistance..............................................................ii

Chapter 1 General Description

Overview.................................................................................................................................... 1

CellSure Battery Controller (CBC).......................................................................................... 2

2V Battery System Modules .................................................................................................... 3

6V/12V Battery System Modules ........................................................................................... 4

Ambient Temperature Sensor ................................................................................................. 5

Current Shunts .......................................................................................................................... 5

Current Sensor (CS04-A11)...................................................................................................... 6

Auxiliary Power Module (APM) ............................................................................................ 7

Chapter 2 Preparation

Overview.................................................................................................................................... 9

Warnings.................................................................................................................................. 10

Inspecting the Equipment and Reporting Damage............................................................ 11

Battery System Types............................................................................................................. 11

Location and Environment.................................................................................................... 11

Chapter 3 Current Shunts/Sensors

Overview.................................................................................................................................. 13

Mounting Current Shunts ..................................................................................................... 14

Mounting CS04-A11 Current Sensors.................................................................................. 14

Chapter 4 2V System Installation

Overview.................................................................................................................................. 19

Task 1 - Mounting the Q.C. Tabs .......................................................................................... 20

Task 2 - Mounting the CBC and APM Modules................................................................. 21

Task 3 - Mounting the C2M-TS and C2M Modules ........................................................... 21

Task 4 - Mounting the Ambient Temperature Sensor ....................................................... 22

Task 5 - Numbering the Monoblocs..................................................................................... 22

Task 6 - Installing the Interconnecting Wiring ................................................................... 23

Single String Battery Systems.......................................................................................................24

Two String Battery Systems..........................................................................................................25

Three String Battery Systems........................................................................................................26

Four String Battery Systems .........................................................................................................27

Task 7 - Installing the Urgent and Non-urgent Alarm Relay Cabling ............................ 28

Task 8 - Powering the CBC.................................................................................................... 29

Powering the CBC from the system dc bus ................................................................................29

Powering the CBC from the SM65 RCP bus...............................................................................30

CellSure Installation Guide

iv

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

Chapter 5 6V/12V System Installation

Overview.................................................................................................................................. 31

Task 1- Mounting the Q.C. Tabs ........................................................................................... 32

Task 2 - Mounting the C6M/C12M, CBC and APM Modules ......................................... 32

Task 3 - Mounting the TS8CM and SP8CM Modules........................................................ 33

Task 4 - Mounting the Ambient Temperature Sensor ....................................................... 34

Task 5 - Numbering the Monoblocs..................................................................................... 34

Task 6 - Installing the Interconnecting Wiring ................................................................... 35

48V Battery Systems consisting of 6V Monoblocs and 1 to 2 Strings ......................................36

48V Battery Systems consisting of 6V Monoblocs and 3 to 4 Strings ......................................37

48V Battery Systems consisting of 12V Monoblocs and 1 to 4 Strings ....................................38

24V Battery Systems consisting of 6V Monoblocs and 1 to 4 Strings ......................................39

24V Battery Systems consisting of 12V Monoblocs and 1 to 4 Strings ....................................40

Task 7 - Installing the Urgent and Non-urgent Alarm Relay Cabling ............................ 42

Task 8 - Powering the C6M/C12M Sensor Modules ......................................................... 43

Task 9 - Powering the CBC.................................................................................................... 43

Powering the CBC from the system dc bus ................................................................................44

Powering the CBC from the SM65 RCP bus...............................................................................44

Chapter 6 Commissioning

Overview.................................................................................................................................. 45

Task 1 - Connecting a PC to the CBC................................................................................... 46

General Notes on Editing the CellSure Configuration..............................................................47

General Notes on Using DCTools................................................................................................47

Task 2 - Configure the Hardware and Battery Settings..................................................... 48

Task 3 - Check Monobloc Numbering................................................................................. 49

Task 4 - Check Temperature Sensors ................................................................................... 50

Task 5 - Calibrate Current Shunts/Sensors......................................................................... 52

Task 6 - Characterize the Batteries ....................................................................................... 55

Task 7 - Using the Characterization Data............................................................................ 62

Task 8 - Configure the CellSure System for Operation ..................................................... 64

Task 9 - Repeat for Other CBCs (if required) ...................................................................... 67

Task 10 - Setup External Communications ......................................................................... 67

Stand-alone Mode..........................................................................................................................67

SC200 Serial Server Mode.............................................................................................................70

Passthrough Communications (with SM45/SM65 only)..........................................................72

Chapter 7 Troubleshooting

CBC Status Indication ............................................................................................................ 78

Troubleshooting...................................................................................................................... 78

Appendix A Specifications

Auxiliary Power Module (APM)..................................................................................................81

Appendix B Alarm Details

Appendix C RS485 Bus Power Limits

RS485 Bus Design Method..................................................................................................... 89

RS485 Bus Power Limits (Cat 5 cable).................................................................................. 90

RS485 Bus Power Limits with Other Cable Types ............................................................. 91

Appendix D Data Management

Copy string data.............................................................................................................................93

Copy data from another CBC.......................................................................................................95

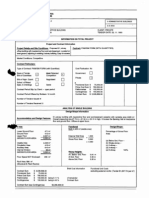

Equipment Incident Report

Worldwide Support

Index

Chapter 1

General Description

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

1

C h a p t e r 1

General Description

Overview

Topic Page

CellSure Battery Controller (CBC) 2

2V Battery System Modules 3

6V/12V Battery System Modules 4

Ambient Temperature Sensor 5

Current Shunts 5

Current Sensor (CS04-A11) 6

Auxiliary Power Module (APM) 7

CellSure Installation Guide

2

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

CellSure Battery Controller (CBC)

The CBC provides the monitoring and control functions for a CellSure battery system. The

CBC is fully configurable for complete operational flexibility. All battery system parameters

are stored in a software configuration file.

Alarms can be mapped to the urgent and non-urgent alarm relays which can be used to

activate an external fault indication device (such as a warning light or audible alarm).

The CBC communicates via a standard RS232 or RS485 serial interface. The standard

communication options are:

Standalone Mode:

RS232 direct to a PC

RS232 to a remote PC (via an Ethernet interface or modem)

Direct connection to an RS485 network.

SC200 Serial Server Mode:

To a local or remote PC through an Eaton SC200 system controller.

Passthrough Mode:

To a local or remote PC through an Eaton SM45 or SM65 supervisory module.

For more information see Setup External Communications on page 67.

Urgent and Non-Urgent alarm relay outputs (XB9)

String communications ports (XB8)

Ambient temperature sensor input (XB5)

Current shunt / sensor inputs (XB6 and XB7)

Bus reference input (XB3)

RS485 communications ports (XB1 and XB2)

RS232 serial communications port (XB4)

Controller OK and communications activity LED

(green)

W

Four String Alarm LEDs (Red)

For details of LED operation see CBC Status Indication on page 78.

General Description

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

3

2V Battery System Modules

The C2M and C2M-TS sensor modules are used with battery strings consisting of 2V cells.

Each module measure a single 2V cell voltage.

The COMMS IN and COMMS OUT ports are used to daisy chain up to 50 sensor modules.

C2M-TS sensor modules are identical to C2M sensor modules apart from a temperature

sensor input. The black TSCM temperature sensor forms an integral part of the C2M-TS

sensor module as shown in the following diagram.

CellSure systems require one C2M-TS sensor module per battery string.

C2M

C2M-TS

Communications input port (COMMS IN)

Communications output port (COMMS OUT)

Cell voltage sense input (on C2M-TS the

negative lead connects to the temperature

sensor)

Negative cell voltage sense output (no short-

circuit protection included)

Nonpolar string temperature sense outputs

Positive cell voltage and string temperature

sense input

CellSure Installation Guide

4

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

6V/12V Battery System Modules

6V/12V Sensor Modules (C6M/C12M)

C6M (for 6V monoblocs) and C12M (for 12V monoblocs) sensor modules measure up to eight

monobloc voltages and accept up to four string temperature signals.

Voltage inputs V1 to V4 and

temperature inputs T1 and T2

(XB22)

Power input (XB21)

Sensor module OK LED (Green)

String communications port (XB20)

Voltage inputs V5 to V8 and

temperature inputs T3 and T4

(XB23)

Short-Circuit Protection Module (SP8CM)

SP8CM modules are used on battery strings of 6V and 12V monoblocs.

SP8CM modules protect the monobloc voltage sense cabling against excessive current flow

during short-circuit conditions. The short-circuit protection device inside the SP8CM

automatically resets after removal of the fault condition.

Monobloc voltage sense output (short-circuit protected)

Monobloc voltage sense input

General Description

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

5

6V/12V String Temperature Sensor (TS8CM)

The TS8CM temperature sensor combines temperature sensing and short-circuit protection in

one single module. Short-circuit protection is identical to the SP8CM. The TS8CM

temperature sensor measures the ambient temperature of one 6V or 12V monobloc in a

battery string.

CellSure requires one TS8CM temperature sensor per battery string of 6V or 12V monoblocs.

Monobloc voltage sense output (short-circuit protected)

Non-polar string temperature sense outputs

Monobloc voltage and string temperature sense input

Ambient Temperature Sensor

A CellSure battery monitoring system includes one TS2-A01 ambient temperature sensor

with 8m (26') of cable.

The TS2-A01 measures the ambient temperature of the battery.

Current Shunts

Resistive current shunts are available for measuring battery string current.

The maximum current ratings are:

CS600: 600A

CS02: 500A

CS300: 300A

CS03: 150A

The current shunts develop a current sense signal of 50mV at maximum rated current.

The current shunts are factory-calibrated for easy set-up, and should not require re-calibration

under normal conditions of use. However, if you observe significant measurement inaccuracies,

use the calibration potentiometer to re-calibrate the current shunt.

CellSure Installation Guide

6

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

The two RJ45 sockets are used to daisy chain current shunts. Each current shunt is supplied

with an 8m (26') long RJ45 cable. Mounting screws are not included.

CS600 CS02 CS300 CS03

RJ 45 input (XU2 - connection to other

shunts, if required)

Calibration potentiometer

RJ 45 current sense signal output (XU1)

Current Sensor (CS04-A11)

The CS04-A11 is a current transducer used for measuring current in a wide range of copper

and aluminum bus bar sizes. The CS04-A11 current sensor mounts directly onto a bus bar.

Because of the many different bus bar sizes in use, CS04-A11 current sensors are not factory

calibrated. Gain adjustment is by means of a jumper (located on the back of the sensor PCB)

and an external trim potentiometer. The maximum output signal amplitude of a CS04-A11

current sensor is 60mV.

Each CS04-A11 is supplied complete with mounting screws and an 8m (26feet) long RJ45

cable.

An optional CS04 Current Sensor Extension PCB is available for measuring current in very

large bus bars.

Extension PCB (optional)

Current sensor pickup contacts

Input inductor

Gain adjustment potentiometer

RJ 45 current sense signal output

(XU1)

RJ 45 input (XU2 - connection to other

CS04, if required)

General Description

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

7

Auxiliary Power Module (APM)

The APM is a DIN-rail mounted twin output multi-purpose dc power supply used to:

Power the CBC module.

Except, an APM may not be required if the CBC is connected to an SM65 supervisory

module. See Powering the CBC (2V cells) on page 29 or Powering the CBC (6V/12V

monoblocs) on page 43.

Power auxiliary equipment such as modems, transducers and other user equipment.

The APM has a non-polar input voltage range of 18 to 60V dc. The twin outputs (9V and 12V)

are unregulated and isolated from each other. Both outputs feature overload protection with

automatic reset after removal of the overload condition.

A green status LED indicates Power On.

For comprehensive details see Specifications on page 81.

Power supply input (XE3)

RS485 serial comms output port (XE2) includes

9V output

RS485 serial comms input port (XE1)

12V output (XE4): three pairs of output terminals

CellSure Installation Guide

8

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

Chapter 2

Preparation

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

9

C h a p t e r 2

Preparation

Overview

Topic Page

Warnings 10

Inspecting the Equipment and Reporting Damage 11

Battery System Types 11

Location and Environment 11

CellSure Installation Guide

10

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

Warnings

^

Batteries

The plastic cases of batteries installed in Eaton dc power system racks must have a

flammability rating of UL 94-V2 or better.

Flooded cell and VRLA lead acid batteries can emit explosive gases and must be installed with

adequate ventilation. Refer to the battery manufacturer or supplier for advice on minimum

ventilation levels.

Do not wear a synthetic dust-coat or overalls. Synthetic fabrics can hold static electric charges

that create sparks during discharge.

Remove rings, wristwatch and other metal jewelry that might be exposed to battery terminals,

before installing batteries.

Batteries are powerful sources of energy and present a potential electrical shock and energy

hazard. The energy hazard is always present, even if the batteries are not connected. Avoid

short circuiting terminals of opposite polarity.

Always use insulated tools.

Do not place tools, loose cables or metal objects (such as interconnecting bars) on top of

batteries.

Do not drop tools, loose cables or metal objects onto intercell connections or terminals of

opposite polarity.

Only terminate cables and interconnecting bars after confirming that the termination will not

create a short circuit.

Always tighten battery terminal bolts according to the battery manufacturers specification.

Failing to do so can cause erratic battery performance, possible damage to the battery, and/or

personal injury.

There is a risk of electric shock if a battery is replaced by an incorrect type.

Dispose of batteries according to the instructions.

^

EMC Compliance

This Eaton product ("the equipment") has been tested and found to comply with the limits for a

Class B digital device, pursuant to part 15 of the Federal Communications Commission (FCC)

Rules. These limits are designed to provide reasonable protection against harmful interference

in a residential installation.

The equipment generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instructions in this installation guide, may cause harmful

interference to radio communications. However, there is no guarantee that the interference will

not occur in a particular installation.

If the equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to which the receiver

is connected.

Consult the dealer or an experienced radio/TV technician for help.

Changes or modifications to the equipment not approved by Eaton Corporation could void the

FCC authority to operate the equipment.

Preparation

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

11

^

Maximum Cable Lengths

EMC compliance is conditional on limiting the maximum length of the interconnecting cables

connected to the following ports:

CBC port XB4 (RS232) < 3m (9.8 feet)

CBC ports XB5, XB6 and XB7 < 10m (32.8 feet)

C6M/C12M ports XB20, XB22 and XB23 < 10m (32.8 feet)

Inspecting the Equipment and Reporting Damage

Unpack the equipment and inspect it carefully for possible damage that may have occurred

while in transit. Do not use any damaged equipment.

Report any damage immediately, using a completed Equipment Incident Report on page 98.

Keep the original packaging to use if any item needs to be returned for replacement or repair.

Battery System Types

CellSure provides real-time monitoring and fault prediction for both 24V and 48V battery

systems.

A single CellSure battery controller module can monitor up to four battery strings. Battery

strings can consist of 2V cells, 6V monoblocs or 12V monoblocs.

CellSure is not suitable for UPS or nickel-cadmium battery systems.

Location and Environment

CellSure is for use with 24V or 48V battery systems in telecommunication and other

applications.

CBC, APM, C6M and C12M modules must not be mounted in a location accessible to

operators. To maintain compliance with the applicable EMC and Safety standards, CBC,

APM, C6M and C12M modules can be mounted:

Inside an enclosed 19-inch cabinet

Inside a wall mounted enclosure

CellSure may be used in close proximity to other electronic equipment, provided the

installation is performed according to the instructions in this guide. However, CellSure may

still cause interference to other equipment or show performance degradation in the presence

of EM disturbances. In some cases, corrective action may be required. If you experience any

problems contact Eaton for advice. See Worldwide Support on page 101.

Always operate the CellSure modules within their rated ambient temperature range of

-10C to +70C (14F to 158F).

The CellSure algorithms provide accurate results within their rated ambient temperature

range of +10C to +40C (50F to 104F). Outside that range, the results may be less

accurate.

CellSure Installation Guide

12

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

Chapter 3

Current Shunts/Sensors

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

13

C h a p t e r 3

Current Shunts/Sensors

Overview

Topic Page

Mounting Current Shunts 14

Mounting CS04-A11 Current Sensors 14

CellSure Installation Guide

14

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

Mounting Current Shunts

If CS04-A11 current sensors are used then go to Mounting CS04-A11 Current Sensors on page

14.

Mount one current shunt per battery string on the common bus.

The recommended torque setting for tightening the M10 termination bolts is 18.7 - 21.9Nm

(166 - 194 inch-pounds).

Ensure correct orientation (see following diagram) of the current shunts before tightening the

termination bolts.

Common bar

To battery strings

Mounting CS04-A11 Current Sensors

If current sensors are used then go to Mounting Current Shunts on page 14.

Using the CS04 Current Sensor Extension PCB

The CS04 current sensor extension PCB increases the distance between the two pickup points

of the CS04-A11 current sensor. Use the CS04 current sensor extension PCB if:

measuring current flow in very large bus bars, or

the required gain of the current sensor is greater than 40.

Current Sensor Preparation

Step 1 Calculate the required gain of the CS04 current sensor

Gain = - Constant x (CSA / IMAX)

Where: CSA = Cross sectional area of the bus bar (mm)

IMAX = Maximum expected current through the bus bar (A)

Constant = 68.24V.W

-1

.mm-

2

(for copper bus bars)

= 43.57V.W

-1.

mm-

2

(for aluminum bus bars)

Current Shunts/Sensors

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

15

Step 2 Determine the need for a CS04 current sensor extension PCB

If the required gain of the current sensor is greater than 40, then calculate the new

required gain of the current sensor as follows:

Gain = - Constant x (CSA / IMAX) x (51/150)

And use the CS04 current sensor extension PCB.

Step 3 Resistance measurement

Measure the resistance of

the inductor located at the

back of the CS04 current

sensor PCB as shown.

Step 4 Set the gain range of the CS04 current sensor

The gain range of the CS04 current sensor depends on:

The required gain, as calculated in step 1 or step 2

The resistance value of the input inductor, as measured in step 3

1 Select the required gain range and jumper configuration for the CS04 current

sensor from the following table.

2 Connect the jumper(s) according to the selected jumper configuration.

CellSure Installation Guide

16

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

Gain Range for input inductor resistance values of

90W 110W 120W

Jumper Configuration

16 21 13 18 12 16

19 29 16 24 15 22

27 52 22 42 20 39

38 132 31 108 29 99

40 160 33 130 30 120

The jumper connection points are located on the back of the CS04-A11 current sensor PCB.

To obtain the required jumper configuration, you might have to break the track between

connection points 1 and 3 and solder additional jumpers between connection points.

Step 5 Apply heat sink compound as shown

Input inductor

Heat sink compound to ensure good thermal

contact between the input inductor and the busbar.

Procedure complete

Mounting the CS04-A11

The CS04-A11 is supplied with M3x35mm screws to attach the CS04-A11 current sensor to a

bus bar.

This section covers the following mounting options:

Through-hole mounting

Threaded-hole mounting

Current Shunts/Sensors

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

17

Step 1 CS04-A11 placement and orientation

CS04-A11 current sensors must always be mounted onto the Common bus bar. (See

following diagram.)

Wherever possible, do not mount the CS04-A11 current sensor closer than 150mm

(6") from:

A bus bar joint

Termination bolts

Bolts joining laminated bus bars

Ensure correct orientation of the CS04-A11 current sensor before drilling the

mounting holes into the bus bar. (See following diagram.)

Common bus

To battery

To rectifiers

Step 2 Drill the mounting holes

Drill two mounting holes according to the template below and tap if the threaded-

hole mounting option is used.

Through-hole Threaded-hole

Drill size M3.5 M2.5

Thread size and

pitch

- M3 x 0.5 ISO

Coarse

CellSure Installation Guide

18

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

Step 3A Mounting a CS04-A11 through-hole mounting option

Mount the CS04-A11 current sensor as shown in the following diagrams.

Ensure correct orientation of the CS04-A11 (see Step 1 for details).

Without Extension PCB With Extension PCB

Step 3B Mounting a CS04-A11 threaded-hole mounting option

Mount the CS04-A11 current sensor as shown in the following diagrams.

Ensure correct orientation of the CS04-A11 (see Step 1 for details).

Without Extension PCB With Extension PCB

Procedure complete

Chapter 4

2V System Installation

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

19

C h a p t e r 4

2V SystemInstallation

Overview

Topic Page

Task 1 - Mounting the Q.C. Tabs 20

Task 2 - Mounting the CBC and APM Modules 21

Task 3 - Mounting the C2M-TS and C2M Modules 21

Task 4 - Mounting the Ambient Temperature Sensor 22

Task 5 - Numbering the Monoblocs 22

Task 6 - Installing the Interconnecting Wiring 23

Task 7 - Installing the Urgent and Non-urgent Alarm Relay Cabling 28

Task 8 - Powering the CBC 29

CellSure Installation Guide

20

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

See instructions on page 32 for installation of 6V/12V battery system modules.

Task 1 - Mounting the Q.C. Tabs

Step 1 - Mount Q.C. tabs

^

Always tighten battery terminal bolts according to the battery manufacturers

specification. Failing to do so can cause erratic battery performance, possible

damage to the battery or personal injury.

Mount a Q.C. tab onto

each battery terminal

Step 2 Ensure that equalizing bars are fitted

Equalizing bars must be fitted as shown in the example below, to allow accurate

monobloc voltage measurement.

Inter-cell bars

Equalizing bars

Procedure complete

2V System Installation

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

21

Task 2 - Mounting the CBC and APM Modules

CellSure modules mount on standard DIN rail.

Place the lower clip of the module under

the bottom of the rail.

Move in top of the module until it clicks into

position on the rail.

To remove, push module up and pull top

forwards away from rail.

It is recommended that the modules are mounted in their numbered sequence and in a

location that is not accessible to operators.

Task 3 - Mounting the C2M-TS and C2M Modules

Step 1 - Mount the C2M-TS module

1 Install only one C2M-TS module per battery string.

The C2M-TS can be installed on any monobloc in the battery string. However,

we recommend installing the C2M-TS module on the battery monobloc

connected to the live bus bar.

2 Push the TSCM temperature sensor onto the Q.C. tab of the negative battery

terminal as shown in the following diagram. This ensures direct thermal

contact with the internals of the battery.

If space constraints prevent connecting the TCSM directly onto the negative

terminal, attach the TSCM to any other appropriate place close to the negative

terminal.

3 Attach the C2M-TS sensor module to the side of the monobloc as shown or any

other appropriate place such as the battery support framework.

TSCM temperature sensor

CellSure Installation Guide

22

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

Step 2 - Mount the C2M sensor modules

Attach a C2M sensor module to the side of each monobloc (as shown) or to any

other appropriate place, such as the battery support framework.

Procedure complete

Task 4 - Mounting the Ambient Temperature Sensor

Mount the temperature sensor at a convenient location to measure the ambient temperature

of the battery.

Task 5 - Numbering the Monoblocs

Step 1 - Locate the monobloc connected to the common bus bar

Step 2 - Number the monoblocs

Numbering must start at the monobloc connected to the common bus bar and end

at the monobloc connected to the live bus bar.

The following diagram is an example of numbering the monoblocs of a battery

string, in this case battery string 1.

2V System Installation

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

23

Connection to common busbar

Connection to live busbar

Step 3 - Repeat these steps for each battery string

Procedure complete

Task 6 - Installing the Interconnecting Wiring

^

Compliance with EMC immunity standards is conditional on limiting the length of the

interconnecting cables, connected to the following ports:

CBC port XB4 < 3m (9.8 feet)

CBC ports XB5, XB6 and XB7 < 10m (32.8 feet)

Use the following table to select the appropriate interconnection diagram for your battery

system and interconnect the CellSure modules accordingly.

Number of strings See

1 Diagram on page 24

2 Diagram on page 25

3 Diagram on page 26

4 Diagram on page 27

CellSure Installation Guide

24

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

Single String Battery Systems

Use this interconnection diagram (in conjunction with the layout diagram on page 28) for

single string battery systems with 2V cells.

Battery string 1

Live bus bar

Common bus bar

VF1 or VF2 (common) voltage feed module.

Must be connected for accurate current readings.

Always connect the black wire to "common".

Battery ambient temperature sensor

CBC. For other connections:

RS485 comms:

- see Powering the CBC on page 29

- see Setup External Communications on page 67.

RS232 comms:

- see Connecting a PC to the CBC on page 46

- see Setup External Communications on page 67.

Alarm relays - see details on page 28.

2V System Installation

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

25

Two String Battery Systems

Use this interconnection diagram (in conjunction with the layout diagram on page 28) for

two-string battery systems with 2V cells.

Battery string 1

Live bus bar

Common bus bar

VF1 or VF2 (common) voltage feed module.

Must be connected for accurate current readings.

Always connect the black wire to "common".

Battery ambient temperature sensor

CBC. For other connections:

RS485 comms:

- see Powering the CBC on page 29

- see Setup External Communications on page 67.

RS232 comms:

- see Connecting a PC to the CBC on page 46

- see Setup External Communications on page 67.

Alarm relays - see details on page 28.

CellSure Installation Guide

26

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

Three String Battery Systems

Use this interconnection diagram (in conjunction with the layout diagram on page 28) for

three-string battery systems with 2V cells.

Battery strings 1, 2 and 3

Live bus bar

Common bus bar

VF1 or VF2 (common) voltage feed module.

Must be connected for accurate current readings.

Always connect the black wire to "common".

Battery ambient temperature sensor

CBC. For other connections:

RS485 comms:

- see Powering the CBC on page 29

- see Setup External Communications on page 67.

RS232 comms:

- see Connecting a PC to the CBC on page 46

- see Setup External Communications on page 67.

Alarm relays - see details on page 28.

2V System Installation

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

27

Four String Battery Systems

Use this interconnection diagram (in conjunction with the layout diagram on page 28) for

four-string battery systems with 2V cells.

Battery strings 1, 2, 3 and 4

Live bus bar

Common bus bar

VF1 or VF2 (common) voltage feed module.

Must be connected for accurate current readings.

Always connect the black wire to "common".

Battery ambient temperature sensor

CBC. For other connections:

RS485 comms/power:

- see Powering the CBC on page 29

- see Setup External Communications on page 67.

RS232 comms

- see Connecting a PC to the CBC on page 46

- see Setup External Communications on page 67.

Alarm relays - see details on page 28

CellSure Installation Guide

28

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

How to connect CellSure modules to monoblocs

Use the following diagram to connect:

the C2M modules to the cells

the communication wiring between the C2M modules, and to the CBC

CellSure Battery Controller (CBC) connected to

C2m on cell 1

TSCM on cell 24

Task 7 - Installing the Urgent and Non-urgent Alarm Relay Cabling

The CellSure Battery Controller (CBC) has an Urgent and a Non-urgent alarm relay with the

following specifications and connector pin assignments.

Relay Outputs

Contact Arrangement One changeover contact per relay

Maximum Switching Voltage 60V dc

30V ac

Maximum Switching Current 500mA

Maximum Continuous Current 500mA

Maximum Power Rating 30W (dc Voltage)

15VA (ac Voltage)

Maximum Cable Size 1.5mm

States and Conditions

Active State Energized or de-energized

State during CBC Start-up De-energized

On Condition Urgent Alarm Relay Any urgent alarm active

On Condition Non-urgent Alarm Relay Any Non-urgent alarm active

Off Condition Urgent Alarm Relay No urgent alarm active

Off Condition Non-urgent Alarm Relay No Non-urgent alarm active

2V System Installation

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

29

Connector Pin Assignment

Task 8 - Powering the CBC

There are two options for powering the CBC:

Power the CBC from the system dc bus

For all installations except SM65-based Eaton dc power systems, use an Auxiliary Power

Module (APM) to power the CBC from the system dc bus.

Power the CBC from the SM65 RCP bus

Use this option only when installing CellSure with an SM65-based Eaton dc power

system.

Powering the CBC from the system dc bus

Power the CBC as shown in the wiring following diagram. Over-current protection of the

APM power cable is required to prevent excessive current flow during accidental short-

circuit conditions.

Common bus

Live bus

Over-current protection*.

Auxiliary Power module (APM)

CellSure battery Controller (CBC)

* Use an Eaton Voltage Feed Module or a 2A (maximum) fuse or MCB (for Live feed only).

CellSure Installation Guide

30

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

Powering the CBC from the SM65 RCP bus

Power the CBC from the rack communications port (XS11) of the SM65 supervisory module.

The same cable provides the communications link from the SM65 to the CBC.

For details refer to the relevant section of the SM65 supervisory module handbook. See

Related Information on page ii.

It may be necessary to use an Auxiliary Power Module (APM) to power the CBC depending

on the number and type of other devices connected to the RS485 (RCP) bus. See RS485 Bus

Power Limit Calculations on page 89.

Chapter 5

6V/12V System Installation

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

31

C h a p t e r 5

6V/12V SystemInstallation

Overview

Topic Page

Task 1- Mounting the Q.C. Tabs 32

Task 2 - Mounting the C6M/C12M, CBC and APM Modules 32

Task 3 - Mounting the TS8CM and SP8CM Modules 33

Task 4 - Mounting the Ambient Temperature Sensor 34

Task 5 - Numbering the Monoblocs 34

Task 6 - Installing the Interconnecting Wiring 35

Task 7 - Installing the Urgent and Non-urgent Alarm Relay Cabling 42

Task 8 - Powering the C6M/C12M Sensor Modules 43

Task 9 - Powering the CBC 43

CellSure Installation Guide

32

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

See instructions on page 20 for installation of 2V battery system modules.

Task 1- Mounting the Q.C. Tabs

Step 1 - Mount Q.C. tabs

^

Always tighten battery terminal bolts according to the battery manufacturers

specification. Failing to do so can cause erratic battery performance, possible

damage to the battery or personal injury.

Mount a Q.C. tab onto

each battery terminal

Procedure complete

Task 2 - Mounting the C6M/C12M, CBC and APM Modules

CellSure modules mount on standard DIN rail.

Place the lower clip of the module under

the bottom of the rail.

Move in top of the module until it clicks into

position on the rail.

To remove, push module up and pull top

forwards away from rail.

It is recommended that the modules are mounted in their numbered sequence and in a location

that is not accessible to operators.

6V/12V System Installation

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

33

Task 3 - Mounting the TS8CM and SP8CM Modules

Step 1 Mount the TS8CM temperature sensor

1 Install only one TS8CM temperature sensor per battery string.

The TS8CM can be installed on any monobloc in the battery string. However,

we recommend installing the TS8CM module on the battery monobloc connected

to the live bus bar.

2 Push the TS8CM onto the Q.C. tab of the negative battery terminal as in the

following diagram. This ensures direct thermal contact with the internals of

the battery.

If space constraints prevent connecting the TS8CM directly onto the negative

terminal, attach the TS8CM to any other appropriate place close to the negative

terminal.

TS8CM temperature sensor

CellSure Installation Guide

34

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

Step 2 Mount the SP8CM short-circuit protection modules

Push the SP8CM modules onto the Q.C. tabs of the battery terminals as shown.

If space constraints prevent connecting the SP8CM modules directly onto the battery

terminals, attach the SP8CM modules to any other appropriate place close to the

battery terminals.

TS8CM temperature sensor

SP8CM short-circuit protection module

Procedure complete

Task 4 - Mounting the Ambient Temperature Sensor

Mount the temperature sensor at a convenient location to measure the ambient temperature

of the battery.

Task 5 - Numbering the Monoblocs

Step 1 - Locate the battery monobloc connected to the common bus bar

Step 2 - Number the battery blocs

Numbering must start at the battery monobloc connected to the common bus bar

and end at the battery monobloc connected to the live bus bar.

6V/12V System Installation

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

35

Step 3 - Repeat these steps for each battery string

Procedure complete

Task 6 - Installing the Interconnecting Wiring

^

Compliance with EMC immunity standards is conditional on limiting the length of the

interconnecting cables, connected to the following ports:

CBC port XB4 < 3m (9.8 feet)

CBC ports XB5, XB6 and XB7 < 10m (32.8 feet)

C6M/C12M ports XB20, XB22 and XB23 < 10m (32.8 feet)

Use the following table to select the appropriate interconnection diagram for your battery

system and interconnect the CellSure modules accordingly.

48V Battery Systems consisting of

1 to 2 strings See the diagram on page 36

6V monoblocs and

3 to 4 strings See the diagram on page 37

12V monoblocs and 1 to 4 strings See the diagram on page 38

24V Battery Systems consisting of

6V monoblocs and 1 to 4 strings See the diagram on page 39

12V monoblocs and 1 to 4 strings See the diagram on page 40

CellSure Installation Guide

36

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

48V Battery Systems consisting of 6V Monoblocs and 1 to 2 Strings

Use this interconnection diagram (in conjunction with the layout diagram on page 41) to

connect CellSure to a 48V battery system consisting of 6V monoblocs and 1 to 2 strings.

Battery strings 1 and 2

Live bus bar

Common bus bar

VF1 or VF2 (common) voltage feed module

Battery ambient temperature sensor

CBC. For other connections:

RS485 comms:

- see Powering the CBC on page 43

- see Setup External Communications on page 67.

RS232 comms:

- see Connecting a PC to the CBC on page 46

- see Setup External Communications on page 67.

Alarm relays - see details on page 42.

6V/12V System Installation

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

37

48V Battery Systems consisting of 6V Monoblocs and 3 to 4 Strings

Use this interconnection diagram (in conjunction with the layout diagram on page 41) to

connect CellSure to a 48V battery system consisting of 6V monoblocs and 3 to 4 strings.

Battery strings 1, 2, 3 and 4

Live bus bar

Common bus bar

VF1 or VF2 (common) voltage feed module

Battery ambient temperature sensor

CBC. For other connections:

RS485 comms:

- see Powering the CBC on page 43

- see Setup External Communications on page 67.

RS232 comms:

- see Connecting a PC to the CBC on page 46

- see Setup External Communications on page 67.

Alarm relays - see details on page 42.

CellSure Installation Guide

38

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

48V Battery Systems consisting of 12V Monoblocs and 1 to 4 Strings

Use this interconnection diagram (in conjunction with the layout diagram on page 41) to

connect CellSure to a 48V battery system consisting of 12V monoblocs and 1 to 4 strings.

Battery strings 1, 2, 3 and 4

Live bus bar

Common bus bar

VF1 or VF2 (common) voltage feed module

Battery ambient temperature sensor

CBC. For other connections:

RS485 comms:

- see Powering the CBC on page 43

- see Setup External Communications on page 67.

RS232 comms:

- see Connecting a PC to the CBC on page 46

- see Setup External Communications on page 67.

Alarm relays - see details on page 42.

6V/12V System Installation

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

39

24V Battery Systems consisting of 6V Monoblocs and 1 to 4 Strings

Use this interconnection diagram (in conjunction with the layout diagram on page 41) to

connect CellSure to a 24V battery system consisting of 6V monoblocs and 1 to 4 strings.

Battery strings 1, 2, 3 and 4

Live bus bar

Common bus bar

VF1 or VF2 (common) voltage feed module

Battery ambient temperature sensor

CBC. For other connections:

RS485 comms:

- see Powering the CBC on page 43

- see Setup External Communications on page 67.

RS232 comms:

- see Connecting a PC to the CBC on page 46

- see Setup External Communications on page 67.

Alarm relays - see details on page 42.

CellSure Installation Guide

40

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

24V Battery Systems consisting of 12V Monoblocs and 1 to 4 Strings

Use this interconnection diagram (in conjunction with the layout diagram on page 41) to

connect CellSure to a 24V battery system consisting of 12V monoblocs and 1 to 4 strings.

Battery strings 1, 2, 3 and 4

Live bus bar

Common bus bar

VF1 or VF2 (common) voltage feed module

Battery ambient temperature sensor

CBC. For other connections:

RS485 comms:

- see Powering the CBC on page 43

- see Setup External Communications on page 67.

RS232 comms:

- see Connecting a PC to the CBC on page 46

- see Setup External Communications on page 67.

Alarm relays - see details on page 42.

6V/12V System Installation

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

41

How to interconnect monoblocs, TS8CM, SP8CM and C6M/C12M

modules

Use the following diagram to connect:

TS8CM and SP8CM modules to monoblocs

The wiring between TS8CM and C6M/C12M and SP8CM and C6M/C12M modules in

two battery strings.

String 1

C6M or C12M sensor module

String 2

SP8CM short circuit protection modules

TS8CM temperature sensor modules

CellSure Installation Guide

42

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

Task 7 - Installing the Urgent and Non-urgent Alarm Relay Cabling

The CellSure Battery Controller (CBC) has an Urgent and a Non-urgent alarm relay with the

following specifications and connector pin assignments.

Relay Outputs

Contact Arrangement One changeover contact per relay

Maximum Switching Voltage 60V dc

30V ac

Maximum Switching Current 500mA

Maximum Continuous Current 500mA

Maximum Power Rating 30W (dc Voltage)

15VA (ac Voltage)

Maximum Cable Size 1.5mm

States and Conditions

Active State Energized or de-energized

State during CBC Start-up De-energized

On Condition Urgent Alarm Relay Any urgent alarm active

On Condition Non-urgent Alarm Relay Any Non-urgent alarm active

Off Condition Urgent Alarm Relay No urgent alarm active

Off Condition Non-urgent Alarm Relay No Non-urgent alarm active

Connector Pin Assignment

6V/12V System Installation

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

43

Task 8 - Powering the C6M/C12M Sensor Modules

C6M/C12M sensor modules are powered from the system dc bus. Over-current protection of

the C6M/C12M power cable is required to prevent excessive current flow during accidental

short-circuit conditions.

Use the following diagram to connect power to a C6M/C12M sensor module.

Common bus

Live bus

Over-current protection*.

C6M or C12M sensor module

* Use an Eaton Voltage Feed Module or a 2A (maximum) fuse or MCB (for Live feed only).

Task 9 - Powering the CBC

There are two options for powering the CBC:

Power the CBC from the system dc bus

For all installations except SM65-based Eaton dc power systems, use an Auxiliary Power

Module (APM) to power the CBC from the system dc bus.

Power the CBC from the SM65 RCP bus

Use this option only when installing CellSure with an SM65-based Eaton dc power

system.

CellSure Installation Guide

44

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

Powering the CBC from the system dc bus

Power the CBC as shown in the wiring following diagram. Over-current protection of the

APM power cable is required to prevent excessive current flow during accidental short-

circuit conditions.

Common bus

Live bus

Over-current protection*.

Auxiliary Power module (APM)

CellSure battery Controller (CBC)

* Use an Eaton Voltage Feed Module or a 2A (maximum) fuse or MCB (for Live feed only).

Powering the CBC from the SM65 RCP bus

Power the CBC from the rack communications port (XS11) of the SM65 supervisory module.

The same cable provides the communications link from the SM65 to the CBC.

For details refer to the relevant section of the SM65 supervisory module handbook. See

Related Information on page ii.

It may be necessary to use an Auxiliary Power Module (APM) to power the CBC depending

on the number and type of other devices connected to the RS485 (RCP) bus. See RS485 Bus

Power Limit Calculations on page 89.

Chapter 6

Commissioning

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

45

C h a p t e r 6

Commissioning

Overview

Topic Page

Task 1 - Connecting a PC to the CBC 46

Task 2 - Configure the Hardware and Battery Settings 48

Task 3 - Check Monobloc Numbering 49

Task 4 - Check Temperature Sensors 50

Task 5 - Calibrate Current Shunts/Sensors 52

Task 6 - Characterize the Batteries 55

Task 7 - Using the Characterization Data 62

Task 8 - Configure the CellSure System for Operation 64

Task 9 - Repeat for Other CBCs (if required) 67

Task 10 - Setup External Communications 67

CellSure Installation Guide

46

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

Task 1 - Connecting a PC to the CBC

Step 1 Check that the CBC is powered

Green status LED on the CBC is on.

If not see Troubleshooting on page 78.

Step 2 - Install the DCTools software

Download DCTools from www.powerquality.eaton.com/downloads and install.

Step 3 Connect the null-modem cable (supplied)

Connect from the CBC RS232 socket (XB4) to a serial port (COM1 or COM2) on the

PC/laptop.

Step 4 Start DCTools

Double-click on the DCTools icon to display the DCTools Connection List.

Step 5 Check that the PC port is specified correctly

Check the Comms Properties column for the COM port to be used. Settings must be:

COM1 (or COM2 as appropriate); S3P Addr: 0

To change, right-click the name and select Properties.

Step 6 Enable the connection

Select

:

the connection check box. The CellSure Battery Monitoring System

Summary screen is displayed.

If the connection is unsuccessful, the message TPC Session Failed: Connection

Error 201 will appear in the Status column. For more information see

Troubleshooting on page 78.

Procedure complete

Commissioning

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

47

General Notes on Editing the CellSure Configuration

Each CellSure battery management system is supplied with a pre-programmed default

configuration file.

The default configuration file can be re-configured on-site for the specific battery system

using DCTools.

General Notes on Using DCTools

DCTools is an easy-to-use software tool for:

Monitoring CellSure alarms and discharges

Diagnosing CellSure installation faults and identifying battery failures

Changing CellSure configuration values

You can connect only to one CellSure battery-management system at a time. For continuous

remote management, use PowerManagerII.

Other very useful buttons and controls are described in the table below.

Buttons and Controls Description

Changes to the configuration file are held and

are not downloaded to the CBC.

Downloads changes to the configuration file to

the CBC.

Most editable items will reset the CBC.

Select a battery string position to display the

graph of that string.

Highlight a specific graph.

Zoom in and out on all graphs.

CellSure Installation Guide

48

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

Task 2 - Configure the Hardware and Battery Settings

Step 1 - Edit Hardware and Battery Setup

1 In DCTools, click Configuration to display the CBC Configuration view.

2 Under Hardware and Battery Setup, edit the following fields to match the

battery system:

Operator Notes (text)

Installer Notes (text)

Monobloc Type (text)

System Polarity

Number Of Strings

Monoblocs Per String

Monobloc Voltage

Do not configure any other configuration parameters at this stage.

Step 2 - Return to Summary view

Click Summary to return to the Summary view.

Procedure complete

Commissioning

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

49

Task 3 - Check Monobloc Numbering

Step 1 Disconnect one voltage sense wire from monobloc 2 of string 1

At battery string 1 disconnect a voltage sense wire from monobloc 2.

Step 2 Check the monobloc voltages in DCTools

1 In DCTools, click Realtime.

2 Check that the monobloc voltage of monobloc 1 is displayed. (If not, see

Troubleshooting on page 78.)

After removing the voltage sense wire from monobloc 2, expect a 30-second delay

before DCTools displays the monobloc voltage.

2V Systems 6V/12V Systems

Step 3 Repeat these steps for the remaining strings

Procedure complete

CellSure Installation Guide

50

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

Task 4 - Check Temperature Sensors

Step 1 Check string temperatures in DCTools

In DCTools, click Realtime and check that the string temperatures are correct. If not,

see Troubleshooting on page 78.

Commissioning

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

51

Step 2 Check that the ambient and string temperatures are similar

Click Summary and check that the ambient temperature is correct. If not see

Troubleshooting on page 78.)

Procedure complete

CellSure Installation Guide

52

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

Task 5 - Calibrate Current Shunts/Sensors

Step 1 Configure the Current Shunt Scaling in DCTools

1 Determine the correct scale factor from the following list:

CS03 3A/mV

CS300 6A/mV

CS02 10A/mV

CS600 12A/mV

CS04-A11 Maximum Current per String (A)/60mV

2 In DCTools, click Configuration.

3 Enter the current shunt scale factor in the Current Shunt Scaling field.

Step 2 Enable Current metering

Commissioning

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

53

Step 3 Connect a test load

1 Select a suitable calibration current.

For the highest measurement accuracy select a calibration current as close as

possible to the maximum current to be measured per battery string.

2 Disconnect the battery string from the LIVE bus.

Do NOT disconnect the current sensor/shunt from the COMMON bus.

3 Connect a test load to that battery string.

Do not switch on the load at this stage.

4 Attach a high accuracy clamp-on dc ammeter around the battery cable.

Step 4 Switch on the load

1 In DCTools, click Realtime to view the string current.

2 Switch on the load. Ensure that a negative current is shown on both the clamp-

on dc ammeter and the laptop PC display, indicating current flow out of the

batteries (discharge).

If a positive current is displayed, then the orientation of the current shunt/sensor

is incorrect. For correct orientation and mounting see Current Shunts/Sensors

on page 13.

3 All current shunts/sensors must be fitted the same way around.

CellSure Installation Guide

54

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

Step 5 Adjust the calibration potentiometer on the current shunt/sensor

1 If there is significant difference between the current readings in DCTools and on

the clamp-on dc ammeter then adjust the calibration potentiometer on the

current shunt (see details on page 5) or sensor (see details on page 14).

2 If you run out of adjustment range when calibrating a CS04-A11 current sensor,

do the following:

Ensure that the gain range is set correctly (see details on page 14).

Change the current shunt scale factor in DCTools.

Changing the current scale factor in DCTools is no substitute for an incorrect

gain range setting on the CS04-A11 current sensor.

3 Switch off then disconnect the test load from the battery string.

Step 6 Set the Current Shunt Offset for each string

1 Use a clamp-on dc ammeter to confirm that there is no current flow through

the current shunt/sensor.

2 In DCTools, click on Realtime.

3 Scroll to the bottom of the Realtime values screen and click

"

to the left of

Current Shunt Adjustment to view a table of the Raw String Current and

Current Shunt Offset for each battery string fitted.

4 If Raw String Current is approximately 0.0A then no change is needed. Go to the

next step.

5 If Raw String Current is not approximately 0.0A then ensure that the

Current Shunt Offset is 0. If not, set it to 0 and click Apply Changes.

6 Double-click on the Current Shunt Offset field and change its value to be the

opposite of the Raw String Current value. Press Enter.

For example, if the Raw String Current equals 7.6A, enter 7.6A in the

Current Shunt Offset field.

7 Click Apply Changes. The offset will now take effect and the Raw String Current

will show 0.0A.

The value may not be exactly zero because there is usually a small amount of

noise present at the current shunt/sensor input.

8 Recheck the current reading by passing a known current through the current

shunt/sensor and adjust the calibration potentiometer, if required. See Step 3

and Step 4.

Step 7 Reconnect the battery string to the system dc bus

Commissioning

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

55

Step 8 Repeat steps 3 to 6 for the remaining battery strings

Do NOT change the current scale factor in DCTools after the first current

shunt/sensor has been calibrated correctly. There is only one current scale factor for

all shunts/sensors used. The remaining current shunts/sensors must be calibrated

accordingly.

Step 9 Fully recharge all batteries after calibration

Procedure Complete

Task 6 - Characterize the Batteries

Characterization data management

DCTools has a Characterization Data Management feature that enables characterization data

to be copied for other strings of the same type and size. This can reduce the time needed to

characterize batteries. For details see Data Management on page 93.

Before you start

Ensure that the batteries are fully charged.

Disable the LVD (if fitted) or reduce its disconnect voltage below the Monobloc End

Voltage.

CellSure Installation Guide

56

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

Step 1 Configure the Discharge Conditions in DCTools

1 Click on Configuration to display the CBC Configuration view.

2 Edit the Discharge Conditions parameters using the following configuration

guidelines.

Parameter Configuration Guidelines

Bloc End Voltage Select the appropriate end voltage in Vpc (Volt per cell) from the battery

manufacturers specification.

This is normally 1.8Vpc. For example, the monobloc end voltage of a

12V monobloc, assuming an end voltage of 1.8Vpc, is 1.8 Vpc x 6 =

10.8V or 10800mV.

Rated Bloc

Capacity

Determine the Rated Monobloc Capacity for the characterization

discharge from the battery manufacturers specification. Ensure that the

Rated Monobloc Capacity relates to the expected discharge rate.

Discharge Rate Determine the Discharge Rate from the discharge time and the discharge

current according to the battery manufacturers discharge tables.

If the average discharge current at the end of a battery discharge is

outside the range, defined by the Discharge Rate Discharge Rate

Tolerance, the battery characterization will fail.

Discharge Rate

Tolerance

Set to 25%. The Discharge Rate Tolerance can be reduced, once the

behavior of the batteries is known.

Commissioning

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

57

Parameter Configuration Guidelines

Discharge Temp Controlled Discharges

(such as an offline discharge in an air-conditioned room)

Set Discharge Temp equal to the ambient temperature of the battery.

Uncontrolled Discharges

(such as an offline discharge in a non-air conditioned room or an

ac supply outage)

Set Discharge Temp 5-10C higher than the ambient temperature of

the battery. The ambient temperature of the battery will rise during a

discharge test because of heat dissipated by the load into the

surrounding atmosphere. The internal temperature of the batteries

will also rise during the discharge.

If the average temperature at the end of a battery discharge is outside the

range, defined by the Discharge Temp Discharge Temp Tolerance, the

battery characterization will fail.

Discharge Temp

Tolerance

Set to 15C. The Discharge Rate Tolerance can be reduced, once the

behavior of the batteries and the environment is known.

Partial Discharge

Depth

Set to 30%.

Minimum

Recharge Time

Set to zero. A full discharge is only valid, after recharging the batteries

for the configured minimum recharge time. By setting the Minimum

Recharge Time to zero, a battery characterization can be performed

immediately.

The parameters Reserve Time Low Urgent Threshold and Reserve Time Low NonUrgent

Threshold are alarm settings and are not used at this stage.

CellSure Installation Guide

58

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

Step 2 Set the date and time in DCTools

The CBC has no battery back-up real-time clock. Every time the CBC resets or the

configuration file changes, date and time return to 01/01/70 00:00:00.

If the CBC is connected to an SM45 or SM65, date and time of the CBC will be

updated to that of the SM45 or SM65.

To set the date and time in DCTools, follow the following steps.

1 Click Apply Changes and wait for the CellSure system to reset.

2 Click Summary then edit the date and time in the Values view.

3 Click Apply Changes. The CBC resets and the new date and time is displayed.

Step 3 Enable data logging (optional)

This is an optional step and does not affect the outcome of the battery

characterization. Logging the CBC data during a discharge can be useful for

troubleshooting or for later analysis.

Do NOT open the data log file during the active logging process, as this will prevent

the logs from being updated. If you need to edit or review the data log file, you must

first create a copy. Open this copy to do any editing or reviewing of the data log file.

To enable data logging:

1 Click PC Log to display the Data Log view.

2 Click to display the Save As dialog.

3 Select a file location and save the CBC Data Log file.

4 Select and set the data log time interval.

The recommended setting is 30 seconds.

5 Click Start. The data logging process starts and data is saved in the data log file

specified in 3.

This data log differs from the data log stored in the CBC.

Commissioning

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

59

Step 4 Check the Running string status field in DCTools

1 From the Available Forms panel, select Realtime to display the Realtime

values view.

2 If the Running string status field is set to false (-), then go to the next step.

3 If the Running string status field is true (

v

):

Disconnect then reconnect power from the CBC, to reset it.

Wait approximately 5 minutes, then check that the Running string status

field is false (-).

Set the date and time (see Step 2 for details).

Step 5 Discharge the batteries

Instead of discharging one string at a time, it is possible to discharge all strings into

the telecommunications load, if permitted under your regulations.

A completed discharge characterization and a further 30% discharge are required

before both Battery Estimated Capacity and Battery State of Health will show

realistic values.

1 Disconnect the battery string from the system dc bus.

2 Connect the load to the battery string(s) under test.

3 Switch on the load.

CellSure Installation Guide

60

Copyright 2001- 2009 Eaton Corporation. All Rights Reserved.

IPN 997-00012-20F J uly 2009

4 In DCTools click Realtime. Check the displayed string current corresponds to

the selected discharge current and that it is negative. If not, see Troubleshooting

on page 78.

5 Ensure that the string Running status field has changed to true (

v

).

There is a time delay (typically up to 1 minute) between switching on the load

and DCTools recognizing the start of a battery discharge.

6 Check that the individual monobloc voltages are in fact dropping.

It is recommended to switch between Trend Graph and Realtime in DCTools

during a discharge.