Beruflich Dokumente

Kultur Dokumente

Aspen Amine

Hochgeladen von

Govind ManglaniCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Aspen Amine

Hochgeladen von

Govind ManglaniCopyright:

Verfügbare Formate

Journal of Energy Technologies and Policy ISSN 2224-3232 (Pa er! ISSN 222"-#"$3 (%nline! &ol.3' No.

3' 2#(3

www.iiste.org

Optimization of Amine Base Process in the Removal of Carbon Dioxide from Natural Gas for LNG Production

)inigo*a'+.S. 2%sharode' ,.I. ('2 ,e art*ent of Petroleu* and -as Engineering' .aculty of Engineering' /ni0ersity of Port 1arcourt 2i0ers State' Nigeria

AB !RAC! 2e*o0al of 3%2 fro* natural gas is currently a glo4al issue' a art fro* *eeting the 3usto*er5s contract s ecifications and for successful li6uefaction rocess in 7N- ro8ect' It is also a *easure for reducing the glo4al 3%2 e*ission. This ro8ect resents a co* rehensi0e re0iew of different rocesses a0aila4le and suita4le for re*o0al of 3%2 fro* natural gas to *eet 7N- roduction s ecifications and technically e9 lores the ca a4ility of 1:S:S rocess si*ulator to redict the o ti*u* 3%2 re*o0al rocess o erating conditions range at which hydrocar4on and che*ical loss (a*ine sol0ent! can 4e *ini*i;ed. .oa*ing and corrosion challenges inherent in acid gas re*o0al rocesses and re0enti0e *easures are co0ered in great detail. < case study of a*ine 4ased 3%2 re*o0al rocess lant is used to create a steady-state si*ulation using 1y rotech 1:S:S 3.2 rocess si*ulator. The si*ulation rogra* de0elo ed is used to *odify the hysical' ther*odyna*ics and trans ort ro erties of the gas and the rocess units in0ol0ed to i* ro0e rocess en0iron*ental erfor*ance. The si*ulation results shows that increasing a*ine 3%2 ca turing ca acity at low te* erature and lowering the a*ine residence ti*e in the stri er' reduces the tendency for 3%2 e*ission and che*ical (sol0ent! loss. "e#$ords= o ti*i;ation' a*ine 4ase' natural gas' *erca tan car4ondio9ide' hy rotech si*ulator %&' (N!ROD)C!(ON The increase in de*and for energy worldwide has aided the search for alternati0e sources of ri*ary energy e0en to the re*otest art of the glo4e. The *a8or alternati0e source with less en0iron*ental i* act disco0ered so*e decade ago is energy fro* natural gas. Natural gas at its geological conditions in so*e de osits contain so*e co* le9 3onta*inants such as 3%2' 12S' 3%' >erca tan (<cid -as!' which constitute great En0iron*ental ha;ards when it gets to the at*os here and also hinders natural gas rocesses (2o4ert' 2##?!. Natural gas is of little 0alue unless it can 4e 4rought fro* the wellhead to the custo*ers' who *ay 4e se0eral thousand of @ilo*etres fro* the source. Natural gas is relati0ely low in energy content er unit 0olu*e' it is e9 ensi0e to trans ort. The *ost o ular way to *o0e gas fro* the source to the consu*er is through i elines. 1owe0er as trans ortation distance increases' i elines 4eco*e unecono*ical' 7i6uefied Natural -as (7N-!' -as to li6uid and che*icals are *ore 0ia4le o tions (3hang and 7ee' 2##$. <ccording to :oshitugi ((??$!. 7i6uefaction rocess which is the transfor*ation of natural gas to li6uid for* in0ol0e o eration at a 0ery low Te* erature (-(A(o3! and as low as at*os heric ressure. <t these conditions 3%2 can free;e out on e9changer surface' lugging lines and reduce lant efficiency. Therefore there is need for re*o0al of 3%2 4efore li6uefaction rocess' this is done not to o0erco*e the rocess 4ottle nec@s 4ut

(4

(

Journal of Energy Technologies and Policy ISSN 2224-3232 (Pa er! ISSN 222"-#"$3 (%nline! &ol.3' No.3' 2#(3

www.iiste.org

also to *eet the 7N- roduct s ecifications' re0ent corrosion of rocess e6ui *ent and en0iron*ental erfor*ance. There are *any acid gas treating rocesses a0aila4le for re*o0al of 3%2 fro* natural gas. These rocesses include 3he*ical sol0ents' Physical sol0ents' <dsor tion Processes'1y4rid sol0ents and Physical se aration. The che*ical sol0ents and hysical sol0ents or co*4ination of these two ha0e 4een used e9tensi0ely in e9isting 4ase load 7N- facilities. Today' co* uter-aided rocess si*ulation is nearly uni0ersally recogni;ed as an essential tool in the rocess industies (Seung 2##?!. Indeed' si*ulation software lays a @ey role in= rocess de0elo *ent B to study rocess alternati0es' assess feasi4ility and reli*inary econo*ics' and inter ret ilot- lant dataC rocess design to o ti*i;e hardware and flow sheets' esti*ate e6ui *ent and o erating cost and in0estigate feedstoc@ fle9i4ilityC and lant o eration to reduce energy use' increase yield and i* ro0e ollution control. The a4ility of the 7N- o tion to continue to co* ete with e9isting and e*erging gas *oneti;ation' o tion will de end on the industry5s success in reducing cost throughout the 7N0alue chain and *aintaining e9ce tional safety' relia4le and less en0iron*ental i* act o erations. Natural gas generally re6uires re*o0al of 1ydrogen Sulfide (12S!' 3ar4on ,io9ide (3%2!' 3ar4onyl Sulfide (3%S!' %rganic sul hur co* ounds' >ercury and water rior to li6uefaction. <ll these co* onents *ay free;e out and cause 4loc@age in the li6uefaction lant. In addition sul hur co* ounds *ust 4e re*o0ed to *eet the rele0ant 12S and sulfur s ecifications for the re-gasified i eline gas' and *ercury *ust 4e re*o0ed to a0oid da*age to alu*inu* alloy heat e9changers (Terry (??D! and (Sang et al' 2##?!. <ccording to Eenstog (2##A!' the cost of the re-treat*ent is de endent on the ty e on the ty e and concentrations of the conta*inants in the natural gas. In the ast *ost feed gases for 4ase load 7N- lants only contained 3%2 (FF (# *olG! with traces of 12S. this ty e of gas re6uires the *ini*u*5 of re-treat*ent. Nowadays a tendency to use feed gases richer in 3%2' 12S and *erca tan is de0elo ing' which naturally increase the cost and co* le9ity of the li6uefaction re-treat*ent. This a er re orts an o ti*i;ation study of the si*ulation of a ty ical a*ine sol0ent 4ased 3%2 re*o0al lant using 1:S:S rocess si*ulator to esta4lish o ti*u* o erating conditions that will i* ro0e rocess en0iron*ental erfor*ance. Si* ly stated' it has 4een o4ser0ed that during the re*o0al of 3ar4on dio9ide fro* natural gas for 7N- roduction B using <*ine rocess' there ha0e 4een losses of <*ine' e9cessi0e e*ission of 3ar4on dio9ide to the at*os here and significant a4sor tion of hydrocar4on 4y <*ine with resultant foa*ing and corrosion ro4le*s. This research wor@ ai*s at= (. /sing <SPEN 1:S:S for si*ulating and redicting an a*ine 4ased 3%2 re*o0al rocess. 2. >odel a unit 4y considering the o erating conditions at which hydrocar4on and che*ical loss (a*ine sol0ent! can 4e *ini*i;ed. *&' R+ +ARC, -+!,OD The research *ethod centered on the use of <SPEN 1:S:S to o ti*i;ed a*ine 4ased rocess in the re*o0al of car4on dio9ide fro* natural gas for 7N- roduction. The sco e of this wor@ in0ol0es 4ut not li*ited to any assu* tion that will facilitate it accuracy. The area to 4e co0ered consists of *ainly <*ine 4ase rocess. It is e9 ected that at the end of this research wor@' a *odel for an a*ine 4ased 3%2 re*o0al rocess will 4e de0elo ed.

("

Journal of Energy Technologies and Policy ISSN 2224-3232 (Pa er! ISSN 222"-#"$3 (%nline! &ol.3' No.3' 2#(3

www.iiste.org

*&% CARBON D(O.(D+ R+-O/AL PROC+ + The re*o0al of acid gases (3%2' 12S and other sulfur co* onents! fro* natural gas is often referred to as gas sweetening rocess. 3ar4on dio9ide resent in the natural gas needed to 4e re*o0ed in other toC increase the heating 0alue of the gas' re0ent corrosion of i eline and gas rocess e6ui *ent and crystalli;ation of 3%2 during cryogenic rocess (li6uefaction rocess!. <ccording to Seung et al (2##?!' the re*o0al of car4on dio9ide can 4e acco* lished in a nu*4ers of ways. &arieties of rocesses and (i* ro0e*ent of each! ha0e 4een de0elo ed o0er the years to treat certain ty es of gas with the ai* of o ti*i;ing ca ital cost and o erating cost' *eet -as s ecifications and for en0iron*ental ur ose. The *a8or rocesses a0aila4le can 4e grou ed as follows= H <4sor tion Processes (3he*ical and Physical a4sor tion! H <dsor tion Process (Solid Surface! H Physical Se aration (>e*4rane' 3ryogenic Se aration! H 1y4rid Solution (>i9ed Physical and 3he*ical Sol0ent! 2.2 Process description The general rocess flow diagra* of an a*ine 3%2 re*o0al rocess is shown in .ig.

0i1ure *&%2 A !#pical Amine Base process Dia1ram The sour gas enters the lant through a se arator to re*o0e any free li6uid or entrain*ent solids. The sour gas lea0es the to of the scru44er and enters the 4otto* of the a4sor4er in countercurrent contact with a6ueous lean a*ine solution. Sweet gas lea0es the to of the a4sor4er and flow to a dehydration unit 4efore 4eing considered ready for li6uefaction. 7ean a*ine flow downward counter currently to the sour gas and a4sor4ed the 3%2 constituent and 4eco*e rich solution. The rich sol0ent fro* the 4otto* of the a4sor4er is flashed in a se arator to reco0er so*e a4sor4ed hydrocar4on in the rich sol0ent and then ass through a*ine-a*ine heat e9changer to the stri er where the acid gas a4sor4ed is stri ed off at a 0ery high te* erature and low ressure.

(A

Journal of Energy Technologies and Policy ISSN 2224-3232 (Pa er! ISSN 222"-#"$3 (%nline! &ol.3' No.3' 2#(3

www.iiste.org

The acid gas then lea0es the to of the stri er colu*n. The lean a*ine fro* the 4otto* of the re4oiler attached to the stri er flow through a*ine-a*ine heat e9changer and through a water air cooler 4efore 4eing introduced 4ac@ to the to of the a4sor4er (<ndress' (??A!. The a*ine-a*ine heat e9changer ser0es as a heat conser0ation de0ice. < art of a4sor4ed acid gas is flashed fro* the heated rich solution on the to tray of the stri er. The re*inder of the rich solution flows downward through the stri er in countercurrent contact with 0a our generated in the re4oilerC which stri s the acid gas fro* the rich solution. The stri er o0erhead roducts (acid gas and stea*! ass through a condenser where the stea* is condensed and cooled and returned to the to of the stri er as a reflu9' while the acid gas is se arated in a se arator and sent to the flare or co* ressed for se6uestration rocess. *&3& -A BALANC+ O0 !,+ ,4 4 PROCC+ (-)LA!(ON PAC"AG+ < non-e6uli4riu* stage *odel de0elo ed to si*ulate the *ultico* onent *ultistage *ass transfer rocess encountered in an a*ine treating unit is used in the a*ines ro erty ac@age. The generali;ed stage *odel shown 4elow gi0es the flow geo*etry and no*enclature for an indi0idual stage in a colu*n. The funda*ental conce t used is that the rate of a4or tionIdesor tion of acid gases toIfro* the a*ine solution *ust 4e considered as a *ass-transfer rate rocess. The rate rocess de ends on the e6uili4riu* and @inetic ara*eters that descri4e the acid gasIa*ine syste*. The *odel incor orates a *odified *ur hree-ty e 0a our efficiency to account for the 0arying *ass-transfer rates of indi0idual acid gas co* onents. The acid gas stage efficiencies are' in turn' functions of *ass-transfer coefficients and the *echanical design of the tray. This setof e6uaitons *ust 4e sol0ed for each colu*n in the flowsheet. < *odified Newton-2a hson *ethod is used to sol0e the rigorous non-linear stage e6uations Si*ultaneously for te* eratue' co* ostion and hase rates on each state in a colu*n.

ta1e efficienc# The stage efficiency as degined under the <*ines ro ety ac@age o tion is gi0en 4y=

n=

(&8 J S&8!:8 B &8J(:i8J( (&8 J S&8!)(8Ki8 B &8J(:i8J(

($

Journal of Energy Technologies and Policy ISSN 2224-3232 (Pa er! ISSN 222"-#"$3 (%nline! &ol.3' No.3' 2#(3

www.iiste.org

,ere2

n

I J ) & K :

L L L L L L L

Stage Efficiency 3o* onent nu*4er Stage nu*4er E6uili4ru* ratio >olar flow rate of 0a our >ole fraction in li6uid hase >ole fraction in 0a our hase

The stage efficiency is a function of the @inetic rate constants for the reactions 4etween each acid gas and the a*ine' the hysioco-che*ical ro erties of the a*ine solution' the ressure' te* erature and the *echanical tray design 0aria4les such as tray dia*eter' weir height and weir length. Non-E6uili4riu* Stage +alance %0eral >aterial +alance

.8 J l8 B ( M (78 J S78! B (&8 J S&8! L #

3o* onent >aterial +alance

.8Ni8 J 78 B (9y B ( J&8 J(:i8 J ( B (78 J S78! 9i8 B(&8 JS&8!yi8 L #

Energy +alance E6uili4ru* 2elationshi

n li)i89l8(&8 J S&8! B (&8 J S&8!yl8 J (I B n i8!&8 J J (( B n i8!&8 J l:i8 B ( L #

Su**ation E6uation

O yi8 -(.# L #

E6uili4riu* Solu4ility )ent P Eisen4erg >odel < *odel 4ased on the )ent Eisen4erg a roach is used to correlate the e6uili4riu* solu4ility of acid gases in the a*ine solutions. The rediction of e6uili4riu* ratios or )-&alue in0ol0es the si*ultaneous solution of a set of non-linear e6uations that descri4e the che*ical and hase e6uili4ria and the electroneutrality and *ass 4alance of the electrolytes in the e6ueous hase. Phase E6uili4ria

:12ScP012SP L 112SQ12SR ................................................( :co2cP0co2P L 1co2Qco2R................................................2 >ass +alance 3(.2-a*ine L Q2(22N1R J Q2(22N12JR J Q2(22N3%%R

(D

Journal of Energy Technologies and Policy ISSN 2224-3232 (Pa er! ISSN 222"-#"$3 (%nline! &ol.3' No.3' 2#(3

www.iiste.org

33-a*ine L Q2(2223NR J Q2(2223N1JR

33#2 (3(.2-a*ine! S3#2 L Q3%2R L Q2(22N3%%-R J Q13%3 R J Q3%3 R

*&5& ,4 4 (-)LA!(ON O0 A-(N+ PROC+ Description of process equipment >ost often' a*ine unit o erating ro4le*s can 4e traced to conta*inants 4rought in with the gas fro* the i eline. Pi eline conta*inants can 4e in the for* of Tdown-holeU corrosion inhi4itors or other TtreatingU che*icals' li6uid slugs caused 4y i eline 0olu*e surges or line igging' well Twor@o0erU fluids sent to the i eline' and co* ressor lu4ricating oils. These conta*inants are re0ented fro* getting into the units 4y slug catcher. .or the 3%2 re*o0al units the following is a 4rief descri tion of the *a8or e6ui *ent necessary for successful si*ulation of a*ine unit to *eet the 7N- s ecifications and to o erate en0iron*ental acce ta4le units. 1ere fictitious units such as *i9er will not 4e discussed. a& ,P (NL+! +PARA!OR6 The function of the inlet se arator is to re*o0e the entrained li6uid a*ine carried o0er with the gas fro* the i elineIslug catcher 4efore getting to the a4sor4er. &ertical se arator is uses to effecti0ely handle so*e antici ated li6uid slugs. It also li*its li6uid re-0a ori;ation. b& D+A CON!AC!OR6 The contactor allows counter-current flow of lean a*ine fro* the to and sour gas fro* the 4otto*. 1ere the a*ine sol0ent a4sor4ed 3%2 and rich a*ine is flow to the 4otto* while the sweet gas is collected at the to for further rocessing. c& !,RO!!L(NG /AL/+6 The 0al0e is used to e9 and the rich a*ine co*ing fro* the high ressure contactor. This is done 4y lowering gas the ressure 4efore entering the flash tan@. d& 0LA , !AN"6 The gas fro* the throttling 0al0e is flashed to re*o0e the hydrocar4ons co* onents carried along with the rich a*ine' this unit ser0es as a reco0ery unit for hydrocar4ons. 1ori;ontal flash tan@ is used to re0ent foa*ing. The flashed o0erhead roduct can 4e used as fuel gas. e& A-(N+7A-(N+ ,+A! +.C,ANG+R6 The richIlean e9changer is a heat conser0ation de0ice where hot lean sol0ent reheats cooler rich sol0ent. In this ro8ect Shell-and-tu4e TE>< ty e E e9changer is used in the si*ulation. The shell and tu4e side ressure dro is set to $# @ a and heat lossIlea@ is assu*ed ;ero. The heat e9changer hel s to raise the rich a*ine sol0ent te* erature 4efore entering the stri er. Thus reduce re-4oiler wor@ load. f& A-(N+ !(LL6 ,e ending u on the sol0ent ty e' this is nor*ally a 2#-tray or e6ui0alent ac@ed tower. 1ere (D- trays were sufficient to stri the 3%2 fro* the rich sol0ent. Physical sol0ents can re6uire fewer trays. Trays dia*eter is a4out 4* with #." s acing. 7i6uid and 8et floods in the A"-$"G range with a $"G foa* factor. It is assu*ed that the trays in the u er third' 4e stainless steel due to the corrosi0ity of the en0iron*ent. 1& A-(N+ COOL+R8 R+0L). COND+N +R6 <ir-cooled' forced draft with auto*atic lou0ers for te* erature control. 3old cli*ate ser0ice *ay re6uire air recirculation andIor reheat *edia on fansIcoils. 3ondenser tu4es should 4e *ade of stainless steel' as this is a wet' acid gas en0iron*ent and slo ed to the outlet side. h& R+0L). ACC)-)LA!OR2 This 0essel se arates the reflu9 water and water saturated acid gases. The water is u* ed 4ac@ to the still and the acid gases are directed to 0ent' incinerator' or sul hur reco0ery unit. < reflu9 accu*ulator with a 4U to DU thic@ *ist ad is used.

(?

Journal of Energy Technologies and Policy ISSN 2224-3232 (Pa er! ISSN 222"-#"$3 (%nline! &ol.3' No.3' 2#(3

www.iiste.org

i& OL/+N! R+BO(L+R2 This is either a direct-fired fire tu4e ty e or ca4in heater' or indirect hot oil or stea* heated unit. Ty ically heat flu9 rate should 4e @e t in the $"## to (#'### +tuIhrIft2 range to assure no surface 4urning of the sol0ent. This e9changer ro0ides the stea* necessary to heat and stri the sol0ent 4ac@ to a TleanU condition. 9& COOL+R6 The lean a*ine sol0ent fro* the re-4oiler through a*ine-a*ine heat e9changer is further cool here 4efore entering the a4sor4er again' since a4sor4ers o erate *ore efficiently at relati0ely low te* erature. The ressure dro across the cooler is a4out 3" @ a with corres onding duty of (.#?$ EJ$ @JIh. :& P)-P 2 The reflu9 and 4ooster centrifugal u* is installed to *aintain the recycle lean sol0ent at the desired o erating ressure of the a4sor4er. The *ain circulation u* choice de ends u on contactor o erating ressure and sol0ent flow rates. 3entrifugal u* considered in this ro8ect is set to $"G adia4atic efficiency for low head cases and large 0olu*e' high head cases which is s ecifically design for a*ine ser0ice and ha0e non-lu4ricated ac@ingIsyste* seal with cera*ic or hard coated fluid arts. *&; ,4 4 (-)LA!(ON PROC+D)R+ < 4ase case was esta4lished using the following ste sC the first ste is to select the a ro riate fluid ac@ageC here a*ine fluid ac@age and )ent-Eisern4erg *odel is selected as in figure 4elowC

0i1ure *2 0luid Pac:a1e Basis <Amine fluid Pac:a1e= The co* onent selection window is o en 4y selecting 0iew in the co* onent-list show in figure (. .igure 2 shows dialog window is use for co* onents selection

2#

Journal of Energy Technologies and Policy ISSN 2224-3232 (Pa er! ISSN 222"-#"$3 (%nline! &ol.3' No.3' 2#(3

www.iiste.org

0i1ure 32 Component selection $indo$s& <fter selecting the co* onent of the fluid' one can now enter the si*ulation en0iron*ent where the rocess flow diagra* (P.,! is 4uilt. <*ine P., si*ulation en0iron*ent is shown in figure 3 4elowC

0i1ure 52 )n7simulated Amine Process 0lo$ Dia1rams The si*ulation of the rocess 4egins with the si*ulation of the feed sour gas strea* 4y s ecifying the gas te* erature' ressure and flow rate (+lue colour! and 1:S:S calculate the re*aining ara*eters (+lac@ colour! as shown in figure 3.4 4elow

2(

Journal of Energy Technologies and Policy ISSN 2224-3232 (Pa er! ISSN 222"-#"$3 (%nline! &ol.3' No.3' 2#(3

www.iiste.org

0i1ure ;2 our Gas specification $indo$s %ther strea*s s ecifications *ade areC the regenerated feed out of the a*ine-a*ine heat e9changer te* erature to control the e9changer ft factor' ,E< to 3ontactor te* erature ressure and flow rate' *a@e u water te* erature and ,E< to recycle te* erature. Eith these s ecifications *ade' 1:S:S *a@e use of its fle9i4ility of calculating forward and 4ac@ward to co* letely si*ulate the rocess. %ne of the rigorous tas@s is the con0ergence of the a4sor4er and the regenerator' to con0erge the a4sor4er the a4sor4erto and 4otto* te* erature and ressure was s ecified and run' figure ". Ehile the regenerator is con0erged 4y s ecifying the condenser and re-4oiler ressure' the reflu9 ratio and the 0ent rate' the colu*n is then run' figure A

22

Journal of Energy Technologies and Policy ISSN 2224-3232 (Pa er! ISSN 222"-#"$3 (%nline! &ol.3' No.3' 2#(3

www.iiste.org

0i1ure >2 Conver1ed $indo$ of the Absorber

0i1ure ?2 Conver1ed $indo$s for re1enerator unit Eith the con0ergence of the a4sor4er and the regenerator units a co* lete a*ine

23

Journal of Energy Technologies and Policy ISSN 2224-3232 (Pa er! ISSN 222"-#"$3 (%nline! &ol.3' No.3' 2#(3

www.iiste.org

si*ulation for the 4ase case was esta4lished as shown in figure (4.% ti*i;ation of the rocess was carried out 4y *odification of so*e ara*eters to *eet the ro8ect ai*s. ,etail ara*eters for the 4ase case and *odified ara*eters are shown in ta4les of data.

0i1ure @2 Complete simulation )nit& 3&' DA!A PR+ +N!A!(ON8 (-)LA!(ON R+ )L! AND D( C) (ON 3&% Basic Ra$ Data and Base Case imulation Data <-aterial tream= !able %2 our Gas 0eed Composition Parameters Te* erature Pressure >olar .low 2ate 3o* onents Nitrogen 1ydrogen Sulfide 3ar4on dio9ide >ethane Ethane Pro ane n-+utane n-Pentane Eater 3#o3 A?##@ a (A? 4ara! (2"#@g*olIh >ole .raction #.##(3$2 #.#### #.#"AD #.D??( #.#2"$ #.##A( #.##(?#2 #.###$D #.####

24

Journal of Energy Technologies and Policy ISSN 2224-3232 (Pa er! ISSN 222"-#"$3 (%nline! &ol.3' No.3' 2#(3

www.iiste.org

!able *2 Amine Lean7Rich ,eat +xchan1er Tu4e %utlet Te* erature Tu4e Side Pressure ,ro Shell Side Pressure ,ro !able 32 Lean Amine to the Contactor Te* erature ?"o3 $#@ a $# @ a

3" o3

Pressure Std Ideal &olu*e .low 3o* >ass .raction (12%! 3o* >ass .raction (,E<*ine!

ADA" @ a 43*3Ih #.$(D( #.2D#(

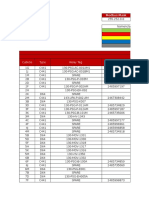

3&* (-)LA!(ON R+ )L! ,etails si*ulation results are shown in the ta4les and figures 4elow. !able 52 Data 1enerated from the imulation -odel

*;$tBD+A8 Circulation rate %5'':1molAhr

Pfeed <:pa= "### 1as Pco* <:pa= 2DA.2 !emp o C 3# 3" 4# 3# 3" 4# 3# 3" 4# -olco*A-olD+A -olC%A-olD+A -olc'*As$eet 1as

#.A(($ #.A#$4 #.A#2( #.A3(4 #.A3#? #.A2D4 #.A4#( #.A4#" #.A4(?

#.#(4#( #.#(3AA #.#(34D #.#2A2" #.#2"A3 #.#2"3( #.#3$3? #.#3A"? #.#3A(D

#.243D #.2A?3 #.3#3? #.(#(4 #.(#"2 #.((43 #.#4D( #.#4?A #.#"3D

(#### "$2.A

("###

D"D.?

2"

Journal of Energy Technologies and Policy ISSN 2224-3232 (Pa er! ISSN 222"-#"$3 (%nline! &ol.3' No.3' 2#(3

www.iiste.org

3'$tBD+A8 Circulation rate %5'':1molAhr

Pfeed <:pa= "###

1as Pco* <:pa= 2DA.2

!emp o C 3# 3" 4# 3# 3" 4# 3# 3" 4#

-olco*A-olD+A -olC%A-olD+A -olC'*As$eet 1as #."3AA #.#(#D4 #.(22$ #."4#2 #.#(#"A #.(23A #."42$ #.#(#3A #.(2A4 #."4D4 #.""2$ #."4?" #.""4( #.""$? #.""D2 #.#23$ #.#(??( #.#2#3$ #.#2?#D #.#2D4D #.#2D(V$ #.#"(4 #.#A(" #.#A23 #.#(?2 #.#24A #.#2$(

(####

"$2.A

("###

D"D.?

3;$tBD+A8 Circulation rate %5'':1molAhr

Pfeed <:pa= "###

1as Pco* <:pa= 2DA.2

!emp o C 3# 3" 4# 3# 3" 4# 3# 3" 4#

-olco*A-olD+A -OLc%A-olD+A -olc'*As$eet 1as #.4ADD #.##DAAD #.(22" #.4$43 #.##D4"( #.(?2$ #.4$$3 #.##D3#2 #.2$DA #.4$A$ #.4D(" #.4D43 #.4D( #.4D"( #.4D$3 #.#(A34 #.#("?D #.#("$3 #.#233A #.#22? #.#22"? #.#4"A #.#4$D #.#4?2 #.#("" #.#(?A #.#2A?

(###

"$2.A

("###

D"D.?

2A

Journal of Energy Technologies and Policy ISSN 2224-3232 (Pa er! ISSN 222"-#"$3 (%nline! &ol.3' No.3' 2#(3

www.iiste.org

!able ;2 +ffect of Lean Amine Circulation Rate on Amine Loadin1 at 3;oC

3;$tBD+A8 ! C 3;oC8 P C %'' bara

,E<*ine (4## ("## (A## (D## (?## 2### molCO*A-olD+A #.4D"( #.""34 #."A$2 #.A#(2 #.A423 #.A"3$ molcC%A-olD+A #.#(D32 #.#(D43 #.#(D$A #.#(?23 #.#2#34 #.#2($" -olc'*As$eet 1as #.#4"$ #.""34 #.#A34 #.#$#2 #.#.D32 #.#?#" molD+AAAcid 1as <%'7@= 3.2AD 4.#(3 ".243 A.#?3 A.3"2 #.$2$$

!able >2 +ffect of Lean Amine Circulation Rate on Amine Loadin1 at 5'oC

3;$tBD+A8 ! C 5'oC8 P C %'' bara

,E<*ine (4## ("## (A## (D## (?## 2###

molCO*A-olD+A #.4?"( #.""$4 #."D$2 #.A3(2 #.A4$3 #.AA3$

molcC%A-olD+A #.#(D32 #.#(D43 #.#(D$A #.#(?23 #.#2#34 #.#2($"

-olc'*As$eet 1as #.#""$ #.#A23 #.#AD4 #.#$D2 #.#D$2 #.#?4"

molD+AAAcid 1as <%'7@= 3.4AD 4.#"3 ".243 A.(?3 A."32 #.$2D$

2$

Journal of Energy Technologies and Policy ISSN 2224-3232 (Pa er! ISSN 222"-#"$3 (%nline! &ol.3' No.3' 2#(3

www.iiste.org

.igffi1u re D2 G of 3%2 in the Sweet -as as a .unction of <*ine 3oncentration Eith 3hanges in <4sor4er Pressure

.igufi 1ure %'2 Effects of Pressure and Te* erature on G 3%2 in the Sweet -as Eith ,E<*ine 3oncentration of 3" wtG

2D

Journal of Energy Technologies and Policy ISSN 2224-3232 (Pa er! ISSN 222"-#"$3 (%nline! &ol.3' No.3' 2#(3

www.iiste.org

.igfi1ure %%= Effects of 3%2 7oading in ,E<*ine with ressure and Te* erature

fir1ue %*2 Partial Pressure of 3%2 in Solution as .unction of 3%2 7oading of 2"wtG ,E<

2?

Journal of Energy Technologies and Policy ISSN 2224-3232 (Pa er! ISSN 222"-#"$3 (%nline! &ol.3' No.3' 2#(3

www.iiste.org

0i1ure %32 Partial Pressure of 3%2 in Solution as .unction of 3%2 7oading of 3#wtG ,E<

0i1ure %5= Partial Pressure of 3%2 in Solution as .unction of 3%2 7oading of 3"wtG ,E<

3#

Journal of Energy Technologies and Policy ISSN 2224-3232 (Pa er! ISSN 222"-#"$3 (%nline! &ol.3' No.3' 2#(3

www.iiste.org

0i1ure %;2 7ean ,E< 3irculation rate 0s. 3%2 loading in 3"wtG ,E<

0i1ure %>2 7ean ,E< 3irculation rate 0s. *ol3%2 in the acid gas with 3"wtG ,E<

3(

Journal of Energy Technologies and Policy ISSN 2224-3232 (Pa er! ISSN 222"-#"$3 (%nline! &ol.3' No.3' 2#(3

www.iiste.org

3&3 D( C) (ON O0 R+ )L! The si*ulation o48ecti0es are to *eet the 7N- s ecifications of a4out "# B (## *0 or 2- 3 G 3%2 concentration in the roduct strea*' and then esta4lish o ti*u* conditions to reduce 3%2 e*ission and che*ical loss. .ro* ta4le A' the G co* osition of 3%2 of the feed gas is a4out ".AG which is a4o0e 7N- 3%2 s ecifications of 2 B 3 G as shown in ta4le $..igure (" shows the treat*ent of feed sour gas with different a*ine concentrations and the o4ser0ed G *ole concentration of 3%2 in the sweet gas. It was o4ser0ed that as the concentration of a*ine increases' the G *ole concentration of 3%2 in the sweet gas decreases. This is attri4uted to the increase in <*ine sol0ent ca acity with increase in concentration of a*ine in the solution. The s ecifications ranges were reached at 2# wtG ,E<*ine and a4o0e. Ta4le 3 shows that for a gi0en artial ressure of 3%2 in the feed gas the a*ine loading increase with increasing a*ine wtG in the solution. Eith 2" wtG ,E<*ine the loading Q*ol3%2I*ol,E<R ranges fro* #.A B #.A4 figure (2' for 3#wtG the loading ranges fro* #."3" B #."A figure (3' with 3" wtG the increase loading ca acity ranges fro* #.4A" B #.4? figure (4' and the loading was o4ser0ed to decrease with increase te* erature at a gi0en 3%2 artial ressure. The G *ole of 3%2 in the sweet gas increases with contactor (<4sor4er! o erating te* erature and decrease with ressure figure (#. Ehile the hydrocar4on (3(! co-a4sor4ed with the 3%2 in the sol0ent increases with ressure and decrease with increase in te* erature. This is due to decrease in a*ine loading ca acity as its 0iscosity decrease with te* erature. .igure (" illustrates the effect of lean a*ine circulation rate on a*ine loading ca acity. 5&' CONCL) (ON 2 In conclusion it can 4e said that the o48ecti0es of this study has 4een achie0ed. (. < *odel has 4een de0elo ed to o ti*;e the o erating conditions at which the hydrocar4on and che*ical losses can 4e *ini*i;ed. 2. < 1:S:S 4ased rogra**e for si*ulating and redicting and a*ine 4ased 3%2 re*o0al rocess has also 4een de0elo ed 4ut to achie0e an enduring o ti*a;ation rocess in the lant the followings should 4e noted= H The loading ca acity of the a*ine sol0ent should 4e increased a ro riately to increase acid gas (3%2! loading in the sol0ent. H The 3%2 e*ission and che*ical loss is directly ro ortional to the a*ine circulation rate. Therefore the lean a*ine circulation rate should 4e *ini*i;ed and at *ini*u* ossi4le te* erature to *ini*i;e sol0ent e0a oration rate and thus increase its loading ca acity. H <4sor4er should 4e o erated at 1igh ossi4le ressure and low Te* erature to enhance a*ine loading ca acityC therefore *ini*i;e 3%2 e*ission and che*ical loss. H The a*ine sol0ent residence ti*e in the stri er should 4e *ini*i;ed to reduce its degradation tendency. H The stri er o erating ressure should 4e nearly or at at*os heric ressure' while the re4oiler te* erature should 4e within the sol0ent sta4ility conditions' for ,E<a*ine the re4oiler te* erature range of a4out ((D B (2( o3 is a ro riate.

32

Journal of Energy Technologies and Policy ISSN 2224-3232 (Pa er! ISSN 222"-#"$3 (%nline! &ol.3' No.3' 2#(3

www.iiste.org

R+0+R+NC+ <ndress' ,. 7. ((??A! TThe Philli s % ti*i;ed 3ascade 7N- Process a Wuarter 3entury of I* ro0e*entU' The Per*ission of the Institute of -as Technology. 3hang' 1. S.' 7ee' +. N.' (2##$! T2aise Plan of 3o* etiti0eness of Internal 3o* any in the %0erseas Plant >ar@et' 3onstruction P Econo*y 2esearch Institute of )oreaU. &ol. (?' . 2-3#' 2o4ert' 3. 2. (2##?! TThe Pro erties of -ases and 7i6uidU 4th Edition' >c-raw-1ill +oo@ 3o* any' Eorld <cade*y of Science' Engineering and Technology' ."? (D? Seung Tae@' (2##?! Si*ulation of 7N- li6uefaction cycle using two stage intercooler' Proceedings of )I-<S S ring conference' . 22"-22D. Sang' -.7.' )un' 1.3.' :oung' >.:.' (2##?! TThe State of <rt of 7N- 7i6uefaction Plant TechnologiesU' The 3rd )orean 3ongress of 2efrigeration' 0ol. 3' . A"-AD. Seung' T.%.' Jung' I. :oon' Sang' -.7.'( 2##?! T,e0elo *ent of 7N- 7i6uefaction ProcessU. Journal of the S<2E)' &ol. 3D' No. 3' . (3-($' Eorld <cade*y of Science' Engineering and Technology Terry' 7. ((??D! T3o* arison of 7i6uefaction ProcessU' 7N- Journal 2(' No. 3' . 2D-33.

Een-sheng 3ao et. al' (2##A! TPara*eter 3o* arison of Two S*all-scale Natural -as 7i6uefaction Process in S@id-*ounted Pac@agesU' < lies Ther*al Engineering' No. 2A' . D?D-?#4' :oshitugi ).'((??$! T,e0elo *ent of 7i6uefaction Process for Natural -asU' Journal of 3he*ical Engineering of Ja an' &ol. 3#' No. 4' . A2"-A3#.

33

This academic article was published by The International Institute for Science, Technology and Education (IISTE). The IISTE is a pioneer in the Open Access Publishing service based in the U.S. and Europe. The aim of the institute is Accelerating Global Knowledge Sharing. More information about the publisher can be found in the IISTEs homepage: http://www.iiste.org CALL FOR PAPERS The IISTE is currently hosting more than 30 peer-reviewed academic journals and collaborating with academic institutions around the world. Theres no deadline for submission. Prospective authors of IISTE journals can find the submission instruction on the following page: http://www.iiste.org/Journals/ The IISTE editorial team promises to the review and publish all the qualified submissions in a fast manner. All the journals articles are available online to the readers all over the world without financial, legal, or technical barriers other than those inseparable from gaining access to the internet itself. Printed version of the journals is also available upon request of readers and authors. IISTE Knowledge Sharing Partners EBSCO, Index Copernicus, Ulrich's Periodicals Directory, JournalTOCS, PKP Open Archives Harvester, Bielefeld Academic Search Engine, Elektronische Zeitschriftenbibliothek EZB, Open J-Gate, OCLC WorldCat, Universe Digtial Library , NewJour, Google Scholar

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Premier MDokument44 SeitenPremier Mthebetterman0511Noch keine Bewertungen

- 797F Off-Highway Truck Transmission System: View A-ADokument2 Seiten797F Off-Highway Truck Transmission System: View A-AramiroNoch keine Bewertungen

- 09-SAMSS-089 Shop Applied FBE Coating Jan 2018Dokument28 Seiten09-SAMSS-089 Shop Applied FBE Coating Jan 2018Ahmed & Rehana MoinuddinNoch keine Bewertungen

- Brahmss Pianos and The Performance of His Late Works PDFDokument16 SeitenBrahmss Pianos and The Performance of His Late Works PDFllukaspNoch keine Bewertungen

- Economics Case StudyDokument28 SeitenEconomics Case StudyZehra KHanNoch keine Bewertungen

- Ganesh Celebration 2015Dokument3 SeitenGanesh Celebration 2015Govind Manglani100% (1)

- Symmetry Notes Hwk8 Che103Dokument3 SeitenSymmetry Notes Hwk8 Che103Govind ManglaniNoch keine Bewertungen

- UCM224446Dokument136 SeitenUCM224446Govind ManglaniNoch keine Bewertungen

- Symmetry Notes Hwk8 Che103 PDFDokument3 SeitenSymmetry Notes Hwk8 Che103 PDFGovind ManglaniNoch keine Bewertungen

- UCM224446Dokument136 SeitenUCM224446Govind ManglaniNoch keine Bewertungen

- Fluidised Bed Pyrolysis of Polypropylene Over Cracking Catalysts For Producing HydrocarbonsDokument8 SeitenFluidised Bed Pyrolysis of Polypropylene Over Cracking Catalysts For Producing HydrocarbonsGovind ManglaniNoch keine Bewertungen

- UCM224446Dokument136 SeitenUCM224446Govind ManglaniNoch keine Bewertungen

- Lewis Structure SchragenDokument2 SeitenLewis Structure SchragenGovind ManglaniNoch keine Bewertungen

- Electronic Supplementary Information: S1.1Preparation of CatalystsDokument9 SeitenElectronic Supplementary Information: S1.1Preparation of CatalystsGovind ManglaniNoch keine Bewertungen

- Redox Property of Vanadium Oxide and Its Behavior in Catalytic OxidationDokument7 SeitenRedox Property of Vanadium Oxide and Its Behavior in Catalytic OxidationGovind ManglaniNoch keine Bewertungen

- ch5 Stereo1 PDFDokument6 Seitench5 Stereo1 PDFyeateshwarriorNoch keine Bewertungen

- Mixed Alcohol Synthesis Catalyst Screening: PNNL-16763Dokument54 SeitenMixed Alcohol Synthesis Catalyst Screening: PNNL-16763Govind ManglaniNoch keine Bewertungen

- The Chemistry and Biochemistry of Vanadium and The Biological Activities Exerted by Vanadium Compounds PDFDokument54 SeitenThe Chemistry and Biochemistry of Vanadium and The Biological Activities Exerted by Vanadium Compounds PDFGovind ManglaniNoch keine Bewertungen

- Advanced Microscopy Simplifi Ed: Bx53M/BxfmDokument28 SeitenAdvanced Microscopy Simplifi Ed: Bx53M/BxfmRepresentaciones y Distribuciones FALNoch keine Bewertungen

- Item 3 Ips C441u c441r Ieb Main ListDokument488 SeitenItem 3 Ips C441u c441r Ieb Main Listcristian De la OssaNoch keine Bewertungen

- Shivani Singhal: Email: PH: 9718369255Dokument4 SeitenShivani Singhal: Email: PH: 9718369255ravigompaNoch keine Bewertungen

- Luyện tâp Liên từ Online 1Dokument5 SeitenLuyện tâp Liên từ Online 1Sơn KhắcNoch keine Bewertungen

- Project Reoprt On JSW SteelsDokument30 SeitenProject Reoprt On JSW SteelsSakthi Krishnan100% (1)

- TEJASWINIDokument4 SeitenTEJASWINIShìVâ KùMàrNoch keine Bewertungen

- Øyvind H. Johansen Et Al - Qualification of An Enhanced Blast Explosive (DPX-6) : According To STANAG 4170Dokument25 SeitenØyvind H. Johansen Et Al - Qualification of An Enhanced Blast Explosive (DPX-6) : According To STANAG 4170MallamaxNoch keine Bewertungen

- Effect of Cryogenic Treatment On CompositesDokument14 SeitenEffect of Cryogenic Treatment On CompositesGauthamNoch keine Bewertungen

- Sony Video Camera Manual PDFDokument118 SeitenSony Video Camera Manual PDFGary Hoehler100% (1)

- Bobcat 3 Phase: Quick SpecsDokument4 SeitenBobcat 3 Phase: Quick SpecsAnonymous SDeSP1Noch keine Bewertungen

- Ibm 3592 Tape Cartridge CatalogueDokument4 SeitenIbm 3592 Tape Cartridge CatalogueamsfibNoch keine Bewertungen

- Guidelines For Xii Plan: Ther Backward Classes (Obc)Dokument15 SeitenGuidelines For Xii Plan: Ther Backward Classes (Obc)SACHCHIDANAND PRASADNoch keine Bewertungen

- Guideline G6 Certification Process v2 0Dokument18 SeitenGuideline G6 Certification Process v2 0Wong Wong WLNoch keine Bewertungen

- Sensus WP Dynamic Cold Water Meter (DN40-300)Dokument4 SeitenSensus WP Dynamic Cold Water Meter (DN40-300)Roderikus Rendy MNoch keine Bewertungen

- Manual Bombas Pozo e ImpulsionDokument112 SeitenManual Bombas Pozo e ImpulsionFernando PuentesNoch keine Bewertungen

- CATALO VetivDokument240 SeitenCATALO VetivHữu CôngNoch keine Bewertungen

- Dutch Cone Penetrometer Test: Sondir NoDokument3 SeitenDutch Cone Penetrometer Test: Sondir NoAngga ArifiantoNoch keine Bewertungen

- Bubble Point Temperature - Ideal Gas - Ideal Liquid: TrialDokument4 SeitenBubble Point Temperature - Ideal Gas - Ideal Liquid: TrialNur Dewi PusporiniNoch keine Bewertungen

- How To Effectively Implement DCIM and Bridge The Gap Between IT and FacilitiesDokument11 SeitenHow To Effectively Implement DCIM and Bridge The Gap Between IT and FacilitiesAbednego TariganNoch keine Bewertungen

- Antony Kungu - Final Project AssignmentDokument11 SeitenAntony Kungu - Final Project Assignmentapi-420816837Noch keine Bewertungen

- Tiger SharkDokument2 SeitenTiger Sharkstefanpl94Noch keine Bewertungen

- Customers at SurveyDokument10 SeitenCustomers at Surveynaren000Noch keine Bewertungen

- COP24SummaryReport 2018Dokument14 SeitenCOP24SummaryReport 2018AlfiahaleNoch keine Bewertungen

- Fuses & Circuit Breakers PDFDokument13 SeitenFuses & Circuit Breakers PDFCarlos Luis Santos SomcarNoch keine Bewertungen

- Marrantz Service Manual Using CS493263 09122113454050Dokument63 SeitenMarrantz Service Manual Using CS493263 09122113454050Lars AnderssonNoch keine Bewertungen