Beruflich Dokumente

Kultur Dokumente

Capsule Filling Guide Answers Common Questions

Hochgeladen von

luismanolo09Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Capsule Filling Guide Answers Common Questions

Hochgeladen von

luismanolo09Copyright:

Verfügbare Formate

C

o

p

y

r

i

g

h

t

,

C

S

C

P

u

b

l

i

s

h

i

n

g

.

T

a

b

l

e

t

s

&

C

a

p

s

u

l

e

s

1

capsule filling

Answers to 10 common questions

about capsule filling

Donald K. Lightfoot

Todays capsulefilling machines produceas many as 200,000

capsulesper hour thankstobetter equipment, better controls, and

a better understanding of theprocess. But if yourejust getting

started in capsulefilling, you probably havesomebasic ques-

tions about theoperation. This articleprovides answers to some

common questions about capsulefilling.

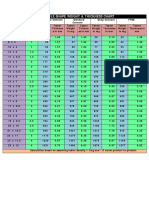

You need to determine the

density of the formulation to

answer this question. For pow-

der formulations, use the

tapped density value. For pel-

lets or granules, use the bulk

density. Once you have this

information and you know the

target fill weight, ask a capsule

supplier for a capacity chart,

such as the one shown in Table

1. Using this chart as an exam-

ple, encapsulating 500 mil-

ligrams of a powder with a

tapped density of 0.8 gram per

milliliter would require a size 0

capsule.

How do I determine the

appropriate capsule size for my

formulation?

Table 1

Capsule volumes and filling capacities

Size 000 00el 00 0el 0 1el 1 2el 2 3 4 5

Capsule 1.37 1.02 0.91 0.78 0.68 0.54 0.50 0.41 0.37 0.30 0.21 0.13

volume (ml)

Powder Capsule capacity (mg)

tapped

density

0.6 g/ml 822 612 546 468 408 324 300 246 222 180 126 78

0.8 g/ml 1096 816 728 624 544 432 400 308 296 240 168 104

1 g/ml 1370 1020 910 780 680 540 500 410 370 300 210 130

1.2 g/ml 1644 1224 1092 936 816 648 600 492 444 360 252 156

Figure 1

Example of a weight control chart

Product: Strength: mg Date:

Batch number: Operator/Checker / Page No. 1

Filling Limits(Avg.): UCL 260 mg LCL 248 mg Range: 20

Sample Time/Weights (mg)

11:17AM 11:18AM 11:30AM 11:45AM 12:00PM 12:15PM 12:30PM 12:45PM 1:00PM

1 254 262 259 251 254 257 252 255 258

2 261 263 257 246 258 255 252 255 252

3 254 257 252 260 256 256 250 249 250

4 258 259 248 253 251 255 251 254 251

5 256 254 255 251 246 255 260 257 255

6 256 261 258 255 254 254 253 259 251

7 257 254 253 250 250 253 254 252 240

8 256 259 249 251 248 251 248 250 261

9 258 258 256 258 255 253 255 248 259

10 253 259 258 252 248 252 253 252 260

Avg. 256 259 255 253 252 254 253 253 254

Range 8 9 11 14 12 6 12 11 21

C

o

p

y

r

i

g

h

t

,

C

S

C

P

u

b

l

i

s

h

i

n

g

.

T

a

b

l

e

t

s

&

C

a

p

s

u

l

e

s

weight variation has changed due to an assignable cause.

Such changes indicate that the capsule filling machine is

no longer in a state of statistical control.

2

You can accomplish this with statistical process con-

trol (SPC) techniques. SPC establishes the process capa-

bility for a specific formulation being encapsulated on a

designated filling machine. Most statistical textbooks and

publications on lean sigmaprovide the procedures and

formulas for establishing process control limits. Ive also

found a website that is particularly helpful [1], and a vari-

ety of SPC software is available.

Ive had excellent results monitoring capsule filling runs

by charting the average weights and range of weights of

the samples. Figure 1 provides an example of a control

chart (UCL stands for upper control limit. LCL stands for

lower control limit). Making a chart like this requires

using SPC procedures to determine the upper and lower

control weight limits and the upper and lower control lim-

its for the average weight and weight range. Then follow

these steps:

Take a sample of 10 capsules at regular intervals (every

15 to 30 minutes), calculate the average and range of

their weights, and plot the results on the control

chart. These plots provide a simple graphical tech-

nique for determining if the average or range val ues

are outside the control limits. See Figure 2.

If the data points are within the acceptable limits,

dont adjust the weight settings unless there is a

trend where the previous six average weight checks

were consistently above or below the centerline.

If either the average or range of weights falls outside

the control limits, stop the filling run and investigate

to determine the cause(s).

Isolate all the production collected from the previous

satisfactory weight check and evaluate it to deter-

mine the disposition for

this segment of produc-

tion. In most cases, this

segment of production is

either discarded or weight-

sorted.

Resume processing only

when you have ascertained

the causes of the change

and taken the required

corrective action to bring

the average and range

back within control limits.

We would usually perform

two weight checks a

minute apart to verify this.

In summary, the upper and

lower control limits for both

the average weight and range

of weights are used to identify

conditions where the process

How do I establish proper filling limits to effectively

monitor and control a capsule filling run?

Figure 2

Weight control chart plot

Average capsule weights

Range

Time

A

v

g

.

(

m

g

)

R

a

n

g

e

(

m

g

)

Time

262

260

258

256

254

252

250

248

246

242

25

20

15

10

5

0

244

11:17 AM 11:18 AM 11:30 AM 12:00 PM 11:45 PM 12:15 PM 12:30 PM 12:45 PM 1:00 PM

11:17 AM 11:18 AM 11:30 AM 12:00 PM 11:45 PM 12:15 PM 12:30 PM 12:45 PM 1:00 PM

Upper control limit

Limit

Range

Target weight

Avg.

Lower control limit

3

How do I ensure capsule filling quality?

The traditional approach is to perform a quality check

on a small sample (usually 10 capsules) every 30 or 60

minutes when you take a weight-check sample. While

this is certainly a good procedure and one that my capsule

filling department followed for many years, we still visu-

ally inspected the batches to remove defects that were not

always found in the routine quality checks.

Every time we analyzed a quality problem, we discov-

ered a high correlation between the setup of the capsule

filling machine and the incidence rate of defects. Based on

this, we began to check a large sample for acceptable

quality level (AQL) after every machine setup and after

every major repair. After adjusting the machine to hit the

target fill weight, we would perform a sustained run for 5

to 10 minutes, stop, and then carefully inspect every cap-

sule for defects. Using such a large sample highlighted

specific defects that, in most cases, we could attribute to

machine setup.

For example, a high incidence rate of telescopedor

split capsules indicates either a misalignment of the upper

and lower capsule segments (or bushings) or an incorrect

setting of the cap hold-down pin (or plate) in the joining

station. Dents in the capsule body indicate either an

incorrect setting of the body joining pins or an incorrect

pin size or pin configuration. Most manufacturers of cap-

sule filling machines supply a troubleshooting guide to

assist with this kind of analysis.

Based on the information obtained from these proce-

dures, we developed a detailed checklist for machine

C

o

p

y

r

i

g

h

t

,

C

S

C

P

u

b

l

i

s

h

i

n

g

.

T

a

b

l

e

t

s

&

C

a

p

s

u

l

e

s

4

7

Where and how should I store my capsules?

Empty capsules. Empty two-piece gelatin capsules are

shipped with a moisture content between 13 to 16 per-

cent. It is important that this moisture content is main-

tained. Avoid exposing the capsules to high temperatures

or to cycles of high and low temperatures. There is also a

tremendous volume of air inside the capsule that can

extract or release moisture from the capsule. Maintain the

area where you store the capsules at 15 to 25C and 35

to 55 percent relative humidity (RH). Do not store empty

What are some of the key factors to make a formula-

tion run effectively on high-speed capsule filling

machines?

The majority of high-speed filling machines dose cap-

sules using either a dosator and piston system or a tamp-

ing and dosing disc method. Each has specific formula-

tion requirements.

Dosator and piston machines require a formulation

that is well lubricated to ensure clean ejection by the pis-

ton. It also must compact well so that the plug does not

break up when the dosator is withdrawn from the powder

bed.

Tamping and dosing disc machines need formulations

with adequate lubrication for efficient plug ejection to

prevent filming and to reduce friction of the sliding com-

ponents. While the formulation must have compactabil-

ity to make coherent plugs that eject cleanly, this is less

critical for tamping and dosing disc machines than it is

for dosator and piston systems. Tamping and dosing

machines also require formulations with good flow char-

acteristics to ensure a uniform powder bed level in the

large-diameter dosing bowl.

5

6

setup, which required operators to measure components

and settings precisely at each critical step. The operator

or mechanic then had to sign off that everything on the

checklist was indeed checked. These procedures allowed

us to build quality into the process and to reduce by 85

percent the time we spent visually inspecting for defects.

That represented a significant labor savings.

What type of formulations may not be suitable for

two-piece gelatin capsules?

The best method for determining suitability is to con-

duct compatibility studies of the API and the excipients.

There are two major API characteristics that can be prob-

lematic: moisture sensitivity and hygroscopicity.

Moisture sensitivity. Two-piece gelatin capsule shells

have a moisture content between 13 and 16 percent, and

the moisture can interact with the encapsulated product

and cause stability problems.

Hygroscopicity. Once encapsulated, hygroscopic

products will remove moisture from the gelatin capsule

shell, which leads to brittleness once moisture content

drops below 10 percent.

There are two capsule alternatives to address the prob-

lems associated with these types of formulations:

Hydroxypropyl methylcellulose (HPMC) capsules and

gelatin-polyethylene glycol (PEG) capsules.

HPMC capsules have a low moisture content (4 to 6

percent), an attractive feature when dealing with mois-

ture-sensitive and hygroscopic formulations. HPMC cap-

sules have an excellent stability profile and resist physical

changes at low humidities.

There are also gelatin capsules that have been spe-

cially developed with PEG 400 to reduce brittleness

when exposed to low-moisture fills. These capsules are

more compatible with hygroscopic formulations or mois-

ture-sensitive ingredients than standard gelatin capsules.

What are some of the difficulties of filling capsules

with pellets?

The capsule filling and dosing mechanisms for pellets

and granules are based on volumetric filling, by using

either a dosing chamber or a vacuumdosator or by directly

filling into the capsule body. Inconsistency can result from

Large differences in the pellet/granule particle size

Agglomeration of the pellets/granules

Poor flow characteristics

Insufficient level of pellets in the supply hopper that

fills the dosing chamber

Electrostatic charge that retards the transfer from the

dosing chamber to the capsule body

In many cases, the pellets or granules have a functional

coating that controls release. Its important to verify that

the dosing system and the material handling system

(product feeder) are not abrading the coating, which

could affect the release profile.

Products that comprise a blend of different pellets

raise the issue of content uniformity, particularly when

the blend includes high- and low-dose pellet groups. The

pellets may segregate (de-blend) during feeding or encap-

sulation. Since many of the modern filling machines can

be equipped with more than one pellet feeding system,

you can resolve this problem by feeding the pellet prod-

ucts separately.

One challenging formulation from my experience

comprised four pellet groups: 1) Product A immediate

release, 75 milligrams; 2) Product A controlled release, 75

milligrams; 3) Product B immediate release, 12.5 mil-

ligrams; and 4) Product B controlled release, 12.5 mil-

ligrams. This formulation was filled using an MG Futura

machine equipped with two pellet dosing systems, each

of which had two dosing chambers. By dosing each pellet

group separately, we resolved the problems of blend uni-

formity and release profiles.

C

o

p

y

r

i

g

h

t

,

C

S

C

P

u

b

l

i

s

h

i

n

g

.

T

a

b

l

e

t

s

&

C

a

p

s

u

l

e

s

capsules in freezers. The empty capsules are also very sus-

ceptible to damage because the capsule walls are unsup-

ported.

Filled capsules. The storage requirements for filled

capsules are based on the product stability profile. The

warehouse storage areas should be temperature-mapped

and monitored to ensure the room temperature is under

control and that product-specific refrigeration/RH

requirements are maintained. Ideally, the storage area

would be equipped with alarms and there would be prod-

uct-specific product handling procedures that explain

how to deal with out-of-limit temperature/humidity inci-

dents. If the product is stored in bulk containers for a sig-

nificant period of time prior to packaging, you should

institute procedures to monitor bulk product stability.

General storage recommendations. Protect the cap-

sules from direct sunlight by storing them away from

windows and skylights. They should also be stored away

from radiators, heat registers, hot water pipes, and steam

pipes. Keep the capsules out from under potential sources

of water condensation, such as water pipes, and keep pal-

let loads off the floor.

8

9

10

What are the tamper-evident requirements for capsules?

The requirements for OTC capsule products are speci-

fied in 21 CFR Part 211. Section 211.132, paragraph (b)

(2) states that In addition to the tamper-evident packag-

ing feature described in paragraph (b) (1) of this section,

any two-piece, hard gelatin capsule covered by this sec-

tion must be sealed using an acceptable tamper-evident

technology.

Paragraph (c) (i) states that container labels must

include a statement that identifies all tamper-evident fea-

Table 2

Capsule banders

Supplier Model Capsules/hour Other features

IMA North America Hermetica 50,000 Automatic single-

Bristol, PA (two models) 100,000 band sealer

Built-in viscometer

Sealing and drying

plates have double row

of capsules to

www.ima.it reduce change parts

Qualicaps Lab scale 3,500 Automatic double-

Whitsett, NC band sealer

S-40 40,000 Automatic double-

band sealer

S-100 100,000 Automatic double-

www.qualicaps.com band sealer

Schaefer STI Lab Depends on Semi-automatic

Technologies top bander number of double-band sealer

Indianapolis, IN banding slats

STI CB-15 15,000 Automatic double-

band sealer

Bonapace 3,000 Automatic single-

BD-3000 band sealer

www.schaefer-technologies.com

Table 3

Excipients and packaging materials containing low levels

of aldehydes

Excipient Formaldehyde Packaging Formaldehyde

content (ppm) material content (ppm)

Starch 2.4 Rayon 2.0

Lactose 0.1 Plastic caps 2.4

Croscarmellose 0.3 Inserts 0.8

HPMC 1.1

Tween 0.3

Sodium 0.3

lauryl sulfate

ture(s) and any capsule sealing technologies used to com-

ply with paragraph (b) of this section.

Capsule banders or sealers that apply a gelatin band

around the seam area of the capsule (cap-body interface)

are considered an acceptable tamper-evident technology.

Table 2 lists the available capsule banders.

One company offers a capsule sealing system alterna-

tive to banding [2]. The FDA is currently evaluating

whether this system provides acceptable tamper-evi-

dence. See the article on page 12 for more information.

What are some things that can go wrong that people

dont anticipate?

I spent more than 30 years of my career involved with

capsule filling, so I could probably fill a novel with my

response to this question. Instead, Ill describe just two

challenging issues I encountered.

The first involved pinholes and cracks that resulted in

gradual leakage of the product from the capsule.

Recovering the batch by weight-sorting was not totally

effective, because some of the acceptable capsules would

continue to leak and would eventually become low-fills in

the package, which could trigger a product recall. Instead,

we first subjected the capsules to excessive vibration in a

vibratory sieve. That accelerated the leakage, creating low-

fills, and then we could successfully weight-sort the batch.

In most cases, pinholes and cracks occur when the

dome of the capsule body fractures due to excessive vac-

uum during separation. The problem can also stem from

incorrect setup of the joining pin. Preventing these situa-

tions is easy: Follow the setup procedures described in the

response to question 3. Installing a check valve on the vac-

uum separator line to limit the maximum suction is also

helpful.

The second incident involved the cross-linking of filled

capsules. The problemcame to our attention during a site

transfer of some products, when an accelerated stability

evaluation indicated a significant decrease in dissolution

profiles. An investigation revealed that this was the result of

the gelatin cross-linking under stress conditions. In addi-

tion, it was discovered that some of the formulations excipi-

C

o

p

y

r

i

g

h

t

,

C

S

C

P

u

b

l

i

s

h

i

n

g

.

T

a

b

l

e

t

s

&

C

a

p

s

u

l

e

s

ents contained trace amounts of aldehyde, which caused

chemical interactions with the gelatin.

Fromsearching the literature we learned that low levels

of aldehydes had been detected both in excipients and in

packaging materials and that they could cause gelatin cross-

linking. See Table 3. Consequently, we added aldehyde

testing to our acceptance specifications for all excipent and

packaging materials used with capsule products.

It should be noted that recent studies of the cross-link-

ing phenomena indicate that the bio-availability of the

drug is not significantly altered [3, 4]. The first of these

referenced studies suggests conducting two-stage in vitro

dissolution tests on dosage forms that contain hard

gelatin. In the first test, use a dissolution medium without

enzymes and in the second, use a dissolution media that

contains enzymes (gastric and intestinal media).

What is the best way to recover product fromcapsules?

Any method of recovering fill materials from capsules

must

Minimize gelatin fines;

Avoid grinding or particle size reduction of the fill

material;

Minimize attrition of the pellet/granule coating system;

Allow for validation and stability evaluation of the

recovered product; and

Be included in the filing or update if the product is

an NDA.

The traditional methods of milling and sieving do not

adequately address the above issues. You may want to

evaluate the recently introduced capsule separator/recov-

ery units listed in Table 4. These machines pull the cap-

sules apart mechanically without damaging the contents.

T&C

References

1. See www.murtongroup.com. At the bottom of the

page, click on Free-SPC Companion to download a

helpful 10-page document.

2. Liquid encapsulation microspray sealing (LEMS),

Capsugel, Greenwood, SC.

3. Digenis, G.A., Gold, T.B., and Shah, V.P. Cross-

linking of gelatin capsules and its relevance to their in

vitro-in vivo performance. J Pharm Sci 83 (7) 915-921

(1994).

4. Meyer, M.C., Straughn, A.B., Mhatre, R.M.,

Hussain, A., Shah, V.P., Bottom, C.C., Cole, E.T., Lesko,

L.L., Mallinowski, H., and Williams, R.L. The effect of

gelatin cross-linking on the bioequivalence of hard and

soft gelatin acetaminophen capsules. Pharm Res 17 (8)

962-966 (2000).

Donald K. Lightfoot is an independent consultant, 2826 W.

Placita Paciente, Tucson, AZ 85742. Tel. 520 229 3506. E-

mail: donald.lightfoot@comcast.net. Herecently retired from

GlaxoSmithKlineafter 46 years of service. As a director of

manufacturingandR&D, hegainedextensiveproduction expe-

riencein capsulefilling and other processes, including granula-

tion, tablet compression, tablet coating, pellet coating, andsup-

pository manufacturing. His expertisespans pharmaceutical

manufacturing of both clinical and commercial supplies.

Table 4

Capsule separators/recovery machinery

Manufacturer/US supplier Maximum output

Sejong Pharmatech 40,000 capsules/hr

(CMS Technologies)

Cranbury, NJ

E-mail: chiminsunwoo@hotmail.com

Vanguard Pharmaceutical 36,000 capsules/hr

Machinery

Spring, TX

www.pharmaceutical-equipment.com

Das könnte Ihnen auch gefallen

- Capsule & Tablet Size ChartDokument1 SeiteCapsule & Tablet Size ChartMahesh Patil KahatulNoch keine Bewertungen

- Corn Starch and Pregelatinized StarchDokument8 SeitenCorn Starch and Pregelatinized StarchSagita WidiyastutiNoch keine Bewertungen

- Tablet Technology EditedDokument42 SeitenTablet Technology EditedPramod Kc100% (1)

- Bruno Hancock Arden House Final HandoutsDokument18 SeitenBruno Hancock Arden House Final Handoutsdepardieu1973Noch keine Bewertungen

- 0.2011 IMA Kilian R+D Concept PDFDokument37 Seiten0.2011 IMA Kilian R+D Concept PDFPaqui Miranda Gualda100% (1)

- GS Coating Equipment enDokument8 SeitenGS Coating Equipment enAkber LakhaniNoch keine Bewertungen

- Capsugel DBcaps Sizing Information 1Dokument1 SeiteCapsugel DBcaps Sizing Information 1luismanolo09Noch keine Bewertungen

- Optimum Tablet Press Optimization - Machine Versus GranulationDokument10 SeitenOptimum Tablet Press Optimization - Machine Versus GranulationbookulNoch keine Bewertungen

- Dissolution - DisintegrationDokument10 SeitenDissolution - DisintegrationKathryn Faith Malabag100% (1)

- CapsulesDokument12 SeitenCapsulesDr-Jagadeesh MangamooriNoch keine Bewertungen

- Flow Through Cell Dissolution ApparatusDokument22 SeitenFlow Through Cell Dissolution ApparatusKimberly MccoyNoch keine Bewertungen

- Capsugel ConiSnap Sizing Information 2Dokument2 SeitenCapsugel ConiSnap Sizing Information 2CRD NEOMEDICNoch keine Bewertungen

- 01 Disintegration Test For Tablets and CapsulesDokument30 Seiten01 Disintegration Test For Tablets and CapsulesmefroNoch keine Bewertungen

- 3 Performa P Basic Machines: 4.1.2 Optional Features and Equipment (See Section 5.2)Dokument23 Seiten3 Performa P Basic Machines: 4.1.2 Optional Features and Equipment (See Section 5.2)Sangram KendreNoch keine Bewertungen

- Techniques of Tablet Coating Concepts and Advancements A Comprehensive Review 1 6Dokument6 SeitenTechniques of Tablet Coating Concepts and Advancements A Comprehensive Review 1 6Stefany Luke0% (1)

- Catalogue of Leak Test ApparatusDokument4 SeitenCatalogue of Leak Test ApparatustixocNoch keine Bewertungen

- CPR-18 - Ed 2010 IIDokument4 SeitenCPR-18 - Ed 2010 IIMin Min ZawNoch keine Bewertungen

- Tablet: Types of TabletsDokument82 SeitenTablet: Types of TabletsKema Akma100% (1)

- Formulation of Topical Products With Antiviral and AntibacterialDokument114 SeitenFormulation of Topical Products With Antiviral and AntibacterialMuhammad Masoom AkhtarNoch keine Bewertungen

- Prospective Validation of Paracetamol Tablet Dosage FormDokument10 SeitenProspective Validation of Paracetamol Tablet Dosage Formedgar palominoNoch keine Bewertungen

- Process Validation: Solid Dosage Forms Part IIDokument84 SeitenProcess Validation: Solid Dosage Forms Part IILien Hong0% (1)

- CTD Checklist DummyDokument1 SeiteCTD Checklist Dummydaizhussain004Noch keine Bewertungen

- Patented Technology in Soft Gelatin Capsule A ReviewDokument16 SeitenPatented Technology in Soft Gelatin Capsule A ReviewFatimahAhmat100% (1)

- Kasus-Film Coated TabletsDokument25 SeitenKasus-Film Coated TabletsCitra Ariani EdityaningrumNoch keine Bewertungen

- Tablet Compression Machine: Prepared By: - Akhilesh Rai (Engineering Officer) Department of Engineering Medreich LimitedDokument36 SeitenTablet Compression Machine: Prepared By: - Akhilesh Rai (Engineering Officer) Department of Engineering Medreich LimitedAkhilesh Rai100% (2)

- Standard Operating Procedure Department: ProductionDokument2 SeitenStandard Operating Procedure Department: Productionasit_mNoch keine Bewertungen

- Uncoated TabletsDokument1 SeiteUncoated Tabletsfopcu91Noch keine Bewertungen

- Pilot Scaleup Techniques For Solid Dosage Form - An Overview For TabletsDokument7 SeitenPilot Scaleup Techniques For Solid Dosage Form - An Overview For TabletsAsifNoch keine Bewertungen

- Process Validation For Atorvastatin Tablet - ArticleDokument13 SeitenProcess Validation For Atorvastatin Tablet - ArticleAnalyst NerdNoch keine Bewertungen

- Guide to Hard Gelatin Capsule ProductionDokument33 SeitenGuide to Hard Gelatin Capsule Productionalay_brahmbhattNoch keine Bewertungen

- Question and Answer For In-Process Parameters For Tablets and CapsulesDokument7 SeitenQuestion and Answer For In-Process Parameters For Tablets and CapsulesMubarak PatelNoch keine Bewertungen

- 2.PV Semisolid Fda PDFDokument37 Seiten2.PV Semisolid Fda PDFYuli SukmawatiNoch keine Bewertungen

- Brexpiprazole - Chem RevDokument112 SeitenBrexpiprazole - Chem RevSam SonNoch keine Bewertungen

- Cleaning Validation ProcessDokument11 SeitenCleaning Validation Processsamia khanNoch keine Bewertungen

- Dissolution MethodsDokument59 SeitenDissolution MethodsShiraz KhanNoch keine Bewertungen

- SOP For HPLC Shimadzu LabSolutionsDokument6 SeitenSOP For HPLC Shimadzu LabSolutionsfawaz khalilNoch keine Bewertungen

- Abstract Book JCDMCOP FinalDokument173 SeitenAbstract Book JCDMCOP FinalKapil SoniNoch keine Bewertungen

- STP Montelukast Sa.Dokument6 SeitenSTP Montelukast Sa.ShagorShagor100% (1)

- Vostem REPORT RegistDokument22 SeitenVostem REPORT RegistFajarRachmadiNoch keine Bewertungen

- Posterior Probability of Passing Compendial TestDokument47 SeitenPosterior Probability of Passing Compendial Testvg_vvgNoch keine Bewertungen

- WHO Certificate E120 2019Dokument4 SeitenWHO Certificate E120 2019Risen ChemicalsNoch keine Bewertungen

- Gkf3000s enDokument6 SeitenGkf3000s enPiotrSikoraNoch keine Bewertungen

- Carrs Index Hausner RatioDokument1 SeiteCarrs Index Hausner Ratiopharmashri5399Noch keine Bewertungen

- Development and Validation of RP-HPLC Method For Simultaneous Determination of Guaifenesin Impurities in Multi Drug CombinationsDokument9 SeitenDevelopment and Validation of RP-HPLC Method For Simultaneous Determination of Guaifenesin Impurities in Multi Drug CombinationsRouag AbdelkarimNoch keine Bewertungen

- URS Deviation ListDokument4 SeitenURS Deviation ListjaiminNoch keine Bewertungen

- VG Glatt PDFDokument14 SeitenVG Glatt PDFPankesin WonkaNoch keine Bewertungen

- LEON PHARMACEUTICALS PRODUCT DATA SHEETSDokument2 SeitenLEON PHARMACEUTICALS PRODUCT DATA SHEETSShagorShagorNoch keine Bewertungen

- Tablets: Popular Dosage FormsDokument7 SeitenTablets: Popular Dosage FormsYuppie Raj100% (1)

- Validation Protocol for Duke Process FRM3Dokument10 SeitenValidation Protocol for Duke Process FRM3Prashansa ShresthaNoch keine Bewertungen

- Art. Enteric CoatingDokument13 SeitenArt. Enteric CoatingDiana Marcela Parra BaronaNoch keine Bewertungen

- PV 01Dokument20 SeitenPV 01Logan KandanNoch keine Bewertungen

- CapsulesDokument35 SeitenCapsulesRochelle AntigNoch keine Bewertungen

- Solid Dosage Forms - CapsulesDokument14 SeitenSolid Dosage Forms - CapsulesHellcroZNoch keine Bewertungen

- Effect of Force Feeder On Tablet Strength During CompressionDokument9 SeitenEffect of Force Feeder On Tablet Strength During CompressionJosé RojasNoch keine Bewertungen

- Addendum 2019 to IP 2018: 66 New MonographsDokument2 SeitenAddendum 2019 to IP 2018: 66 New MonographspawnammalNoch keine Bewertungen

- Tamsulosina + DutasterideDokument13 SeitenTamsulosina + DutasterideJavier Hernandez100% (1)

- Asiklovir tablet product profileDokument16 SeitenAsiklovir tablet product profileAnita RuliyaniNoch keine Bewertungen

- Cleaning and disinfection of food factories: a practical guideVon EverandCleaning and disinfection of food factories: a practical guideNoch keine Bewertungen

- GCP Sect8 Packaging PerformanceDokument10 SeitenGCP Sect8 Packaging Performancelevanvui161Noch keine Bewertungen

- Performa II 07022590005Dokument180 SeitenPerforma II 07022590005Rodney Vitorino DiasNoch keine Bewertungen

- 50 Communication Activities Icebreakers and ExercisesDokument248 Seiten50 Communication Activities Icebreakers and ExercisesVaithiyanathan HaranNoch keine Bewertungen

- RM-Background-Eng Registro Medicamentos BackgroundDokument5 SeitenRM-Background-Eng Registro Medicamentos Backgroundluismanolo09Noch keine Bewertungen

- Final Report IcrelDokument207 SeitenFinal Report Icrelluismanolo09Noch keine Bewertungen

- D Cade BAS 2010Dokument4 SeitenD Cade BAS 2010luismanolo09Noch keine Bewertungen

- MRCT Proyect ReportDokument92 SeitenMRCT Proyect Reportluismanolo09Noch keine Bewertungen

- QA-QC viewpoint favors capsules over tablets for pharmaceutical preparationsDokument4 SeitenQA-QC viewpoint favors capsules over tablets for pharmaceutical preparationsluismanolo09Noch keine Bewertungen

- Capsugel DBcaps Sizing Information 1Dokument1 SeiteCapsugel DBcaps Sizing Information 1luismanolo09Noch keine Bewertungen

- QA-QC viewpoint favors capsules over tablets for pharmaceutical preparationsDokument4 SeitenQA-QC viewpoint favors capsules over tablets for pharmaceutical preparationsluismanolo09Noch keine Bewertungen

- Laboratory Techniques Option One Report SolvedDokument5 SeitenLaboratory Techniques Option One Report SolvedYasmeen AlnajjarNoch keine Bewertungen

- Calculation of Surface Area and Volume of Ponds and AssociatDokument16 SeitenCalculation of Surface Area and Volume of Ponds and AssociatLai SerranoNoch keine Bewertungen

- Department of Mechanical EngineeringDokument7 SeitenDepartment of Mechanical EngineeringMd TouhidNoch keine Bewertungen

- Soil Mechanic - Ch2Dokument31 SeitenSoil Mechanic - Ch2Yassine Kandoussi100% (1)

- Aspects of Lead Acid Battery Technology 6 Designing For Capacity PDFDokument43 SeitenAspects of Lead Acid Battery Technology 6 Designing For Capacity PDFtjkiddNoch keine Bewertungen

- ASTM D4253-16 Maximum Index Density and Unit Weight of Soil Using A Vibratory TableDokument19 SeitenASTM D4253-16 Maximum Index Density and Unit Weight of Soil Using A Vibratory TableAbeiku Naanye Bondziedu ImpraimNoch keine Bewertungen

- Lab Manual Fluid MechanicsDokument26 SeitenLab Manual Fluid MechanicsFarahSyazwaniNoch keine Bewertungen

- Extraction of Ethanol From Mixtures With N-Hexane by DesDokument8 SeitenExtraction of Ethanol From Mixtures With N-Hexane by Dessweety vermaNoch keine Bewertungen

- Introduction and Basic Concepts: Thermodynamics: An Engineering ApproachDokument49 SeitenIntroduction and Basic Concepts: Thermodynamics: An Engineering Approachtevin sessa100% (1)

- 1083ch6 1Dokument9 Seiten1083ch6 1Emad EmadNoch keine Bewertungen

- Physico-Mechanical Properties of Sapota (Achras Sapota L.)Dokument5 SeitenPhysico-Mechanical Properties of Sapota (Achras Sapota L.)Shailendra RajanNoch keine Bewertungen

- Geotechnical Engineering: Lab ManualDokument78 SeitenGeotechnical Engineering: Lab ManualajaykumarNoch keine Bewertungen

- Is 2386 2 1963 PDFDokument21 SeitenIs 2386 2 1963 PDFsherlin100% (1)

- A Different Approach To Estimate Air MoistureDokument7 SeitenA Different Approach To Estimate Air MoistureVal MosNoch keine Bewertungen

- Lab Manual For Soil TestingDokument58 SeitenLab Manual For Soil TestingSanjay MuthekarNoch keine Bewertungen

- Chapters 1, 2, & 3 - MUODokument99 SeitenChapters 1, 2, & 3 - MUOamanuelNoch keine Bewertungen

- Understanding Pressure: Units, Measurements, and CalculationsDokument2 SeitenUnderstanding Pressure: Units, Measurements, and Calculationsirma elNoch keine Bewertungen

- Measuring Real Yarn Diameter and Its Effect on Fabric QualityDokument6 SeitenMeasuring Real Yarn Diameter and Its Effect on Fabric QualityBoubker Kharchafi100% (1)

- Saso Din 51562 3 2016 eDokument13 SeitenSaso Din 51562 3 2016 eMaria AspriNoch keine Bewertungen

- Effect of Wetting Conditions On The in Situ DensitDokument10 SeitenEffect of Wetting Conditions On The in Situ DensitAlexander Angel Valda MelgarNoch keine Bewertungen

- Fluid Mechanics FundamentalsDokument15 SeitenFluid Mechanics FundamentalsJoseph ChanNoch keine Bewertungen

- Density of Soil and Rock In-Place at Depths Below Surface by Nuclear MethodsDokument7 SeitenDensity of Soil and Rock In-Place at Depths Below Surface by Nuclear MethodsIonut VasilescuNoch keine Bewertungen

- Astm D 2726 - 2000Dokument4 SeitenAstm D 2726 - 2000NazarethNoch keine Bewertungen

- Past Exam Soil MechDokument19 SeitenPast Exam Soil MechRyne TatendaNoch keine Bewertungen

- Formation of Integral Skin Polyurethane FoamsDokument11 SeitenFormation of Integral Skin Polyurethane FoamsHariHaran RajendranNoch keine Bewertungen

- Physics Daily Practice ProblemsDokument6 SeitenPhysics Daily Practice ProblemsRahulNoch keine Bewertungen

- Two Phase Flow RegimeDokument4 SeitenTwo Phase Flow RegimeRafael ReyesNoch keine Bewertungen

- Physics Grade 8Dokument5 SeitenPhysics Grade 8AshaNoch keine Bewertungen

- Mix Design Report For M-30 Grade of Concrete: M/s Aegis Logistics LTDDokument5 SeitenMix Design Report For M-30 Grade of Concrete: M/s Aegis Logistics LTD123shripadNoch keine Bewertungen

- Drying Lab ReportDokument26 SeitenDrying Lab ReportAriel Joseph Stern100% (2)