Beruflich Dokumente

Kultur Dokumente

Grinding Attachments For Lathe

Hochgeladen von

Prasath SubbuOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Grinding Attachments For Lathe

Hochgeladen von

Prasath SubbuCopyright:

Verfügbare Formate

Internal Grinding Attachments in Lathe

In the absence of agrinding machinemany repair shops complete repairs by boring and turning, when a fine degree of accuracy would be advisable. Many owners of small shops do not care to go to the expense ofinstallinggrinding machinesalthough desiringtheir use. In accompanying illustration, Fig. 336, a grindingattachmentis shown, that the designer states may be attached to anyengine latheof sufficient center capacity. The grinder itself is carried by a slab and studshaft, the arm of which is about 1.75 inches in diameter, so as to insure the necessary rigidity. The slab is attached to the face plate of the lathe by means of two .75 inch bolts, of which the top one is arranged in a radial slot, to facilitate adjustment of the work in hand. Upon the arm of the studshaft is mounted a length of solid drawn hydraulic tubing, which revolves on two brassbushingsforced and sweated into the ends of it, thus leaving an annular space for the lubricant. The tube carries a driving pulley on its inner end, thegrinding wheelbeing attached to the outer end. The driving pulley is secured to the tube by means of two set screws. This pulley is fitted with a sufficiently convex face, in order to eliminate lateral slip of the belt. The outer end of the tube is threaded to receive a thimble which is screwed and sweated into place. Owing to the path which the wheelspindlefollows the use of a floating countershaft is necessary. The connecting rod to the latter is shown broken off in the lower illustration and the arrangement of the floating countershaft is depicted in the upper drawing. As previously mentioned thefeedof thegrinding wheelis adjusted by the bolt situated in the radial slot while the travel is supplied by the lathe slide rest.

Fig. 336. - GrindingAttachmentfor Lathe Using Floating Countershaft

Some machinists display considerable ingenuity in building grinding attachments for the lathe and such a device is shown at Fig. 337. It will be noted that the design does not employ a floating countershaft. With it the inventor claims he is able to grindhardened steelspindles,camshafts, crankpins, valves, cylinders, etc., and states that in planning theattachmentconsiderable thought was given to have the equipment as rigid as possible and that all parts operated on with it should be ground quite circular. The maker states that theattachmentcan be used either for grinding internal or external work and that it can be fitted easily to the ordinary lathe. The left hand figure shows the end elevation and that at the right the grinding spindle and method of attaching it to the tool clamp of the top portion of a compound slide rest. The smaller figure shows a plan of the grinding arm itself, which is somewhat after the style of a Land is grinder. Theattachmentcan be made fairly easily, but if desired can be purchased. For internal work it is provided with a long arm but for external work, the latter is only about 3 inches in length.

Fig. 337. - GrindingAttachmentfor Lathe Using Overhead Drum. A small pulley for driving the arm is seen located between two bearings, so that it will be realized that there is no overhang to set up vibration. The method of driving the spindle consists of a countershaft carrying a drum supported by a pair of hangers placed in front of the ordinary overhead shop shaft and about central with the lathe, so that theattachmentcan travel about 6 inches on either side without materially altering the relative position of the driving belt. The driving drum consists of two 12-inch diameter pulleys about 2 inches wide. These are placed about 3 feet apart and then lagged with strips of wood one inch in width, these being placed lengthwise and attached to the pulleys by means of cap screws. The whole is then skimmed up in a lathe, and it will be found that this makes quite a nice light overhead drum, which gives nearly three feet of travel over thegrinding wheel. The small pulley is so arranged that it may be driven off the existing cone pulley on the overhead shaft which drives the lathe. By this means a good increase of velocity is given by the emery wheel. The cut is put on by means of a cross fed screw in the lathe saddle. If a taper movement is required the top rest is of course set to taper just as if one were going to machine taper in the ordinary way. The

maker of theattachmentstates that he considers the rig simple, that it will provide accuracy in grinding, and can be fitted by any average machinist.

Read more:http://chestofbooks.com/home-improvement/woodworking/Lathe-Operation/GrindingAttachments-For-Lathe.html#.UwIblPmSxic#ixzz2tabvKgvm

Das könnte Ihnen auch gefallen

- Essay PTEDokument2 SeitenEssay PTEPrasath SubbuNoch keine Bewertungen

- Git Hub LogDokument49 SeitenGit Hub LogPrasath SubbuNoch keine Bewertungen

- Codeanalysisusingsonarqubev0slideshare 140622092958 Phpapp02Dokument30 SeitenCodeanalysisusingsonarqubev0slideshare 140622092958 Phpapp02Prasath SubbuNoch keine Bewertungen

- Jim March: Senior Enterprise Microsoft Systems EngineerDokument3 SeitenJim March: Senior Enterprise Microsoft Systems EngineerPrasath SubbuNoch keine Bewertungen

- Access Rights To The EmployeeDokument3 SeitenAccess Rights To The EmployeePrasath SubbuNoch keine Bewertungen

- Install NotesDokument1 SeiteInstall NotesJoão FilipeNoch keine Bewertungen

- Hfu It Helpdesk Sla3dDokument26 SeitenHfu It Helpdesk Sla3dseventh100% (1)

- UbuntuDokument2 SeitenUbuntuPrasath SubbuNoch keine Bewertungen

- Course 6419B:: Configuring, Managing and Maintaining Windows Server 2008-Based ServersDokument10 SeitenCourse 6419B:: Configuring, Managing and Maintaining Windows Server 2008-Based ServersPrasath SubbuNoch keine Bewertungen

- XenDesktop 7.1 Hands-On Lab GuideDokument299 SeitenXenDesktop 7.1 Hands-On Lab GuidePrasath SubbuNoch keine Bewertungen

- Gas Dynamics and Jet Propulsion (May2008)Dokument4 SeitenGas Dynamics and Jet Propulsion (May2008)anon_247325887Noch keine Bewertungen

- Win7 ActivaterDokument1 SeiteWin7 ActivaterPrasath SubbuNoch keine Bewertungen

- University of Madras: Application For Revaluation of Answer ScriptDokument1 SeiteUniversity of Madras: Application For Revaluation of Answer ScriptPrasath SubbuNoch keine Bewertungen

- PicDokument1 SeitePicPrasath SubbuNoch keine Bewertungen

- Gas Dynamics and Jet Propulsion (May2008)Dokument4 SeitenGas Dynamics and Jet Propulsion (May2008)anon_247325887Noch keine Bewertungen

- IRCTC LTD, Booked Ticket PrintingDokument2 SeitenIRCTC LTD, Booked Ticket PrintingPrasath SubbuNoch keine Bewertungen

- How To Install WSUS ServerDokument34 SeitenHow To Install WSUS ServerMozertechNoch keine Bewertungen

- Vmware Web Client AddressDokument1 SeiteVmware Web Client AddressPrasath SubbuNoch keine Bewertungen

- Installing SharePoint 2013 On Windows Server 2012 R2 PreviewDokument14 SeitenInstalling SharePoint 2013 On Windows Server 2012 R2 PreviewPrasath SubbuNoch keine Bewertungen

- Installing SharePoint 2013 On Windows Server 2012 R2 Preview - Aviv RothDokument14 SeitenInstalling SharePoint 2013 On Windows Server 2012 R2 Preview - Aviv RothPrasath SubbuNoch keine Bewertungen

- How To Deploy Windows XP Professional Using Windows Deployment Services (WDS)Dokument4 SeitenHow To Deploy Windows XP Professional Using Windows Deployment Services (WDS)Prasath SubbuNoch keine Bewertungen

- Thermal Engineering (May2013)Dokument3 SeitenThermal Engineering (May2013)Prasath SubbuNoch keine Bewertungen

- Me2301 ND 2010Dokument0 SeitenMe2301 ND 2010Prasath SubbuNoch keine Bewertungen

- DB and Schema Creation Scripts MSSQL - PsDokument1 SeiteDB and Schema Creation Scripts MSSQL - PsPrasath SubbuNoch keine Bewertungen

- Applied Hydra A Pne ND11 ME2305Dokument3 SeitenApplied Hydra A Pne ND11 ME2305Prasath SubbuNoch keine Bewertungen

- Thermal Engg AM11 ME2301Dokument0 SeitenThermal Engg AM11 ME2301Prasath SubbuNoch keine Bewertungen

- How To Deploy Windows XP Professional Using Windows Deployment Services (WDS)Dokument4 SeitenHow To Deploy Windows XP Professional Using Windows Deployment Services (WDS)Prasath SubbuNoch keine Bewertungen

- Windows Deployment Services - IT Admin Tips and InformationDokument12 SeitenWindows Deployment Services - IT Admin Tips and InformationPrasath SubbuNoch keine Bewertungen

- Vmware Web Client AddressDokument1 SeiteVmware Web Client AddressPrasath SubbuNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Ar109406 19Dokument12 SeitenAr109406 19SEMENIUC MIHAELANoch keine Bewertungen

- KUBOTA Engines: Model SV Governing ACTUATORDokument5 SeitenKUBOTA Engines: Model SV Governing ACTUATORJohn YangNoch keine Bewertungen

- TrackindoDokument16 SeitenTrackindoFasya AbelNoch keine Bewertungen

- Operator'S Manual GB: Hiab X-Hiduo 138/158/188/228/258/298Dokument72 SeitenOperator'S Manual GB: Hiab X-Hiduo 138/158/188/228/258/298Jahaziel VegaNoch keine Bewertungen

- MM1001 Meritor Trailer Axle Service Manual LM & LC SeriesDokument60 SeitenMM1001 Meritor Trailer Axle Service Manual LM & LC SeriesLUKASNoch keine Bewertungen

- Centrifugal Pump: Notes, Application, Methods, Principle and DiagramDokument15 SeitenCentrifugal Pump: Notes, Application, Methods, Principle and DiagramRenNoch keine Bewertungen

- DTC Summaries: WWW - Bmwpost.ru - JOIN US!!!Dokument7 SeitenDTC Summaries: WWW - Bmwpost.ru - JOIN US!!!Александр АлександрNoch keine Bewertungen

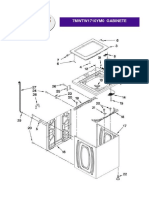

- 7MWTW1710YM0Dokument8 Seiten7MWTW1710YM0Izack-Dy JimZitNoch keine Bewertungen

- Servo MotorDokument21 SeitenServo Motorthreephasefault100% (1)

- Komatsu Wa500-6 Wheel LoadersDokument16 SeitenKomatsu Wa500-6 Wheel LoadersAbd Alkarem SalamhNoch keine Bewertungen

- Kioti DS4110 (HS), DS4510 (HS) Tractor Operator's ManualDokument15 SeitenKioti DS4110 (HS), DS4510 (HS) Tractor Operator's ManualLisakolyNoch keine Bewertungen

- Jamison-B.M.P. Industrial Rapid Doors Dynamicroll® Pe InstallationDokument30 SeitenJamison-B.M.P. Industrial Rapid Doors Dynamicroll® Pe InstallationMiroslava BiroNoch keine Bewertungen

- Study of Milling MachineDokument7 SeitenStudy of Milling Machineসুবোধ বালক0% (1)

- EotDokument16 SeitenEotMayuresh GoregaonkarNoch keine Bewertungen

- DDDDokument1 SeiteDDDKashif AliNoch keine Bewertungen

- ТрансмиссияDokument98 SeitenТрансмиссияПавлик МорозNoch keine Bewertungen

- Cat Blade 6a 6S Ser 15C 16C 85CDokument71 SeitenCat Blade 6a 6S Ser 15C 16C 85Cwiluxaju100% (1)

- MF 2615-4WD (Brosur)Dokument2 SeitenMF 2615-4WD (Brosur)ayi3xtremistNoch keine Bewertungen

- 0 200 EngeineDokument6 Seiten0 200 EngeineVipin ChahalNoch keine Bewertungen

- Rough Terrain Crane 1: ModelDokument73 SeitenRough Terrain Crane 1: Modelhung100% (2)

- 2 TFB 4Dokument16 Seiten2 TFB 4blasspascalNoch keine Bewertungen

- Evolution Series E9000 Motor Control Centers: Installation & Maintenance Guide DEH-40472 Rev. 04Dokument36 SeitenEvolution Series E9000 Motor Control Centers: Installation & Maintenance Guide DEH-40472 Rev. 04Wilson VelásquezNoch keine Bewertungen

- Mazda5 Manual ServiceDokument344 SeitenMazda5 Manual Servicegosman iosifNoch keine Bewertungen

- Jurassic Production Facility P&IDDokument5 SeitenJurassic Production Facility P&IDBiswasNoch keine Bewertungen

- GR-500EX-2 Hydraulic and Electrical System DiagramsDokument34 SeitenGR-500EX-2 Hydraulic and Electrical System DiagramsRobet carles100% (1)

- Indesit Idl500eu.2Dokument14 SeitenIndesit Idl500eu.2Biljana Stojkovic Ex MiletićNoch keine Bewertungen

- Scania dc12 Generator Engine Spec Sheet PDFDokument2 SeitenScania dc12 Generator Engine Spec Sheet PDFCharl Pietersen50% (4)

- 02 Medium Speed Diesel EngineDokument15 Seiten02 Medium Speed Diesel EngineNaveen Kumar100% (1)

- Plano Electrico 1HLDokument2 SeitenPlano Electrico 1HLRamon Hidalgo100% (1)

- Terex GTH 2506 From 10841 To 18956 Part Manual PDFDokument116 SeitenTerex GTH 2506 From 10841 To 18956 Part Manual PDFMiller Andres ArocaNoch keine Bewertungen