Beruflich Dokumente

Kultur Dokumente

Cooling Tower Fan V44 en

Hochgeladen von

padminittOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Cooling Tower Fan V44 en

Hochgeladen von

padminittCopyright:

Verfügbare Formate

3

Fans for the Closed-Loop Control of a Cooling Circuit

SINAMICS G120P_CU230P-2 from FW 4.4 Application May 2012

Applications & Tools

Answers for industry.

Siemens Industry Online Support This article is taken from the Siemens Industry Online Support. The following link takes you directly to the download page of this document: http://support.automation.siemens.com/WW/view/en/43297078

You can also actively use our Technical Forum from the Siemens Industry Online Support regarding this subject. Add your questions, suggestions and problems and discuss them together in our strong forum community: http://www.siemens.com/forum-applications

Copyright Siemens AG 2012 All rights reserved

Fans for the closed-loop control of a cooling circuit V1.3, Article ID: 43297078

Introduction Connection circuit diagram

1 2 3 4 5 6 7

Script functionality

Fans for the closed-loop control of a cooling circuit

SINAMICS G120P_CU230P-2 from FW 4.4

Description of the parameterization Motor Staging circuit diagram

Contact

History

Copyright Siemens AG 2012 All rights reserved

Fans for the closed-loop control of a cooling circuit V1.3, Article ID: 43297078

Warranty and Liability

Warranty and Liability

Note The Application Examples are not binding and do not claim to be complete regarding the circuits shown, equipping and any eventuality. The Application Examples do not represent customer-specific solutions. They are only intended to provide support for typical applications. You are responsible for ensuring that the described products are used correctly. These application examples do not relieve you of the responsibility to use safe practices in application, installation, operation and maintenance. When using these Application Examples, you recognize that we cannot be made liable for any damage/claims beyond the liability clause described. We reserve the right to make changes to these Application Examples at any time without prior notice. If there are any deviations between the recommendations provided in these application examples and other Siemens publications e.g. Catalogs the contents of the other documents have priority.

We do not accept any liability for the information contained in this document. Any claims against us based on whatever legal reason resulting from the use of the examples, information, programs, engineering and performance data etc., described in this Application Example shall be excluded. Such an exclusion shall not apply in the case of mandatory liability, e.g. under the German Product Liability Act (Produkthaftungsgesetz), in case of intent, gross negligence, or injury of life, body or health, guarantee for the quality of a product, fraudulent concealment of a deficiency or breach of a condition which goes to the root of the contract (wesentliche Vertragspflichten). The damages for a breach of a substantial contractual obligation are, however, limited to the foreseeable damage, typical for the type of contract, except in the event of intent or gross negligence or injury to life, body or health. The above provisions do not imply a change of the burden of proof to your detriment. Any form of duplication or distribution of these Application Examples or excerpts hereof is prohibited without the expressed consent of Siemens Industry Sector.

Copyright Siemens AG 2012 All rights reserved

Fans for the closed-loop control of a cooling circuit V1.3, Article ID: 43297078

Table of Contents

Table of Contents

Warranty and Liability ................................................................................................. 4 1 2 3 4 Introduction........................................................................................................ 6 Connection circuit diagram .............................................................................. 7 Script functionality ............................................................................................ 9 Description of the parameterization .............................................................. 10 4.1 4.2 4.2.1 4.2.2 4.2.3 4.2.4 4.2.5 4.2.6 4.2.7 4.2.8 4.2.9 4.2.10 4.2.11

Copyright Siemens AG 2012 All rights reserved

4.2.12 4.2.13 4.2.14 4.2.15 4.2.16 4.2.17 4.2.18

4.2.19 4.2.20 4.2.21 4.2.22 4.2.23 4.2.24 5 6 7

Importing and executing the script ..................................................... 10 Parameterization sequence ............................................................... 11 Verifying of online status .................................................................... 11 CU module interrogation .................................................................... 12 Query, scope of the parameterization ................................................ 13 Factory setting.................................................................................... 14 Quick commissioning ......................................................................... 14 Motor temperature sensing ................................................................ 15 Calculating the minimum speed ......................................................... 15 Evaluation, external belt monitoring ................................................... 15 Application.......................................................................................... 15 Pre-connecting the PID controller ...................................................... 15 Actual value sensor setting ................................................................ 16 Sensor with voltage output ................................................................. 16 Sensor with current output 0 20mA ............................................... 16 Sensor with current output 4 20mA ............................................... 16 Technology standardization (Sensor with voltage/current output)..... 16 Ni1000 resistance thermometer ......................................................... 17 Pt1000 resistance thermometer ......................................................... 17 Configuration of the PID controller ..................................................... 17 Query - starting behavior.................................................................... 18 Automatic restart ................................................................................ 19 Flying restart....................................................................................... 19 Motor Staging ..................................................................................... 19 Hibernation Mode ............................................................................... 20 Set point input .................................................................................... 20 One set point ...................................................................................... 20 Set point change ................................................................................ 21 Automatic mode ................................................................................. 21 Manual mode...................................................................................... 22 Setting of the application identifier ..................................................... 22 Setting the time and the date ............................................................. 22 Copying RAM to ROM........................................................................ 23 Applying the script .............................................................................. 23

Motor Staging circuit diagram........................................................................ 24 Contact.............................................................................................................. 25 History............................................................................................................... 25

Fans for the closed-loop control of a cooling circuit V1.3, Article ID: 43297078

1 Introduction

Introduction

Water and other cooling mediums are used in process technology and building systems in order to dissipate process heat or power lost in the form of heat. Cooling towers are used to cool down the hot cooling medium. For open circuit systems, the hot water is sprayed out through nozzles, routed through a mechanical cooler and collected in a basin or reservoir. For closed circuit systems, the cooling medium circulates through a plate-type cooler (heat exchanger). Air is used for the cooling - which flows upwards through the cooling tower. The air is either drawn in through fans at the top of the cooling tower or fans at the air intake or then forced through the cooling tower. A pump circulates the cooling medium in the cooling circuit.

Copyright Siemens AG 2012 All rights reserved

Fig. 1-1: Closed-loop fan speed control depending on the cooling medium temperature

The speed of the fan/fans can be controlled (closed-loop) by measuring the temperature of the cooling medium that flows out. At low cooling medium temperatures, only a low airflow is required; the fan rotates slowly and only blows air at a low rate. At higher cooling medium temperatures, the cooling airflow is increased, the fan now blows up to the maximum flowrate (volume flow) - and when the cascade circuit function is used, additional fans are switched-in.

Fans for the closed-loop control of a cooling circuit V1.3, Article ID: 43297078

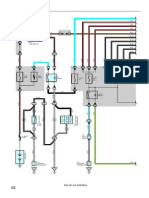

2 Connection circuit diagram

Connection circuit diagram

Copyright Siemens AG 2012 All rights reserved

Fig. 2-1 Connection circuit diagram of the inverter

Fans for the closed-loop control of a cooling circuit V1.3, Article ID: 43297078

2 Connection circuit diagram

The terminal assignment for the subsequent parameterization is as follows: DI0 On/Off DI1 Optional connection of external belt monitoring DI2 fault acknowledgement DI3 Increases the set point (MOP) in manual operation DI4 = Reduces the set point (MOP) in manual operation DI5 Changes over between automatic operation (closed-loop temperature control) and manual operation (open-loop controlled operation via MOP) AI1+/- - connection for the temperature sensor (voltage/current) AI2+/- - Connection for a resistance thermometer (switch AI2 to TEMP) PTC A/B Connection for the temperature sensor of the variable-speed fan DO0 Drive signal, fault DO1 Drive signal, alarm

Copyright Siemens AG 2012 All rights reserved

DO2 Drive signal, operation

Fans for the closed-loop control of a cooling circuit V1.3, Article ID: 43297078

3 Script functionality

Script functionality

Check the CU module (CU230P-2) and SW Version (V4.4) Select between complete parameterization or subsequent set point change Factory setting Quick commissioning Motor temperature monitoring Enter the minimum speed Sensor selection /0 - 10V/0 - 20mA/4 20mA/Ni1000/Pt1000) incl. technological calibration (xx.x Degrees Celsius) PID controller setting Select automatic restart, yes/no Select soft starting (PID controller enable is delayed), yes/no Select Hibernation Mode, yes/no A fixed set point or two set points - alternating using timer 1 and 2 (input in Degrees Celsius) BiCo wiring of the PID controller, the DI, DO incl. automatic/manual operation

Copyright Siemens AG 2012 All rights reserved

Fans for the closed-loop control of a cooling circuit V1.3, Article ID: 43297078

4 Description of the parameterization

4

4.1

Description of the parameterization

Importing and executing the script

In order to be able to work with scripts, a script folder must first be created below the CU module in STARTER. This is done by marking the CU module Select Expert using the right-hand mouse key Insert script folder

Copyright Siemens AG 2012 All rights reserved

Fig. 4-1 Importing the script folder

The scripts available as text file are imported using the "ASCII Import" link.

Fig. 4-2: Importing the script

When importing the script, the file manager opens with which the file to be run can be selected. The imported scripts are saved in the directory structure of the project in the Scripts folder.

10

Fans for the closed-loop control of a cooling circuit V1.3, Article ID: 43297078

4 Description of the parameterization

Figure 4-3 Executing the script

Copyright Siemens AG 2012 All rights reserved

The script is started by selecting the script using the right-hand mouse key and selecting "Accept and execute". The further sequence of the script is controlled using input screen forms, in which Yes/No prompts or value inputs are expected.

Note

The script can only run in online operation as it includes a reset to the factory setting (where the factory settings are restored) and motor commissioning.

4.2

Parameterization sequence

The parameterization that is carried out using the script is described in the following. Most of the settings are carried out in the background, parameters shown in bold () require that users make the appropriate entries.

4.2.1

Verifying of online status

This script can only run in online operation as it includes a reset to the factory setting (where the factory settings are restored) and motor commissioning. Because of this the script tries to establish a connection to the CU if not already online. If there is still no online connection a fault message is performed.

Fans for the closed-loop control of a cooling circuit V1.3, Article ID: 43297078

11

4 Description of the parameterization

Fig. 4-4: Message no connection to CU

4.2.2

CU module interrogation

The script is only coordinated to the functionality of the CU230P-2 HVAC, CU230P2 DP, and CU230P-2 CAN control modules; other modules are rejected.

Copyright Siemens AG 2012 All rights reserved

Fig. 4-5 Message, incorrect CU module

Further, it is assumed that the module has a minimum firmware version of V4.3. For firmware version 4.3.2 exits a separate script.

Fig. 4-6: Message, incorrect firmware version Both of these facts are queried in the background; if they are not fulfilled, then the script is interrupted.

12

Fans for the closed-loop control of a cooling circuit V1.3, Article ID: 43297078

4 Description of the parameterization

4.2.3

Query, scope of the parameterization

A selection can be made as to whether the complete parameterization is run through or whether only set points and other inputs should be subsequently changed.

Fig. 4-7: Selection screen form, scope of parameterization

CAUTION

Copyright Siemens AG 2012 All rights reserved

Make sure that no On-Signal at DI-0 is active!

To finish the parameterization successful, make sure that there is no On-signal at DI-0.

Figure 4-8

In order that set points can be subsequently displayed and entered so that they are correctly technologically scaled/normalized, the maximum pressure is entered in p2900[0]. To identify the application macro, an identifier is entered into P2901[0]. Using this identifier, the script can identify that a basic parameterization was already performed.

Fig. 4-9: Message stating that the basic parameterization has not been performed

Fans for the closed-loop control of a cooling circuit V1.3, Article ID: 43297078

13

4 Description of the parameterization

4.2.4

Factory setting

The parameterization using the script assumes that the inverter parameters are set to the values of the factory setting. Because of this the fully parameterization can only start, if factory setting is performed. In case of CU230P-2 DP the command source is changed to Terminals after the factory setting has been done. After that in a number of parameters settings will be done. At CU230P-2 DP the connections from control word will be removed. Parameter P0015 P0844[0], [1] P0852[0], [1] P0854[0], [1] P1140[0], [1] P1141[0], [1] P1142[0], [1] P1035[0] P1036[0] P1055[0], [1] P1056[0], [1] P1070[0] P1070[1] P1113[0], [1] P2103[0], [1] P2030 Value 0 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 Comment Macro drive unit No coast-down / coast-down (OFF2) Enable operation/inhibit operation Control by PLC/no control by PLC Enable ramp-function generator Continue ramp-function generator Enable set point Motorized potentiometer set point raise Motorized potentiometer lower set point Jog bit 0 Jog bit 1 Main set point Main set point Set point inversion Acknowledge faults Field bus protocol selection

Copyright Siemens AG 2012 All rights reserved

4.2.5

Quick commissioning

For the quick commissioning, a square-law V/f characteristic for the fans as well as a low overload factor is entered. After this, the system prompts you to enter the rated supply voltage, the rated current, the rated power and rated frequency as well as the rated speed. Depending on the motor standard the power factor or the efficiency factor will be prompted. This completes the quick commissioning. Parameter P0205 P0300[0] P0100 Value 1 1 0 1 2 2 Comment Load cycle with low overload Selects induction motor, rotary IEC motor (50Hz, SI units) NEMA motor (60Hz, US units) NEMA motor (60Hz, SI units) Enter rated motor voltage Enter rated motor current Enter rated motor power Rated motor power factor or Rated motor efficiency Enter rated motor frequency Enter rated motor speed V/f characteristic with parabolic characteristic

P0304[0] P0305[0] P0307[0] P0308[0], P0309[0] P0310[0] P0311[0] P1300[0]

14

Fans for the closed-loop control of a cooling circuit V1.3, Article ID: 43297078

4 Description of the parameterization

4.2.6

Motor temperature sensing

The query allows you to select between either no sensor, PTC or KTY84. As a result of the quick commissioning, the motor over temperature is specified; for deviations, parameter P0604 can be changed. Parameter P0601[0] Value 0 1 2 Comment No sensor PTC KTY84 Enter alarm threshold, motor over temperature

P0604[0]

4.2.7

Calculating the minimum speed

The minimum speed is set to 20% of the maximum frequency. Other values can be set. Parameter P1080[0] Value Comment Enter a minimum speed

Copyright Siemens AG 2012 All rights reserved

4.2.8

Evaluation, external belt monitoring

Digital input 1 is provided to connect an external sensor to monitor the belt drive between the motor and fan. This function can also be deselected. Parameter P2106[0] P2106[1] Value r722.1 r722.1 Comment DI1 external fault, automatic operation DI1 external fault, manual operation

4.2.9

Application

For closed-loop temperature control, parameter P2901[0] is set temporary to a value of 1. Because of this the script identifies that the configuration is a closedloop temperature control. Parameter P2901[0] Value 1 Comment Identifier, not finished closed-loop temperature control

4.2.10

Pre-connecting the PID controller

A fixed set point is used as step-in for the PID controller. The control sense for the closed-loop temperature control is inverse, i.e. the drive operates for as long as the actual value is greater than the set point, (actual value set point = fan speed). If the actual value is equal to or also lower than the set point, the drive operates at the minimum speed and may be switched-off as a result of the Hibernation Mode. To invert the sense of the controller, Parameter P2306 will be set to 1.

Fans for the closed-loop control of a cooling circuit V1.3, Article ID: 43297078

15

4 Description of the parameterization

Parameter P2253[0] P2306

Value r2224 1

Comment Fixed set points are used Technology controller fault signal inversion

4.2.11

Actual value sensor setting

It is possible to connect sensors with a voltage output or current output as well as Ni1000 and Pt1000 resistance thermometers.

Copyright Siemens AG 2012 All rights reserved

Fig. 4-10: Selection screen form, actual value sensor

For sensors with a voltage output, the maximum voltage can also be entered, which is then normalized (scaled) to 100% in the set point channel (e.g. sensors with 5V output voltage are generally used). Sensors with voltage and current output are connected at analog input AI1, Ni1000 and Pt1000 resistance thermometers are directly connected at analog input AI2.

Sensor with voltage output Parameter P0756[1] P0759[1] Value 0 Comment Voltage input, unipolar (0 10V) Enter the max. output voltage

Sensor with current output 0 20mA Parameter P0756[1] Value 2 Comment Current input, unipolar (0 20mA)

Sensor with current output 4 20mA Parameter P0756[1] Value 3 Comment Voltage input, unipolar (4 20mA)

Technology standardization (Sensor with voltage/current output) For sensors with voltage and current output the technological standardization is performed as followed. The maximum and minimum temperature that can be

16

Fans for the closed-loop control of a cooling circuit V1.3, Article ID: 43297078

4 Description of the parameterization

measured must be entered to normalize (scale) the technology values. The maximum value is saved in P2900[0] and the ratio of both in P758[1]; the set points refer to this value. An actual value smoothing of 100 ms is specified using parameter P2265. The actual value is connected from analog input AI1. Parameter P2900[0] 758[1] P2265 P2264 Value 0.1 r755[1] Comment Enter the maximum temperature that can be measured Ratio of min. to max. Temp. Time constant, actual value filter Actual value from analog input AI1

Ni1000 resistance thermometer Parameter P0756[2] P2900[0] P2265 P2264

Copyright Siemens AG 2012 All rights reserved

Value 6 100 0.1 r755[2]

Comment Ni1000 temperature sensor Maximum temperature that can be measured Time constant, actual value filter Actual value from analog input AI2

By selecting analog input AI2 for the resistance thermometer, the inverter performs a normalization 100% = 100 Degrees Celsius. The set point is limited to 100 Degrees Celsius.

NOTE

Switch AI2 must be set to TEMP at the front of the CU230P-2 module.

Pt1000 resistance thermometer Parameter P0756[2] P2900[0] P2265 P2264 Value 7 100 0.1 r755[2] Comment Ni1000 temperature sensor Maximum temperature that can be measured Time constant, actual value filter Actual value from analog input AI2

By selecting analog input AI2 for the resistance thermometer, the inverter performs a normalization 100% = 100 Degrees Celsius. The set point is limited to 100 Degrees Celsius.

NOTE

Switch AI2 must be set to TEMP at the front of the CU230P-2 module.

4.2.12

Configuration of the PID controller

The PID controller is interconnected as main set point. The actual value is connected from analog input AI1. Fans are only operated with a positive direction of rotation. This is the reason that the PID controller limiting is set from 0% to 100%. Three windows are opened one after the other to input the gain factor, the integral time as well as the derivative action time.

Fans for the closed-loop control of a cooling circuit V1.3, Article ID: 43297078

17

4 Description of the parameterization

Parameter P2200[0] P2251 P2297 P2298 P2280 P2285 P2274

Value 1 0 p2291 p2292

Comment Enables the PID controller Technology controller as main set point Value, positive limit Value, negative limit Enter the proportional gain Enter the integral time Enter the differentiating time

4.2.13

Query - starting behavior

A distinction can be made between immediately enabling the PID controller when switching-on the drive and soft starting; in this case, the PID controller output is opened using an up ramp that can be set. Parameter P2293 Value Comment Technology controller, ramp-up/ramp-down time in sec

Copyright Siemens AG 2012 All rights reserved

18

Fans for the closed-loop control of a cooling circuit V1.3, Article ID: 43297078

4 Description of the parameterization

4.2.14

Automatic restart

It is possible to select an automatic restart after power failure. Parameter P1210 Value 4 Comment Restart after power failure

4.2.15

Flying restart

It is possible to combine the restart after power failure with the flying restart. Search in the set point direction is preset (default setting). Parameter P1200 Value 4 Comment Flying restart active (search in the set point direction)

NOTE

Copyright Siemens AG 2012 All rights reserved

This value can only be changed in a status without faults, because of this an automatic fault acknowledge is performed. If the fault message is still active a warning message will appear and the script will go on without activating this function.

4.2.16

Motor Staging

Using the Motor Staging function, when required up to three fans can be switchedin with a fixed speed in order to maintain the air flow rate. It is possible to quickly set the Motor Staging function. You can chose between 1 to 3 auxiliary motors. It is expected that all 3 Motors have the same size. The settings of the Motor Staging are set to experience values. Depending on the particular customer requirements, post-optimization is recommended. Parameter P2370 P2371 P2373 P2374 P2375 P2376 P0732 P0731 P0730 Value 1 5.0% of p2900 10.0 10.0 15% of p2900 r2379.0 r2379.1 r2379.2 Comment Enables Motor Staging Motor Staging configuration Switch-on threshold, Motor Staging Delay time, Motor Staging Delay time, Destaging Override value, Motor Staging Control auxiliary motor 1 Control auxiliary motor 2 (if configured) Control auxiliary motor 3 (if configured)

Fans for the closed-loop control of a cooling circuit V1.3, Article ID: 43297078

19

4 Description of the parameterization

4.2.17

Hibernation Mode

The Hibernation Mode ensures that the inverter switches itself off if the temperature actual value is less than the set point for a specific time. The PID controller also remains active with the inverter switched-off. The delay time can be set as to how long the fan operates at the minimum frequency before it is switched off. The restart value is used to set the accuracy with which the inverter is switched-on again if the actual value again rises above the set point. Low setting values in the range of several percent result in a quite narrow switch-in bandwidth; high setting values in the range greater than 10% mean that the temperature can rise more before the drive is switched-in again.

NOTE

When using Motor Staging, the Hibernation delay time must be set higher than the Destaging time, as otherwise the inverter goes into the Hibernation Mode before the additional fixed-speed drives would be switched-off.

Copyright Siemens AG 2012 All rights reserved

Parameter P2398 P2391[0] P2392

Value 1

Comment Hibernation Mode activated Enter the hibernation delay time Enter the hibernation restart value

4.2.18

Set point input

The set point is entered in Degrees Celsius. Due to the normalization (scaling) of the actual value, the value is converted into a percentage and then entered as fixed set point. If a value is entered, which is greater than the maximum possible actual value, then value is rejected - and the input screen form is redisplayed. It is possible to only select one set point; using the timer, a changeover can then be made between two set points in a time-controlled fashion. If there is a gap between the timers where no set point is active, the drive will be switched off in this time.

One set point Parameter P2201[0] P0840[0] P2216 P2220[0] Value r722.0 1 1 Comment Technology controller, fixed value 1 DI0 - Drive EIN/AUS Fixed value direct selection Fixed value selection, bit 0

20

Fans for the closed-loop control of a cooling circuit V1.3, Article ID: 43297078

4 Description of the parameterization

Set point change Parameter P2201[0] P2202[0] P2216 P8410[0] P8410[1] P8410[2] P8410[3] P8410[4] P8410[5] P8410[6] P8420[0] P8420[1] P8420[2] P8420[3] P8420[4] P8420[5] P8420[6] P8411[0] P8411[1] P8412[0] P8412[1] P8421[0] P8421[1] P8422[0] P8422[1] P20030[0] P20030[1] P20030[2] P20030[3] P20032 P840[0] P2220[0] P2221[0] Value 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 r722.0 r2225.0 1 1 5 r20031 r8413.0 r8423.0 Comment Technology controller, fixed value 1 Technology controller, fixed value 2 Fixed value direct selection Activation, weekday time switch 1 Activation, weekday time switch 1 Activation, weekday time switch 1 Activation, weekday time switch 1 Activation, weekday time switch 1 Activation, weekday time switch 1 Activation, weekday time switch 1 Activation, weekday time switch 2 Activation, weekday time switch 2 Activation, weekday time switch 2 Activation, weekday time switch 2 Activation, weekday time switch 2 Activation, weekday time switch 2 Activation, weekday time switch 2 Switch-on time, time switch - 1 hour Switch-on time, time switch - 1 minute Switch-off time, time switch - 1 hour Switch-off time, time switch - 1 minute Switch-on time, time switch - 2 hours Switch-on time, time switch - 2 minutes Switch-off time, time switch - 2 hours Switch-off time, time switch - 2 minutes AND 0 Inputs, Input I0 DI0 AND 0 Inputs, Input I1 Fixed set point active AND 0 Inputs, Input I2 1 AND 0 Input, Input I3 1 AND 0 Run time group Ein/Aus1 Selection, fixed value 1 using time switch 1 Selection, fixed value 2 using time switch 2

Copyright Siemens AG 2012 All rights reserved

4.2.19

Automatic mode

In the automatic mode, the fan is operated with closed-loop control using the PID controller depending on the required control version; the set points are saved as fixed set points. Depending on the selection, the drive operates with the Hibernation Mode Parameter P20030[0] P2106[0] P2104[0] P810 Value r722.0 r722.1 r722.2 r722.5 Comment DI0 - AND 0 Input Drive on (time-dependent) DI1 External Fault (dry running protection) DI2 - Fault acknowledgement DI5 - CDS0/1 changeover

Fans for the closed-loop control of a cooling circuit V1.3, Article ID: 43297078

21

4 Description of the parameterization

4.2.20

Manual mode

The drive can be switched over from the automatic into the manual mode using DI5. In the manual mode, the PID controller is not operational, with DI3 and DI4, the motorized potentiometer, which is used as set point source, is controlled either higher or lower. The initial value of the motorized potentiometer is set to the minimum frequency, the maximum value to the maximum frequency. Parameter P840[1] P2106[1] P2104[1] P1035[1] P1036[1] P810[1] P2200[1] P1070[1] P1038[1] P1037[1] P1040[1] Value r722.0 r722.1 r722.2 r722.3 r722.4 r722.5 0 1050 p1080[0] p1082[0] p1080[0] Comment DI0 - Drive ON/OFF DI1 - External fault (dry running protection) DI2 - Fault acknowledgement DI3 - Set point, increase (raise) DI4 - Set point, decrease (lower) DI5 - CDS0/1 changeover Inhibit PID controller Main set point MOP Motorized potentiometer, minimum speed Motorized potentiometer, maximum speed Start speed, motorized potentiometer

Copyright Siemens AG 2012 All rights reserved

4.2.21

Setting of the application identifier

The identifier of the application identifier is completed as a sign of the finished script. The application identifier is the addition of 140, the common identifier of a cooling tower fan and the already in P2901 existing identifier of the closed-loop control type. Parameter P2901[1] Value 141 Comment closed-loop temperature control

4.2.22

Setting the time and the date

The internal real-time clock is set to the time and date of the PC. Parameter P8400[0] P8400[1] P8400[2] P8401[0] P8401[1] P8401[2] Value Comment RTC time, hour RTC time, minute RTC time, second RTC date, day RTC date, month RTC date, year

22

Fans for the closed-loop control of a cooling circuit V1.3, Article ID: 43297078

4 Description of the parameterization

Fig. 4-11: Message, system time was set

4.2.23

Copying RAM to ROM

When parameterization has been completed, data is backed-up by copying from RAM to ROM.

Copyright Siemens AG 2012 All rights reserved

Fig. 4-12: Message, save parameterization

4.2.24

Applying the script

After the complete parameterization has been performed, a message is displayed indicating that the script has been successfully applied. This completes parameterization. After full parameterization some changes only become effective after a Power On.

Fig. 4-13: Application of the script

Fans for the closed-loop control of a cooling circuit V1.3, Article ID: 43297078

23

5 Motor Staging circuit diagram

Motor Staging circuit diagram

Copyright Siemens AG 2012 All rights reserved

Fig. 5-1: Power wiring - inverter and fixed speed drives

Fig. 5-2: Control wiring

24

Fans for the closed-loop control of a cooling circuit V1.3, Article ID: 43297078

6 Contact

Contact

Siemens AG Industry Sector I DT MC PMA APC Frauenauracher Strae 80 D - 91056 Erlangen mailto: tech.team.motioncontrol@siemens.com

History

Table 7-1 Version V1.0 V1.1 V1.2 V1.3 Date 12/2010 02/2011 05/2011 05/2012 First Edition Revised documentation Revised Script file Revised for SINAMICS FW4.4 Modifications

Copyright Siemens AG 2012 All rights reserved

Fans for the closed-loop control of a cooling circuit V1.3, Article ID: 43297078

25

Das könnte Ihnen auch gefallen

- Cooling Tower TroubleshootingDokument4 SeitenCooling Tower TroubleshootingTobaNoch keine Bewertungen

- 05 PPT System Effects 06Dokument60 Seiten05 PPT System Effects 06Anonymous 6lLH9TMOlNoch keine Bewertungen

- Cooling Tower TDPDokument34 SeitenCooling Tower TDPjayan perkasaNoch keine Bewertungen

- Exp 2 Cooling TowerDokument15 SeitenExp 2 Cooling TowerNur amirahNoch keine Bewertungen

- AMCA 500 Damper Pressure Drop PDFDokument4 SeitenAMCA 500 Damper Pressure Drop PDFsinofreebird0% (1)

- Pump EfficiencyDokument2 SeitenPump EfficiencyRsn786Noch keine Bewertungen

- 5.energy Audit of CW SystemDokument39 Seiten5.energy Audit of CW Systembharadwaj037Noch keine Bewertungen

- Compressed Air Energy Savings ProjectsDokument64 SeitenCompressed Air Energy Savings ProjectsjaimeNoch keine Bewertungen

- Instructions for Centrifugal Fan Maintenance and TroubleshootingDokument13 SeitenInstructions for Centrifugal Fan Maintenance and TroubleshootingSusan LamNoch keine Bewertungen

- Vibration of Cooling Tower Par PDFDokument17 SeitenVibration of Cooling Tower Par PDFsanjai yadavNoch keine Bewertungen

- Best Practice Guide PumpDokument39 SeitenBest Practice Guide PumpjavgeekNoch keine Bewertungen

- Epri Cooling Tower Water Rfi PDFDokument4 SeitenEpri Cooling Tower Water Rfi PDFdrjonesg19585102Noch keine Bewertungen

- Part 1 - Fundamentals of Airflow, Fans & DuctDokument49 SeitenPart 1 - Fundamentals of Airflow, Fans & Ductkhanh.vecNoch keine Bewertungen

- Fans BlowersDokument25 SeitenFans BlowersJohn Bernard VillarosaNoch keine Bewertungen

- H&I. Condenser Performance MonitoringDokument43 SeitenH&I. Condenser Performance MonitoringRajendran SrnNoch keine Bewertungen

- Cooling Tower and Gearbox OverhaulDokument17 SeitenCooling Tower and Gearbox OverhaulIrfan UllahNoch keine Bewertungen

- HVAC Made Easy - Selection Tips For Chiller Compressors PDFDokument9 SeitenHVAC Made Easy - Selection Tips For Chiller Compressors PDFPulak MandalNoch keine Bewertungen

- Energy Savings in PumpsDokument44 SeitenEnergy Savings in PumpsAshif ARNoch keine Bewertungen

- Cooling Ponds and Cooling TowersDokument31 SeitenCooling Ponds and Cooling Towersphanendra2Noch keine Bewertungen

- Cooling TowerDokument10 SeitenCooling TowerKeshav Rao100% (1)

- Rotary Joint Reliability-2014Dokument24 SeitenRotary Joint Reliability-2014Edgar Cordova HerreraNoch keine Bewertungen

- Pump & FanDokument14 SeitenPump & FanBalraj PadmashaliNoch keine Bewertungen

- FMECA Worksheet: No. Functional Failures Failure Modes Causes EffectDokument15 SeitenFMECA Worksheet: No. Functional Failures Failure Modes Causes EffectBarathNoch keine Bewertungen

- Filter MaintenanceDokument6 SeitenFilter MaintenanceTanmay MajhiNoch keine Bewertungen

- Cooling Towers: Energy Efficient Heat ExchangersDokument17 SeitenCooling Towers: Energy Efficient Heat ExchangersAnup MauryaNoch keine Bewertungen

- Study of Booster Fan Rev. 5Dokument11 SeitenStudy of Booster Fan Rev. 5Arif Susetyo100% (1)

- Fabric Ducting&Diffusers: Technical DataDokument32 SeitenFabric Ducting&Diffusers: Technical DataJeghiNoch keine Bewertungen

- CTI Test Summary Report (Advent IT Park) T43A 178 16A 2016Dokument9 SeitenCTI Test Summary Report (Advent IT Park) T43A 178 16A 2016nagrajuNoch keine Bewertungen

- Chiller Cooling Tower AHUDokument9 SeitenChiller Cooling Tower AHUAli Hassan RazaNoch keine Bewertungen

- Cooling Tower Direct Drive ACS880 Package Training For Ext Use May 2015Dokument42 SeitenCooling Tower Direct Drive ACS880 Package Training For Ext Use May 2015Ahmed El-ShafeiNoch keine Bewertungen

- CenPEEP Cooling Tower Performance AssessmentDokument40 SeitenCenPEEP Cooling Tower Performance AssessmentHamid Ariz100% (1)

- Fatigue Failure Analysis of A Cooling Fan Blade: A Case StudyDokument7 SeitenFatigue Failure Analysis of A Cooling Fan Blade: A Case StudyJay Dee11Noch keine Bewertungen

- 45Kg Cylinder & Valve Assembly PN.81-100067-002Dokument4 Seiten45Kg Cylinder & Valve Assembly PN.81-100067-002max_powerNoch keine Bewertungen

- TRANSCO Profile - English 2012Dokument24 SeitenTRANSCO Profile - English 2012Zaher Mhd SharafNoch keine Bewertungen

- Accord Boiler Safety Program Infopack PDFDokument10 SeitenAccord Boiler Safety Program Infopack PDFTimeNoch keine Bewertungen

- Engineering Tips-Cooling TowerDokument6 SeitenEngineering Tips-Cooling TowerSharon LambertNoch keine Bewertungen

- Central Plant Optimization For Waste Energy Reduction (CPOWER)Dokument58 SeitenCentral Plant Optimization For Waste Energy Reduction (CPOWER)Chhaya ThakorNoch keine Bewertungen

- Cooling TowerDokument20 SeitenCooling Towerashish2783100% (1)

- Optimization of Cooling TowersDokument49 SeitenOptimization of Cooling TowersKhalil LasferNoch keine Bewertungen

- Compressed Air Audit - Plant Services 2Dokument11 SeitenCompressed Air Audit - Plant Services 2Swapnil PatadeNoch keine Bewertungen

- Control chilled water system for energy efficient cleanroomsDokument6 SeitenControl chilled water system for energy efficient cleanroomsSing Yew LamNoch keine Bewertungen

- District Cooling Systems ExplainedDokument7 SeitenDistrict Cooling Systems ExplainedMarzook50% (2)

- Condition Monitoring of Cooling Tower Fan Gearboxes PSM 2000 - LibreDokument10 SeitenCondition Monitoring of Cooling Tower Fan Gearboxes PSM 2000 - LibreNilma Rosa Barsallo PachecoNoch keine Bewertungen

- Rules Of Thumb For Air CompressorsDokument2 SeitenRules Of Thumb For Air CompressorsHoney Tiwari100% (1)

- Cooling TowersDokument11 SeitenCooling TowersSlim Kat Nkosi0% (2)

- Fan Inlet System EffectsDokument4 SeitenFan Inlet System EffectsEzrizal Yusuf100% (1)

- Central Plant Optimization - WhitePaper PDFDokument8 SeitenCentral Plant Optimization - WhitePaper PDFEric DunnNoch keine Bewertungen

- Class 01 Presentation - Fans in VAV Systems"Dokument62 SeitenClass 01 Presentation - Fans in VAV Systems"billyjamNoch keine Bewertungen

- Rotary CompressorDokument30 SeitenRotary CompressorSobhan PanditNoch keine Bewertungen

- Cooling Tower QuestionsDokument2 SeitenCooling Tower QuestionsNimantha Narampanawa0% (1)

- Types of Centrifugal Pump Casings ExplainedDokument2 SeitenTypes of Centrifugal Pump Casings ExplainedAsad KhanNoch keine Bewertungen

- Calculating Dryer Capacity and Size BrazilianDokument16 SeitenCalculating Dryer Capacity and Size BrazilianSteve DennisNoch keine Bewertungen

- Applikationen & Tools: Configuration of Override ControlDokument23 SeitenApplikationen & Tools: Configuration of Override Controljricardo01976Noch keine Bewertungen

- SINAMICS G120 at S7-300400-PN DOKU v10 enDokument59 SeitenSINAMICS G120 at S7-300400-PN DOKU v10 enanon_885892448Noch keine Bewertungen

- Pid Temp Doku v1 0 enDokument40 SeitenPid Temp Doku v1 0 enRoy ChaiNoch keine Bewertungen

- SINAMICS S120 PN at S7-300400 DOCU V1d0 enDokument67 SeitenSINAMICS S120 PN at S7-300400 DOCU V1d0 enAbez FiveNoch keine Bewertungen

- 2013 11 21 Simapress (Presa)Dokument151 Seiten2013 11 21 Simapress (Presa)Abez FiveNoch keine Bewertungen

- Webserver DOKU v10 enDokument76 SeitenWebserver DOKU v10 endaisy_mendoza_42Noch keine Bewertungen

- SINAMICS S120 DP at S7-300400 DOCU V1d0 enDokument69 SeitenSINAMICS S120 DP at S7-300400 DOCU V1d0 enAbez FiveNoch keine Bewertungen

- Advanced Temperature Measurement and Control, Second EditionVon EverandAdvanced Temperature Measurement and Control, Second EditionNoch keine Bewertungen

- LV 429449Dokument1 SeiteLV 429449padminittNoch keine Bewertungen

- LV 429563Dokument2 SeitenLV 429563padminittNoch keine Bewertungen

- c32 DC Return c60 Return ClarioDokument1 Seitec32 DC Return c60 Return ClariopadminittNoch keine Bewertungen

- A9V44225Dokument2 SeitenA9V44225padminittNoch keine Bewertungen

- Official Receipt for CBSE Class 1 CourseDokument1 SeiteOfficial Receipt for CBSE Class 1 CoursepadminittNoch keine Bewertungen

- Official Receipt for CBSE Class 1 CourseDokument1 SeiteOfficial Receipt for CBSE Class 1 CoursepadminittNoch keine Bewertungen

- Official Receipt for CBSE Class 1 CourseDokument1 SeiteOfficial Receipt for CBSE Class 1 CoursepadminittNoch keine Bewertungen

- A9V44263Dokument2 SeitenA9V44263padminittNoch keine Bewertungen

- Weight Per Support 1Dokument1 SeiteWeight Per Support 1Yrty KdfgNoch keine Bewertungen

- Voltage Drop CalculatorDokument2 SeitenVoltage Drop CalculatorpadminittNoch keine Bewertungen

- A9F73216Dokument3 SeitenA9F73216padminittNoch keine Bewertungen

- 2500 VA 230V safety isolation transformerDokument1 Seite2500 VA 230V safety isolation transformerpadminittNoch keine Bewertungen

- Scada SystemDokument48 SeitenScada SystemAbilraj PurathetharayilNoch keine Bewertungen

- A9R74225Dokument2 SeitenA9R74225padminittNoch keine Bewertungen

- RCA remote control data sheetDokument2 SeitenRCA remote control data sheetpadminittNoch keine Bewertungen

- Understanding Ground Fault and Leakage CurrentDokument2 SeitenUnderstanding Ground Fault and Leakage CurrentFrancis OwusuNoch keine Bewertungen

- MUX Base Module specifications and connectionsDokument2 SeitenMUX Base Module specifications and connectionspadminittNoch keine Bewertungen

- Plist TEPL9000 2010Dokument23 SeitenPlist TEPL9000 2010padminittNoch keine Bewertungen

- HMI - 22 InchDokument11 SeitenHMI - 22 InchpadminittNoch keine Bewertungen

- HMI - 15 InchDokument11 SeitenHMI - 15 InchpadminittNoch keine Bewertungen

- Apollo BFV Price SheetDokument4 SeitenApollo BFV Price SheetpadminittNoch keine Bewertungen

- Meeting NEC For Selective CoordinationDokument213 SeitenMeeting NEC For Selective CoordinationRodel Fadrogane100% (2)

- EA PRO - Ext Circular - DTD 27 11 2012 - Product Information Duobias M 7SR24...Dokument1 SeiteEA PRO - Ext Circular - DTD 27 11 2012 - Product Information Duobias M 7SR24...padminittNoch keine Bewertungen

- Datasheet WFL2-40B416 6036821 enDokument7 SeitenDatasheet WFL2-40B416 6036821 enpadminittNoch keine Bewertungen

- Excel Sheet For Luminous CalculationDokument4 SeitenExcel Sheet For Luminous Calculationaniltandon1978Noch keine Bewertungen

- Cotmac Pay Slip November 2013Dokument1 SeiteCotmac Pay Slip November 2013padminittNoch keine Bewertungen

- Plist GGC 2011Dokument13 SeitenPlist GGC 2011padminittNoch keine Bewertungen

- Plist GGC 2011Dokument13 SeitenPlist GGC 2011padminittNoch keine Bewertungen

- Comfort Point HoneywellDokument8 SeitenComfort Point Honeywellpadminitt0% (1)

- Boiler Water Level ControlDokument16 SeitenBoiler Water Level ControlYayan MulyanaNoch keine Bewertungen

- BNR Word HBW PDFDokument86 SeitenBNR Word HBW PDFHendrik BastiwNoch keine Bewertungen

- Manual de KrausDokument47 SeitenManual de Krausdavid torres rodriguezNoch keine Bewertungen

- Optimus STAV-3370 Digital Synthesized A/V Surround Receiver Owner's ManualDokument32 SeitenOptimus STAV-3370 Digital Synthesized A/V Surround Receiver Owner's ManualShane ShaneNoch keine Bewertungen

- EBE Electronic EngineeringDokument51 SeitenEBE Electronic EngineeringImisebe TelecomsNoch keine Bewertungen

- CNC MACHINE CONTROLLER SOLUTION FOR MACHINE TOOLSDokument12 SeitenCNC MACHINE CONTROLLER SOLUTION FOR MACHINE TOOLSsh.machining industries100% (1)

- Engine Control Celica 2000Dokument12 SeitenEngine Control Celica 2000Giovanni Morales100% (2)

- Application Note AN6016: LCD Backlight Inverter Drive IC (FAN7311)Dokument18 SeitenApplication Note AN6016: LCD Backlight Inverter Drive IC (FAN7311)Osama YaseenNoch keine Bewertungen

- Chapter02 PDFDokument109 SeitenChapter02 PDFJomz MagtibayNoch keine Bewertungen

- ISF2 Catalog PDFDokument8 SeitenISF2 Catalog PDFbdikicNoch keine Bewertungen

- TLE4275 q1Dokument28 SeitenTLE4275 q1GG Módulos AutomotivosNoch keine Bewertungen

- Real Time KernelsDokument39 SeitenReal Time KernelsHamdan Mahat0% (1)

- Accuforce 12v 40ah Data SheetDokument2 SeitenAccuforce 12v 40ah Data SheetAntoine GrsNoch keine Bewertungen

- Comparative Analysis of Isolated and Non-Isolated Bi-Directional DC-DC Converters For DC MicrogridDokument6 SeitenComparative Analysis of Isolated and Non-Isolated Bi-Directional DC-DC Converters For DC Microgridmamatha_sNoch keine Bewertungen

- Sony CDX GT121 GT220 GT222Dokument38 SeitenSony CDX GT121 GT220 GT222ady_f_cNoch keine Bewertungen

- Electronics and Instrumentation - 2020Dokument28 SeitenElectronics and Instrumentation - 2020RahulNoch keine Bewertungen

- 57 - Linear Predictive Coding PDFDokument7 Seiten57 - Linear Predictive Coding PDFJeya Shree Arunjunai RajNoch keine Bewertungen

- A630 A640 Advanced - Manual.enDokument147 SeitenA630 A640 Advanced - Manual.enRogue AndreeaNoch keine Bewertungen

- Madison U4359 Madisonic SensorDokument2 SeitenMadison U4359 Madisonic SensorMiguel RuizNoch keine Bewertungen

- Product Data: DescriptionDokument2 SeitenProduct Data: Descriptionjhon vargasNoch keine Bewertungen

- MTG 5MW Technical Specifications EFE 10292016Dokument1 SeiteMTG 5MW Technical Specifications EFE 10292016Anonymous wze4zUNoch keine Bewertungen

- Car & Marine Audio: Superb - Give Your Music A New Expression!Dokument13 SeitenCar & Marine Audio: Superb - Give Your Music A New Expression!taseas aivaNoch keine Bewertungen

- Siemens Hvac Damper gdb.3 1 glb.3 1Dokument10 SeitenSiemens Hvac Damper gdb.3 1 glb.3 1RAMESH RAMASAMYNoch keine Bewertungen

- Data Sheet 9 3 3 0 0 É L A N C E: FeaturesDokument8 SeitenData Sheet 9 3 3 0 0 É L A N C E: FeaturesReji RajuNoch keine Bewertungen

- System Sensor APA151 Data SheetDokument2 SeitenSystem Sensor APA151 Data SheetJMAC SupplyNoch keine Bewertungen

- CT PTDokument20 SeitenCT PTtalha0703097100% (1)

- BDA 30703 Sem 1 1213 PDFDokument7 SeitenBDA 30703 Sem 1 1213 PDFJevine LaiNoch keine Bewertungen

- VTU Seminar Report on Plastic MemoryDokument31 SeitenVTU Seminar Report on Plastic MemoryKasetti BharathiNoch keine Bewertungen

- Atys CatalogueDokument31 SeitenAtys CatalogueepicenterrulezNoch keine Bewertungen

- EV7748S-F-00A: 2.1 Channels SE and BTL Class D Audio Amplifier Evaluation BoardDokument8 SeitenEV7748S-F-00A: 2.1 Channels SE and BTL Class D Audio Amplifier Evaluation BoardJesus fuentesNoch keine Bewertungen