Beruflich Dokumente

Kultur Dokumente

Modula Rot

Hochgeladen von

Nadeem MohdCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Modula Rot

Hochgeladen von

Nadeem MohdCopyright:

Verfügbare Formate

MODULAR Operation Theatre

Clean room solutions

B RY S M E DI C A R E S OL U T ION S

QUALITY, CARE & COMPASSION

Formed with a radical thought to completely transform the Medical Equipments sector exactly the way it had done the real estate sector, BRYS Medicare, an enterprise of Rahul Gaur, seeks to bring about quality, care and compassion in the most critical area of our life HEALTH. With access to quality health care still a distant dream for majority of our countrymen, BRYS Medicare seeks to speed up the process of reaching health care to the masses through the import of stateoftheart medical equipments at affordable cost. At the same time, as the country is becoming a booming medical tourism destination, BRYS Medicare also seeks to bridge the mismatch between the demand of quality medical equipments and their supply. It is also a huge opportunity. As the Medical Devices and Supplies Market in the country is growing at a whopping pace, it places a big onus on this hitherto unorganized sector, lacking quality control and any form of standards, answerable to no one. BRYS Medicare also seeks to bring about some form of organization into this sector along with total transparency,which is backed up by strict adherence to quality norms and values. It is planning to achieve the high goals it has set before itself through Public Private Partnership model.

CLEAN ROOMS, SYSTEMS AND REDEVELOPMENT

The flexible prefabricated modular wall system for Operation Theatre interior installation has a modular grid construction. The design of the modular wall system is carried out in accordance with specified technical building requirement. The specialization of installation made by BRYS Medicare includes the following features: Technically qualified and well trained technician perform the installation with expertise Fast and well coordinated installation as per architects approval Up gradation of existing conventional Operation Theatre systems to Modular Operating Theatre Various parts are built on CNC / Laser cutting machines to give accurate dimension and finish Inside Operation Theatre Air Conditioning ducting and medical gas pipe lining is also done as per requisite specification Customized solutions to suit individual needs and surgery requirements Option of wall panel to be made of Stainless Steel sheet or Stainless Steel PU sandwich panels, Glass and Impact Project Management Complete design & construction of Operating Theatre Operating Theatre Ceilings Bacteria Free Air Flow System Ceiling Pendants Hospital & Clean room Doors with Hermetic sealing Medical Gas Pipe Line & AHU Ducting Laboratory & Corridors with central air circulation Operation Theatre and Hospital Equipments

MODULAR OPERATION THEATRE

HOSPITAL

OPERATING THEATRE INTENSIVE CARE UNIT CORRIDOR / MODULAR FURNITURE DOOR SYSTEMS

LABORATORY

STERILISATION/HOSPITAL LAB HIGH SAFETY LAB RESEARCH LAB ANIMAL TEST ROOMS

MODULAR OPERATION THEATRE

Amongst a few stateoftheart product in the offering from BRYS Medicare is the Modular Operation Theatre / Clean Room Solutions for Operation Theatres, ICUs, Laboratories and Corridors. Besides we also provide with high quality products such as Operating Tables, Lights, Hospital Furniture, Intensive care Beds and Sterilization Equipments. The Modular Operating Theatres or the Clean Rooms can effectively maintain desired sterilized environment with superior laminar air flow system and a perfect working environment for any surgeon with zero contamination. 1. The room walls are formed by Stainless Sheet, Glass or Impact prefabricated panels with a coat of antibacterial paint. 2. The outer shell panels can maintain a controlled internal environment suitable for various surgeries, not affected by the outer conditions. 3. Central Filtration System effectively generates Laminar flow with unique air flow technology to remove infection and other contamination.

MODULAR OPERATION THEATRE

METAL

Versions: Stainless steel, grounded with grain Stainless steel with powder coating Steel galvanized with powder coating Quality Material/surface: Microscopic flat and free of pores, resistant against living organism and chemical substances, resistant against all general hospital detergents and disinfectants

GLASS

Versions: Safety glass Insulated Transparent With coloured foil Satined With backlit Quality Material/surface: Microscopic flat and free of pores, resistant against living organism and chemical substances, resistant against all general hospital detergents and disinfectants

IMPACT

Versions:

Fibre cement panel: 12mm with fire resistance class, non flammable

Coating

Full colour UV hardened finish on acrylic coating covers up colour, coloured glaze with translucent structure of the fibre cement Laminate Laminated Ceramic

Quality

Laminated coating: Plain, high abrasion resistant, UV-stable, water resistant, impact resistant, resistant against living organism and chemical substances, resistant against all general hospital detergents and disinfectants

MODULAR OPERATION THEATRE

MODULAR OPERATION THEATRE

INTRACARDIAC CATHETER/ANGIOGRAPHY

Endoscopic surgery of the heart by catheter and/or diagnostic body-imaging systems with contrast agents require special Shielding Against: X-Rays Electromagnetic Fields The shielding is integrated in the wall system for all ducts for media systems.

MODULAR OPERATION THEATRE

10

MODULAR OPERATION THEATRE

OPERATION THEATRE

AREA WITH 6 OPERATING THEATRES Areas Day Surgery General surgery Heart OT Design Large protection zone under the laminar flow ceiling for open heart operations - to minimize the infection risk.

11

MODULAR OPERATION THEATRE

12

MODULAR OPERATION THEATRE

MEDICAL COMPETENCE CENTRE

Areas Reconstructive plastic surgery Aesthetic surgery Microsurgery Radiology Design Glass wall with flush integration of imaging, electric and media systems Shielding against x-rays integrated in the wall system

13

MODULAR OPERATION THEATRE

14

MODULAR OPERATION THEATRE

OPERATION THEATRE

AREA WITH MAGNETIC RESONANCE IMAGING Areas 8 General surgery OTs 1 MRI-OT Design X-ray protection up to 2 mm Pb in the wall system Control desk with free-standing shielded wall with 2.5 mm Pb Free glide path for the MRI Scanner

15

MODULAR OPERATION THEATRE

16

MODULAR OPERATION THEATRE

RECONSTRUCTION OF OPERATION THEATRE AREA

Areas 3 OTs Preparation rooms Corridor area with scrubs Furniture Design Full-high glass-system The rebuilding can be done within three months during ongoing operation handling with minimum disturbance

17

MODULAR OPERATION THEATRE

18

MODULAR OPERATION THEATRE

SPORTS CLINIC WITH LARGE CAPACITY

For optimum communication of the clinical personnel Areas Orthopaedics Sports trauma centre Cardiology Trauma surgery Design Operation theatre with 2 OT-areas

19

MODULAR OPERATION THEATRE

20

MODULAR OPERATION THEATRE

OPERATION THEATRE-AREA WITH 18 THEATRE UNITS

Areas General surgery Endoscopy Orthopaedics Cardiology Neurosurgery Recovery with 24 beds Anterrooms Scrubs Preparation rooms Stock rooms Corridor Patients transfer Furniture Vascular surgery Thorax surgery Trauma surgery Head surgery

21

MODULAR OPERATION THEATRE

22

MODULAR OPERATION THEATRE

OPERATION THEATRE ROOMS FOR MINIMAL-INVASIVE OPERATIONS

Areas Corridor walls OT rooms Changing rooms Design Medical furniture integrated in the wall system Surface for cabinets and walls are identical

23

MODULAR OPERATION THEATRE

COMPETENCE CYCLE

SERVICE AFTER SALES SERVICE INSTALLATION

ADVICE AND CONCEPT

PROJECT DEVELOPMENT AND LAYOUT

PRODUCTION

DESCRIPTION OF SERVICES PROVIDED

PROJECT PLANNING AND ENGINEERING

QUOTATION

24

MODULAR OPERATION THEATRE

SUBSTRUCTURE

CEILING PANEL SYSTEM

25

MODULAR OPERATION THEATRE

OT AIR CONDITIONING

Pre-Filter F7-F9 HEPA-Filter H13-H14

HEPA-Filter H13-H14

EXHAUST AIR CABINET

26

MODULAR OPERATION THEATRE

AIR HANDLING UNIT

DOOR SYSTEMS

VERSIONS 1-leaf hinged 2-leaf hinged Sliding Telescopic sliding Manual or automatic drive EXTRAS Windows Venetian blinds Roller blinds Radiation protection Noise or fire protection

27

MODULAR OPERATION THEATRE

SURGICAL CONTROL PANEL

Mounted flush with the wall panel Touch-screen glass interface or conventional operating interface Control functions Air conditioning Medical gases Venetian blinds Lights Intercom OT table control

DIGITAL IMAGE VIEWING SYSTEM

Digital data processing Combined with X-ray viewer Completely disinfectable

Adjustable keyboard Optional DVD/CD-burner

28

MODULAR OPERATION THEATRE

PASS-THROUGH AND BUILT-IN CABINETS

SCRUB WASHING FACILITIES

29

MODULAR OPERATION THEATRE

GLAZING

Safety glass Fire protection glass Radiation shielding glass Double glazed Venetian blinds Roller blinds Flush mounted with wall panels

REQUIREMENTS / COMPETENCE

Hygiene / Tightness

Certificates of inspection for all components

X-Ray Protection

Double wall 0.50 50 mm Pb Single wall 0.25 50 mm Pb Doors 0.25 50 mm Pb Windows 0.25 50 mm Pb Fire Protection Double wall F90 A Single wall F30 A Window F30 Sliding door T30 / EI30 Gas tight door T30 / EI30

Noise Protection Wall / Ceiling Without mineral fibre >Rw 44 dB With mineral fibre >Rw 56 dB Sliding doors with -> Rw 39 dB 30

MODULAR OPERATION THEATRE

ADVANTAGES OF MODULAR ROOM SYSTEMS

Integral and flexible construction kit system Innovative detail solutions for built-in components Certified hygiene, fire, noise and radiation protection Clearly calculable investment High planning reliability prior to installation Fast, easy and labour cost-efficient installation Ready for flexible integration of today and future systems

OUR PHILOSOPHY

BRYS MEDICARE develops, manufactures and supplies worldwide a range of integrated modular operation room solutions and components, which allow efficient and flexible use of the available space in hospitals and laboratories. We work together with professional architects, medical planners and consultants in close partnership with leading hospitals and laboratories, to achieve our aim. We develop new solutions to optimise existing ones, in order to help our customers to improve the quality and efficiency of their daily work. Process coordination Adopt design duties and responsibilities Reduce workflow Assure the quality Achieve building requirements Develop demand-oriented We are pleased about every completed project In highest quality With innovative architecture And economic success for all.

31

A division of BRYS INTERNATIONAL PVT. LTD.

A- 64, Sector 63, Noida - 201301 (U.P.), India Phone: +91.120.4532211 | Fax: +91.120.4532243 Email: info@brysmedicare.com | Web: www.brysmedicare.com

32

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- UPSC IES Weightage For ECEDokument4 SeitenUPSC IES Weightage For ECEPriyaKumar0% (1)

- T3000CS2264744 - 0 Calculation - Blast Wall SupportsDokument104 SeitenT3000CS2264744 - 0 Calculation - Blast Wall SupportsnpwalNoch keine Bewertungen

- D-11 Chapter 9 Turb Alignment and S P ClearancesDokument17 SeitenD-11 Chapter 9 Turb Alignment and S P ClearancesHernan Giraut100% (2)

- Tactics Paper 3 PDFDokument20 SeitenTactics Paper 3 PDFNadeem MohdNoch keine Bewertungen

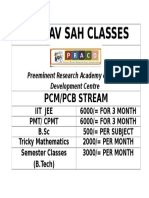

- Saurav Sah ClassesDokument1 SeiteSaurav Sah ClassesNadeem MohdNoch keine Bewertungen

- Saurav Sah Classes: E-Research LabDokument1 SeiteSaurav Sah Classes: E-Research LabNadeem MohdNoch keine Bewertungen

- Saurav Sah Classes: E-Research LabDokument2 SeitenSaurav Sah Classes: E-Research LabNadeem MohdNoch keine Bewertungen

- Curriculum Vitae: Name: Abhishek PandeyDokument2 SeitenCurriculum Vitae: Name: Abhishek PandeyNadeem MohdNoch keine Bewertungen

- Joint Entrance Screening Test: Application FeeDokument2 SeitenJoint Entrance Screening Test: Application FeeNadeem MohdNoch keine Bewertungen

- Experiment No.1 Object: Evaluate 4 Point DFT of and IDFT of X (N) 1.0 N 3 0 ElsewhereDokument1 SeiteExperiment No.1 Object: Evaluate 4 Point DFT of and IDFT of X (N) 1.0 N 3 0 ElsewhereNadeem MohdNoch keine Bewertungen

- Experiment No 3Dokument2 SeitenExperiment No 3Nadeem MohdNoch keine Bewertungen

- Experiment No. 3: Q. Transient and DC Analysis of Nor Gate InverterDokument1 SeiteExperiment No. 3: Q. Transient and DC Analysis of Nor Gate InverterNadeem MohdNoch keine Bewertungen

- 2011 CatalogDokument25 Seiten2011 CatalogClaudiaPagginiNoch keine Bewertungen

- Nanoparticle-Stabilized Foam With Controllable Structure For Enhanced Foamed ConcreteDokument12 SeitenNanoparticle-Stabilized Foam With Controllable Structure For Enhanced Foamed ConcreteDm EerzaNoch keine Bewertungen

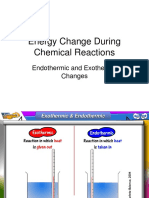

- Energy Change During Chemical ReactionsDokument36 SeitenEnergy Change During Chemical ReactionsMonday VerdejoNoch keine Bewertungen

- Waste To WealthDokument33 SeitenWaste To WealthrexNoch keine Bewertungen

- Emcable enDokument96 SeitenEmcable enm00h00Noch keine Bewertungen

- Ionpure® VNX High Flow Continuous Electrodeionization (CEDI) ModulesDokument2 SeitenIonpure® VNX High Flow Continuous Electrodeionization (CEDI) ModulesEdwinNoch keine Bewertungen

- Upholstery Leather Collection (Superhouse Limited)Dokument13 SeitenUpholstery Leather Collection (Superhouse Limited)PROFESSIONAL STUDIESNoch keine Bewertungen

- Catalytic Dewaxing ProcessDokument45 SeitenCatalytic Dewaxing ProcessBóng Đá- Quán bia tổng hợpNoch keine Bewertungen

- IS Standard For Isolators and DisconnectorsDokument44 SeitenIS Standard For Isolators and DisconnectorsdillehNoch keine Bewertungen

- Electrical Installation For Second Floor For G+2Dokument1 SeiteElectrical Installation For Second Floor For G+2Welday GebremichaelNoch keine Bewertungen

- Waste Heat Recovery Ppi00443en PDFDokument56 SeitenWaste Heat Recovery Ppi00443en PDFdsahmedNoch keine Bewertungen

- 计量泵metering pump PDFDokument43 Seiten计量泵metering pump PDFAnonymous Tj3ApePIrNoch keine Bewertungen

- Copper (II) OxideDokument5 SeitenCopper (II) OxideWill Aguilar MamaniNoch keine Bewertungen

- Swaged and Lightweight Welding NozzlesDokument5 SeitenSwaged and Lightweight Welding NozzlesDries VandezandeNoch keine Bewertungen

- Manual Triplex PumpDokument45 SeitenManual Triplex PumpSalineñoApasionado100% (1)

- Series 4000 - Bituminous Layers and SealsDokument52 SeitenSeries 4000 - Bituminous Layers and SealsBatenda Felix0% (1)

- Metal WindowsDokument21 SeitenMetal Windowsshubhankar mishraNoch keine Bewertungen

- Spairality of Weft Knit FabricDokument5 SeitenSpairality of Weft Knit FabricObak Prithibi100% (1)

- Catalogo de Aire Acondicionado Compacto Carrier 50TC-17-30-V-02PD (17 A 30 T.R)Dokument98 SeitenCatalogo de Aire Acondicionado Compacto Carrier 50TC-17-30-V-02PD (17 A 30 T.R)Luis Eduardo Carmona VasquezNoch keine Bewertungen

- PadajucebrtveDokument11 SeitenPadajucebrtveMonk3y MNoch keine Bewertungen

- SP 1099Dokument34 SeitenSP 1099Muthu KumaranNoch keine Bewertungen

- HSCDokument13 SeitenHSCrexdindigulNoch keine Bewertungen

- Lecture 9 Life Cycle AssessmentDokument18 SeitenLecture 9 Life Cycle AssessmentAmmar SafwtNoch keine Bewertungen

- AFS, KanpurDokument5 SeitenAFS, Kanpurdipmoip2210Noch keine Bewertungen

- Report 2506Dokument12 SeitenReport 2506Ari Wibowo NugrohoNoch keine Bewertungen

- Reduction in Steam NeDokument14 SeitenReduction in Steam NeArif ShafiNoch keine Bewertungen

- Transmission Electrical Testing On 096Dokument45 SeitenTransmission Electrical Testing On 096Michelle KerriganNoch keine Bewertungen