Beruflich Dokumente

Kultur Dokumente

Water Proofing

Hochgeladen von

raghuram prasad100%(2)100% fanden dieses Dokument nützlich (2 Abstimmungen)

457 Ansichten2 SeitenWater proofing creates an impervious barrier to prevent water from entering or escaping building structures. It can be applied to substrates like cement, concrete, render, fiber cement, gypsum boards and timber. There are different types of water proofing products and methods, including membrane/barrier water proofing, in-depth water proofing via crystallization, and grouting structures. Membrane water proofing forms an external layer barrier and can use cementitious, polymer membrane, or a combination of both materials.

Originalbeschreibung:

Copyright

© Attribution Non-Commercial (BY-NC)

Verfügbare Formate

DOC, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenWater proofing creates an impervious barrier to prevent water from entering or escaping building structures. It can be applied to substrates like cement, concrete, render, fiber cement, gypsum boards and timber. There are different types of water proofing products and methods, including membrane/barrier water proofing, in-depth water proofing via crystallization, and grouting structures. Membrane water proofing forms an external layer barrier and can use cementitious, polymer membrane, or a combination of both materials.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

100%(2)100% fanden dieses Dokument nützlich (2 Abstimmungen)

457 Ansichten2 SeitenWater Proofing

Hochgeladen von

raghuram prasadWater proofing creates an impervious barrier to prevent water from entering or escaping building structures. It can be applied to substrates like cement, concrete, render, fiber cement, gypsum boards and timber. There are different types of water proofing products and methods, including membrane/barrier water proofing, in-depth water proofing via crystallization, and grouting structures. Membrane water proofing forms an external layer barrier and can use cementitious, polymer membrane, or a combination of both materials.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

WATER PROOFING

Water proofing is the formation of an impervious barrier which is

designed to prevent water entering or escaping from various sections of

building structures.

Water proofing can be applied to various substrates and back grounds

such as

• Cement

• Concrete

• Render

• Fiber

• Cement sheets

• Gypsum boards and

• Timber.

WATER PROOFING PRODUCTS :

Water proofing products such as mainly classified into categories.

• Bituminous

• Butyl rubber

• Neoprene rubber

• Hypalon etc…,

TYPES OF WATER PROOFING:

Water proofing can be classified into three types.

1. Membrane or Barrier water proofing.

2. In depth water proofing or water proofing by Crystallization.

3. Grouting of structure.

1.MEMBRANE WATER PROOFING:

In Membrane or Barrier water proofing an external layer is formed

which makes barrier to water leakage. This system can be classified as

further into the following.

a) Cementitous water proofing.

b) Polymer membrane water proofing.

c) Combination of Cementitous and Polymer membrane waofingter

proofing.

a.CEMENTITOUS WATER PROOFING :

Cementitous water proofing systems are one that uses cementitous materials.

E.g.:

i. External plaster

ii. Box type water proofing using stones

iii. Brick bat coba systems.

These are used in Indian Civil Industries.”

b.POLYMER MEMBRANE WATER PROOFING:

These membranes are classified further into two categories

i. Pre- fabricated water proofing.

ii. In- situ water proofing membranes.

PRE-FABRICATED WATER PROOFING:

These membranes are fabricated in the factory and joints are sealed at

the site.

IN-SITU WATER PROOFING MEMBRANES :

The water proofing chemicals comes in liquid form brush or spray

applied at site. The solvent evaporates (either organic solvent or

water based) and a water proofing membrane is formed over the

surface. Materials are used

• Acrylic

• Polyurethane

• Bituminous and

• Epoxy .

Acrylic and Polyurethane can be used for exposed areas and are

considered to be more durable systems. These systems can have high

flexibility and excellent bonding with substrates. These systems also

have good reflectivity. These systems are more suitable where we

expect movement of substrates.

c.COMBINATION OF CEMENTITOUS AND POLYMER MEMBRANE

WATER PROOFING :

These systems are either two components considering of dry

cementitous powder and liquid, to be mixed together to get brushable slurry

or single component having cement and polymer together in dry form. These

are most commonly used water proofing systems because of cause of

application and excellent bonding with cementitous substrates. The

membrane can with stand high water proofing pressure.

2.IN-DEPTH WATER PROOFING OR WATER PROOFING BY

CRYSTALLIZATION :

In-depth water proofing means water proofing treatment deep into the

concrete structure. It is a treatment to the body of the concrete inside. There

is a no layer get damaged. There is no layer to be protected. This is the only

technology, which shows whether structure has only bad concrete to treat

(honey-combed concrete) or the structures is cast better concrete particles.

Das könnte Ihnen auch gefallen

- Self-Cleaning Materials and Surfaces: A Nanotechnology ApproachVon EverandSelf-Cleaning Materials and Surfaces: A Nanotechnology ApproachWalid A. DaoudBewertung: 5 von 5 Sternen5/5 (1)

- WaterproofingDokument23 SeitenWaterproofingKenneth Ituralde BesmonteNoch keine Bewertungen

- Hygard Plast - RebtradeDokument1 SeiteHygard Plast - RebtradeWrec SerranoNoch keine Bewertungen

- C W Rystalline Aterproofing: (An 9001: 2015, 14001: 2015 & 18001: 2007 Certified Company) ISO ISO OhsasDokument8 SeitenC W Rystalline Aterproofing: (An 9001: 2015, 14001: 2015 & 18001: 2007 Certified Company) ISO ISO OhsasgangadevimgmNoch keine Bewertungen

- AdmixtureDokument7 SeitenAdmixturevinay rodeNoch keine Bewertungen

- Gypsum: Gypsum As A Construction MaterialDokument29 SeitenGypsum: Gypsum As A Construction Materialsarah KhalidNoch keine Bewertungen

- Drfixit Torchshield PDFDokument4 SeitenDrfixit Torchshield PDFshashiNoch keine Bewertungen

- VINNAPAS® Polymer Powders PDFDokument34 SeitenVINNAPAS® Polymer Powders PDFnznikosNoch keine Bewertungen

- Cement, Concrete & Mortar: Product Characteristics Brand NameDokument2 SeitenCement, Concrete & Mortar: Product Characteristics Brand NameAliaksandr PrybauNoch keine Bewertungen

- 2021 Exterior Paint Program ApplicationDokument4 Seiten2021 Exterior Paint Program ApplicationKaylyn Renee100% (3)

- KrytonDokument4 SeitenKrytonProject Manager IIT Kanpur CPWDNoch keine Bewertungen

- BPD Master Catalogue-2Dokument18 SeitenBPD Master Catalogue-2Dr. Manamohan R KalgalNoch keine Bewertungen

- EXPANDIT 10 Mortar Comparison TestDokument1 SeiteEXPANDIT 10 Mortar Comparison TestLaura GarcíaNoch keine Bewertungen

- Dokumen - Tips - Waterborne Silicates in Coatings and Construction Waterborne Silicates inDokument37 SeitenDokumen - Tips - Waterborne Silicates in Coatings and Construction Waterborne Silicates inLong An Đỗ100% (2)

- Formulation Techniques Using Feve Resins in Waterborne and HighDokument10 SeitenFormulation Techniques Using Feve Resins in Waterborne and HighManuel ChireNoch keine Bewertungen

- Construction Chemicals: Total Solution ofDokument4 SeitenConstruction Chemicals: Total Solution ofdwijNoch keine Bewertungen

- Brochure DHP - PU 3000 R1Dokument17 SeitenBrochure DHP - PU 3000 R1Zainudin Zuhri100% (1)

- Marketing Plan AkimDokument10 SeitenMarketing Plan AkimqpwoeirituyNoch keine Bewertungen

- S# Item C Waterproofing On SurfacesDokument8 SeitenS# Item C Waterproofing On SurfacesDeepa Junnarkar Degwekar100% (1)

- Incozol 2 DataDokument2 SeitenIncozol 2 DataJeffrey Bempong100% (1)

- Product Presentation: Technical Service Department Pacific Paint (BOYSEN) Philippines, IncDokument62 SeitenProduct Presentation: Technical Service Department Pacific Paint (BOYSEN) Philippines, Incmark manalangNoch keine Bewertungen

- Steelguard: The Superior Cellulosic Fire Protection SolutionDokument8 SeitenSteelguard: The Superior Cellulosic Fire Protection Solutionengindmec100% (1)

- Wanhua Interior Coating SolutionsDokument28 SeitenWanhua Interior Coating SolutionsThanh Vu100% (1)

- Report On Crystaline WaterproofingDokument11 SeitenReport On Crystaline WaterproofingAnkita Baban GavadeNoch keine Bewertungen

- Waterproofing Systems GuideDokument28 SeitenWaterproofing Systems GuideAlex Bocica100% (1)

- BOQ Water Proofing With BASF RangeDokument1 SeiteBOQ Water Proofing With BASF Rangehemantrulz0% (1)

- 2,1.1 How To Prepare Concrete For Acid StainingDokument14 Seiten2,1.1 How To Prepare Concrete For Acid StainingJoebert RendonNoch keine Bewertungen

- Acronal MB 6476Dokument3 SeitenAcronal MB 6476jose mondacaNoch keine Bewertungen

- Super Plasticizers: Classification and Uses - Concrete TechnologyDokument8 SeitenSuper Plasticizers: Classification and Uses - Concrete TechnologyLASA VADODARANoch keine Bewertungen

- Mastertop 1205: Three Component Solvent Free High Build Epoxy Floor CoatingDokument3 SeitenMastertop 1205: Three Component Solvent Free High Build Epoxy Floor CoatingEngTamerNoch keine Bewertungen

- Paten US8957127 - Liquid Glue Formulated With Acrylic Emulsions - Google PatenDokument4 SeitenPaten US8957127 - Liquid Glue Formulated With Acrylic Emulsions - Google PatenSepvan ValeriNoch keine Bewertungen

- Polymer Modified Mortars and CementDokument9 SeitenPolymer Modified Mortars and CementKunwar Apoorv Singh Parihar100% (1)

- What Is GlueDokument15 SeitenWhat Is Gluekhan100% (1)

- GFRCDokument4 SeitenGFRCrahulchandokNoch keine Bewertungen

- Incozol 2 TDSDokument1 SeiteIncozol 2 TDSArmando Van BuurenNoch keine Bewertungen

- Admixture Brochure PDFDokument16 SeitenAdmixture Brochure PDFFrancois-Noch keine Bewertungen

- RubberDokument17 SeitenRubberJoann DavinaNoch keine Bewertungen

- Fundamentals of Dispersion PDFDokument24 SeitenFundamentals of Dispersion PDFEugene PaiNoch keine Bewertungen

- Cymel® 303 LF: Product Description Typical PropertiesDokument2 SeitenCymel® 303 LF: Product Description Typical Propertiesهیمن مNoch keine Bewertungen

- One Component Pu Foams - FormulationDokument10 SeitenOne Component Pu Foams - FormulationgunelNoch keine Bewertungen

- Polyurea Spray PDFDokument9 SeitenPolyurea Spray PDFSesha GiriNoch keine Bewertungen

- Waterproof Casein AdhesiveDokument1 SeiteWaterproof Casein AdhesiveDayanand RudraNoch keine Bewertungen

- Sika Tilling SystemsDokument32 SeitenSika Tilling SystemsEduardo Rojas100% (1)

- Dr. C. D. Modhera - Day 3 - Session 1Dokument93 SeitenDr. C. D. Modhera - Day 3 - Session 1mbgfknjhgfNoch keine Bewertungen

- VN110 Cross-Linked PVA GLUEDokument2 SeitenVN110 Cross-Linked PVA GLUEDgek LondonNoch keine Bewertungen

- Comparitive of Waterproofing WorkDokument12 SeitenComparitive of Waterproofing WorkReshik KannanNoch keine Bewertungen

- Pergut EDokument17 SeitenPergut ECesar MartinezNoch keine Bewertungen

- Acronal - Plus - 7023 - Jan 2020Dokument3 SeitenAcronal - Plus - 7023 - Jan 2020Nikhil GoyalNoch keine Bewertungen

- Rheofibre - BasfDokument2 SeitenRheofibre - BasftheshadowknightNoch keine Bewertungen

- BCT Assignment 2Dokument26 SeitenBCT Assignment 2Sanskriti SrivastavaNoch keine Bewertungen

- Marine Paint Guide: 4. Theoretical & Practical CoverageDokument6 SeitenMarine Paint Guide: 4. Theoretical & Practical CoverageTanmay GorNoch keine Bewertungen

- Activated Chemicals of Cementitious Capillary Crystalline WaterproofingDokument10 SeitenActivated Chemicals of Cementitious Capillary Crystalline Waterproofingshahriz amriNoch keine Bewertungen

- Floor FinishesDokument23 SeitenFloor FinishesHafizah Ezani100% (1)

- Acronal NX 3587: ConstructionDokument3 SeitenAcronal NX 3587: ConstructionRajuNSanaboinaNoch keine Bewertungen

- CLC BricksDokument19 SeitenCLC BricksAJ Darphynit100% (1)

- Wood Coatings 101 Part 1Dokument26 SeitenWood Coatings 101 Part 1No NameNoch keine Bewertungen

- Formulators and Suppliers To The Paint, Coatings, and Ink IndustryDokument16 SeitenFormulators and Suppliers To The Paint, Coatings, and Ink IndustryDharmendra B MistryNoch keine Bewertungen

- Geosynthetics in Seepage Control SystemDokument15 SeitenGeosynthetics in Seepage Control SystemDonna May YatcoNoch keine Bewertungen

- Water ProofingDokument23 SeitenWater ProofingSIDDHANT VERMANoch keine Bewertungen

- Refresher-Module 12 (S8) USD Beams 2Dokument1 SeiteRefresher-Module 12 (S8) USD Beams 2Fely Joy RelatoresNoch keine Bewertungen

- 419 - Composites Catalogue-AtulDokument12 Seiten419 - Composites Catalogue-AtulVaittianathan Mahavapillai100% (1)

- PBN DatasheetDokument1 SeitePBN DatasheetLove MishraNoch keine Bewertungen

- Vision Filter CatalogueDokument9 SeitenVision Filter CataloguevisionfilterNoch keine Bewertungen

- Astm A 29 (1030)Dokument10 SeitenAstm A 29 (1030)Rizki FebriyantoNoch keine Bewertungen

- Wear of Silicon Nitride Bonded Sic Bricks in Aluminium Electrolysis CellsDokument6 SeitenWear of Silicon Nitride Bonded Sic Bricks in Aluminium Electrolysis CellsOctaviano MichinelNoch keine Bewertungen

- Handouts-Concrete Common Field ProblemsDokument20 SeitenHandouts-Concrete Common Field ProblemsAndresPeresNoch keine Bewertungen

- Concrete Industrial Ground Floor Slab Desig1Dokument3 SeitenConcrete Industrial Ground Floor Slab Desig1Mahata PriyabrataNoch keine Bewertungen

- Civil Thumb RulesDokument8 SeitenCivil Thumb RulesNasreen khushi muhammad Nasree100% (1)

- e-StatementBRImo 107101000260307 Aug2023 20230905 004028Dokument12 Seitene-StatementBRImo 107101000260307 Aug2023 20230905 004028Fedy HermawanNoch keine Bewertungen

- 11 3921 01 Advanced Silicone Adhesives and SealantsDokument16 Seiten11 3921 01 Advanced Silicone Adhesives and SealantsDung TranNoch keine Bewertungen

- ASTM Codes Designation1111 PDFDokument7 SeitenASTM Codes Designation1111 PDFTres Marias HernandezNoch keine Bewertungen

- Earthing Cable Cu/Xl-Lszh To Bs En: 50525-3-41: Construction of The CableDokument4 SeitenEarthing Cable Cu/Xl-Lszh To Bs En: 50525-3-41: Construction of The Cabletees220510Noch keine Bewertungen

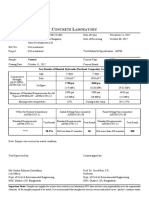

- Oncrete Aboratory: Test Results of Blended Hydraulic (Portland Composite) CementDokument2 SeitenOncrete Aboratory: Test Results of Blended Hydraulic (Portland Composite) CementNadira PervinNoch keine Bewertungen

- ISA 20T2201 Pick ListDokument9 SeitenISA 20T2201 Pick ListJeff SauckNoch keine Bewertungen

- Inconel Alloy 690Dokument8 SeitenInconel Alloy 690Zeeshan SajidNoch keine Bewertungen

- BRK Electronic Descaling SystemDokument5 SeitenBRK Electronic Descaling SystemSuresh DNoch keine Bewertungen

- Refractory Material COTS Vendor Survey-AppendixBDokument6 SeitenRefractory Material COTS Vendor Survey-AppendixBAdrian García MoyanoNoch keine Bewertungen

- FRCore Sewing Factory ListDokument8 SeitenFRCore Sewing Factory ListSean WangNoch keine Bewertungen

- Tentative Program-12 ICSP-SepDokument14 SeitenTentative Program-12 ICSP-SepmohammadrezaNoch keine Bewertungen

- Bentone 34Dokument2 SeitenBentone 34Kris SzongNoch keine Bewertungen

- Cargo Inspection Checklist - SafetyCultureDokument10 SeitenCargo Inspection Checklist - SafetyCultureTayebiNoch keine Bewertungen

- WRAS+Approvals+Guidance+App+a+V2 8+apr+07Dokument14 SeitenWRAS+Approvals+Guidance+App+a+V2 8+apr+07davethiyaguNoch keine Bewertungen

- Sealants: Caulking Is ADokument12 SeitenSealants: Caulking Is ASheeza ShaanNoch keine Bewertungen

- LEXAN™ Resin ML3290 - SABICDokument5 SeitenLEXAN™ Resin ML3290 - SABICbobNoch keine Bewertungen

- Fosroc Structuro W420: Constructive SolutionsDokument2 SeitenFosroc Structuro W420: Constructive SolutionsVincent JavateNoch keine Bewertungen

- Half Day CC Roads Construction 9th March 2023 and Joints and ExmplesDokument123 SeitenHalf Day CC Roads Construction 9th March 2023 and Joints and ExmplesrajibchattarajNoch keine Bewertungen

- Cathodic Protection Corrosion Control and PreventionDokument67 SeitenCathodic Protection Corrosion Control and PreventionRully KurniawanNoch keine Bewertungen

- Empire State BuildingDokument5 SeitenEmpire State BuildingPayal GolwalaNoch keine Bewertungen

- Ingredient Percentage in Cement: Lime Silica Alumina Magnesia Iron Oxide Calcium Sulfate 0.1-0.5 Sulfur Trioxide AlkalineDokument13 SeitenIngredient Percentage in Cement: Lime Silica Alumina Magnesia Iron Oxide Calcium Sulfate 0.1-0.5 Sulfur Trioxide AlkalineAnupam KumarNoch keine Bewertungen