Beruflich Dokumente

Kultur Dokumente

4 Minimize Total Landed Cost (Lectura para Quitz 3 Primera Parte)

Hochgeladen von

John Gutierrez TapiasOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

4 Minimize Total Landed Cost (Lectura para Quitz 3 Primera Parte)

Hochgeladen von

John Gutierrez TapiasCopyright:

Verfügbare Formate

Search inf ormation & articles on this site:

Go

Robert Bianco is president of Menlo Worldwide January, 2006 | List all 3PL Line articles 650-378-5200

Minimize Total Landed Cost: Strategize, Model, Act

By Robert Bianco

T ot a l landed cost is the sum of a ll costs associated with m aking a nd delivering pr oducts t o the point where t hey produce r evenue -- u sually your custom er's door . So, if y ou em ploy tactics to r educe costs in a ll discrete functions from m anufacturing t h rough delivery, you'll have a lower t otal landed cost, r ight? T heoretically, yes. But in t he real world, cost savings in on e area often r esult in cost increases in another. Ra w m aterials and freight are cheaper in volume, for example. Bu t warehousing and in v entory costs go u p when that volume land s on your dock. Conversely, show me a w a rehouse that operates on just-in-tim e deliveries, and I'll show you a high freight bill. T o fin d the lowest total landed cost, you have t o think strategically. Rather than v iew y our supply chain as a series of discrete functions, think of it as a whole. Y our goal is t o r educe the cost of t hat whole. T h is approach h elps you think outside the box. Ra ther t han focus on lower w a rehouse costs, for example, you begin t o wonder if you need that warehouse at all. T h at idea, in turn, sets off a chain of t houghts -- t r ansportation changes, stable in v entory, different sources of raw material...you get the picture. On ce you'v e conceived a strategic approach for lowering total landed cost, it's t ime t o m odel it. Spreadsheets are cumbersom e, and m odeling software is expensive and h a s a steep learning curve, so ou tsourcing t he developm ent of y our m odel is often y our best bet.

W h en choosing som eone to dev elop the m odel, look for an expert in supply chain desig n and operations, not just a techie who knows h ow t o drive the software. Y ou n eed som eone who can create solutions from practical logistics experience. It 's g ood t o r un v arious "what-if" scenarios. Don 't sim ply m odel a pre-conceived solu t ion and a ccept the result. If y ou have a supply source in China, for example, run a m odel that com pares it to a source in t he United States. T his t ests and qu antifies t h e trade-offs between a longer chain t hat has lower unit costs but greater inventory, a n d a sh orter chain with less inventory but higher unit costs. It 's a lso g ood t o run sensitivity analyses to determine how robust the m odel's design is. T est it by m odelling transportation costs a gainst oil prices, or a t otal disruption in y our supply chain, such as a port strike. What are y ou r options in those situations? A s y ou m ight guess, a model's quality depends on the qu antity and quality of t he da t a it is built upon. Models are also t ime -dependent: the m ore com plex y our supply ch ain, the longer it takes to dev elop a model. The potentia l savings, however, are g r eat -- ty pical com panies save 6 percent t o 12 percent. A da pting the Model W it h a su ccessful model in hand, and continuing focus on the total landed cost, you ca n put on your t actical hat, and fuss ov er discrete t actical functions. W ork the su pply chain backward from the custom er, on e function at a tim e -- keep in m ind t h at ev ery supply chain process or function you com prom ise fr om the m odel a ffects ot h er processes, either positively or negatively. Rem em ber t hat supply chains are perpetually changing, so t he r ight m odel t oday ca n easily be wrong t om orrow. A n ew product introduction, a different vendor, in creased freight costs -- t h ese all im pact your t otal landed cost strategy. T h e g ood n ews is t hat a strategy is easier to m odify t han t o create. The m odel you u sed t o finalize t he first a pproach will still be there to t inker with.

TOMADO DE: http://www.inboundlogistics.com/articles/3plline/3plline0106.shtml Logistics Inbound, revista logstica.

Das könnte Ihnen auch gefallen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Cheats de Pokemon Radical Red My BoyDokument14 SeitenCheats de Pokemon Radical Red My BoyHyrum MamaniNoch keine Bewertungen

- EVMS Gold CardDokument1 SeiteEVMS Gold CardHaneefa ChNoch keine Bewertungen

- FM QPDokument4 SeitenFM QPtimepass3595Noch keine Bewertungen

- Aboitiz Subcontractor's Profile FormDokument6 SeitenAboitiz Subcontractor's Profile FormRizza Jane ArriesgadoNoch keine Bewertungen

- International Cotton GradesDokument5 SeitenInternational Cotton GradesSamir AliyevNoch keine Bewertungen

- Topic 8 AsphaltDokument20 SeitenTopic 8 Asphaltvirkaalam02Noch keine Bewertungen

- Bba 1st Sem - Microeconomics-Mid Term QuestionDokument4 SeitenBba 1st Sem - Microeconomics-Mid Term QuestionSanjay Kumar isNoch keine Bewertungen

- L3.3 - Comparative AdvantageDokument1 SeiteL3.3 - Comparative Advantage12A1-41- Nguyễn Cẩm VyNoch keine Bewertungen

- Ownership History: Vehicle InformationDokument3 SeitenOwnership History: Vehicle InformationChinni SwethaNoch keine Bewertungen

- Brilliant Negotiations What Brilliant Negotiators Know, Do and SayDokument153 SeitenBrilliant Negotiations What Brilliant Negotiators Know, Do and SayThomas FederuikNoch keine Bewertungen

- Enrich Chap7Dokument6 SeitenEnrich Chap7hmtuanbkNoch keine Bewertungen

- Examen Final Semana 8 INGLES 1 1 INTENTODokument13 SeitenExamen Final Semana 8 INGLES 1 1 INTENTOClaudia100% (1)

- Homework Chap 25Dokument2 SeitenHomework Chap 25An leeNoch keine Bewertungen

- Math For JU Admision Test PDFDokument43 SeitenMath For JU Admision Test PDFUzma ProthomaNoch keine Bewertungen

- Chapter1. Financial Accounting Theoretical FrameworkDokument5 SeitenChapter1. Financial Accounting Theoretical FrameworkadiNoch keine Bewertungen

- 01 Place of Supply - GST IDTC - CA. Vishal Poddar - 23-Sep-2020Dokument58 Seiten01 Place of Supply - GST IDTC - CA. Vishal Poddar - 23-Sep-2020TheEnigmatic AccountantNoch keine Bewertungen

- MULTIPLE CHOICE. Choose The One Alternative That Best Completes The Statement or Answers The QuestionDokument14 SeitenMULTIPLE CHOICE. Choose The One Alternative That Best Completes The Statement or Answers The QuestionSoweirdNoch keine Bewertungen

- Performance BudgetingDokument2 SeitenPerformance BudgetingDr Ringco TrozanNoch keine Bewertungen

- ASTM E84 Rev 11 1 2017 ED 10 31 2019Dokument7 SeitenASTM E84 Rev 11 1 2017 ED 10 31 2019Phương HoàngNoch keine Bewertungen

- Liebherr Crane Liccon Service TrainingDokument20 SeitenLiebherr Crane Liccon Service Trainingcalvin100% (53)

- Total Qty - 4 Nos Material - UNS F33100 / ASTM A536 65-45-12Dokument1 SeiteTotal Qty - 4 Nos Material - UNS F33100 / ASTM A536 65-45-12sudipta dasNoch keine Bewertungen

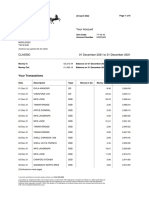

- Your AccountDokument6 SeitenYour AccountJean FurtadoNoch keine Bewertungen

- Tuning Lua Don't StarveDokument28 SeitenTuning Lua Don't StarveDirga PwNoch keine Bewertungen

- 2016 Preqin Global Private Equity & Venture Capital: Sample PagesDokument15 Seiten2016 Preqin Global Private Equity & Venture Capital: Sample PagesJZNoch keine Bewertungen

- Alisa Firsova. Assignment On Topic 1. The Transnationality Index Task 1Dokument2 SeitenAlisa Firsova. Assignment On Topic 1. The Transnationality Index Task 1Alice FirsovaNoch keine Bewertungen

- Invoice Local: Bank Bank Bri No. Va: 131064210008527Dokument1 SeiteInvoice Local: Bank Bank Bri No. Va: 131064210008527Carvahal JamesNoch keine Bewertungen

- Sheet Metal Products 3940Dokument298 SeitenSheet Metal Products 3940maxisinc.in100% (1)

- Project Report On Grocery Shop: Mrs Atsü PhomDokument5 SeitenProject Report On Grocery Shop: Mrs Atsü PhomShyamal DuttaNoch keine Bewertungen

- Planned Maintenance Manual: GEK-75889J SUP. 2, REV. 1Dokument2 SeitenPlanned Maintenance Manual: GEK-75889J SUP. 2, REV. 1ait mimouneNoch keine Bewertungen

- FinmanDokument9 SeitenFinmanCharles MateoNoch keine Bewertungen