Beruflich Dokumente

Kultur Dokumente

A Fully Differential Potentiostat

Hochgeladen von

guiburCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

A Fully Differential Potentiostat

Hochgeladen von

guiburCopyright:

Verfügbare Formate

IEEE SENSORS JOURNAL, VOL. 9, NO.

2, FEBRUARY 2009

135

A Fully Differential Potentiostat

Steven M. Martin, Member, IEEE, Fadi H. Gebara, Timothy D. Strong, Member, IEEE, and Richard B. Brown, Senior Member, IEEE

AbstractLow-voltage, single-ended (SE) potentiostats are unable to detect many analytes of interest because the oxidation potentials of these analytes are greater than the voltage that the potentiostat can deliver to the electrodes. In this work, a fully-differential (FD) potentiostat is described which enables detection of a wide range of analytes using a supply voltage of 1.8 V. The FD potentiostat was implemented in TSMCs 0.18 m CMOS process and has been veried experimentally. A theoretical discussion of the FD potentiostat is given and comparisons to SE potentiostats are provided. Biological and environmental analytes are chemically detected using the FD potentiostat. Index TermsChemical transducers, CMOS analog integrated circuits, electrochemical analysis, potentiostat.

I. INTRODUCTION RANSDUCERS which utilize electrochemical sensing principles are capable of detecting many important analytes and are utilized in applications such as biomedical devices, environmental monitoring, and laboratory research [1], [2]. A common electrochemical transducer for the study of liquid analytes is the amperometric sensor. The electronic interface for these transducers is a circuit known as a potentiostat [3]. The potentiostat serves two main functions. It is used to induce a specied potential drop between a sensing electrode and a liquid solution. It also serves to amplify the resulting current from the chemical reaction at the sensing electrode. Historically, the induced voltage was held constant throughout an experiment. However, many current electrochemical analyses, known as voltammetric techniques, continuously vary the applied potential. Research on integrated CMOS potentiostats generally falls into three categoriespotentiostats designed to improve accuracy and detection limit, multiple potentiostats integrated onto a single chip for biological array applications, and potentiostats

Manuscript received May 13, 2008; accepted June 21, 2008. Current version published January 09, 2009. This work was supported in part by a U.S. National Science Foundation Graduate Research Fellowship and by the Engineering Research Centers Program of the U.S. National Science Foundation under Award EEC-9986866. The associate editor coordinating the review of this paper and approving it for publication was Prof. Evgeny Katz. S. M. Martin was with the University of Michigan, Ann Arbor, MI 48109 USA. He is now with Avago Technologies, Fort Collins, CO 80525 USA (e-mail: stevenmm@umich.edu). F. H. Gebara was with the University of Michigan, Ann Arbor, MI 48109 USA. He is now with IBM Research, Austin, TX 78753 USA (e-mail: fhgebara @us.ibm.com). T. D. Strong was with the University of Michigan, Ann Arbor, MI 48109 USA. He is now with GE Analytical Instruments, Ann Arbor, MI 48108 USA (e-mail: strongtd@ieee.org). R. B. Brown was with the University of Michigan, Ann Arbor, MI 48109 USA. He is now with the University of Utah, Salt Lake City, UT 84112 USA (e-mail: brown@utah.edu). Digital Object Identier 10.1109/JSEN.2008.2011085

integrated with mixed-signal functionality. Wei et al. [4] demonstrated a chopper-stabilized potentiostat to improve DC offset, Kakerow et al. [5] demonstrated a switched-capacitor potentiostat for high accuracy measurements, Breten et al. [6] demonstrated an integrating potentiostat with dual-slope ADC for improved detection limits, and Martin et al. [7] demonstrated a pseudo-differential potentiostat to enable a highly accurate analysis technique known as subtractive anodic stripping voltammetry. Bandyopadhyay et al. [8] implemented a distributed potentiostat system for neural applications. Schienle et al. [9], created arrays of potentiostats for DNA applications. Others have demonstrated potentiostats integrated with data converters [10], [11], with digital control [12], on general purpose microcontrollers [13], and with the amperometric sensors themselves [9], [12], [14], [15]. These potentiostat designs, however, do not address the problems that arise when the supply voltage is scaled. An analyte can be detected only when the applied potential is in excess of the chemical species standard potential. (This is described in greater detail in Section II.) As the supply voltage is scaled, the number of detectable analytes is reduced because the maximum potential difference that can be applied between the electrode and the solution is diminished. Narula et al. [16] demonstrated a potentiostat that improved the dynamic range of chemical sensors in low-voltage processes by dynamically translating the sensor signals into time-encoded values. That potentiostat, however, did not address the reduction in maximum applied electrode potential. Furthermore, its dynamic range can degrade as the rate of the voltammetric sweep increases. All aforementioned potentiostats utilized a single-ended (SE) architecture. This work, which extends a short conference paper [17], describes a fully differential (FD) potentiostat that doubles the dynamic range of the system, but more importantly, maximizes the number of detectable analytes for a given supply voltage. The FD potentiostat was implemented in TSMCs CMOS process and operates with a nominal supply 0.18 voltage of 1.8 V. This process and operating voltage were chosen because the potentiostat was designed as a standard cell for the low-power, mixed-signal, WIMS microcontroller [18]. The WIMS microcontroller can serve as a platform for many integrated sensing applications which require chemical detection including remote environmental monitoring and neural prosthesis. An introduction to electrochemical sensors is presented in Section II. In Section III, a standard, SE potentiostat is described. The FD potentiostat is presented in Section IV and compared to the SE potentiostat. Measured characteristics for both circuits are given. Electroanalytical experiments performed using the FD potentiostat are also reported.

1530-437X/$25.00 2009 IEEE

136

IEEE SENSORS JOURNAL, VOL. 9, NO. 2, FEBRUARY 2009

II. ELECTROCHEMISTRY REVIEW The following description highlights only the aspects of electroanalytical chemistry which are germane to understanding the development of the FD potentiostat. The interested reader is directed to Bard et al. [3] for a more detailed discussion of electrochemistry. A. Faradaic Current Under equilibrium, and in the absence of an externally applied voltage, a single polarizable electrode resting in solution will develop a potential based on the ratio of the solutions chemical species [3]. When a voltage sufciently larger than this equilibrium potential (an overpotential) is applied to the electrode, this forces the system out of equilibrium and results in a reduction/oxidation (redox) reaction of the form (1) where is the oxidized form of the species, is the number of is an electron, electrons per molecule oxidized or reduced, and is the reduced form of the species. For every reduction or oxidation, electrons are transferred from solution to electrode or vice versa. This results in a faradaic current at the is a function of electrode surface. Among other parameters, the concentration of the oxidized species and the electrode area. Thus, the measured faradaic current corresponds to a specic ion concentration. B. Overpotentials In aqueous solutions, the overpotential required to induce a redox reaction for a given chemical species is approximately equivalent to that species standard potential [3]. If a sufcient overpotential cannot be applied to the electrode, then an analytical measurement of that chemical species cannot be obtained. Using a platinum electrode, a water-based solution tends to breakdown for overpotentials more positive than 1.5 V and [19]. Applying overpotentials outmore negative than side of is of minimal analytical value. As we will see in Section III, a standard, SE potentiostat operating with a voltage supply below 3 V, cannot detect every species within waters potential window. This is an important (and detrimental) consequence of operating in low-voltage processes and led to the development of the FD potentiostat. C. Amperometric Sensors Single electrode systems are operationally impractical. A typical sensor conguration is the three-electrode amperometric cell. The three electrodes are: the auxiliary electrode (AE), the reference electrode (RE), and the working electrode (WE), as shown in Fig. 1(a). The faradaic reaction of interest occurs at the WE. The RE, which ideally draws zero current, is a nonpolarizable electrode that tracks the solution potential. Consequently, the potential between the electrode and solution which induces the faradaic reaction, is given by (2)

Fig. 1. Three-electrode amperometric sensor. (a) Schematic representation. (b) Simplied electrical-equivalent model.

where and are the potentials at the WE and RE, reis dened by spectively. The amperometric cells potential (2). The AE enables the potential of the solution to be set via secondary redox reactions and sources the current necessary for the faradaic reaction. Fig. 1(b) shows an electrical-equivalent model of a three-electrode amperometric cell. Solution impedances, which are typiand represent faradaic resiscally small, are neglected. tances, and and are the double-layer capacitances associated with the AE and WE, respectively. These double-layer capacitances are given by (3) is the capacitance of electrode , is the area of the where is a constant with an approximate value of electrode , and [20]. is dened as 0.36 (4) Note, that if changes, must be recalculated based on the measured . It is inappropriate to assume that an increase necessarily causes an increase in . Recall that is in proportional to electrode area. Since, the AE is designed to be . much larger than the WE, A microfabricated, platinum (Pt) WE measuring 0.004 was used in this work [21]. The double-layer capacitance of this WE was approximately 1.4 nF, and for chemical concentrations was approximately 1 . The AE in the millimolar range, was a platinum wire with a measured double-layer capacitance of approximately 10 . A of approximately 1 uF and an macrosized saturated calomel RE was used. For low frequencies, the electrical-equivalent sensor model simplies into two series resistors. This two-resistor model, and , is used for the remainder with of the analyses in this work.

MARTIN et al.: A FULLY DIFFERENTIAL POTENTIOSTAT

137

Fig. 2. SE potentiostat.

Fig. 3. Fully differential potentiostat.

III. SINGLE-ENDED (SE) POTENTIOSTAT Fig. 2 shows a typical potentiostat using the standard, SE topology [3]. As stated previously, a primary function of the potracks an applied source voltage, tentiostat is to ensure that , under varying current-loading conditions. The negative creates a virtual ground at the WE. feedback around opamp is given by Thus, neglecting opamp offset, (5) to ensure that no curThe REs potential is buffered by rent is drawn through the RE. The negative feedback around (which is connected via the amperometric cell) forces node to ground. The voltage seen at node is 1/2 of the sum of and . It follows that node is only equal to zero (ground) or by (5), when . Thus, the negwhen ative feedback of the potentiostat ensures that tracks . Since the WE is statically held at virtual ground, the value of can only be altered by changing the potential at the AE. This limits the use of the SE potentiostat in low-voltage sysin the SE architems-on-chip (SoC). The voltage swing of , assuming that has rail-to-rail output, is then tecture, dened by the voltage swing at the AE (6) is the positive supply voltage and is the negative where supply voltage. The potentiostat also amplies the sensors faradaic current. . The sensors current ows This is accomplished with through (which is referenced to virtual ground) to provide an amplied current-to-voltage conversion such that (7)

version. The circuit operates as follows. The potentials on both the reference and WEs are buffered by and and are summed with the differentially applied source voltage. Since the , is congured for negative feedback, the differFD opamp, ential voltage at its input terminals is ideally equal to zero and is given by (8) Rearranging this equation yields (9) The right-hand side of this equation is equivalent to the cell voltage and thus, the FD potentiostat works to ensure that tracks . has rail-to-rail output, the voltage swing Assuming that , is given by for the FD potentiostat (10) Comparing this to the swing of the SE potentiostat yields (11) Assuming is negligible, the voltage swing is doubled. serves to develop a voltage proportional to the faradaic current and is inserted in each half of the circuit to maintain symmetry is differentially buffered around ground. The voltage across and , and the output of the FD potentiostat is using given by (12) Equations (10) and (12) demonstrate a tradeoff in sizing . Increasing the value of , increases the gain of the circuit, but it also reduces the signal swing of the FD potentiostat. In practice, this is not a concern since typical currents from microelectrodes is 10 the are in the microampere range or below. Thus, if is only 10 mV. voltage drop across In addition to the improved signal swing, the FD potentiostat suppresses common-mode noise and doubles the dynamic range of the sensors output due to its differential nature [22].

IV. FULLY DIFFERENTIAL POTENTIOSTAT A. Theory The new, fully differential potentiostat is shown in Fig. 3. In contrast to the SE architecture, the FD potentiostat can dynamically control the voltages on both the auxiliary and WEs. The FD potentiostat can, thus, double the voltage range of the SE

138

IEEE SENSORS JOURNAL, VOL. 9, NO. 2, FEBRUARY 2009

The amplication of the faradaic current to an output voltage also suffers from offset problems. Unfortunately, the FD potentiostats output voltage has double the offset variation of the SE versions output voltage. 3) Noise: Electronic noise on the cell potential is of negligible concern due to its small value compared to typical applied voltages and the fact that the typical impedance between the solution and the WE is large. Noise on the signal output voltages, however, directly affects the minimum detectable signal (or chemical concentration) of the circuit. In the absence of is leakage currents, the only current that can ow through the faradaic current and the equivalent input-noise current of as it ows to the output of . The signal-to-noise ratio (SNR) of the FD potentiostat is given by

Fig. 4. Magnitude of V

=V

versus opamp gain and R .

(17) is the equivalent squared input current noise of , where is the equivalent squared input voltage noise of , and is the equivalent squared noise of . The SE potentiostats SNR is given by (18) is the equivalent squared input current noise of where and is the equivalent squared noise of . The FD potentiostat has an additional voltage noise term in the denominator which lowers its SNR. Thus, to achieve performance equivalent to the SE potentiostat, the FD circuit must reduce the noise and . This can require larger bias curassociated with rents and/or larger device geometries depending on the dominant form of the opamp noise. In ultra-low-current applications, and can be sized in the multimegaohm range and resistor thermal noise may overpower the noise from the active electronics. C. Design Both FD and SE potentiostats were implemented in TSMCs CMOS process using the nominal supply 0.18 voltage. As shown in (13) and (14), large gains are required and . The common-mode range of the signals for can occur anywhere within the range of the supplies, therefore opamps with rail-to-rail inputs are required. To achieve the maximum signal swing, the opamps must also have rail-to-rail outputs. Additionally, the outputs must drive the large double-layer capacitances of the working and AEs. Based on these requirements, the opamps were designed using an architecture presented in [23] that combines a rail-to-rail input stage, foldedcascode gain stage, and class AB common-source output stage. The schematic of the FD opamp is shown in Fig. 5. The transistor dimensions are given in micrometers. The SE opamps have a similar topology, but do not require the common-mode feedback (CMFB) circuit, have a diode connection in each half of the folded-cascode stage, and have only a single branch of the class AB output stage. The compensation capacitors were set to 5 pF to ensure stability. For the specied values of the

B. Nonidealities Since the FD potentiostat is composed of opamps, it is instructive to examine how opamp nonidealities affect the function of the circuit. These are compared to nonidealities in the SE potentiostat. The analyses presented in this section utilize the low-frequency, electrical-equivalent sensor model. be the open-loop gain of opamp 1) Open-Loop Gain: Let . Assuming that , a detailed circuit analysis of the FD potentiostat yields

(13) Fig. 4 shows the plot of (13) versus the choice of , the open, and the open-loop gain . For , a gain of loop gain about 100 (40 dB) sets the transfer function close to the ideal value of 1. To make the transfer function tolerant of large values , and thus achieve higher gains, opamp requires an of open-loop gain of nearly 10 000 (80 dB). The transfer function for the SE potentiostat has a similar form given by (14) are similar to those of in the The requirements of FD potentiostat. 2) Opamp Offset: The circuit analysis of the FD potentiostat including opamp offset yields a cell voltage offset given by (15) where is the offset of . Comparatively, the equation for the offset in the SE potentiostat is approximated by (16) if is assumed to be much greater than 2. Note the similarity between (15) and (16). Thus, the cell potentials offset is similar for the FD and SE potentiostats.

MARTIN et al.: A FULLY DIFFERENTIAL POTENTIOSTAT

139

Fig. 5. Fully differential opamp.

Fig. 6. Micrograph of the potentiostat test chip. Fig. 7. (a) V

three-electrode cell and this value of compensation capacitor, the simulated phase margin of the FD opamp was 51 . and were chosen to provide identical curResistors rent-to-voltage gains while still maintaining adequate signal and were set to 10 and implemented in swing. Both and were a high-resistance polysilicon layer. Resistors . also set to 10 V. EXPERIMENTAL RESULTS Fig. 6 is a micrograph of the 0.18 potentiostat test chip. All bond pads were connected to standard ESD structures. The /0.36 . The FD and SE ESD transistors measured 2800 opamps were experimentally veried. Both opamps had openloop gains greater than 90 dB, bandwidths equal to approximately 440 kHz into a 16 pF load, and full-scale output voltages at 4 kHz into 0.1 uF loads, slew rates greater than 0.5 V/us, PSSR values greater than 80 dB, and input resistances greater

. (b) Sinusoidal control of both RE and WE.

than 100 . The FD opamp consumed 533 , whereas the . SE opamp consumed 225 and set to 10 and 1 , A dummy load cell with respectively, was used to characterize the potentiostats. Fig. 7(a) to for both the is a plot of the transfer function from FD and SE potentiostats. The plot shows that the transfer function is close to unity for both cases. As predicted by theory, the swing of the FD potentiostat is twice the swing of the SE potentiostat. An oscilloscope screen capture [Fig. 7(b)] shows that in the FD potentiostat both the RE and WE voltages are dynamically changing. Note, that although the signal is almost twice occurs. The offset of the supply voltage, no clipping of was measured on 22 different dice. The mean offset for , whereas the mean offset the FD potentiostat was for the SE potentiostat was 0.7 mV. The standard deviations

140

IEEE SENSORS JOURNAL, VOL. 9, NO. 2, FEBRUARY 2009

Fig. 10. Noise spectral density of FD potentiostats output. Fig. 8.

versus temperature.

TABLE I SUMMARY OF CHARACTERIZATION RESULTS FOR THE FD AND SE POTENTIOSTATS

Fig. 9. On-chip gain for the (a) FD potentiostat and (b) SE potentiostat.

of the offsets for the FD and SE potentiostats were 2.7 and over 24 h was measured 3.1 mV, respectively. The drift of and for the FD and SE potentiostats, as respectively. The transfer function to was also measured versus temperature. This is an important specication if the potentiostat is integrated onto a substrate with circuits dissipating large amounts of power. Fig. 8 shows the plot of transfer function magnitude and offset versus operating temperature. Fit to straight lines, the temperature coefcients for slope error are and 50 for the FD and SE potentiostats, re20 spectively. The offset scales similarly for both potentiostats at . To further amplify the output voltage before sending the of both the FD and SE potentiostats signal off chip, the was routed through on-chip gain stages as shown in Fig. 9. The output noise was measured using a high-impedance active probe (Agilent 48100A) connected to a spectrum analyzer. Fig. 10 shows the noise spectral density for the FD potentiostats output. The total integrated noise in a 500 Hz bandwidth for the

FD and SE potentiostats was 2.5 and 2.9 mV, respectively. Most chemical experiments are not operated above 500 Hz. Due to the FD potentiostats differential nature, the dynamic range of is expected to improve by 6 dB. Since the measured output noise of the FD potentiostat was slightly lower than the noise in the SE potentiostat, the dynamic range improved by 7 dB. The FD potentiostat increased the common-mode signal rejection by over 20 dB versus the SE potentiostat. This noise rejection was ultimately limited by on-chip resistor matching. The for both potengain error versus temperature was tiostats while the FD potentiostat had a gain offset variation of and the SE potentiostat had a gain offset variation . These results indicate that the FD potentiostat of is well-suited for integrated system-on-chip (SoC) applications, where low voltages and high switching noise are common. Table I compares the two potentiostats based on measured data. The supply currents were large because the opamps were designed for 1 nF loads to facilitate use of the potentiostats with macroelectrodes if necessary. Additionally, to speed development, only high-current opamps were implemented. With further optimization and exclusive use of the potentiostats with microelectrodes, the power consumption could be reduced to the microwatt range and could provide for long-term, remote SoC use. VI. ELECTROCHEMICAL ANALYSES The FD potentiostat and the previously described microfabricated amperometric sensor were used to perform electrochemical analyses. Fig. 11 shows cyclic voltammograms (CVs) [3] using a Pt electrode in a solution of 5 for the detection of mM NaBr, 100 mM NaCl electrolyte. Bromide has a standard

MARTIN et al.: A FULLY DIFFERENTIAL POTENTIOSTAT

141

in solutions were created with concentrations from 0.6 to 1 100 mM KCl, pH 4.3 buffer solution. Dopamine was detected using CVs with the following parameters: starting potential of , scan rate of 2 V/s, and a 1.2 V, nal potential of step size of 2 mV. Lead was detected using CVs with the following parameters: starting potential of 300 mV, nal poten, scan rate of 1 V/s, and a step size of 2 mV. tial of The resulting calibration curves (Fig. 12) are plots of the peak output voltage versus concentration. The calibration curves are values of 0.97 and 0.94 for dopamine and Pb, linear with respectively. VII. CONCLUSION

Fig. 11. CV of NaBr using a commercial potentiostat (ideal), and the FD and SE integrated potentiostats.

A new circuit, the FD potentiostat, has been developed that enables chemical microtransducers to detect a large suite of analytes even when implemented in modern, low-voltage processes. CMOS The FD potentiostat was fabricated in TSMCs 0.18 process and experimentally veried. Electrochemical analyses were conducted using the potentiostatic test chip and a microfabricated amperometric sensor. Results from these experiments show good agreement with electrochemical theory. The FD potentiostat will enable a large number of analytes to be sensed despite their oxidation and reduction potentials being outside the voltage range of modern semiconductor processes. ACKNOWLEDGMENT The authors would like to thank the MOSIS MEP research support program for fabrication of the potentiostat test chip. REFERENCES

[1] P. Kissinger et al., Laboratory Techniques in Electroanalytical Chemistry Second Edition, Revised and Expanded, P. Kissinger and W. Heineman, Eds. New York: Marcel Dekker, 1996. [2] J. Wang, Stripping AnalysisPrinciples, Instrumentation, and Applications. New York: VCH, 1985. [3] Bard and L. Faulkner, Electrochemical Methods. New York: Wiley, 1980. [4] S. Wei and H. Lin, CMOS chopper amplier for chemical sensor, IEEE Trans. Instrum. Measure., vol. 41, pp. 7780, Feb. 1992. [5] R. Kakerow, H. Kappert, E. Spiegel, and Y. Manoli, Low-power single-chip CMOS potentiostat, in Proc. Int. Conf. Solid-State Sensors and Actuators, Stockholm, Sweden, Jun. 2529, 1995. [6] M. Breten, T. Lehmann, and E. Bruun, Integrating data converters for picoampere currents from electrochemical transducers, in Proc. ISCAS 2000IEEE Int. Symp. Circuits and Systems, Geneva, Switzerland, May 2831, 2000. [7] S. Martin, F. Gebara, B. Larivee, and R. Brown, A CMOS-integrated microinstrument for trace detection of heavy metals, IEEE J. SolidState Circuits, vol. 40, pp. 27772786, Dec. 2005. [8] A. Bandyopadhyay, G. Mulliken, G. Cauwenberghs, and N. Thakor, VLSI potentiostat array for distributed electrochemical neural recordings, in Proc. IEEE Int. Symp. Circuits and Systems, (ISCAS 2002), May 2629, 2002, vol. 2, pp. 740743. [9] M. Schienle, C. Paulus, A. Frey, F. Hofmann, B. Holzap, P. SchindlerBauer, and R. Thewes, A fully electronic DNA sensor with 128 positions and in-pixel a/D conversion, IEEE J. Solid-State Circuits, vol. 39, pp. 24382445, Dec. 2004. [10] R. Reay, S. Kounaves, and G. Kovacs, An integrated CMOS potentiostat for miniaturized electroanalytical instrumentation, in Proc. IEEE Int. Solid-State Circuits Conf., Feb. 1618, 1994, pp. 162163. [11] J. G. Ryan, L. Barry, C. Lyden, J. Alderman, B. Lane, L. Schniffner, J. Boldt, and H. Thieme, A CMOS chip-set for detecting 10 ppb concentrations of heavy metals, in Proc. 5 IEEE Int. Solid-State Circuits Conf., Feb. 1517, 1995, pp. 158159. [12] E. Lauwers, J. Suls, W. Gumbrecht, D. Maes, G. Gielen, and W. Sansen, A CMOS multiparameter biochemical microsensor with temperature control and signal interfacing, IEEE J. Solid-State Circuits, vol. 36, pp. 20302038, Dec. 2001.

Fig. 12. Chemical calibration curves for (a) Br and (b) dopamine Pb

potential which is outside the range of the SE potentiostat. The data was captured using both the FD and SE potentiostats and also using a nonvoltage-limited commercial potentiostat which generated the curve labeled ideal. The parameters of the CV are as follows: starting potential of 500 mV, nal potential of 1.2 V, scan rate of 1 V/s, and a step size of 2 mV. The gure renders the SE clearly shows that the redox potential of potentiostat incapable of accurately capturing either the anodic or cathodic peaks of the CV, whereas the CV captured with the FD potentiostat closely resembles the ideal curve. A calibraby varying the concentration tion curve was obtained for of NaBr dissolved into the solution. The results are shown in Fig. 12. The plot is in agreement with electrochemical theory value of 0.98. (i.e., it is linear) with an The FD potentiostat was next used to determine calibration curves for the neurotransmitter dopamine and the toxic metal lead (Pb). Dopamine was dissolved in 10 mM phosphate buffer solution, pH 7.4, in concentrations of 0.2 to 10 mM and lead

142

IEEE SENSORS JOURNAL, VOL. 9, NO. 2, FEBRUARY 2009

[13] K. Kraver, M. Guthaus, T. Strong, P. Bird, G. Cha, W. Hold, and R. Brown, A mixed-signal sensor interface microinstrument, Sens. Actuators A, vol. 91, pp. 266277, 2001. [14] P. Kim, N. Kohli, A. Mason, R. M. Worden, and R. Ofoli, An electrochemical interface for integrated biosensors, in Proc. IEEE Int. Conf. Sensors, Toronto, Canada, Oct. 2427, 2003, pp. 3639. [15] S. Martin, T. Strong, and R. Brown, Monolithic liquid chemical sensing systems, in Materials, Integration and Technology for Monolithic Instruments, J. Theil, Ed. et al. Warrendale, PA: , 2005, pp. 109118. [16] H. Narula and J. Harris, VLSI potentiostat for amperometric measurements for electrolytic reactions, in Proc. IEEE Int. Symp. Circuits and Systems, Vancouver, Canada, May 2326, 2004, pp. I, 457460. [17] S. Martin, F. Gebara, T. Strong, and R. Brown, A low-voltage, chemical sensor interface for systems-on-chip: The fully-differential potentiostat, in Proc. 2004 IEEE Int. Symp. Circuits and Systems, Vancouver, Canada, May 2326, 2004, pp. IV892. [18] R. Senger, E. Marsman, M. McCorquodale, F. Gebara, K. Kraver, M. Guthaus, and R. Brown, A 16-bit mixed-signal microsystem with integrated CMOS-MEMS clock reference, in Proc. 40th Design Automa. Conf., Anaheim, CA, Jun. 26, 2003, pp. 520525. [19] S. Saban and R. Darling, Multi-element heavy metal ion sensors for aqueous solutions, Sens. Actuators B, vol. 61, pp. 128137, 1999. [20] S. Martin, CMOS-integrated liquid chemical microdetection systems, Ph.D. dissertation, Univ. Michigan, Ann Arbor, MI, 2005. [21] M. Poplawski, H. Cantor, A. Midgley, and R. Brown, Microfabricated amperometric biosensors, in Transducers 91: Digest of Tech. Papers, San Francisco, CA, Jun. 2428, 1991, pp. 5153. [22] J. Karki, Fully-differential ampliers Texas Instruments, Application Report SLOA054D, 2002, . [23] R. Baker, H. Li, and D. Boyce, CMOS Circuit Design, Layout, and Simulation. Piscataway, NJ: IEEE Press, 1998.

Fadi H. Gebara was born in Detroit, MI, in 1978. He received the B.S., M.S., and Ph.D. degrees in electrical engineering from the University of Michigan, Ann Arbor, in 2000, 2002, and 2005, respectively. In 2004, he began work at the IBM Austin Research Laboratory and in 2005, he became a research staff member. During his time at IBM, he has developed numerous clocking strategies for high-performance microprocessors. Currently, he is working on adaptive cache designs for reduced latency and increased throughput.

Timothy D. Strong (S91M92) received the B.S. degree from Michigan Technological University, Houghton, in 1992, the M.S. degree and the Ph.D. degree in electrical engineering from the University of Michigan, Ann Arbor, in 1997 and 2004, respectively. He worked from 1992 to 1995, as a Design Engineer for International Business Machines Corporation, Burlington, VT, developing high-end microprocessors. From 2004 to early 2008, he conducted research and development of drinking water test equipment for Sensicore, Inc., Ann Arbor. He is currently with General Electric Analytical Instruments and is involved in research on portable amperometric and potentiometric water quality test instruments.

Steven M. Martin (S99M05) received the B.S. degree from the University of Florida, Gainesville, in 1999, and the M.S. and Ph.D. degrees in electrical engineering from the University of Michigan, Ann Arbor, in 2001 and 2005, respectively. He has designed high-speed I/O links for the Itanium line of processors from Intel, and has also worked with several startups where he developed sensor interface and system electronics for next generation biomedical devices. He currently serves as an Adjunct Professor at Colorado State University. He currently develops orthogonal sensor technologies and products for Avago Technologies. He coauthored a book chapter on chemical sensor interfaces. He continues to conduct research in the area of transducers and high-performance circuits. Dr. Martin serves as an Ofcer of the Denver Solid-State Circuit Society. He was the recipient of an NSF Graduate Research Fellowship in 2000 and in 2008,

Richard B. Brown (S74M76SM91) received the B.S. and M.S. degrees in electrical engineering from Brigham Young University, Provo, UT, in 1976 and the Ph.D. degree in electrical engineering (solid-state sensors) from the University of Utah, Salt Lake City, in 1985. From 1976 to 1981, he was Vice-President of Engineering at Holman Industries, Oakdale, CA, and then Manager of Computer Development at Cardinal Industries, Webb City, MO. In 1985, he joined the faculty of the Department of Electrical Engineering and Computer Science, University of Michigan, Ann Arbor. He became Dean of Engineering at the University of Utah in July 2004. He has conducted major research projects in the areas of solid-state sensors, mixed-signal circuits, GaAs and silicon-on-insulator circuits, and high-performance and low-power microprocessors. Prof. Brown is a member of ACM. He is Chairman of the MOSIS Advisory Council for Education. He was Chair of the 1997 Conference on Advanced Research in VLSI and the 2001 Microelectronic System Education Conference. He has served as Guest Editor of the IEEE JOURNAL OF SOLID-STATE CIRCUITS and PROCEEDINGS OF THE IEEE, and as Associate Editor of IEEE TRANSACTIONS ON VERY LARGE SCALE INTEGRATION (VLSI) SYSTEMS.

Das könnte Ihnen auch gefallen

- Stress Corrosion Crack Growth Behavior of Cold Worked Austenitic Stainless Steel in High Temperature WaterDokument7 SeitenStress Corrosion Crack Growth Behavior of Cold Worked Austenitic Stainless Steel in High Temperature Wateramd mhmNoch keine Bewertungen

- ATPLViva QuestionsDokument27 SeitenATPLViva QuestionscaptravipooniaNoch keine Bewertungen

- The Practical Salinity Scale 1978 and Its AntecedentsDokument6 SeitenThe Practical Salinity Scale 1978 and Its AntecedentsVinícius MartinsNoch keine Bewertungen

- AutoLog Cathodic Protection GSM RTUDokument10 SeitenAutoLog Cathodic Protection GSM RTUAhmed NabilNoch keine Bewertungen

- Degradation Internal P WRDokument198 SeitenDegradation Internal P WRAndres_Pastor1987100% (1)

- Estimating Loss-of-Coolant Accident (LOCA) Frequencies Through The Elicitation ProcessDokument448 SeitenEstimating Loss-of-Coolant Accident (LOCA) Frequencies Through The Elicitation ProcessEnformableNoch keine Bewertungen

- Hydrogen Permeation ThesisDokument16 SeitenHydrogen Permeation ThesisAlberto SerranoNoch keine Bewertungen

- NULIFE-07-21 - Guideline For The Development of High Quality SCC Growth DataDokument26 SeitenNULIFE-07-21 - Guideline For The Development of High Quality SCC Growth DataOtso CronvallNoch keine Bewertungen

- CPU and Its Working PrincipleDokument11 SeitenCPU and Its Working Principlekeshavpoudel83% (6)

- Evaluation of Limit Load Data For Cracked Pipe Bends Under Opening Bending and Comparisons With Existing Solutions PDFDokument10 SeitenEvaluation of Limit Load Data For Cracked Pipe Bends Under Opening Bending and Comparisons With Existing Solutions PDFhamanoelgenNoch keine Bewertungen

- Electrochemistry PresentationDokument36 SeitenElectrochemistry PresentationMuhammad HaziqNoch keine Bewertungen

- Bridge Axi AhbDokument22 SeitenBridge Axi Ahbkrishnaav100% (1)

- Electroplating of Cu-Sn Alloys andDokument81 SeitenElectroplating of Cu-Sn Alloys andcicerojoiasNoch keine Bewertungen

- Title: UKOPA Pipeline Product Loss Incidents (1962-2010) : Report Number: UKOPA/11/0076 Issue: Final v1.0Dokument32 SeitenTitle: UKOPA Pipeline Product Loss Incidents (1962-2010) : Report Number: UKOPA/11/0076 Issue: Final v1.0Jorge VelasquezNoch keine Bewertungen

- DC and AC InterferenceDokument40 SeitenDC and AC InterferenceREJI JOY ThoppilNoch keine Bewertungen

- Enhancing Pipeline Integrity Using ECDA - Case Study of UEP by Fahad Muhammad and Sheikh Muhammad AbdullahDokument4 SeitenEnhancing Pipeline Integrity Using ECDA - Case Study of UEP by Fahad Muhammad and Sheikh Muhammad AbdullahSheikh AbdullahNoch keine Bewertungen

- A Review of Hydrogen Embrittlement of Martensitic Advanced High Strength SteelsDokument35 SeitenA Review of Hydrogen Embrittlement of Martensitic Advanced High Strength SteelsAndress SsalomonnNoch keine Bewertungen

- On Oxygen-Induced Corrosion of An Oil Refinery Condensate Fraction at Ion UnitDokument17 SeitenOn Oxygen-Induced Corrosion of An Oil Refinery Condensate Fraction at Ion UnitAzmi Mohammed NorNoch keine Bewertungen

- L51800 PDFDokument101 SeitenL51800 PDFHernan GeovannyNoch keine Bewertungen

- Biological Treatment of Microbial Corrosion: Opportunities and ChallengesVon EverandBiological Treatment of Microbial Corrosion: Opportunities and ChallengesNoch keine Bewertungen

- Chapter 3 - Corrosion ThermodynamicsDokument34 SeitenChapter 3 - Corrosion ThermodynamicsEDU Academic Programs CoordinatorNoch keine Bewertungen

- "EduPotStat" - Construction and Testing of A Low Cost PotentiostatDokument9 Seiten"EduPotStat" - Construction and Testing of A Low Cost PotentiostatDhammika RathnayakeNoch keine Bewertungen

- Detection and Mitigation of Ac Interference On 200Km PipelineDokument5 SeitenDetection and Mitigation of Ac Interference On 200Km PipelineMarcelo Varejão CasarinNoch keine Bewertungen

- Cathodic Protection An Overview 2Dokument18 SeitenCathodic Protection An Overview 2Johnson KurienNoch keine Bewertungen

- A Review On Pipeline Integrity Management Utilizing In-Line Inspection DataDokument41 SeitenA Review On Pipeline Integrity Management Utilizing In-Line Inspection Datasanu patil100% (1)

- Breaking Down AC Corrosion of PipelinesDokument7 SeitenBreaking Down AC Corrosion of PipelinesHenryNoch keine Bewertungen

- Astm G 96 PDFDokument10 SeitenAstm G 96 PDFJORGE ARTURO TORIBIO HUERTANoch keine Bewertungen

- BS en 12068.1999Dokument33 SeitenBS en 12068.1999yy20100% (1)

- Nernst Equation and Pourbaix Diagrams: Introduction and BackgroundDokument8 SeitenNernst Equation and Pourbaix Diagrams: Introduction and BackgroundGrant HosieNoch keine Bewertungen

- A Model To Estimate The Failure Rates of Offshore PipelinesDokument11 SeitenA Model To Estimate The Failure Rates of Offshore Pipelinesrovlad2000Noch keine Bewertungen

- Corrosion and Corrosion Control: An Introduction to Corrosion Science and EngineeringVon EverandCorrosion and Corrosion Control: An Introduction to Corrosion Science and EngineeringNoch keine Bewertungen

- Evaluation and Validation of Aboveground Techniques For Coating Condition AssessmentDokument63 SeitenEvaluation and Validation of Aboveground Techniques For Coating Condition AssessmentMajid SattarNoch keine Bewertungen

- Meccoct18 12573Dokument9 SeitenMeccoct18 12573Malik Ansar HayatNoch keine Bewertungen

- Tubular Vent BinderDokument12 SeitenTubular Vent BinderbayuNoch keine Bewertungen

- Flow in Flow-Accelerated Corrosion For Nuclear Power PlantDokument16 SeitenFlow in Flow-Accelerated Corrosion For Nuclear Power PlantSalih Gürkan üyümezNoch keine Bewertungen

- Corrosion and Runoff Behavior of Carbon Steel in Simulated Acid RainDokument3 SeitenCorrosion and Runoff Behavior of Carbon Steel in Simulated Acid RainIvan GutierrezNoch keine Bewertungen

- TR External Polymeric FailureDokument3 SeitenTR External Polymeric FailureJuliano SampaioNoch keine Bewertungen

- Anodic ProtectionDokument50 SeitenAnodic ProtectionEngr Arfan Ali DhamrahoNoch keine Bewertungen

- Impact of Potable Water Disinfectants On Pe PipeDokument35 SeitenImpact of Potable Water Disinfectants On Pe PipeSaif AhmedNoch keine Bewertungen

- Acegirdle DNVGL RP F101CorrodedPipelinesDokument42 SeitenAcegirdle DNVGL RP F101CorrodedPipelinesDimkNoch keine Bewertungen

- Calculation Procedure For Ground Potentials With Multiple AnodesDokument17 SeitenCalculation Procedure For Ground Potentials With Multiple AnodesIwan Husdiantama100% (1)

- Corrosion Behavior of Carbon Steel in Oxygenated Sodium Sulphate Solution Under Different Operating ConditionsDokument11 SeitenCorrosion Behavior of Carbon Steel in Oxygenated Sodium Sulphate Solution Under Different Operating ConditionsSEP-PublisherNoch keine Bewertungen

- Standard Guide For Acoustic Emission System Performance VerificationDokument5 SeitenStandard Guide For Acoustic Emission System Performance VerificationArpan NandyNoch keine Bewertungen

- Deep Anode SystemsDokument26 SeitenDeep Anode Systemsaliyildizx17730Noch keine Bewertungen

- Pfeifer Group PDF Schalungstraeger Durchbiegung enDokument2 SeitenPfeifer Group PDF Schalungstraeger Durchbiegung enaraboooNoch keine Bewertungen

- Corrosion Loop - Wikipedia PDFDokument10 SeitenCorrosion Loop - Wikipedia PDFEndhy Wisnu NovindraNoch keine Bewertungen

- An Electrochemical Study of Cathodic Protection of Steel Used For Marine StructuresDokument6 SeitenAn Electrochemical Study of Cathodic Protection of Steel Used For Marine StructureshamidNoch keine Bewertungen

- BS 7910:2013 in Brief: International Journal of Pressure Vessels and Piping July 2018Dokument12 SeitenBS 7910:2013 in Brief: International Journal of Pressure Vessels and Piping July 2018Arnab DebNoch keine Bewertungen

- Study of Corrosion Behavior and Mechanism of Carbon Steel in The Presence of Chlorella VulgarisDokument11 SeitenStudy of Corrosion Behavior and Mechanism of Carbon Steel in The Presence of Chlorella VulgarisAnh Quang PoNoch keine Bewertungen

- Keyword For API 580 PDFDokument9 SeitenKeyword For API 580 PDFRaymundo ACNoch keine Bewertungen

- Corrosion Rate Vs Grain Size PDFDokument4 SeitenCorrosion Rate Vs Grain Size PDFGajendra Pratap SinghNoch keine Bewertungen

- FDA Guidance Document For Testing Orthopedic Implants - Porous CoatingsDokument10 SeitenFDA Guidance Document For Testing Orthopedic Implants - Porous Coatingsmaven3Noch keine Bewertungen

- New Earth Potential Equations and Applications PDFDokument16 SeitenNew Earth Potential Equations and Applications PDFapar demangNoch keine Bewertungen

- Using Cathodic Protection To Control Corrosion of Coastal Reinforced Concrete Infrastructures PDFDokument7 SeitenUsing Cathodic Protection To Control Corrosion of Coastal Reinforced Concrete Infrastructures PDFBoussaid SouheilNoch keine Bewertungen

- 2018 ASME International Pipeline Conference - Breathing New Life To Aging Pipeline InfrastructureDokument9 Seiten2018 ASME International Pipeline Conference - Breathing New Life To Aging Pipeline InfrastructureAlex GutierrezNoch keine Bewertungen

- D 3032 - 98 - RdmwmzitukveDokument52 SeitenD 3032 - 98 - RdmwmzitukvePrakash MakadiaNoch keine Bewertungen

- Metallographic Investigation On The Cladding FailureDokument18 SeitenMetallographic Investigation On The Cladding FailureAndres_Pastor1987Noch keine Bewertungen

- Surfacing of 3.25% Nickel Steel With Inconel 625 by The Gas Metal Arc Welding-Pulsed Arc ProcessDokument8 SeitenSurfacing of 3.25% Nickel Steel With Inconel 625 by The Gas Metal Arc Welding-Pulsed Arc ProcessMoses_JakkalaNoch keine Bewertungen

- Liquid Metal Embrittlelment-B.joseph Et Al.-Eur - Phys.journal AP 5-19-31 - 1999Dokument13 SeitenLiquid Metal Embrittlelment-B.joseph Et Al.-Eur - Phys.journal AP 5-19-31 - 1999angelogontijoNoch keine Bewertungen

- Ipc1998-2028 - Repairing Pipe Defects Without Operational Outages With PetrosleeveDokument9 SeitenIpc1998-2028 - Repairing Pipe Defects Without Operational Outages With PetrosleeveDietmar WengerNoch keine Bewertungen

- Ferrochromium: Standard Specification ForDokument3 SeitenFerrochromium: Standard Specification ForleonciomavarezNoch keine Bewertungen

- Tank MMO Ext CPDokument8 SeitenTank MMO Ext CPmostafaNoch keine Bewertungen

- Sensors 15 22941Dokument15 SeitenSensors 15 22941guiburNoch keine Bewertungen

- Impedancia ManfeldDokument7 SeitenImpedancia ManfeldguiburNoch keine Bewertungen

- Accuracy and Approved Methods For Nano-Band SensorsDokument1 SeiteAccuracy and Approved Methods For Nano-Band SensorsguiburNoch keine Bewertungen

- Plata Cong Rafi ToDokument4 SeitenPlata Cong Rafi ToguiburNoch keine Bewertungen

- Square Wave Anodic Stripping Voltammetry Determination of Eco-Toxic Metals in Samples of Biological and Environmental ImportanceDokument10 SeitenSquare Wave Anodic Stripping Voltammetry Determination of Eco-Toxic Metals in Samples of Biological and Environmental ImportanceguiburNoch keine Bewertungen

- Simplified Construction of Electrochemical Cells: A or of Flasks) A. of Are To andDokument1 SeiteSimplified Construction of Electrochemical Cells: A or of Flasks) A. of Are To andguiburNoch keine Bewertungen

- A Small-Scale and Low-Cost Apparatus For The Electrolysis of WaterDokument2 SeitenA Small-Scale and Low-Cost Apparatus For The Electrolysis of WaterguiburNoch keine Bewertungen

- ad65cdd43c3dff81d7451e4237efd5ebDokument2 Seitenad65cdd43c3dff81d7451e4237efd5ebguiburNoch keine Bewertungen

- Self-Made Non-Enzymatic Silver Electrode From Recordable Cds For Fast Detection of Glucose in BloodDokument7 SeitenSelf-Made Non-Enzymatic Silver Electrode From Recordable Cds For Fast Detection of Glucose in BloodguiburNoch keine Bewertungen

- Inside Pstricks: Timothy Van ZandtDokument10 SeitenInside Pstricks: Timothy Van ZandtguiburNoch keine Bewertungen

- Computer Organization and Architecture (COA) May June Supply 2018 Solved Question PaperDokument32 SeitenComputer Organization and Architecture (COA) May June Supply 2018 Solved Question PapermaharshisanandyadavNoch keine Bewertungen

- 3.3 Autocorrelation and Power Spectral Density of Random Pulse TrainsDokument10 Seiten3.3 Autocorrelation and Power Spectral Density of Random Pulse TrainsYaseenNoch keine Bewertungen

- The Analysis and Detection of Single-Line-ground Fault in Ungrounded Solar PlantDokument4 SeitenThe Analysis and Detection of Single-Line-ground Fault in Ungrounded Solar PlantGundeboyina GopiNoch keine Bewertungen

- Tda 4858Dokument44 SeitenTda 4858utilscNoch keine Bewertungen

- Lecture: Fiber Bragg Grating Based DevicesDokument16 SeitenLecture: Fiber Bragg Grating Based DevicesnTech WorldNoch keine Bewertungen

- Simple 10 Bit DAC For The ArduinoDokument5 SeitenSimple 10 Bit DAC For The ArduinogacalaNoch keine Bewertungen

- LAB 7: IIR Filter Design ObjectivesDokument13 SeitenLAB 7: IIR Filter Design Objectivesmjrahimi.eee2020Noch keine Bewertungen

- Appliance Quantity Power Ratings/kW Duration of Use/week: Tablet Charger 0.01 N/A Tablet Computer 0.005 N/A Light BulbDokument5 SeitenAppliance Quantity Power Ratings/kW Duration of Use/week: Tablet Charger 0.01 N/A Tablet Computer 0.005 N/A Light BulbCrystal FrostNoch keine Bewertungen

- Campbell nl100 - RS232 - Internet InterfaceDokument42 SeitenCampbell nl100 - RS232 - Internet InterfaceMassimo De StefanoNoch keine Bewertungen

- 6 Tute Sheets ACSDokument6 Seiten6 Tute Sheets ACSAman KumarNoch keine Bewertungen

- Modbus GWDokument2 SeitenModbus GWKhaled KadryNoch keine Bewertungen

- A Simple Circuit Approach To Reduce Delay Variations in Domino Logic GatesDokument9 SeitenA Simple Circuit Approach To Reduce Delay Variations in Domino Logic GatesKarthick NpNoch keine Bewertungen

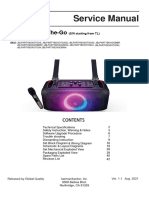

- JBL Partybox OnthegoDokument42 SeitenJBL Partybox Onthegovs674584Noch keine Bewertungen

- Sample Test 2 ElectricityDokument2 SeitenSample Test 2 ElectricitybatoulNoch keine Bewertungen

- Panasonic Th-50phd5 50phw5 CH Gph5d2Dokument196 SeitenPanasonic Th-50phd5 50phw5 CH Gph5d2Jesus MartinezNoch keine Bewertungen

- Digital Design of Filters (FIR,IIR) -part2 ايادDokument18 SeitenDigital Design of Filters (FIR,IIR) -part2 ايادMohammed YounisNoch keine Bewertungen

- Wiring Operation of Washing Machine FDDokument18 SeitenWiring Operation of Washing Machine FDRamil Tuason100% (2)

- List of 8-Bit Computer Hardware PalettesDokument17 SeitenList of 8-Bit Computer Hardware PalettesTheBluestoneGuyNoch keine Bewertungen

- Zeppelin Air 30pin ConnectivityDokument9 SeitenZeppelin Air 30pin ConnectivitytkicorpNoch keine Bewertungen

- Hardware QuestionnaireDokument2 SeitenHardware QuestionnaireShakila ShakiNoch keine Bewertungen

- TUGx-Abstracts 190702 PDFDokument15 SeitenTUGx-Abstracts 190702 PDFMahesh MahiNoch keine Bewertungen

- In-Vehicle NetworkingDokument59 SeitenIn-Vehicle NetworkingSam AnuNoch keine Bewertungen

- Smart Relay - Zelio Logic SR2 - SR3 - SR2B121FU PDFDokument5 SeitenSmart Relay - Zelio Logic SR2 - SR3 - SR2B121FU PDFHung Cuong PhamNoch keine Bewertungen

- Electrical Circuits Lab EE 213Dokument7 SeitenElectrical Circuits Lab EE 213Ahmed QanahNoch keine Bewertungen

- JW24F - JOYWARRIOR Datasheet - 01Dokument15 SeitenJW24F - JOYWARRIOR Datasheet - 01Angelito Dela CruzNoch keine Bewertungen

- Aoc 912vwa+Service+ManualDokument55 SeitenAoc 912vwa+Service+ManualtcwsNoch keine Bewertungen

- BSNL 5-EssDokument28 SeitenBSNL 5-EssGaurav100% (1)