Beruflich Dokumente

Kultur Dokumente

Keppel Seghers Hardpelletiser

Hochgeladen von

cumpio425428Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Keppel Seghers Hardpelletiser

Hochgeladen von

cumpio425428Copyright:

Verfügbare Formate

Biosolids & Sludge Solutions

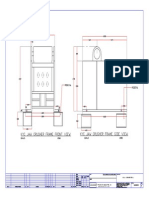

Process Overview

Sludge reception Sludge silo Thermal oil Separation hopper Coater Pellet cooler

HARDPELLETISER - the Pearl Process

Condensor

Sludge pump

Baghouse filter

Pellet silo

Keppel Seghers' HARDPELLETISER allows you to turn sludge into a useful, environmental-friendly product. Hazardous products such as waste sludge are turned into a valuable pathogen-free dried biosolids (>90%DS). These biosolids are easy to handle, transport and store for long periods of time. The dried pellets can be used in a flexible way for different endpurposes, as soil improver or as green energy (CO2-neutral fuel). Principle The HARDPELLETISER uses heat convection to evaporate water through a vertical, multi-stage, indirect drying unit. This unit produces dried, hard, round and dust-free pellets in a single and safe operation. Similar to the pearl formation process in an oyster, biosolids particles grow layer by layer and become hard pellets. Application This drying/pelletising technology is installed into major water reclamation stations, large wastewater treatment plants worldwide. The Keppel Seghers pellets can be used for many applications, ranging from soil improver and fertiliser to green fuel.

Baltimore, USA - Capacity 3 x 6.000kg H2O/h BOO project Deurne, Belgium - Capacity 3.700 kg H2O/h

Soil improver and fertiliser: Pellets produced by Keppel Seghers' Pearl Process are ClassA according to the US EPA 503 rules section "hygienisation of sludge". Land application of Keppel Seghers pellets results in improved soil properties: the minerals contained in the dried sludge provide a natural source of nitrogen, phosphorus and other valuable plant nutrients and the organic matter contributes to well-structured soil with greater erosion resistance and higher water retention capability. Keppel Seghers pellets can be profitably used as a slow release fertiliser and soil improver on agriculture and grassland or in forestry and soil reclamation pro-jects (e.g. former mining sites and areas destroyed by fire). They have been successfully applied for various crops such as lawns, field flower production, nursery stock planting, golf greens and citrus fruit. Keppel Seghers pellets are also used as a potting soil ingredient and a commercial fertilising bulking agent where it acts as a superior substitute for granular limestone.

Green fuel: The high heating value of Keppel Seghers pellets (8 to 18 MJ/kg LHV thereby approaching the heating value of brown coal) makes them an excellent fuel for co-incineration in coal power stations and cement kilns. Thermal beneficial re-use of sludge Use of Keppel Seghers pellets and other biosolids also allows the saving of fossil fuels and results in a global emission reduction. Process Description The HARDPELLETISER is based on the proprietary Pearl Process . It is a complete thermal sludge drying technology that transforms biosolids into valuable and pathogen-free dried pellets (> 90 % DS) in a single & safe operation. This gentle process with efficient heat exchange and gravitationaided biosolids movements results in low electricity consumption and reduction in operation and maintenance costs. Keppel Seghers' HARDPELLETISER units are available for all kinds of sludge and other biosolids with variable composition and for an evaporation capacity ranging from 50 to 15,000 kg H20/hour. Thanks to its high environmental and safety standards as well as to its economic assets, this techno-logy has been elected for major sludge processing projects worldwide. Zero-emission solutions are easily implemented, which also makes the HARDPELLETISER particularly suitable in densely populated areas. Features . Inherently safe design (no oxygen allowed into the system) . Better quality pellets are naturally round, hard and dust-free. . Zero-emission plant . Higher flexibility . Minimal footprint through vertical and compact design. . Higher return on investment by integrating water evaporation and granulation into one installation.

Keppel Seghers' pellets as high quality soil improver and fertiliser

On golf courses

For soil improvement

In a power plant or cement kilm

As fertiliser

www.keppelseghers.com info@keppelseghers.com

MStore_4F_en_002_C Copyright, Keppel Seghers, 2008

Das könnte Ihnen auch gefallen

- 3.1 Data From Process Data Sheet: Short Text CF Blower, 530 CFM, Ss316 Contact Part Moc Sr. No. AIL Attributes UOM ValuesDokument1 Seite3.1 Data From Process Data Sheet: Short Text CF Blower, 530 CFM, Ss316 Contact Part Moc Sr. No. AIL Attributes UOM ValuesBhaumik BhuvaNoch keine Bewertungen

- Fan Data SheetDokument1 SeiteFan Data SheetSamir Ahmed100% (1)

- Se Downloads Paddle Dryer DataDokument16 SeitenSe Downloads Paddle Dryer DataJignesh PanchalNoch keine Bewertungen

- Naugatuck CT Odor Control EvaluationDokument133 SeitenNaugatuck CT Odor Control EvaluationRepublican-American100% (2)

- The Prediction of Mineral Solubilities in Natural Waters: A Chemical Equilibrium Model For The Na-Ca-CI-S04-H20 System, To High Temperature and ConcentrationDokument17 SeitenThe Prediction of Mineral Solubilities in Natural Waters: A Chemical Equilibrium Model For The Na-Ca-CI-S04-H20 System, To High Temperature and ConcentrationBiain A SecasNoch keine Bewertungen

- Kinetics of Ethane PyrolysisDokument11 SeitenKinetics of Ethane PyrolysisErika ScheeleNoch keine Bewertungen

- An Explicit Equation For Friction Factor in PipeDokument2 SeitenAn Explicit Equation For Friction Factor in PipeRiddhesh PatelNoch keine Bewertungen

- (Hinze, 1955) Fundamentals of The Hydrodynamic Mechanism of Splitting in Dispersion ProcessDokument7 Seiten(Hinze, 1955) Fundamentals of The Hydrodynamic Mechanism of Splitting in Dispersion ProcessVeli Can CosarNoch keine Bewertungen

- Types of GasifierDokument13 SeitenTypes of GasifierMehul ZareNoch keine Bewertungen

- 1bottles Group Production of Bisphenol-ADokument112 Seiten1bottles Group Production of Bisphenol-AJames BelciñaNoch keine Bewertungen

- Flash Point TutorialDokument8 SeitenFlash Point TutorialS. GreenNoch keine Bewertungen

- 37 - 4 - Washington DC - 08-92 - 1855 PDFDokument9 Seiten37 - 4 - Washington DC - 08-92 - 1855 PDFMohamadMostafaviNoch keine Bewertungen

- Graphite Heat ExchangersDokument9 SeitenGraphite Heat ExchangersRehinaNoch keine Bewertungen

- 3.2 Drying ProcessesDokument31 Seiten3.2 Drying Processesahmed20210% (1)

- Pressurized Glycol Dehy SystemsDokument11 SeitenPressurized Glycol Dehy SystemsJagan BoseNoch keine Bewertungen

- Design of Air IDokument5 SeitenDesign of Air IInvedeNoch keine Bewertungen

- Fischer Tropsch ProcessDokument23 SeitenFischer Tropsch ProcessItsura AnnetteNoch keine Bewertungen

- Lbs Stone Cladding Brochure Feb2020 SDokument24 SeitenLbs Stone Cladding Brochure Feb2020 SWylieNoch keine Bewertungen

- Drying of Solid BasicsDokument5 SeitenDrying of Solid BasicsMuhammad SaadullahNoch keine Bewertungen

- Chapter 4 Heat Exchangers With High-Finned Trufin TubesDokument0 SeitenChapter 4 Heat Exchangers With High-Finned Trufin TubesManuel ArroyoNoch keine Bewertungen

- Ceramic Heat Pipe For High Temperature Heat RecoveryDokument11 SeitenCeramic Heat Pipe For High Temperature Heat RecoveryChander Prakash KamraNoch keine Bewertungen

- Globe ValvesDokument12 SeitenGlobe ValvesVivekanandan VaiyapuriNoch keine Bewertungen

- Molten SaltDokument27 SeitenMolten SaltvesipkaNoch keine Bewertungen

- PEBD-EVA Blends PDFDokument9 SeitenPEBD-EVA Blends PDFDiana Carolina CalvoNoch keine Bewertungen

- Omestic Refrigerator: StatementDokument4 SeitenOmestic Refrigerator: StatementHoracio RodriguezNoch keine Bewertungen

- Process Design of Spray Chamber or Spray Tower Type Absorber PDFDokument12 SeitenProcess Design of Spray Chamber or Spray Tower Type Absorber PDFsong1088Noch keine Bewertungen

- 02 Basics Mixing Technology PDFDokument7 Seiten02 Basics Mixing Technology PDFjokishNoch keine Bewertungen

- Antioxidants For Fuel ApplicationsDokument35 SeitenAntioxidants For Fuel ApplicationsVictor Castrejon100% (1)

- HTF DegradationDokument13 SeitenHTF DegradationcarzanteNoch keine Bewertungen

- Characterizing Adsorbents For Gas SeparationsDokument8 SeitenCharacterizing Adsorbents For Gas SeparationsJohn AnthoniNoch keine Bewertungen

- Info Raschig Pall Ring 350Dokument22 SeitenInfo Raschig Pall Ring 350Adriana HernandezNoch keine Bewertungen

- Nasa O2clean 2001Dokument49 SeitenNasa O2clean 2001benNoch keine Bewertungen

- HYSYS Simulation BasisDokument527 SeitenHYSYS Simulation BasisAbdallah FEKKAINoch keine Bewertungen

- Feedstock Recycling and Pyrolysis of Waste Plastics - IndexDokument30 SeitenFeedstock Recycling and Pyrolysis of Waste Plastics - Indexprem101Noch keine Bewertungen

- Solubility FESO4Dokument9 SeitenSolubility FESO4Jesse JohnsonNoch keine Bewertungen

- Dynamic Reaction Inside Co-Rotating Twin Screw Extruder. II. Waste Ground Rubber Tire Powder - Polypropylene BlendsDokument11 SeitenDynamic Reaction Inside Co-Rotating Twin Screw Extruder. II. Waste Ground Rubber Tire Powder - Polypropylene Blendspickpocket27Noch keine Bewertungen

- Whytheat K 60Dokument1 SeiteWhytheat K 60RAVI KIRAN CHALLAGUNDLANoch keine Bewertungen

- Fuel Production From Pyrolysis of Natural and Synthetic RubbersDokument8 SeitenFuel Production From Pyrolysis of Natural and Synthetic RubbersMary Grace VelitarioNoch keine Bewertungen

- Optimization of Plate Fin Heat Exchangers Used in Natural Gas Liquefaction - ICFD10-EG-3073Dokument6 SeitenOptimization of Plate Fin Heat Exchangers Used in Natural Gas Liquefaction - ICFD10-EG-3073fujiman35Noch keine Bewertungen

- KST ValuesDokument2 SeitenKST ValuesJohn0% (1)

- Manufacturing Process of Potato FlakesDokument5 SeitenManufacturing Process of Potato FlakesandreaNoch keine Bewertungen

- Boiling & CondensationDokument22 SeitenBoiling & CondensationNITISH KUMARNoch keine Bewertungen

- Impact of Heating Rates On The Vibrated Bulk Density of CPCDokument23 SeitenImpact of Heating Rates On The Vibrated Bulk Density of CPCVinodh KumarNoch keine Bewertungen

- Burners For Glass Melting Furnaces FinalDokument9 SeitenBurners For Glass Melting Furnaces FinalDavid WattsNoch keine Bewertungen

- Dryness FractionDokument3 SeitenDryness Fractionmurali_228Noch keine Bewertungen

- Biomass Value PropositionDokument10 SeitenBiomass Value PropositionInvestInCanadaNoch keine Bewertungen

- All Heat Exchangers Are Not EqualDokument5 SeitenAll Heat Exchangers Are Not EqualGesar GesarNoch keine Bewertungen

- Thermochemical Ethanol Via Direct Gasification and Mixed Alcohol Synthesis of Lignocellulosic BiomassDokument144 SeitenThermochemical Ethanol Via Direct Gasification and Mixed Alcohol Synthesis of Lignocellulosic BiomassCristina Garcia RamosNoch keine Bewertungen

- Activity CoefficientDokument45 SeitenActivity CoefficientAlexander MintsNoch keine Bewertungen

- Aq4 Ahri Certified Plate Heat Exchanger PDFDokument2 SeitenAq4 Ahri Certified Plate Heat Exchanger PDFmarko absNoch keine Bewertungen

- Main Fractionator Water Wash Systems PTQ REVAMPS 2006 PDFDokument5 SeitenMain Fractionator Water Wash Systems PTQ REVAMPS 2006 PDFmajope1966Noch keine Bewertungen

- 0.drying Heat Pumps-Part IDokument17 Seiten0.drying Heat Pumps-Part IDr-Abhijit SinhaNoch keine Bewertungen

- Alfa VapDokument2 SeitenAlfa Vapkresimir.mikoc9765Noch keine Bewertungen

- Pyrolysis of Mixed Polymers ReviewDokument21 SeitenPyrolysis of Mixed Polymers ReviewDoug OhnemusNoch keine Bewertungen

- Service Manual VD (E1) 12-05 - enDokument45 SeitenService Manual VD (E1) 12-05 - enPhong LeNoch keine Bewertungen

- 04 - Absorbers PDFDokument7 Seiten04 - Absorbers PDFlaiping_lumNoch keine Bewertungen

- Handbook of Formulae and Physical ConstantsDokument56 SeitenHandbook of Formulae and Physical ConstantsAliRezaKarimi100% (1)

- (English (Auto-Generated) ) How Color Blind People See The World (DownSub - Com)Dokument6 Seiten(English (Auto-Generated) ) How Color Blind People See The World (DownSub - Com)Trung LêNoch keine Bewertungen

- Rice Husk Based Energy GenerationDokument25 SeitenRice Husk Based Energy GenerationTU_MTECH_ENV11Noch keine Bewertungen

- Production of Activated CarbonDokument11 SeitenProduction of Activated CarbonShii Bautista100% (1)

- 30,000 DWT Dolomite Out-Loading FacilityDokument2 Seiten30,000 DWT Dolomite Out-Loading Facilitycumpio425428Noch keine Bewertungen

- Barchart SteleronDokument4 SeitenBarchart Steleroncumpio425428Noch keine Bewertungen

- ABC Offer To TelequitDokument1 SeiteABC Offer To Telequitcumpio425428Noch keine Bewertungen

- Weight Per Course Tank ADokument1 SeiteWeight Per Course Tank Acumpio425428Noch keine Bewertungen

- Abcumpio MJV DP BillingDokument1 SeiteAbcumpio MJV DP Billingcumpio425428Noch keine Bewertungen

- Auxin Price MargaritaDokument2 SeitenAuxin Price Margaritacumpio425428Noch keine Bewertungen

- Fire Protection Labor Cost Final (Riofil Ref)Dokument2 SeitenFire Protection Labor Cost Final (Riofil Ref)cumpio425428Noch keine Bewertungen

- Drum Scrubber Ausimm PDFDokument11 SeitenDrum Scrubber Ausimm PDFcumpio425428Noch keine Bewertungen

- 12.5 Ton Per Hour Sugar RefineryDokument1 Seite12.5 Ton Per Hour Sugar Refinerycumpio425428Noch keine Bewertungen

- Billing For Rotary ScrubberDokument1 SeiteBilling For Rotary Scrubbercumpio425428Noch keine Bewertungen

- A.B. Cumpio Engineering Services: Agro Power PhilippinesDokument3 SeitenA.B. Cumpio Engineering Services: Agro Power Philippinescumpio425428Noch keine Bewertungen

- You Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterDokument7 SeitenYou Created This PDF From An Application That Is Not Licensed To Print To Novapdf Printercumpio425428Noch keine Bewertungen

- Shell Thickness CalculationDokument247 SeitenShell Thickness Calculationcumpio425428Noch keine Bewertungen

- Attachment B - Bid PriceDokument14 SeitenAttachment B - Bid Pricecumpio425428Noch keine Bewertungen

- Kyc Jaw Crusher Detail: Canatuan, Tabayo, Siocon, Zamboanga Del NorteDokument1 SeiteKyc Jaw Crusher Detail: Canatuan, Tabayo, Siocon, Zamboanga Del Nortecumpio425428Noch keine Bewertungen

- BLG2000 Plant Design Matl BalanceDokument51 SeitenBLG2000 Plant Design Matl Balancecumpio425428100% (1)

- TVI Resource Development Phils., Inc: Canatuan, Tabayo, Siocon, Zamboanga Del NorteDokument1 SeiteTVI Resource Development Phils., Inc: Canatuan, Tabayo, Siocon, Zamboanga Del Nortecumpio425428Noch keine Bewertungen

- Rethink The Business Model For Sustainable DevelopmentDokument26 SeitenRethink The Business Model For Sustainable DevelopmentLudor EngineeringNoch keine Bewertungen

- Hazelo Lab EIA ReportDokument41 SeitenHazelo Lab EIA ReportakhileshguptamnreNoch keine Bewertungen

- Powlson Et Al. 2011Dokument11 SeitenPowlson Et Al. 2011João MadeiraNoch keine Bewertungen

- Production of Eco Bricks From Industrial Waste Using Alkali Activated Technology - Civil Engineering Project TopicsDokument6 SeitenProduction of Eco Bricks From Industrial Waste Using Alkali Activated Technology - Civil Engineering Project TopicsmynameisgunaNoch keine Bewertungen

- CONTENTSDokument60 SeitenCONTENTSsalmanNoch keine Bewertungen

- Nigeria EEE Regulations 2011Dokument70 SeitenNigeria EEE Regulations 2011Ricardo Oroca100% (2)

- Hazardous Waste ImpactsDokument118 SeitenHazardous Waste ImpactsAngel CMNoch keine Bewertungen

- Remocion de FosforoDokument51 SeitenRemocion de FosforoyhorsNoch keine Bewertungen

- WABAG Image ENG 2016 WebDokument20 SeitenWABAG Image ENG 2016 WebNguyen AnNoch keine Bewertungen

- Hammarby SjostadDokument15 SeitenHammarby SjostadayluyNoch keine Bewertungen

- Sludge Dewatering PDFDokument36 SeitenSludge Dewatering PDFPaul Maposa100% (2)

- Sludge - : of MunicipalDokument32 SeitenSludge - : of MunicipalAivaras CNoch keine Bewertungen

- EPA Water Treatement Man Charac Indust Wastewaters2Dokument61 SeitenEPA Water Treatement Man Charac Indust Wastewaters2Félix LidaNoch keine Bewertungen

- 3) Production of Soil-Cement Bricks Using Sludge As A Partial SubstituteDokument3 Seiten3) Production of Soil-Cement Bricks Using Sludge As A Partial SubstitutewaheedNoch keine Bewertungen

- Egyptian Journal of Petroleum: Hussein I. Abdel-Shafy, Mona S.M. MansourDokument16 SeitenEgyptian Journal of Petroleum: Hussein I. Abdel-Shafy, Mona S.M. MansourfranklinNoch keine Bewertungen

- ES-RQ-220 Waste Manangement RequirmentsDokument14 SeitenES-RQ-220 Waste Manangement RequirmentsGautam Vijay SimhaNoch keine Bewertungen

- Form-1 Application For Prior Environmental ClearanceDokument11 SeitenForm-1 Application For Prior Environmental ClearanceSESHASALAM MURUGESANNoch keine Bewertungen

- Proposed Design of Wastewater Treatment Facility in Southern Luzon State University Main CampusDokument18 SeitenProposed Design of Wastewater Treatment Facility in Southern Luzon State University Main CampusAce Mikko Bernardo JubeleaNoch keine Bewertungen

- Se-Downloads-Drying Technologies For Sewage Sludge Web en - PDFFDokument9 SeitenSe-Downloads-Drying Technologies For Sewage Sludge Web en - PDFFkosmc123Noch keine Bewertungen

- Tinjauan Pemanfaatan Sludge Cake Pabrik Pulp Kraft Sebagai Energi Alternatif Melalui Proses GasifikasiDokument14 SeitenTinjauan Pemanfaatan Sludge Cake Pabrik Pulp Kraft Sebagai Energi Alternatif Melalui Proses Gasifikasiboy.jansen4455Noch keine Bewertungen

- Proposal For 10 CMD STPDokument19 SeitenProposal For 10 CMD STPHaneesh PanickerNoch keine Bewertungen

- Env Module 3 Question BankDokument32 SeitenEnv Module 3 Question BankDeepti KulkarniNoch keine Bewertungen

- Malaviya National Institute of Technology Jaipur: Department of Chemical EngineeringDokument29 SeitenMalaviya National Institute of Technology Jaipur: Department of Chemical EngineeringSHIVANK CHATURVEDINoch keine Bewertungen

- May 2014Dokument112 SeitenMay 2014Treatment Plant Operator MagazineNoch keine Bewertungen

- 1 Treatment Process: 1.1 ThickeningDokument10 Seiten1 Treatment Process: 1.1 ThickeningAnang ARNoch keine Bewertungen

- Journal of Analytical and Applied PyrolysisDokument13 SeitenJournal of Analytical and Applied PyrolysisCarlos AlvarezNoch keine Bewertungen

- LESSON PLAN Waste DisposalDokument17 SeitenLESSON PLAN Waste Disposalannu panchal100% (1)

- Documentation ManualDokument62 SeitenDocumentation ManualAdilNoch keine Bewertungen

- Zhu 2008Dokument9 SeitenZhu 2008Naveen RajahNoch keine Bewertungen

- Functional Design ReportDokument94 SeitenFunctional Design Reportrlowe55Noch keine Bewertungen

- University of Chicago Press Fall 2009 CatalogueVon EverandUniversity of Chicago Press Fall 2009 CatalogueBewertung: 5 von 5 Sternen5/5 (1)

- University of Chicago Press Fall 2009 Distributed TitlesVon EverandUniversity of Chicago Press Fall 2009 Distributed TitlesBewertung: 1 von 5 Sternen1/5 (1)