Beruflich Dokumente

Kultur Dokumente

BI109 1 Intro PDF

Hochgeladen von

aaronlhuangCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

BI109 1 Intro PDF

Hochgeladen von

aaronlhuangCopyright:

Verfügbare Formate

9/9/09 !

BIO 109 Prof. Edith Mathiowitz

Introduction (2 hr.) Suggested reading: 1) Young Ch. 1 2) Notes 3) Rosen I,II Topics: Polymers as materials Distinction between synthetic polymers, biopolymers, primary & secondary tertiary structure, (Cantor Schimmel) Types of polymers, thermoplastics, thermosets Basic definitions and nomenclature Bonds in polymers: bond distance and strengths Molecular architecture and classification of polymers Molar mass and degree of polymerization Stereoisomers: atactic, isotactic, syndiotactic

1 !

9/9/09 !

From the preface of the first edition of Principle of Polymer Systems by Ferdinand Rodriguez.

!!

!!

!!

A man was asked the question "Do you have trouble making decisions?" He thought for a while and then finally answered "Well, yes and no." The engineer or scientist who is asked to make generalizations about polymers often finds himself in the same position. In the interests of organizing the body of information about polymers which has accumulated since Baekeland, Staudinger, Mark, Carothers, and other pioneers started their word, there is a tendency to over generalize.

From the preface of the first edition of Principle of Polymer Systems by Ferdinand Rodriguez.

!! !! !!

!! !!

!!

In the older literature one finds such pronouncements as: "All polymer crystals are submicroscopic," "Five-membered rings are too stable to be opened to form linear polymers, "Maleic anhydride cannot be homopolymerized," "Stereoregular polymers can be made only with an optically active catalyst." All of these have been disproved or qualified. In this book, any generalizations that are encountered are subject to the following caveat: "All generalizations are partially untrue, except this one.

!!

!!

(from Fundamentals of Polymeric Materials by Rosen, Ch. 1)

INTRODUCTION

!!

Since World War II, polymeric materials have been the fastest growing segment of the US chemical industry. More than 25% of the chemical research dollar is spent on polymers. A modern automobile contains over 200 lbs. (100 kg) of plastics, (not including paints, the rubber in tires, or the fibers in tires and upholstery). The applications of polymers in the building construction industry (piping, resilient flooring, siding, thermal and electrical insulation, paints, decorative laminates, etc., etc.) are already impressive and will become even more so in the future. A trip through a supermarket will quickly convince anyone of the importance of polymers in the packaging industry (bottles, films, trays, etc.). ****(your first project this year locate a topic)****

!!

!!

!!

!!

!!

2 !

9/9/09 !

There are eight major areas of application for polymers:

!!

!!

(1) plastic, (2) rubbers or elastomers, (3) fibers, (4) surface finishes and protective coatings, (5) adhesives, (6) biopolymers, (7) drug delivery and (8) gene delivery. (9) tissue engineering What is the common need for each area? It was only after Dr. Herman Staudinger proposed the "macromolecular hypothesis" in the 1920s explaining the common molecular makeup of these materials (for which he won the 1953 Nobel Prize in chemistry), that polymer science began to evolve from the independent technologies.

!!

Polymers are important because of:

!! !!

!! !! !!

Economic considerations Interesting and useful properties that cannot be explained or handled in design situations by the traditional approaches Flexible Strong Versatile properties

A description of three simple experiments should make this obvious:

!!

Silly putty!!

a silicone polymer; bounces like rubber when rolled into a ball and dropped; if the ball is placed on a table, it will gradually spread to a puddle. The material behaves like an elastic solid under certain conditions and like a very viscous liquid under others.

3 !

9/9/09 !

A description of three simple experiments should make this obvious:

!!

!! !!

If a weight is suspended from a rubber band and the band is then heated (taking care not to burn it), the rubber band will contract . All materials other than polymers will undergo the expected thermal expansion upon heating (assuming no phase transformation has occurred over the temperature range).

A description of three simple experiments should make this obvious:

!!

!! !!

!!

When a rotating rod is immersed in a molten polymer or a fairly concentrated polymer solution, The liquid will actually climb up the rod. This phenomenon, the Weissenberg effect, is contrary to what is observed with non-polymer liquids. Those develop a parabolic surface profile with the lowest point at the rod as the material is flung outward by centrifugal force.

The molecular structure of polymers is the key to an understanding of the science and technology of polymers. The question to be considered Is: what are the key roles of molecular structure in polymer science and technology ?.

4 !

9/9/09 !

Points to be considered

!! !!

!!

!!

!!

(1) How is the desired molecular structure obtained? (2) How do the polymer's processing (i.e. formability) properties depend on its molecular structure? (3) How do material properties (mechanical, chemical, optical, etc.) depend on molecular structure? (4) How do material properties depend on a polymer's processing history? (5) How do its applications depend on its material properties?

!!

What is a polymer ? Polymer: Molecule made by repetition of some simpler unit, the mer or monomer. Polymer: comes from the Greek manymembered.Large molecule that is formed from a relatively large number of smaller units or "mers," held together by covalent bonding. Macromolecules: (big molecule) Molecules built from a large number of atoms which can be found in materials of natural origin, like cellulose, proteins, and natural rubber, or those synthetically produced, like polyethylene, nylon, and silicones. Macromolecules consist of at least one chain of atoms bonded together and running through the molecule's backbone.

!!

!!

!!

!!

Backbone consisting of carbon atoms: R ( C H2)nR' (polyethylene) Backbone consisting of carbon and oxygen atoms: R ( O C H2CH2)nR' ( p o lyoxyethylene) Backbone consisting of carbon and nitrogen atoms: R ( N H - C H R " - C O )nR' (polypeptide) Backbone containing no carbon atoms: R ( O - S i ( C H3)2)nR '(poly(dimethyl siloxane)) n = degree of polymerization (DP) = number of repeat units in a chain A simple calculation of molecular weight(MW): MW = Mr X n where Mr = weight of the repeat unit

5 !

9/9/09 !

SIZE AND COMPLEXITY OF BIOPOLYMERS

From Biophysical Chemistry - Cantor and Schimmel (Table 1-1)

Typical MW No. of subunits 100(or 10) 102-103 (or 103-104) 102-103 (or 103-104) 10-102 10-102 10-102 10-102

Class Oligomers Small proteins Nucleic acids Large proteins

Specific Example Typical Size Actinomysin D Chymotrypsin tRNA 20 sphere 40 sphere 100 rod

Subunits

103-104 atoms (or residues) 104-105 amino acid residues (or atoms) 104-105 Nucleotide residues (or atoms)

Aspartate 70 sphere transcarbamoylase 200 sphere

105-107 Subunits or covalent chains 105-107 Subunits or covalent chains

Small assemblies Ribosome Large assemblies Membranes, viruses Intact DNA E. coli DNA

1000 sphere 107-1012 Regions, fragments, components 0.1 cm rod 107-1012 Regions, fragments, components

The whole system is called a single molecule when parts are present in a welldefined stoichiometry and when little tendency for them to dissociate spontaneously under physiological conditions.

LEVELS OF STRUCTURE IN BIOLOGICAL MACROMOLECULES

PRIMARY STRUCTURE

!! !!

!!

The complete covalent structure Primary Structure (1 structure) = sequence Typical linear polymers: Some synthetic materials (e.g. polyamides) have no preferred chain direction, whereas other synthetics and most biopolymers are head-to-tail arrangements of monomers. From Biophysical Chemistry Cantor and Schimmel (Figure 1-2)

!!

6 !

9/9/09 !

SECONDARY STRUCTURE

!!

!!

!!

(2 structure) (three-dimensional structure) - list of all threedimensional regions that have ordered, locally symmetric backbone structures. (alpha helix, beta helix, random coil) The geometry of a simple helix: The helix axis is coincident with the z-axis. P is the pitch, zo the vertical rise per residue. The location of the zeroth residue is further specified by ! (which defines its position in the x-y plane). All identical repeating units are the same distance, r, from the helix axis; this distance is called the radius of the helix. The radius is shown more clearly in the top view. n the example illustrated, the helix is 8-fold, so the x and y coordinates of residues spaced eight residues ( 8 zo) apart are identical. From Biophysical Chemistry - Cantor and Schimmel (Figure 1-3)

!!

TERTIARY STRUCTURE

!!

!!

!!

(3 structure) The complete three-dimensional structure of one, effectively indivisible unit. (simple covalent strand in RNA or two complementary double strands in most DNAs Myoglobin, consisting mostly of " helices, labeled A through H, and contains a heme group (dark) that binds oxygen. From Biophysical Chemistry - Cantor and Schimmel (Figure 1-4))

QUARTERNARY STRUCTURE

!!

!!

!!

(4 structure) non-covalent association of independent tertiary structure units. Hemoglobin: There are four subunits, each with one bound heme. A twofold rotational symmetry axis exists in the center of the molecule perpendicular to the plane of the page. From Biophysical Chemistry - Cantor and Schimmel (Figure 1-5)

7 !

9/9/09 !

SELECTED CHRONOLOGY OF POLYMER SCIENC

!! !! !!

1806 1838 1859 1884-1919 and 1920 1928 1929 polymers 1930-1934 WW II

!!

!! !!

!!

Gough (England) experiments with elasticity of natural rubber Regnault (France) polymerizes vinylidene chloride via sunlight Joule (England) demonstrates the thermodynamic principles of elasticity of rubber Emil Fisher (Germany) establishes formulae of many sugars proteins Staudinger (Germany) advances macromolecular hypothesis Meyer and Mark (Germany) measure crystallite sizes in cellulose and rubber Carothers (U.S.) synthesizes and characterizes condensation Kuhn, Guth, and Mark (Germany) derive mathematical models for polymer configurations; theory of rubber elasticity Debeye, light scattering of polymer solutions; Flory, viscosity of polymer solutions; Harkins, theory of emulsion polymerization; Weissenberg, normal stresses in polymer flow

!!

!!

SELECTED CHRONOLOGY OF POLYMER SCIENC 1950's Ziegler, coordination of complex polymerization; Natta, tacticity in polymers; Swarc, living polymers; interfacial

!!

!! !!

!! !! !! !! !! !! !! !! !! !!

polymerization 1955 Williams-Landel-Ferry equation for time-temperature superposition of mechanical properties 1957 Keller and Till, single crystals of polyethylene characterized 1960 T. Smith, the failure envelope 1960's NMR applied to polymer structure analysis Maxwell, orthogonal rheometer Moore, GPC analysis for molecular weight distribution Differential scanning calorimetry Marvel, polybenzimidazoles Gilham, torsional braid analysis 1970's Interpenetrating networks High-performance liquid chromatography From Principles of Polymer Systems - Rodriguez (Table 1-5)

!!

8 !

9/9/09 !

SELECTED CHRONOLOGY OF POLYMER TECHNOLOGY

!!

!!

1770 erase 1839

!!

!!

!!

!!

!! !! !!

rubber 1860's Molding of natural plastics such as shellac and gutta-percha 1868 Hyatt (U.S.), celluloid (cellulose nitrate molded articles) 1891 Chardonnet (France), regenerated cellulose via nitrate 1893-1898 Cross, Bevan, Beadle, Stern (England), viscous rayon fibers 1907 Baekland (U.S.), phenol-formaldehyde resins 1910 First rayon plant in United States WW I Cellulose acetate solutions ("dope") for aircraft; laminated plywood and fabric construction for aircraft fuselages

Priestly givers rubber its name because it can marks on paper Goodyear (U.S.) MacIntosh and Hancock (England), vulcanization (crosslinking) of natural

SELECTED CHRONOLOGY OF POLYMER TECHNOLOGY

!! !! !! !! !!

1920's 1924 1926 1927 1929

!!

!!

!!

!! !!

Cellulose Nitrate laquers for autos Cellulose acetate fibers Alkyld resins from drying oils for coatings Poly(vinyl chloride), cellulose acetate plastics Polysulfide (Thiokol) rubber, urea-formaldehyde resins 1931 Poly(methyl methacrylate) plastics, neoprene (Duprene) synthetic rubber 1936 Poly(vinyl acetate) and poly(vinyl butyral) for laminated safety glass 1937 Polystyrene, styrene-butadiene (Buna S) and acrylonitrile-butadiene (Buna N) rubbers (Germany) 1938 Nylon 66 fibers 1939 Melamine-formaldehyde resins, poly(vinylidene chloride)

9 !

9/9/09 !

SELECTED CHRONOLOGY OF POLYMER TECHNOLOGY

!! !! !! !!

1940 1941 1942 WW II

!! !! !! !! !! !!

Butyl rubber (U.S.) Polyethylene production (England) Unsaturated polyesters for laminates Silicones, fluorocarbon resins, polyurethanes (Germany), styrene-butadiene rubber in United States, latex-based paints 1947 Epoxy resins 1948 ABS polymers 1950 Polyester fibers 1948-1950 Acrylic fibers 1954 Polyurethane foams in U.S. 1956 Linear polyethylene, acetals [poly(oxymethylene)]

SELECTED CHRONOLOGY OF POLYMER TECHNOLOGY

!! !!

!! !! !!

1957 1959 and 1960 1962 1965 1960's 1970 1971 1970's 1977

!!

!! !! !!

!!

Polypropylene, polycarbonates Chlorinated polyether, synthetic cis-polyisoprene cis-polybutadiene rubbers Ethylene-propylene rubber, spandex fibers Phenoxy resins, polyimide resins Poly(phenylene oxide), polysulfones, styrenebutadiene block copolymers Cyanoacrylate adhesives, aromatic polyamides, polyimides, silane coupling agents Isotactic polybutadiene Poly(butyl terephthalate) Thermoplastic elastomers based on copolyesters, poly(phenylene sulfide) Polynorbornene (rubber)

POLYMER CONSUMPTION IN THE UNITED STATES (IN UNITS OF 106 kg)

Plastics Thermosets Alkyd Epoxy Phenolic Polyester(unsaturated) Polyurethane foams Urea and melamine Thermoplastics Acrylic Cellulosics Nylon Polycarbonate Polyester(saturated) Polyethylene (high density) Polyethylene (low density) Polypropylene Polystyrene and other styreneics Poly(vinyl chloride) Others Rubber (production figures) Natural rubber (consumption) Styrene-butadiene Polybutadiene Neoprene Ethylene-propylene Butyl Nitrile Other 1968 6,870 1,423 150 70 408 244 277 274 5,477 145 87 33 12 --545 1,364 377 1,416 1,095 373 3,149 593 1,488 327 (with "other") 116 154 82 389 1978 16,124 3,037 215 143 700 549 840 590 13,087 253 74 126 95 280 1,893 3,249 1,389 2,741 2,641 346 3,234 779 1,377 379 160 174 152 72 141

10 !

9/9/09 !

POLYMER CONSUMPTION IN THE UNITED STATES (IN UNITS OF 106 kg)

Plastics Fibers (consumption figures) Natural and mineral Cotton Wool Glass Synthetic organic fibers Rayon Cellulose acetate Nylon Polyester Acrylic Polyolefin

1968 6,870 4,400 2,240 1,885 172 183 2,160 548 220 578 459 233 122

1978 16,124 5,677 1,769 1,287 60 422 3,908 253 137 1,156 1,722 328 312

CLASSIFICATION SCHEMES

!!

1.

STRUCTURE: Does the polymer exist in a mass of

separable, individual molecules or as a macroscopic network?

!!

2.

PHYSICAL STATE: The polymer could be crystalline or completely disordered, molten, or glassy. REACTION TO THE ENVIRONMENT THERMOPLASTIC: Materials that soften and flow upon application of pressure and heat. !! THERMOSET: materials that react irreversibly once heated.

!!

!!

3.

!!

4.

CHEMICAL: The elemental composition of a polymer, the

chemical groups which are present.

!!

5.

FINAL USE: Adhesives, fiber, rubber, biomaterials

MOLECULAR ARCHITECTURE

!!

!! !! !!

!!

!!

Thermoplastics: referred to as plastics are linear or branched polymers which can be melted upon the application of heat. Can be molded and remolded. Make up the largest bulk of polymers used. Can be sub-divided into polymers that crystallize on cooling and those which do not - polymer glasses. Crystallization depends on the degree of branching, and the regularity of the molecules. Crystalline thermoplastics are only partly (semi-) crystalline and do not crystallize completely when cooled from the melt.

Schematic representation of different types of polymer molecules.

11 !

9/9/09 !

MOLECULAR ARCHITECTURE

!! !!

!!

!!

Rubbers: materials which display elastomeric properties. They can be stretched easily to high extensions and will spring back rapidly when the stress is released. This property is a reflection of the molecular structure of the polymer which consists of a highly cross-linked macromolecular network. The molecules slide past each other on deformation, but the crosslinks prevent permanent flow and the molecules spring back to their original position on removal.

Schematic representation of different types of polymer molecules.

POLYMER CLASSIFICATION

Polymers

Thermoplastics

Rubbers

Thermosets

Liquid-crystalline

Crystalline

Amorphous

Classification of polymers

12 !

9/9/09 !

SINGLE POLYMER MOLECULES

The single molecules may be linear or branched (Fig. 2-1). In a polymer chain that contains carbon atoms with two different substituents, the carbon is asymmetric. Asymmetric atoms can exist in two different spatial configurations which are not interchangeable without breaking covalent bonds-optical isomerism.

!!

!!

!!

SINGLE POLYMER MOLECULES

!!

!! !! !! !!

Example: Consider the case of polypropylene with the repeating unit: CH3 | [CH2CH] Every other carbon is asymmetric. Three structures can result. These visualized by looking at the main polymer chain in an extended planar zigzag conformation. Changes in structure are caused by rotations about single bonds are termed conformations and isomers that cannot be interchanged without bond breaking are termed configurations

Figure 2-1: Polymer arrangements MOLECULAR STRUCTURE

Linear

Branched

Crosslinked (network)

13 !

9/9/09 !

SINGLE POLYMER MOLECULES

14 !

9/9/09 !

15 !

9/9/09 !

BONDING IN POLYMERS

Types of bonds Various types of bonding hold the atoms together in polymeric materials, as opposed to metals, for example, where only one type of bonding exists. These types are: (1) primary covalent, (2) hydrogen bonding, (3) dipole interaction, (4) van der Waals, and (5) ionic, examples of which are shown in Fig. 3.1. Hydrogen bonding, dipole interaction, van der Waals, and ionic bonding are known collectively as secondary forces.

16 !

9/9/09 !

BONDING IN POLYMERS

Bond distances and strengths The potential energy of the interacting atoms as a function of the separation between them represented qualitatively by the potential function sketched in Fig. 3.2. As the interacting centers are brought together from large separation, an increasingly great attraction tends to draw them together (negative potential energy). Beyond the separation rm, as the atoms are brought closer together, their electronic "atmospheres" begin to interact, and a repulsion is set up. At rm the system is at a potential energy minimum, most probable equilibrium separation, the equilibrium bond distance. !, is the energy required to break the bond. Primary covalent bonds are stronger than the others. As the material's temperature is raised and its thermal energy (kT) is thereby increased, the primary covalent bonds will be the last to dissociate when the available thermal energy exceeds the dissociation energy.

EQUIVALENTS FOR SELECTED SI QUANTITIES

!!

Quantity

SI unit Value in CGS units

Value in British units

!! !! !! !! !! !! !! !! !! !! !! !! !! !! !!

Mass Length Area Volume

1000 g 2.2 lb. 100 cm 3.281 ft 10,000 cm2 10.76 ft2 1,000,000 cm3 or 35.31 ft3 or 1000 liter 264.2 gal (U.S.) Force N 100,000 dyn 0.2248 lbf Energy J, N-m 10,000,000 erg or 0.7376 ft-lbf or 0.2389 cal 0.9481 x 10-3 Btu Pressure Pa, N/m210 dyn 1.45 x 10-4 psi Viscosity Pa-s 10 P (poise) 6.72 lbm/ft-s Power W, J/s 1 x 107 erg/s or 1.341 x 10-3 hp or 14.34 cal/min 3.413 Btu/h Specific heat J/kg-K 238.9 cal/g-C 238.9 Btu/lbm-F 2 2 Heat transfer W/m -K 0.2389 cal/m -s-C 0.1761 Btu/ft2-h coefficient Impact strength J/m 1.873 x 10-2 ft-lbf/in

kg m m2 m3

!!

17 !

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- A Plastic Solution For Plastic PollutionDokument54 SeitenA Plastic Solution For Plastic PollutionDurga Prasad KalamNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Cooper 1983Dokument10 SeitenCooper 1983Amsha ProagNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Spandex Fiber: Dorlastan.) Invista, Radicispandex CorporationDokument20 SeitenSpandex Fiber: Dorlastan.) Invista, Radicispandex CorporationShantnu MittalNoch keine Bewertungen

- Kinetics of Iodination of Acetone Catalyzed by HCL and H2so4 A Colorimetric Investigation of Relative StrengthDokument2 SeitenKinetics of Iodination of Acetone Catalyzed by HCL and H2so4 A Colorimetric Investigation of Relative StrengthHansel VereitelnNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Project Report PDFDokument66 SeitenProject Report PDFTEAM LUASKARTNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- 01 2016 09 fiberEX 12S ENDokument12 Seiten01 2016 09 fiberEX 12S ENAlam GomezNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

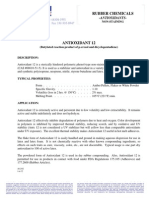

- Antioxidant 12Dokument1 SeiteAntioxidant 12Daniel MartinsNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Unit Iv Polymers - PPTDokument69 SeitenUnit Iv Polymers - PPTAbhishek GuptaNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- NCERT Class 12 Chemistry Answers and SolutionsDokument5 SeitenNCERT Class 12 Chemistry Answers and SolutionsAishwarya ShirkeNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Study of Chitosans Interaction With Cu (II) From The Corresponding Sulfate and Chloride SaltsDokument17 SeitenStudy of Chitosans Interaction With Cu (II) From The Corresponding Sulfate and Chloride SaltsFernanda Stuani PereiraNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Ijddt 1st ArticleDokument6 SeitenIjddt 1st ArticleShiv SMSNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Chemistry Form 4 Chapter 9 Manufacture Substances in IndustryDokument18 SeitenChemistry Form 4 Chapter 9 Manufacture Substances in Industrychulan93100% (15)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Organic Name Reactions: Nutshell Review & Preview ofDokument9 SeitenOrganic Name Reactions: Nutshell Review & Preview ofSai YashwanthNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Handling Silica in Cooling WaterDokument17 SeitenHandling Silica in Cooling WaterLekhamani YadavNoch keine Bewertungen

- 1 PDFDokument18 Seiten1 PDFMasood HassanNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- R - Us20070178239a1 PDFDokument8 SeitenR - Us20070178239a1 PDFbutuh ganalNoch keine Bewertungen

- Advances in Polymer ScienceDokument374 SeitenAdvances in Polymer ScienceLANoch keine Bewertungen

- Datasheet Kynar 2500Dokument20 SeitenDatasheet Kynar 2500mlombardiTONoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Kollicoat IRDokument12 SeitenKollicoat IRMd.ali-bin-saifullah100% (1)

- Make Your Own Hot Glue Sticks 2Dokument8 SeitenMake Your Own Hot Glue Sticks 2Gamal FouadNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Adhesives For WoodDokument500 SeitenAdhesives For WoodJoão Victor WorkNoch keine Bewertungen

- Sol-Gel Transition of Poly (Vinyl Alcohol) - Borate ComplexDokument6 SeitenSol-Gel Transition of Poly (Vinyl Alcohol) - Borate ComplexHaroon RashidNoch keine Bewertungen

- Polymer Molar Masses and SizesDokument27 SeitenPolymer Molar Masses and Sizesfrency13Noch keine Bewertungen

- Polystyrene - Properties, Performance, and Applications - James E. Gray (Nova, 2011)Dokument199 SeitenPolystyrene - Properties, Performance, and Applications - James E. Gray (Nova, 2011)BoulHich BoulHichNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Highway Engg Unit 4 NotesDokument17 SeitenHighway Engg Unit 4 NotesRajha RajeswaranNoch keine Bewertungen

- The Products We Rely OnDokument14 SeitenThe Products We Rely Onjaslinda_jamalNoch keine Bewertungen

- Thelma G. Manning and Zafar Iqbal - Polymeric Nitrogen Stabilized On Carbon Nanotubes: A Highly Energetic, Green ExplosiveDokument13 SeitenThelma G. Manning and Zafar Iqbal - Polymeric Nitrogen Stabilized On Carbon Nanotubes: A Highly Energetic, Green ExplosiveYsam2Noch keine Bewertungen

- Product Data Sheet: Eastman™ Cellulose Acetate Butyrate (CAB-551-0.2) Application/UsesDokument2 SeitenProduct Data Sheet: Eastman™ Cellulose Acetate Butyrate (CAB-551-0.2) Application/UsesBERKAT RAJA SEMESTANoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Chapter 1 Introduction On Material ScienceDokument33 SeitenChapter 1 Introduction On Material ScienceZjian Wai100% (1)

- Dilute Solution ViscosityDokument7 SeitenDilute Solution Viscosityjulio070983Noch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)