Beruflich Dokumente

Kultur Dokumente

Pressurised Systems: Vessel With Various Types of Stiffeners Located in The Cylindrical & Conical Parts

Hochgeladen von

Joemarie MartinezOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Pressurised Systems: Vessel With Various Types of Stiffeners Located in The Cylindrical & Conical Parts

Hochgeladen von

Joemarie MartinezCopyright:

Verfügbare Formate

16587 Pressurised Systems

108

9.4 9.4 SHELLS UNDER EXTERNAL PRESSURE SHELLS UNDER EXTERNAL PRESSURE

This topic involves quite different problems from those arising in the design of internally

pressurised vessels. It is important to give attention to :-

(a) Elastic and Plastic Buckling

(b) Shape imperfections

(c) Residual Stresses due to the manufacturing processes.

The Design Approach in PD 5500

The aim of the method is to :

predict the pressure at which buckling will occur in each part.

If this pressure is less than the required working pressure then:-

(i) the shell may be thickened;

(ii) stiffening rings can be added;

(iii) if rings are already present they can be placed more

frequently or increased in size;

(iv) for dished ends, the thickness could be increased, or the

geometry changed.

To illustrate the approach and give some background, to at least part of the method, a series

of figures are presented;

Vessel with various types of stiffeners located in the cylindrical & conical parts

In PD 5500, there is a margin of at least 50% between the design pressure specified and the

pressure at which signs of buckling might first appear - providing the vessel is circular to

within 0.5% of the radius.

16587 Pressurised Systems

109

In Cylinders, there is a multitude of elastic buckling modes which can occur and describe,

analytically, the behaviour of the vessel. The technique in BS 5500 is to design the cylinders

by considering three simple cases only.

(a) interstiffener buckling

(b) overall buckling

(c) stiffener tripping

The photograph shows interstiffener buckling as

exhibited in a test model. Note the wrinkles occur

between those parts which remain circular. This can

be clearly seen on the above diagram.

In this course, only interstiffener

buckling will be dealt with in detail.

However, be aware of the existence of

the other two and be capable of

describing them in some detail.

The following photograph and

diagram show overall buckling where

the whole cylinder has collapsed. The

light stiffeners have given way and

only those major portions of shell with

substantial stiffening remain circular.

16587 Pressurised Systems

110

Elastic Analysis of Equally Spaced Stiffeners in a Cylindrical Vessel Elastic Analysis of Equally Spaced Stiffeners in a Cylindrical Vessel

As a first step to understanding the distribution of the stresses in such a vessel an elastic

analysis can be carried out.

The cylinder equation:-

d

dx

d

dx D z

4

4

2 2

2

2

4

4 4 1

+ +

_

,

can be used. This can be solved for the cylinder shown.

There are 4 stresses of importance

(1) the circumferential stress on the outer flange of the stiffener

s

(2) the axial stress on the vessel

7

(3) the circumferential stress on the outside surface between the stiffeners

s

(4) The circumferential stress at the centre of the wall, between the stiffeners

5

It is therefore necessary to find that the value of the external pressurewhich will cause each

of these four stresses to each reach the material yield point,

. In general, the lowest stress

is

5

. It is a compressive membrane stress and thus seems a good candidate for being used

as the stress to cause buckling. This value is called the Yield Pressure, p

y

and is given by the following expression,

( )

p

sfe

R G

y

1

The value sf is a modified design stress, and can be thought of as a reduced yield value.

It relates f to an effective yield point: s = 1.4 for carbon steels

s = 1.1 for stainless steels

5

7

s

R

External pressure

16587 Pressurised Systems

111

One could argue for s = 1.5, so that sf =

y

. A lower s value introduces a factor of safety.The

in the above equation is a rather complicated value, which is a function of the stiffeners. It

is generally taken as 0 as a first approximation. Such an assumption produces an

underestimation for the allowable pressure, and therefore is safe to do so. Therefore,

p

sfe

R

(Note: f s

pR

e

)

Recall, this is the membrane equation again.

Elastic Buckling

This graph is a pressure-deflection response for cylinders. The line OA shows a uniform

response, single value of deflection and only slight non-linearity. Displacement is

axisymmetric.At A, the response becomes unstable - bifurcation point. From A to B - In

theory the shell displacement would continue along AB and buckle axi-symmetrically at high

pressure. However, the slightest disturbance at A would cause a dynamic motion. A fly

breathing at the other end of the Universe ! Note: the pressure at A - Elastic Buckling

Pressure p

m

Shape of vessel in circumferential direction

From point A, the cylindrical shell develops into a series of sine waves in the circumferential

direction, n = 2, 3, 4 etc. There will be a similar behaviour in the axial direction. There are

C

C

B

A

2

1

imperfect

cylinders

perfect cylinders

axisymmetric

behaviour

bifurcation

occurs

Deflection

P

r

e

s

s

u

r

e

Pm

non-axisymmetric

behaviour

16587 Pressurised Systems

112

thus innumerable elastic buckling modes. For each n(circumferential), there will be an

infinite number of longitudinal mode shapes. In practice number is finite, because the wave

lengths must be several times the wall thickness. It has been found that one can design

cylinders by considering the Three Simple Cases - as noted above.

The possibility is passible because, for a given vessel of radius R and wall thickness e,

(1) Interstiffener buckling is governed by stiffener spacing, L

s

.

(2) Overall buckling is governed in the main by the size of the stiffeners, and

(3) Stiffener tripping by the proportions of the stiffener.

Interstiffener Buckling Interstiffener Buckling

In this course, only the analysis of interstiffener buckling is dealt with. The other forms of

buckling are presented in the standard and in detail in BS Document PD 6550 Part:2 1989.

In this, the treatment assumes the following:-

(a) effect of stiffeners on pre-buckling stress in shell is neglected

(b) rotational and axial restraint to shell buckling due to stiffeners is neglected

(c) stiffeners remain circular during buckling.

Governing equation is given as:

( )

{ } ( )

[ ]

( )

[ ]

p

Ee

R

n

n

e

R

n

m

R

L

L

R

R

L

+

+

+

'

1

1

1

1

12 1

1

2

1

2

2

2

2

2

2

2 2

2

2

2

( )

This is an expression for p

m

- the Elastic Buckling Pressure)

p

e

R

m

(notice this is another membrane type equation, since is the circumferential buckling strain

and E is a stress)

If this function is graphed, for a specific cylinder with the following dimensions;

R = 2700mm, L

s

= 750mm, e = 25mm, E = 207,000N/mm

2

, = 0.3.

The equation above can be used with a range of n values to find p

m

. There is a minimum

value at p

m

= 7.31N/mm

2

and n = 14.

16587 Pressurised Systems

113

The fuller version of this graph appears as Figure 3.6(3) of the standard. Values of n at

which the minimum occurs are given on this figure from the BS Code. The plot enables -

the Circumferential Buckling Strain to be found and from this, p

m.

The cusps on Fig 3.6(3) represent the points at which the mode associated with the minimum

pressure occurs. This figure can be been marked up to show the values of n corresponding

to the minimum nodal buckling pressures.

This value of p

m

is a theoretical value for infinitely long ring stiffened cylinders which are

perfectly circular.

In real shells, however, the Shape Imperfections lower the collapse pressure. Also, as the

shell thickness increases, or small diameter vessels are employed, plastic buckling occurs

and the collapse pressure is close to p

y

, which is much less than p

m

.

Because of these effects, an empirical method is employed which uses p

y

and p

m

but also a

large number of results from well documented tests.This graph has been prepared from data

from 700 well documented tests which have taken place over the last 100 years.

Actual Measured Collapse Pressure p

p

p

p

c m

~

These parameters minimised the scatter.

16587 Pressurised Systems

114

The values were bounded, then divided by 1.5 to give the design curve in PD 5500. Its Fig

3.6(3) in PD 5500.

Curve (a) for cylinders and cones and (b) for spheres or cylinders to subject to axial stress.

The reason curve (b) is lower is because spheres and cylinders subject to axial stress are very

sensitive to imperfections.

16587 Pressurised Systems

115

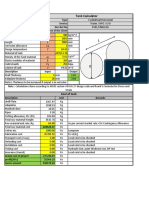

Example of Designing for External Pressure - Example of Designing for External Pressure - Interstiffener Buckling Only Interstiffener Buckling Only

Design data:

Design External Pressure

Mean radius of shell

Stiffener spacing

Material for shell and stiffeners

Design stress

Effective yield,

Modulus of elasticity

p

R

L

s

s

f

sf

E

= 6.9 bar

= 2500 mm

= 1000 mm

= 1.4

= 165 N/mm

2

= 231 N/mm

2

= 2.0710

5

N/mm

2

This is trial and error procedure, so a range of values must be taken. Assume a thickness of

12.5mm as an initial value. This value would be at least the minimum required internal

pressure thickness for an equivalent internal pressure loading.

2R/e 400 300 250 200

e 12.5 16.7 20 25

p

y

=sfe/R 1.155 1.540 1.848 2.310

for L/2R = 0.2 from Fig 3.6(2) 0.00088 0.0013 0.0018 0.0026

p

m

=Ee /R 0.911 1.798 2.981 5.382

K = p

m

/p

y

0.789 1.167 1.613 2.330

= p/p

y

from Fig 3.6(3) 0.263 0.380 0.470 0.525

Allowable pressure, p (N/mm

2

) 0.306 0.585 0.869 1.213

From this table, 12.5mm and 16.7mm provide insufficient allowable pressures. Thicknesses

of 20mm and 25mm yield adequate results. Linearly interpolating in the table for an

allowable pressure of 0.69N/mm

2

gives a required thickness of 17.9mm.

Spheres under External Pressure Spheres under External Pressure

Spheres are designed to prevent either yielding or buckling from occurring due to the applied

external pressure loading. As with the design of cylindrical shells, the aim is to ensure the

geometry can carrying sufficient pressure loading to prevent either of the two failure

mechanisms arising. Typical failures can be seen in the photographs shown overleaf.

The pressure to cause yield of a sphere is found from the membrane expression

p

sfe

R

yss

2

(subscript yss denotes yield of a spherical shell.)

16587 Pressurised Systems

116

The theoretical pressure to cause elastic buckling is given by the following expression;

p

Ee

R

e

121

2

2

.

However, since this value is only the theoretical value, and shape imperfections must be

considered, then it is possible to use Figure 3.6(3) to evaluate the actual allowable pressure.

This is a non-dimensional curve which relates the theoretical elastic buckling pressure to the

actual buckling pressure with a safety factor of at least 50%. The curve axes values are non-

dimensionalised by dividing through by the yield pressure value.

Photographs of collapsed dished ends.

Hemispherical Ends under External Pressure Hemispherical Ends under External Pressure

As far as PD 5500 is concerned, hemi-spherical ends are designed as spherical shells.

Torispherical Ends under External Pressure Torispherical Ends under External Pressure

Tori-spherical ends are designed as spherical shells of a mean radius R equal to the external

crown radius.

Ellipsoidal Ends under External Pressure Ellipsoidal Ends under External Pressure

Ellipsoidal ends are designed as spherical shells with a mean radius R equal to the maximum

crown radius i.e. D

2

/4h.

Das könnte Ihnen auch gefallen

- Discrete Element Method to Model 3D Continuous MaterialsVon EverandDiscrete Element Method to Model 3D Continuous MaterialsNoch keine Bewertungen

- Large Horizontal Vessel Supported by Two Saddles Stress AnalysisDokument7 SeitenLarge Horizontal Vessel Supported by Two Saddles Stress AnalysisSiva baalan100% (1)

- Screw Conveyor Size 350, Input Data SR No Description Metric Unit in Fts SrnoDokument2 SeitenScrew Conveyor Size 350, Input Data SR No Description Metric Unit in Fts SrnoTheodoros AtheridisNoch keine Bewertungen

- Ellipsoidal Flange To Circular ConverterDokument3 SeitenEllipsoidal Flange To Circular Converternaveenkumar_madasett100% (1)

- PV Elite Vessel Analysis Program HorizontalDokument55 SeitenPV Elite Vessel Analysis Program HorizontalMarizta Perdani PutriNoch keine Bewertungen

- Unstiffened Cylinders EN 13445-3 - 8.5.2 PDFDokument4 SeitenUnstiffened Cylinders EN 13445-3 - 8.5.2 PDFfrlamontNoch keine Bewertungen

- PSV Reaction Force CalculationDokument2 SeitenPSV Reaction Force CalculationSuthanNoch keine Bewertungen

- Project JG Summit Stage1 Expansion Title: Screening Procedure As Per ASME Section VIII, Div 2. PE3-E6552Dokument1 SeiteProject JG Summit Stage1 Expansion Title: Screening Procedure As Per ASME Section VIII, Div 2. PE3-E6552Darshan PanchalNoch keine Bewertungen

- Coupling Calculations and Ug-32 Unstayed Head CalculationsDokument9 SeitenCoupling Calculations and Ug-32 Unstayed Head CalculationsLcm TnlNoch keine Bewertungen

- Output Summary: SI UnitsDokument42 SeitenOutput Summary: SI UnitsAkhil JoseNoch keine Bewertungen

- Saddle Support CalculationDokument7 SeitenSaddle Support CalculationrichardchiamNoch keine Bewertungen

- WI06-0260 Calculations For Obround Nozzle ConnectionsDokument4 SeitenWI06-0260 Calculations For Obround Nozzle ConnectionskumarNoch keine Bewertungen

- Design and Analysis of Pressure Vessel Skirt Considering Seismic Load As Per Uniform Building Code IJERTCONV4IS10007Dokument5 SeitenDesign and Analysis of Pressure Vessel Skirt Considering Seismic Load As Per Uniform Building Code IJERTCONV4IS10007RSalehNoch keine Bewertungen

- Bulk Air Eliminator R1Dokument1 SeiteBulk Air Eliminator R1hydrothermsNoch keine Bewertungen

- Spreaer Beam&Lifting Line Beam p5Dokument2 SeitenSpreaer Beam&Lifting Line Beam p5Sabrang LorNoch keine Bewertungen

- Chap 01 SMDokument20 SeitenChap 01 SMMohammed GhisheerNoch keine Bewertungen

- Xcalcs: Circular Flat Flanges Without Hubs: 2.7:+looseDokument2 SeitenXcalcs: Circular Flat Flanges Without Hubs: 2.7:+looseayushNoch keine Bewertungen

- WRC Loadings and Sign ConventionDokument9 SeitenWRC Loadings and Sign ConventionGovindan KrishnamoorthybashyamNoch keine Bewertungen

- PV Elite ResultDokument239 SeitenPV Elite ResultChaitanya Sai TNoch keine Bewertungen

- Pin StressesDokument5 SeitenPin Stressesprajakt_pieNoch keine Bewertungen

- Design Calculations of Storage Tank: According To API 650 Code, 11 EditionDokument3 SeitenDesign Calculations of Storage Tank: According To API 650 Code, 11 EditionAkash Kazama100% (1)

- Body Flange .PVDB FlangeDokument1 SeiteBody Flange .PVDB FlangeAnonymous aBg51lbe18Noch keine Bewertungen

- PVElite RefDokument6 SeitenPVElite RefakhilNoch keine Bewertungen

- Pressure Vessel Inspection ReportDokument34 SeitenPressure Vessel Inspection ReportJinlong Su100% (1)

- Spreaer Beam&Lifting Line Beam p3Dokument2 SeitenSpreaer Beam&Lifting Line Beam p3Sabrang LorNoch keine Bewertungen

- Seismic Load Calculation of The Tank As Per IS 1893Dokument1 SeiteSeismic Load Calculation of The Tank As Per IS 1893ParthibanNoch keine Bewertungen

- 0.0bolt Torque Calculation - R0Dokument9 Seiten0.0bolt Torque Calculation - R0Darshan PanchalNoch keine Bewertungen

- KIRK KWM Mist EliminatorsDokument3 SeitenKIRK KWM Mist EliminatorsperrychemNoch keine Bewertungen

- NozzleDokument11 SeitenNozzleharyfadlyNoch keine Bewertungen

- (Pressure Safety Valve Kick Force On Gas Relief) : Technip Geoproduction (M) Sdn. Bhd. Stress Standard ProcedureDokument7 Seiten(Pressure Safety Valve Kick Force On Gas Relief) : Technip Geoproduction (M) Sdn. Bhd. Stress Standard ProcedurecelonevesNoch keine Bewertungen

- Horizontal Vessel Support: Vertical Saddle ReactionsDokument12 SeitenHorizontal Vessel Support: Vertical Saddle ReactionsSanket BhaleraoNoch keine Bewertungen

- Stress at Junction of Shell & HeadDokument13 SeitenStress at Junction of Shell & HeadRey Fiedacan100% (2)

- Calculations For Rectangular Storage TankDokument44 SeitenCalculations For Rectangular Storage TankSiva ShankarNoch keine Bewertungen

- API 650 Tank Nozzle Stand OutDokument5 SeitenAPI 650 Tank Nozzle Stand Outtry&try100% (1)

- PV Newsletter - Skirt Connections PDFDokument5 SeitenPV Newsletter - Skirt Connections PDFDivyesh PatelNoch keine Bewertungen

- Beam Spreadsheet: Ignore Lateral Torsional BucklingDokument5 SeitenBeam Spreadsheet: Ignore Lateral Torsional BucklingPurnima ArkalgudNoch keine Bewertungen

- PV Elite 2014 Licensee Filename: Rectangular Vessel Rectves Analysis: New Rectangular Item: 1 8:09P Aug 25,2015Dokument7 SeitenPV Elite 2014 Licensee Filename: Rectangular Vessel Rectves Analysis: New Rectangular Item: 1 8:09P Aug 25,2015Pressure VesselNoch keine Bewertungen

- Section VIII CalDokument22 SeitenSection VIII CalthodathersNoch keine Bewertungen

- BAEK Et Al. Fatigue Life Prediction Based On The Rainflow Cycle Counting Method For The End Beam of A Freight Car BogieDokument7 SeitenBAEK Et Al. Fatigue Life Prediction Based On The Rainflow Cycle Counting Method For The End Beam of A Freight Car BogiePPNNoch keine Bewertungen

- Welding Neck Flanges 1Dokument3 SeitenWelding Neck Flanges 1bikkelbobNoch keine Bewertungen

- Conventional JacketsDokument4 SeitenConventional JacketskayeNoch keine Bewertungen

- Design of Partition PlateDokument5 SeitenDesign of Partition Platepippo2378793Noch keine Bewertungen

- UHX - Osweiller - WhitePaper PDFDokument20 SeitenUHX - Osweiller - WhitePaper PDFMichael BasaNoch keine Bewertungen

- Liting Lug Calculation VesselsDokument11 SeitenLiting Lug Calculation VesselsSudar Mysha0% (1)

- Roof Nozzle Reinforcement API 620 Section 5.16 - ColdDokument1 SeiteRoof Nozzle Reinforcement API 620 Section 5.16 - ColdtutuionutNoch keine Bewertungen

- External Pressure Calculation ResultsDokument8 SeitenExternal Pressure Calculation ResultsAndika DearsonNoch keine Bewertungen

- Finglowv2Dokument16 SeitenFinglowv2RobinReyndersNoch keine Bewertungen

- Piping Engineering - Tank Nozzle Loads 1Dokument1 SeitePiping Engineering - Tank Nozzle Loads 1Nasrul Adli100% (1)

- 50KL Tank - API CalcDokument1 Seite50KL Tank - API CalcRathika100% (1)

- Deaera DesignDokument13 SeitenDeaera DesignBhanu K PrakashNoch keine Bewertungen

- Vessel Data Sheet Process Specification Sheet FormDokument1 SeiteVessel Data Sheet Process Specification Sheet FormunitedmanticoreNoch keine Bewertungen

- Tailing LugDokument2 SeitenTailing Lugjagannadha varmaNoch keine Bewertungen

- Tank Nozzle Loads - CalcstressDokument11 SeitenTank Nozzle Loads - CalcstressDam Vo100% (1)

- 181-F Secondary Reformer Jacket Cooling Water Pit - R0 (1) - 12082018 PDFDokument17 Seiten181-F Secondary Reformer Jacket Cooling Water Pit - R0 (1) - 12082018 PDFManish542Noch keine Bewertungen

- L-CV-155-VA-24XX01 Nitrogen: ASME Sec VIII Div 1+ PED97/23/ECDokument1 SeiteL-CV-155-VA-24XX01 Nitrogen: ASME Sec VIII Div 1+ PED97/23/ECevrim77Noch keine Bewertungen

- Sample FLG CalcDokument6 SeitenSample FLG CalcameyyammaiNoch keine Bewertungen

- Analysis of Corrugated Web Beam To Column Extended End Plate Connection UsingDokument75 SeitenAnalysis of Corrugated Web Beam To Column Extended End Plate Connection UsingLina Lina LoulouNoch keine Bewertungen

- 00000-JDS-015 (ERV Manhole) Rev 0Dokument10 Seiten00000-JDS-015 (ERV Manhole) Rev 0sithulibraNoch keine Bewertungen

- Design of Tooth Locked Quick Open Die Pressure VesselDokument4 SeitenDesign of Tooth Locked Quick Open Die Pressure VesselSEP-PublisherNoch keine Bewertungen

- Catalogo Cyclo 6000 (Ing - MM)Dokument371 SeitenCatalogo Cyclo 6000 (Ing - MM)Mauricio Kookc100% (1)

- Hinge Specification GuideDokument4 SeitenHinge Specification GuideJoemarie MartinezNoch keine Bewertungen

- Job Order Request: Phll. Flbertech Lndustrles, LNCDokument4 SeitenJob Order Request: Phll. Flbertech Lndustrles, LNCJoemarie MartinezNoch keine Bewertungen

- Ground Granulated Blast-Furnace Slag: Production and CompositionDokument3 SeitenGround Granulated Blast-Furnace Slag: Production and CompositionJoemarie MartinezNoch keine Bewertungen

- Time Frame NewDokument2 SeitenTime Frame NewJoemarie MartinezNoch keine Bewertungen

- Plane Geometry - EsplanaDokument100 SeitenPlane Geometry - EsplanaJoemarie Martinez100% (3)

- HNU Logo Witness To The Word CMYKDokument1 SeiteHNU Logo Witness To The Word CMYKJoemarie MartinezNoch keine Bewertungen

- RFS-CT-2006-00031 - HISTWIN High-Strength Steel Tower For Wind TurbineDokument15 SeitenRFS-CT-2006-00031 - HISTWIN High-Strength Steel Tower For Wind TurbineJoemarie MartinezNoch keine Bewertungen

- Beam Bending (Chapter 13) Shear and Moment Diagrams/EquationsDokument36 SeitenBeam Bending (Chapter 13) Shear and Moment Diagrams/EquationsJoemarie MartinezNoch keine Bewertungen

- Daily Work Accomplishment FormDokument1 SeiteDaily Work Accomplishment FormJoemarie Martinez0% (1)

- SSS Contribution Form - 2013Dokument6 SeitenSSS Contribution Form - 2013Joemarie MartinezNoch keine Bewertungen

- Phll. Flbertech Lndustrles, LNC.: Overtime AuthorizationDokument1 SeitePhll. Flbertech Lndustrles, LNC.: Overtime AuthorizationJoemarie MartinezNoch keine Bewertungen

- Calculator TechniquesDokument23 SeitenCalculator TechniquesJoa See100% (1)

- Syllabus - Vishwakarma Institute of TechnologyDokument211 SeitenSyllabus - Vishwakarma Institute of TechnologyAditya PophaleNoch keine Bewertungen

- History of The Bernoulli Principle: June 2019Dokument19 SeitenHistory of The Bernoulli Principle: June 2019ADIN RAFAEL LYANONoch keine Bewertungen

- ScramjetDokument3 SeitenScramjetVenkatNoch keine Bewertungen

- Elevated Temperature Physical Properties of Stainless SteelsDokument4 SeitenElevated Temperature Physical Properties of Stainless SteelsJulio Frederico BaumgartenNoch keine Bewertungen

- Black Body RadiationDokument7 SeitenBlack Body Radiationatif irshadNoch keine Bewertungen

- Introduction To Actran For Acoustics Radiation Analysis: Chanhee JeongDokument20 SeitenIntroduction To Actran For Acoustics Radiation Analysis: Chanhee JeongJitendra ItankarNoch keine Bewertungen

- Panel MethodsDokument19 SeitenPanel Methodschandru_anniyanNoch keine Bewertungen

- Vehicle Cooling System Radiator Experiment: Prepared ForDokument12 SeitenVehicle Cooling System Radiator Experiment: Prepared ForcfellowNoch keine Bewertungen

- Calculating The System Head PDFDokument9 SeitenCalculating The System Head PDFIrfanshah2013Noch keine Bewertungen

- (Fast Download) Steam Tables by Rs Khurmi - PDF (Verified Download) STEAM TABLES BY RS KHURMI - ZIP (Direct Download) Steam Tables by Rs Khurmi - RarDokument3 Seiten(Fast Download) Steam Tables by Rs Khurmi - PDF (Verified Download) STEAM TABLES BY RS KHURMI - ZIP (Direct Download) Steam Tables by Rs Khurmi - RarHerat HirparaNoch keine Bewertungen

- Lecture - 1 - Thermal Equipment Design - IntroductionDokument14 SeitenLecture - 1 - Thermal Equipment Design - IntroductionAbed Baayoun100% (2)

- Rate Dependent Plasticity Theory ManualDokument69 SeitenRate Dependent Plasticity Theory ManualkbkshanakaNoch keine Bewertungen

- POLB WDC Ver 3 0Dokument92 SeitenPOLB WDC Ver 3 0Anonymous iM2totBr100% (1)

- Physics For Scientists and Engineers, With Modern Physics, 4 EditionDokument56 SeitenPhysics For Scientists and Engineers, With Modern Physics, 4 EditionNur SyahirahNoch keine Bewertungen

- 7 - CE 511 - Bolted Connection - EccentricDokument19 Seiten7 - CE 511 - Bolted Connection - EccentricJayson Ramos100% (1)

- Steel Fiber Reinforced ConcreteDokument24 SeitenSteel Fiber Reinforced ConcreteDivya JalligampalaNoch keine Bewertungen

- Hardy Cross TutorialDokument16 SeitenHardy Cross TutorialNurul Shaheera50% (2)

- Fluid Mechanics Fundamentals and Applications 4Th Edition Cengel Solutions Manual Full Chapter PDFDokument67 SeitenFluid Mechanics Fundamentals and Applications 4Th Edition Cengel Solutions Manual Full Chapter PDFfionaalexandrahukc100% (12)

- Ring Formation in Rotary KilnsDokument30 SeitenRing Formation in Rotary Kilnsmohamed ElsayedNoch keine Bewertungen

- Chapter 2, Lesson 1 Activity Sheet AnswersDokument2 SeitenChapter 2, Lesson 1 Activity Sheet Answersjustin pastidioNoch keine Bewertungen

- Column Design - As Per BS CodeDokument16 SeitenColumn Design - As Per BS CodefatinamilinNoch keine Bewertungen

- TUTORIAL 6 Heat ExchangerDokument4 SeitenTUTORIAL 6 Heat ExchangerFikri Rahim50% (2)

- Metering DeviceDokument11 SeitenMetering DeviceAshutosh PandeyNoch keine Bewertungen

- AS-T-T013 A15Air Conditioning System and Anti-TheftDokument56 SeitenAS-T-T013 A15Air Conditioning System and Anti-TheftMtto Proyecto FúqueneNoch keine Bewertungen

- Composite and Non-Composite Behaviors of Foam-Insulated Concrete Sandwich PanelsDokument9 SeitenComposite and Non-Composite Behaviors of Foam-Insulated Concrete Sandwich Panelstimtoihochoi1Noch keine Bewertungen

- Sonic Nozzle DesignDokument86 SeitenSonic Nozzle Designsb ali100% (1)

- Condenser Cycle TempoDokument15 SeitenCondenser Cycle TempoAgung SubangunNoch keine Bewertungen

- Tensile TestDokument12 SeitenTensile Testmeysam1215100% (3)

- Lecture 7Dokument4 SeitenLecture 7minoNoch keine Bewertungen

- Lift Shaft Working Platform (11052023)Dokument39 SeitenLift Shaft Working Platform (11052023)Kin Man YeungNoch keine Bewertungen

- To Engineer Is Human: The Role of Failure in Successful DesignVon EverandTo Engineer Is Human: The Role of Failure in Successful DesignBewertung: 4 von 5 Sternen4/5 (138)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureVon EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureBewertung: 4.5 von 5 Sternen4.5/5 (2)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindVon EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNoch keine Bewertungen

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresVon EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresBewertung: 1 von 5 Sternen1/5 (2)

- Advanced Modelling Techniques in Structural DesignVon EverandAdvanced Modelling Techniques in Structural DesignBewertung: 5 von 5 Sternen5/5 (3)

- Structural Cross Sections: Analysis and DesignVon EverandStructural Cross Sections: Analysis and DesignBewertung: 4.5 von 5 Sternen4.5/5 (19)

- Arduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Von EverandArduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Bewertung: 4 von 5 Sternen4/5 (3)

- Onshore Structural Design Calculations: Power Plant and Energy Processing FacilitiesVon EverandOnshore Structural Design Calculations: Power Plant and Energy Processing FacilitiesBewertung: 4.5 von 5 Sternen4.5/5 (13)

- Non-destructive Testing and Evaluation of Civil Engineering StructuresVon EverandNon-destructive Testing and Evaluation of Civil Engineering StructuresJean-Paul BalayssacNoch keine Bewertungen

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsVon EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsNoch keine Bewertungen

- SAM: One Robot, a Dozen Engineers, and the Race to Revolutionize the Way We BuildVon EverandSAM: One Robot, a Dozen Engineers, and the Race to Revolutionize the Way We BuildBewertung: 5 von 5 Sternen5/5 (5)

- Mechanics of Flow-Induced Sound and Vibration, Volume 2: Complex Flow-Structure InteractionsVon EverandMechanics of Flow-Induced Sound and Vibration, Volume 2: Complex Flow-Structure InteractionsNoch keine Bewertungen

- Piping Engineering Leadership for Process Plant ProjectsVon EverandPiping Engineering Leadership for Process Plant ProjectsBewertung: 5 von 5 Sternen5/5 (1)

- Digital Twin Development and Deployment on the Cloud: Developing Cloud-Friendly Dynamic Models Using Simulink®/SimscapeTM and Amazon AWSVon EverandDigital Twin Development and Deployment on the Cloud: Developing Cloud-Friendly Dynamic Models Using Simulink®/SimscapeTM and Amazon AWSNoch keine Bewertungen

- Artificial Intelligence: Learning about Chatbots, Robotics, and Other Business ApplicationsVon EverandArtificial Intelligence: Learning about Chatbots, Robotics, and Other Business ApplicationsBewertung: 5 von 5 Sternen5/5 (3)

- Bridge Engineering: Classifications, Design Loading, and Analysis MethodsVon EverandBridge Engineering: Classifications, Design Loading, and Analysis MethodsBewertung: 4 von 5 Sternen4/5 (16)

- A Welder’s Handbook to Robotic ProgrammingVon EverandA Welder’s Handbook to Robotic ProgrammingBewertung: 5 von 5 Sternen5/5 (3)

- The AI Generation: Shaping Our Global Future with Thinking MachinesVon EverandThe AI Generation: Shaping Our Global Future with Thinking MachinesBewertung: 4 von 5 Sternen4/5 (2)

- Artificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.Von EverandArtificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.Bewertung: 4 von 5 Sternen4/5 (5)