Beruflich Dokumente

Kultur Dokumente

Engleski Zadaca

Hochgeladen von

Dženana Delić - AgićOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Engleski Zadaca

Hochgeladen von

Dženana Delić - AgićCopyright:

Verfügbare Formate

Before a material can safely be used in the making of structural parts or members, a number of its properties must be known.

In the case of metals such as steel, cast iron, brozne, aluminum, and others which are widely used as structural members and machine parts, we must have reliable information concerning such properties as strenght, elasticty, stiffness, ductility, malleability, toughness, etc.

Strength is the ability of a material to resist stress without failure. Several materials, such as structural steel, wrought iron, aluminium, and copper, have approximately equal strength in tension and compression, while their strength in shear is about two-thirds of that in tension. The measure of the strength of a a material is its ultimate stress, or the greatest force per unit area it can withstand without rupture.

Elasticity is that property of a material whereby a body, when deformed, automatically recovers its original size and shape after removal of a deforming force. This property is imortant in all structures subjected to varying loads and is exceedingly important in precision tools and machines. Stiffness is the property by virtue of which a material can resist deformation. This property is desirable in materials used in beams, columns, machines, and machine tools. The measure of the stiffness of a material is its modlulus of elasticity, obtained by dividing the unit stress by the unit deformation caused by that stress. Ductility is a measure of the ability of a metal to plastically deform without fracturing. Ductility is generally associated with tensile properies or the ability to be cold drawn, as in wire drawing. Copper, aluminium, and wrought iron are among the ductile metals. Percent elongation and reduction of area in the tension test are the usual measure of ductility. Ductility is desirable in a member or part which max be subjected to sudden and severe loads, since evident excessive deformation would give a warning of impending failure.

Brittleness is the opposite of ductility. Brittle materials fail suddenly without warning when stressed beyond their strength. Malleability can be defined as the same as ductility, except that it is applied to compression. Thus, this property enables a material to undergo great change in shape without rupture under compressive stress, as for example, copper, aluminium, or wrought iron being hammered into various shapes or steel being rolled into structural shapes or sheets. Hardness is the ability of a material to resist indentation or abrasion. It is most commonly measured by the Brinell test, in which a hardened-steel ball 10 mm in diameter is forced into a flat surface of a test specimen by a force of 3000 kg. The force devised by the surface area of the spherical indentation is called the Brinell hardness number.

Das könnte Ihnen auch gefallen

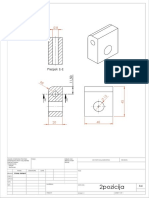

- 2 DrskaDokument1 Seite2 DrskaDženana Delić - AgićNoch keine Bewertungen

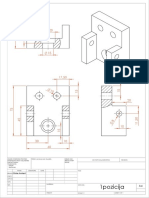

- 1 Postolje PDFDokument1 Seite1 Postolje PDFDženana Delić - AgićNoch keine Bewertungen

- The Roughing TabDokument11 SeitenThe Roughing TabDženana Delić - AgićNoch keine Bewertungen

- Area Roughing For ImpellersDokument3 SeitenArea Roughing For ImpellersDženana Delić - AgićNoch keine Bewertungen

- 1 Postolje PDFDokument1 Seite1 Postolje PDFDženana Delić - AgićNoch keine Bewertungen

- Mandatory Requirements For Wood Processing in The Fields of Certification, Labelling, Marking and StandardisationDokument4 SeitenMandatory Requirements For Wood Processing in The Fields of Certification, Labelling, Marking and StandardisationDženana Delić - AgićNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- ABLS Provider Manual 2018Dokument133 SeitenABLS Provider Manual 2018Anca RoxanaNoch keine Bewertungen

- 67 Pediatric Burn Injuries in The Developing World FINAL PDFDokument57 Seiten67 Pediatric Burn Injuries in The Developing World FINAL PDFBogdan UrsuNoch keine Bewertungen

- Return To Running Program Steve Cole WM MaryDokument6 SeitenReturn To Running Program Steve Cole WM Marygb tradeNoch keine Bewertungen

- DIY Armor ZineDokument8 SeitenDIY Armor Zinesnidely_whiplash0% (1)

- Complications of ExodontiaDokument41 SeitenComplications of ExodontiasamhitaNoch keine Bewertungen

- Risk Assessment Switchgear Testing CommissioningDokument7 SeitenRisk Assessment Switchgear Testing Commissioningaaktgt Mep100% (1)

- Operation & Maintenance Manual Model Aph Hydraulic ActuatorDokument69 SeitenOperation & Maintenance Manual Model Aph Hydraulic ActuatorSasan AbbasiNoch keine Bewertungen

- English Idioms in UseDokument50 SeitenEnglish Idioms in UseYohana RojasNoch keine Bewertungen

- Traumatic Brain Injuries: Pathophysiology and Potential Therapeutic TargetsDokument23 SeitenTraumatic Brain Injuries: Pathophysiology and Potential Therapeutic TargetsTrajceNoch keine Bewertungen

- Napfa Resource Book For Pe Teachers 20140506Dokument25 SeitenNapfa Resource Book For Pe Teachers 20140506api-259265137100% (1)

- N1J02 Week #2 Musculoskeletal Handout ROM For StudentsDokument4 SeitenN1J02 Week #2 Musculoskeletal Handout ROM For StudentsNatalie UrquhartNoch keine Bewertungen

- Manual PS-100 Limpiador UltrasonicoDokument6 SeitenManual PS-100 Limpiador UltrasonicoAlexis Barnabás CollinsNoch keine Bewertungen

- Legg Calve PerthesDokument7 SeitenLegg Calve PerthesAdrian Mallar100% (1)

- A Painful Big ToeDokument2 SeitenA Painful Big Toesantana2007Noch keine Bewertungen

- Lect 2 Descending Motor IMPROVED PathwaysDokument24 SeitenLect 2 Descending Motor IMPROVED PathwaysMudassar Roomi100% (1)

- PolytraumaDokument19 SeitenPolytraumaSri MahadhanaNoch keine Bewertungen

- Article 2183Dokument2 SeitenArticle 2183Aleli Joyce Bucu100% (5)

- Yile Xu - Torts Essay 1Dokument2 SeitenYile Xu - Torts Essay 1Yile XuNoch keine Bewertungen

- AH26 Is Root Canal Sealer Consist ofDokument4 SeitenAH26 Is Root Canal Sealer Consist ofHadil AltilbaniNoch keine Bewertungen

- Behavior of Materials at Cold Region TemperaturesDokument72 SeitenBehavior of Materials at Cold Region Temperaturesradou99Noch keine Bewertungen

- Basics in Laser Therapy and Laser Acupuncture: 32 International Congress On Veterinary AcupunctureDokument10 SeitenBasics in Laser Therapy and Laser Acupuncture: 32 International Congress On Veterinary Acupuncturebob marleyNoch keine Bewertungen

- John Carlton Power Words Special Report PDFDokument22 SeitenJohn Carlton Power Words Special Report PDFelena alinaNoch keine Bewertungen

- Material Handling JHA - Boom Truck, Crane Lifts & Forklift - SampleDokument4 SeitenMaterial Handling JHA - Boom Truck, Crane Lifts & Forklift - Sampleluis VelozNoch keine Bewertungen

- Government LiabilityDokument3 SeitenGovernment LiabilityKamarulAzimMuhaimiNoch keine Bewertungen

- HPWJ Medical Alert Card SampleDokument2 SeitenHPWJ Medical Alert Card SampleSameer Kumar JubailNoch keine Bewertungen

- Torsio Testis FDHDokument21 SeitenTorsio Testis FDHDwiyanti OktaviaNoch keine Bewertungen

- Netbook of TrapsDokument26 SeitenNetbook of Trapsgrb2000Noch keine Bewertungen

- Question Preparation Exam2023-1Dokument350 SeitenQuestion Preparation Exam2023-1alicNoch keine Bewertungen

- The Skeletal SystemDokument3 SeitenThe Skeletal SystemMiguel GumatayNoch keine Bewertungen

- Evaluate A Casualty PDFDokument2 SeitenEvaluate A Casualty PDFRobertNoch keine Bewertungen