Beruflich Dokumente

Kultur Dokumente

CD Mechanism Type CDM53F-K2BD38

Hochgeladen von

AlejandroVCMXOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

CD Mechanism Type CDM53F-K2BD38

Hochgeladen von

AlejandroVCMXCopyright:

Verfügbare Formate

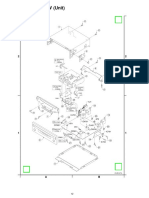

2-7.

CD MECHANISM DECK (CDM53F-K2BD38)

4 Four screws (BVTP 3 8) 5 Remove the CD mechanism deck section. 3 Chassis

2 Two screws (BVTP 3 8)

1 Three screws (BVTP 3 8)

2-8. TAPE MECHANISM DECK (TCM-230AWR12)

3 Remove the tape mechanism deck section.

1 Two screws (BVTP 3 8)

2 Two screws (BVTP 3 8)

11

2-9. CD BASE UNIT (BU-K2BD38)

5 CD base unit (BU-K2BD38)

4 Compression spring (black)

2 Compression spring (sliver)

3 Two screws (PTPWH M2.6)

1 Two screws (PTPWH M2.6)

2-10.

FITTING BASE (GUIDE) ASSY, BRACKET (CHASSIS) AND MAGNET ASSY

8 Four screws (BVTP M2.6) 6 Bracket (chassis)

2 Four screws (BVTP M2.6)

4 Screw (BVTP M2.6)

7 Connector (CN710)

9 Magnet assy 5 Screw (BVTP M2.6)

3 Fitting base (guide) assy 1 Two connectors (CN709, 715)

12

2-11.

TRAY (SUB)

1 Rotating the pulley (LD), shift the slider (selection) in the arrow A direction. 2 Rotating the pulley (mode) in the arrow direction, adjust the tray (sub) to be removed. 3 Rotating the pulley (LD), shift the slider (selection) in the arrow B direction. 4 Rotating the pulley (mode) in the arrow direction, remove the tray (sub) to be removed.

Slider (selection)

Pully (LD)

Stocker section

A B

Pully (mode)

Tray (sub)

2-12.

CHASSIS (MOLD B) SECTION, STOCKER SECTION AND SLIDER (SELECTION)

Note: In mounting the parts, refer to page 14 and 15.

6 Two screws (PTPWH M2.6) 5 Stocker section

7 Slider (selection) 8 Washer

Pully (LD)

9 Compression spring

1 Three screws (BVTP M2.6)

4 Two step screws

2 Chassis (mold B) section Note: Rotating the pully (LD), shift the slider (selection) to the left.

4 Two step screws

3 Gear (eject)

13

2-13.

GEARS INSTALLATION

3 Gear (gear B) Portion A

Adjust the gear (gear B) with the portion A as shown.

1 Slide the slider (u/d) fully in the arrow direction.

2 Gear (U/D slider)

4 Gear (gear A)

Slider (U/D) gear

Gear (gear B)

Linearly

Adjust the gear so that it meshes with the bottom tooth of slider (U/D) gear, as shown.

Adjust so as to be aligned with gear B linearly, as shown.

2-14.

SLIDER (SELECTION) INSTALLATION

6 Two screws (PTPWH M2.6) 2 Gear (chuking)

Rotary encoder

5 Washer 4 Compression spring 7 Insert the slider (selection) into the portion A.

Align with the slot of rotary encoder.

Portion A

3 Convex portion of slider (selection) Gear (chuking) 1 Rotary encoder

Insert a convex portion into a groove of gear (chuking). Align marking

14

2-15.

STOCKER SECTION INSTALLATION

2 Portion A of tray (sub) 1 Stocker section

Hook the portion A of tray (sub) to the slider (selection).

Portion A of tray (sub)

3 Two step screws

Sticking of slider (selection)

3 Two step screws

2-16.

CHASSIS (MOLD B) SECTION INSTALLATION

3 Three screws (BVTP M2.6)

2 Insert the gear (eject0 under the gear (LD deceleration).

Portion A

1 Insert the portion A of chassis (mold B) section into the portion B of slider (selection).

Gear (LD deceleration)

Portion B of slider (selection)

15

Das könnte Ihnen auch gefallen

- Rear Suspension System: Problem Symptoms TableDokument20 SeitenRear Suspension System: Problem Symptoms TableTung NguyenNoch keine Bewertungen

- Muncie PtoDokument12 SeitenMuncie Ptoneil superNoch keine Bewertungen

- Manual de Srvicio HCD-DX80 PDFDokument74 SeitenManual de Srvicio HCD-DX80 PDFGerardo ReyesNoch keine Bewertungen

- Denison Hydraulics M5B, M5BS, M5BF Vane-Type Motor / Flügelzellen - Motor Moteur À Palettes / Motore A Palette Motor de Paletas Service InformationDokument10 SeitenDenison Hydraulics M5B, M5BS, M5BF Vane-Type Motor / Flügelzellen - Motor Moteur À Palettes / Motore A Palette Motor de Paletas Service InformationBruno SamaeianNoch keine Bewertungen

- PC - Portable Parts ConveyorDokument8 SeitenPC - Portable Parts ConveyorLuis DemyanenkoNoch keine Bewertungen

- 06 639Dokument15 Seiten06 639Fernando Sabino100% (1)

- Manual AvensisDokument23 SeitenManual AvensisBogdan-Andrei Pînzaru100% (4)

- Hyundai Santa Fé 2.7L 2008 - Cabeçote - Remoção Recolocação PDFDokument31 SeitenHyundai Santa Fé 2.7L 2008 - Cabeçote - Remoção Recolocação PDFLeonardo Limberger0% (1)

- HCD GRX9000Dokument86 SeitenHCD GRX9000j arturoNoch keine Bewertungen

- Timing Belt DocumentDokument26 SeitenTiming Belt DocumentAnonymous H2ZgelNoch keine Bewertungen

- 721b TransmissionDokument36 Seiten721b TransmissionMohamed Mahgoub100% (1)

- 5R55S Exploded Diagram PDFDokument6 Seiten5R55S Exploded Diagram PDFMiguel Angel Saintjour Rudolph100% (4)

- Pages de Panasonic Cx-dv1071l VWDokument3 SeitenPages de Panasonic Cx-dv1071l VWarthur_1569Noch keine Bewertungen

- Bevel and Transfer Gears - AssembleDokument14 SeitenBevel and Transfer Gears - AssembleIginio Malaver VargasNoch keine Bewertungen

- Bensme-Ys/Yn Benrme-Ys/Yn: Parts ListDokument69 SeitenBensme-Ys/Yn Benrme-Ys/Yn: Parts ListJonathan Lara FandiñoNoch keine Bewertungen

- Guia de Remoción de Piston Motor CAT G3600Dokument9 SeitenGuia de Remoción de Piston Motor CAT G3600Kervin GarciaNoch keine Bewertungen

- Trasmisiond 5 HDokument41 SeitenTrasmisiond 5 HRonaldo GaleanoNoch keine Bewertungen

- Daihatsu Terios II J200, J210, J211 2006-2014 StartingDokument23 SeitenDaihatsu Terios II J200, J210, J211 2006-2014 Startingfauzi sulistiyonoNoch keine Bewertungen

- 09082612038372Dokument129 Seiten09082612038372jlsmelloNoch keine Bewertungen

- Can ShaftDokument4 SeitenCan ShaftVita AlexNoch keine Bewertungen

- Drive Shaft & Propeller ShaftDokument21 SeitenDrive Shaft & Propeller ShaftMusat Catalin-MarianNoch keine Bewertungen

- 1994-1997 Camaro/Firebird LT1 Engine RemovalDokument106 Seiten1994-1997 Camaro/Firebird LT1 Engine Removaldoww301100% (1)

- RA61 Manual TransaxleDokument77 SeitenRA61 Manual TransaxlelogammicNoch keine Bewertungen

- Transmission Planetary - Disassemble: Disassembly and AssemblyDokument23 SeitenTransmission Planetary - Disassemble: Disassembly and AssemblyMbahdiro KolenxNoch keine Bewertungen

- Instrument PanelDokument7 SeitenInstrument Panelindrajith.meNoch keine Bewertungen

- 307-01 Automatic Transmission 10 Speed - Description and Operation - DescriptionDokument12 Seiten307-01 Automatic Transmission 10 Speed - Description and Operation - DescriptionCARLOS LIMADANoch keine Bewertungen

- 722 3Dokument12 Seiten722 3Daniel AlvaradoNoch keine Bewertungen

- ARDFDF3060D578)Dokument25 SeitenARDFDF3060D578)asdrefNoch keine Bewertungen

- Bomba de PistonDokument22 SeitenBomba de PistonAlexSora100% (1)

- Casio CD-311s SMDokument52 SeitenCasio CD-311s SMClaudio Hector ArrosaNoch keine Bewertungen

- Sony cdx-600 cdx-606 cdx-626Dokument36 SeitenSony cdx-600 cdx-606 cdx-626u4rishi100% (1)

- Manual Da Furadeira MakitaDokument10 SeitenManual Da Furadeira Makitaani_matrixx4733Noch keine Bewertungen

- DF 2010Dokument24 SeitenDF 2010visual619Noch keine Bewertungen

- Transfer Clutch s5, O588: Automatic TransmissionDokument6 SeitenTransfer Clutch s5, O588: Automatic Transmissionorangewedge32Noch keine Bewertungen

- 42 - ClutchDokument24 Seiten42 - ClutchArif WidayuniNoch keine Bewertungen

- Armado de Direccion DiferencialDokument15 SeitenArmado de Direccion DiferencialDjPukNoch keine Bewertungen

- But 32 Boom KitsDokument5 SeitenBut 32 Boom KitstraukomanNoch keine Bewertungen

- ManualDokument4 SeitenManualMano Negra100% (1)

- 12M Montagem Freio de ServiçoDokument10 Seiten12M Montagem Freio de ServiçoPaulo_GleriaNoch keine Bewertungen

- Food Processor ©Dokument17 SeitenFood Processor ©pukymottoNoch keine Bewertungen

- MT PDFDokument66 SeitenMT PDFRolfs Almonte DiazNoch keine Bewertungen

- 336D Cat Mando Final EnsambleDokument16 Seiten336D Cat Mando Final EnsambleAlicia Serje100% (1)

- Engine Assembly PDFDokument35 SeitenEngine Assembly PDFSebastian Olmos71% (7)

- Air Handling Units 39 GDokument42 SeitenAir Handling Units 39 Gthanh_79Noch keine Bewertungen

- CDJ 2000 Nxs Assembly ManualDokument12 SeitenCDJ 2000 Nxs Assembly Manualalex20192100% (1)

- Bomba Vicker Triple 2520vqsv10s21a1155Dokument6 SeitenBomba Vicker Triple 2520vqsv10s21a1155Angel DlsgNoch keine Bewertungen

- 6 Speed PowerShift Transmission DPS6 ComponentDokument3 Seiten6 Speed PowerShift Transmission DPS6 ComponentCarlos SerapioNoch keine Bewertungen

- Pioneer Deh-3750mpDokument61 SeitenPioneer Deh-3750mpElena Palacios GalecioNoch keine Bewertungen

- Podizna Osovina SAFDokument9 SeitenPodizna Osovina SAFPavle StevanovicNoch keine Bewertungen

- Assembly ProcedureDokument115 SeitenAssembly ProcedureAlex Castillo100% (1)

- CD Changer Service ManualDokument72 SeitenCD Changer Service Manualsalloum3Noch keine Bewertungen

- 994F Wheel Loader 44200001-UP (MACHINE) POWERED by 3516 Engine (SEBP3851 - 50) - Systems & ComponentsDokument58 Seiten994F Wheel Loader 44200001-UP (MACHINE) POWERED by 3516 Engine (SEBP3851 - 50) - Systems & ComponentsEvan AT YoelNoch keine Bewertungen

- Design and Analysis of Centrifugal CompressorsVon EverandDesign and Analysis of Centrifugal CompressorsNoch keine Bewertungen

- Kinematic Differential Geometry and Saddle Synthesis of LinkagesVon EverandKinematic Differential Geometry and Saddle Synthesis of LinkagesNoch keine Bewertungen

- Atlas LCR45: Preliminary Product DataDokument2 SeitenAtlas LCR45: Preliminary Product DataAlejandroVCMXNoch keine Bewertungen

- AM4825PDokument5 SeitenAM4825PAlejandroVCMXNoch keine Bewertungen

- SPD39T 39B6X Service Manual-01-0226 PDFDokument63 SeitenSPD39T 39B6X Service Manual-01-0226 PDFAlejandroVCMXNoch keine Bewertungen

- WTMC WTXD BOSCH Siemens Gas and Electric DryerDokument76 SeitenWTMC WTXD BOSCH Siemens Gas and Electric DryerAlejandroVCMX100% (1)

- 31 9090 SXS Variable Speed CompDokument45 Seiten31 9090 SXS Variable Speed CompAlejandroVCMXNoch keine Bewertungen

- Valleylab Force EZ 8C高频电刀维修手册 (英文)Dokument208 SeitenValleylab Force EZ 8C高频电刀维修手册 (英文)AlejandroVCMXNoch keine Bewertungen

- Reliance Selection Guide - RSGBR00413Dokument2 SeitenReliance Selection Guide - RSGBR00413AlejandroVCMXNoch keine Bewertungen

- Sony HCD Gnx660Dokument87 SeitenSony HCD Gnx660AlejandroVCMXNoch keine Bewertungen

- Wiring Diagram: Power CordDokument2 SeitenWiring Diagram: Power CordAlejandroVCMXNoch keine Bewertungen

- Reliance Product Catalog 2012Dokument13 SeitenReliance Product Catalog 2012AlejandroVCMXNoch keine Bewertungen

- ClassDAmps ReviewBook LRDokument58 SeitenClassDAmps ReviewBook LRAlejandroVCMXNoch keine Bewertungen

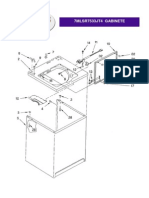

- Whirlpool - 7mlsr7533jt4Dokument16 SeitenWhirlpool - 7mlsr7533jt4AlejandroVCMXNoch keine Bewertungen

- Service Manual BA-4: Trinitron Color TVDokument74 SeitenService Manual BA-4: Trinitron Color TVAlejandroVCMXNoch keine Bewertungen

- Danby Dac5088m User ManualDokument12 SeitenDanby Dac5088m User ManualElla MariaNoch keine Bewertungen

- Astm E53 98Dokument1 SeiteAstm E53 98park991018Noch keine Bewertungen

- Ajp Project (1) MergedDokument22 SeitenAjp Project (1) MergedRohit GhoshtekarNoch keine Bewertungen

- What Is Retrofit in Solution Manager 7.2Dokument17 SeitenWhat Is Retrofit in Solution Manager 7.2PILLINAGARAJUNoch keine Bewertungen

- Urun Katalogu 4Dokument112 SeitenUrun Katalogu 4Jose Luis AcevedoNoch keine Bewertungen

- 4109 CPC For ExamDokument380 Seiten4109 CPC For ExamMMM-2012Noch keine Bewertungen

- What Caused The Slave Trade Ruth LingardDokument17 SeitenWhat Caused The Slave Trade Ruth LingardmahaNoch keine Bewertungen

- 1SXP210003C0201Dokument122 Seiten1SXP210003C0201Ferenc SzabóNoch keine Bewertungen

- Wendi C. Lassiter, Raleigh NC ResumeDokument2 SeitenWendi C. Lassiter, Raleigh NC ResumewendilassiterNoch keine Bewertungen

- Feasibility Study of Diethyl Sulfate ProductionDokument3 SeitenFeasibility Study of Diethyl Sulfate ProductionIntratec SolutionsNoch keine Bewertungen

- How To Control A DC Motor With An ArduinoDokument7 SeitenHow To Control A DC Motor With An Arduinothatchaphan norkhamNoch keine Bewertungen

- TAB Procedures From An Engineering FirmDokument18 SeitenTAB Procedures From An Engineering Firmtestuser180Noch keine Bewertungen

- SILABO 29-MT247-Sensors-and-Signal-ConditioningDokument2 SeitenSILABO 29-MT247-Sensors-and-Signal-ConditioningDiego CastilloNoch keine Bewertungen

- Doas - MotorcycleDokument2 SeitenDoas - MotorcycleNaojNoch keine Bewertungen

- Dry Canyon Artillery RangeDokument133 SeitenDry Canyon Artillery RangeCAP History LibraryNoch keine Bewertungen

- Marine Lifting and Lashing HandbookDokument96 SeitenMarine Lifting and Lashing HandbookAmrit Raja100% (1)

- Cic Tips Part 1&2Dokument27 SeitenCic Tips Part 1&2Yousef AlalawiNoch keine Bewertungen

- Lab 6 PicoblazeDokument6 SeitenLab 6 PicoblazeMadalin NeaguNoch keine Bewertungen

- General Diesel Engine Diagnostic Guide PDFDokument3 SeitenGeneral Diesel Engine Diagnostic Guide PDFan0th3r_0n3Noch keine Bewertungen

- The Electricity Act - 2003Dokument84 SeitenThe Electricity Act - 2003Anshul PandeyNoch keine Bewertungen

- Unit 2Dokument97 SeitenUnit 2MOHAN RuttalaNoch keine Bewertungen

- Vangood Quotation - Refrigerator Part - 2023.3.2Dokument5 SeitenVangood Quotation - Refrigerator Part - 2023.3.2Enmanuel Jossue Artigas VillaNoch keine Bewertungen

- TSB 120Dokument7 SeitenTSB 120patelpiyushbNoch keine Bewertungen

- Arduino Based Voice Controlled Robot: Aditya Chaudhry, Manas Batra, Prakhar Gupta, Sahil Lamba, Suyash GuptaDokument3 SeitenArduino Based Voice Controlled Robot: Aditya Chaudhry, Manas Batra, Prakhar Gupta, Sahil Lamba, Suyash Guptaabhishek kumarNoch keine Bewertungen

- BCG - Your Capabilities Need A Strategy - Mar 2019Dokument9 SeitenBCG - Your Capabilities Need A Strategy - Mar 2019Arthur CahuantziNoch keine Bewertungen

- Wiley Chapter 11 Depreciation Impairments and DepletionDokument43 SeitenWiley Chapter 11 Depreciation Impairments and Depletion靳雪娇Noch keine Bewertungen

- GL 186400 Case DigestDokument2 SeitenGL 186400 Case DigestRuss TuazonNoch keine Bewertungen

- Sweet Biscuits Snack Bars and Fruit Snacks in MexicoDokument17 SeitenSweet Biscuits Snack Bars and Fruit Snacks in MexicoSantiagoNoch keine Bewertungen

- BS 8541-1-2012Dokument70 SeitenBS 8541-1-2012Johnny MongesNoch keine Bewertungen

- A. The Machine's Final Recorded Value Was P1,558,000Dokument7 SeitenA. The Machine's Final Recorded Value Was P1,558,000Tawan VihokratanaNoch keine Bewertungen