Beruflich Dokumente

Kultur Dokumente

Use of Orthogonal Transformations in Data Classification-Reconciliation

Hochgeladen von

savanOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Use of Orthogonal Transformations in Data Classification-Reconciliation

Hochgeladen von

savanCopyright:

Verfügbare Formate

Computers chem. Engng Vol. 20, No. 5, pp.

483-493, 1996

Pergamon

0098-1354(95)00212-X

Copyright 1996 Elsevier Science Ltd Printed in Great Britain. All rights reserved 0098-1354196 $15.00 + 0.00

USE OF O R T H O G O N A L T R A N S F O R M A T I O N S IN D A T A CLASSIFICATION-RECONCILIATION

MABEL S.~NCHEZ I a n d J o s ~ ROMAGNOLI 2 t

IPlanta Piioto de Ingenieria Quimica, UNS-CONICET, 12 de Octubre 1842, (8000) Bahia Blanca, Argentina; 2ICI Laboratory of Process System Engineering, Department of Chemical Engineering, University of Sydney, Sydney, NSW 2006, Australia

(Received 4 April 1994;final revision received 18 May 1995)

Abstract--In this paper, the use of orthogonal factorizations, more precisely the Q-R decomposition, to analyze, decompose and solve the linear and bilinear data reconciliation problem is further investigated. It is shown that the decomposition provides additional insight in identifying structural singularities in the system topology, allowing the problem to decompose into lower dimension subproblems. Energy balances are explicitly considered. Two examples of application are presented.

1. INTRODUCTION

In the course of daily operation of a chemical plant, it is common practice to adjust the measurements taken from the process, so that random measurement errors can be compensated for. The application of these methods to large-scale complex chemical plants creates problems of very large dimensionality which are difficult to solve. This last feature motivated V~iclavek (1969) to attempt to reduce the size of the least-squares problem through an elegant classification of the measured and unmeasured process variables for linear systems. Such classification allowed the size reduction of the initial problem and its easier solution. In a later work V~clavek and Loucka (1976) covered also the case of bilinear balances. A similar approach was undertaken by Mah et al. (1976) in their attempt to organize the analysis of the process data and to systematize the estimation and measurement correction problem. A simple graph-theoretic procedure for single component flow networks was developed. They later extended the treatment, first to multicomponent flow networks (Kretsovalis and Mah, 1987) and then to the generalized process networks including energy balances and chemical reactions (Kretsovalis and Mah, 1988a, b). Romagnoli and Stephanopoulos (1980) proposed an equation oriented approach. Solvability of the nodal equations was examined and an output set assignment algorithm (Stadtherr et al., 1974) was employed to classify simultaneously measured and unmeasured variabes. t To whom all correspondence should be addressed.

More recently, a general treatment using projection matrices was proposed by Crowe et al. (1983) for linear systems and extended later (Crowe, 1986, 1989) for bilinear systems. Crowe suggested a useful method to decouple the measured variables from the constraint equations, using a projection matrix to eliminate the unmeasured process variables. Orthogonal factorization were first used by Swartz (1989) in the context of successive linearization techniques to eliminate the unmeasured variables from the constraint equations. In this paper, the use of orthogonal factorizations, more precisely the Q - R decomposition, to analyze, decompose and solve the linear and bilinear data reconciliation problem is further investigated. A sequence of simple expressions to be applied in instrumentation analysis and data reconciliation is outlined and they are obtained using sub-products of Q - R factorizations. Furthermore, the use of this method, when energy balances are included in the set of process constraints, is also discussed. Results of the application for linear and bilinear systems are provided in terms of two flowsheeting examples, one of them being an existing operating plant.

2. LINEAR CASE

2.1. Problem statement

In the absence of systematic errors, we consider the following measurement model ~=x+e (1)

where x is a (g x 1) vector of measured variables, is a (g 1) vector of measured values and e is a (g x 1) vector of random errors. The measurement 483

484

M. SANCHEZand J. ROMAGNOLI of matrix A2 is easily accomplished. From one code instruction, matrices Q., R. and the permutation matrix l'I. are obtained, such that:

errors are assumed to be normally distributed with zero mean and known variance-covariance matrix tttx. A set of m linear balance equations for a steady-state process can be written as: AIx+A2u=0 (2)

A21-I. = Q.R.

where Q. and R. can be divided into:

(7)

where u is a (n x 1) vector of unmeasured variables and Al(m g ) , A2(m u) are matrices of known constants. In the presence of measurement errors, the balance equations are not satisfied exactly. To compensate for random measurements errors, a general data reconciliation procedure must solve the following least-squares problem: min s.t. (x- i)rqJxl(X- i) A~x +A2u = 0. (3)

as is indicated in the Appendix, with ru = rank(A2) = rank(R.,). In the same way, the unmeasured process variables can be partitioned into two subsets:

[ "-I. LUn-r.J

with this notation, the balance equations (2) become:

2.2. Solution using Q - R factorizations

Several techniques were proposed to reduce the size of the reconciliation problem by eliminating unmeasured variables (V~iclavek, 1969; Mah et al., 1976; Romagnoli and Stephanopouios, 1980). An elegant and useful way of obtaining this decomposition was due to Crowe et al. (1983). The method was based on the use of a projection matrix P. It was defined such that pre-multiplying matrix A2 with P yields:

The Q,~ matrix is such that its rows span the null space of A~'. That is:

T Q.2A2-O

(11)

PA2 = 0

(4)

where the rows of P span the null space of A2 r, and thus the unmeasured variables are eliminated. The constrained least-squares problem for the overall plant (3) can be replaced now by the equivalent twoproblem formulation. (i) Least-squares estimation of x: min s.t. (x - ~)TqJx I(X -- ~) Gx=0.

(5)

so Q,~ works as the projection matrix P proposed by Crowe. It differs, however, from P in that the numerical values have no physical significance. Pre-multiplying the system of equations (2) by Q r the unmeasured variables are eliminated. Remark 1. In M A T L A B , the Q - R decomposition can be easily accomplished through one code instruction. Furthermore, Q.r2 is obtained as subproduct of Q-R(A2) without extra computing effort for the user. 2.2.2. Least-squares estimation of x. The following problem must be solved: min (x- i)r~xl(X- i) Gxx=0 (12)

The solution of this problem is given by:

~ = i - q J , Gr(GWxGr)-lGi

(6) where

s.t.

where G = P*AI. (ii) Estimation of u using ~ and the balance equa-

tions

Both the application of Crowe's matrix projection method and the solution of the reduced leastsquares problem can be simplified by using Q - R orthogonal transformations. A brief description of Q - R transformation is included in the Appendix. The application of Q - R factorizations to different stages of the data reconciliation problem (3) follows.

a x = Q,:A,. T

(13)

2.2.1. Elimination of unmeasured variables.

By applying software packages for matrix computation, such as M A T L A B , the Q - R decomposition

Zero columns of Gx correspond to non-redundant measurements; the others belong to redundant measurements as indicated by Crowe et al. (1983) and Crowe (1989). We can solve this constrained problem by the Lagrangian approach; however, using Q - R factorizations, it can be transformed into an unconstrained problem. The constraints equations may be used to solve, functionally, for as many variables as there are constraints. Then an unconstrained least-squares

Orthogonal transformations in data classification-reconciliation problem is solved to estimate the remaining variables. The procedure is as follows. (i) Computation of the general solution of the undetermined system (G,x = 0): A Q-R orthogonal factorization of G. gives Q~, R~, H~ and allows one to obtain Q~, Q w R~, R~:, x,~, Xg.... such that

485

(ii) if rank(Ru) = ru < n, then at least n - ru + 1 variables cannot be calculated from the available information. For case (ii), the estimability condition of unmeasured variables can be expressed in terms of Q-R decomposition results of A2 matrix. The permutation matrix FIn allows the division of the unmeasured process variables into subsets ur. and U.-ru. The subset u._r. corresponds to ( n - ru) indeterminable unmeasured process variables. Regarding the subset u~., some variables can be calculated using only the reconciled measurement values and some depend also on the assumption of the u._~u variables. This result is obtained by pre-multiplying the system equations (10) by Q r and reordering the first r. equations of system (21) as indicated below:

G.I-Ix=Q~R~ Q~=[Q~,Q~I]

(14) R = JR,,

R.~] (15)

(16)

1-ITx = [ xgX~rx]

with r~ = rank(R~l ) = rank(G 0. The general solution of this problem is: Xr, =

--

R~ lR~2x~_rx

(17)

where xg_~. is arbitrary. (ii) Formulation of the unconstrained problem: Using the previous results, the vector ( x - i ) from the objective function is modified, as equation (18) indicates: (x-i)=[I~, I~] xg , - - i

Qu,A~ Ru~ Q,2A1

-1

0

T -

lrxl

u~,

I u. . . . I

=0

(21)

u~ = - R u , QulAlx-R~XRu2u .... .

(22)

To classify variables in subset u~., it is necessary to look at the rows of the matrix:

Rw =

(18)

Rul I Ru 2

(23)

The following can be stated:

=(I.2-1~,R~'R~2)Xg_,-i

where ll-I~=[I., I,:]

I=I.~-I~R~,'R~ 2.

(19)

I is a (g x g) identity matrix and [ is a [g x (g - r0] matrix with independent columns. (iii) Estimation of x: The solution of the unconstrained problem is:

(i) A variable in subset ur. is said to be determinable if the corresponding row in the Rw matrix is zero. (ii) A variable in subset u~ is said indeterminable otherwise. Remark 3. The classification matrix analysis has been done by Crowe (1989) in terms of the projection matrix P. Here, similar results are obtained in a clearer way using Q-R factorization. In M A T L A B , inspection of matrix Rm can be easily accomplished in an automatic way.

3. N O N - L I N E A R

%_~ = ( F ~ ; ~ i ) - ~ F ~ ; ~i

(20)

with the value of ig_r,, one can solve for xr. using (17). Remark 2. The previous approach has two advantages: it avoids the direct use of the constraints into the least-squares estimation and reduces the number of variables to be simultaneously estimated. The process of eliminating part of the variable using the constriants is easily accomplished by means of Q-R factorizations.

CASE

3.1. Problem statement

Let us now consider a process containing K units denoted by k = 1 . . . . , K, and J oriented streams j=l,...J, with C components c = 1 , . . . C. Plant topology is represetned by the incidence matrix L, with rows corresponding to units and columns to streams. Then lkj= if stream j enters node k, lkj = - 1 if stream j leaves mode k, lkj= 0 otherwise. The general process constraints are as follows. Total molar balances:

2.2.3. Estimation

of

unmeasured

variables.

Matrix R. in the Q-R factorization of the Az matrix contains the topological information about the system in terms of the available measurements. (i) if rank(Ro)= r. = n, all unmeasured process variables are determinable from the available information.

El~+EESk,

j r c

rc~k,rc=O.

(24)

486 Component molar balances:

M.S.~NCHEZ and J. ROMAGNOLI Table 1. Categoriesof component and energyflowrates Category

F

M

U

m/ T

M

M

E l~jFjm/c+E Sk rc~k r = 0 '

' '

(25)

1

2

M/U

Energy balances:

E IkjFjhj+EHk'r+qk=O"

I r

(26)

Normalization equations: E ~rnjc - ~ = 0

c

(27)

in Table 1, where M and U indicate measured and unmeasured variables respectively. For energy balances, an expression of specific enthalpy as function of temperature (T) is obtained by using a thermodynamic package, for a stream with constant steady-state simulated values of pressure and composition. Table 1 also represents the categorization of energy flowrates when this approach is applied. Component/energy balances: B l f + B2 Vd + n3v = 0. Normalization equations: (29)

where ~ is the total molar flowrate of stream j, Sk, rc is the coefficient of the stoichiometric matrix (Crowe et al., 1983) of component c for reaction r in unit k, ~k, is the extent of reaction r in unit k, mj.c is the molar fraction of component c in stream j, hj represents the specific enthalpy of stream j, Hk.r is the total heat of reaction r in unit k and depends on Sg, r, and ~., qk is the vector of pure energy flows of unit k. To compensate for random measurements errors, the data reconciliation procedure must solve the following least-squares problem: min s.t. ( y - y ) r U j y ~ ( y - y) W(y, z) = 0 (28)

EIf+E2Vd+E3v+E4FM+EsFv=O

(30)

where W(y, y) represents a subset of balances and normalization equations; y and z are the vectors of measured and unmeasured variables for bilinear problems.

where f is the vector of component or enthalpy flowrates of Category 1; d is the vector of measured concentrations and calculated specific enthalpy for component or enthalpy flowrates of Category 2; v is the vector of component or enthalpy flowrates of Category 3, extent of reaction, unknown pure energy flows, etc; FM stands for measured total flowrates and Fv for the unmeasured ones; V represents the diagonal matrix of unmeasured total flow rates for component and enthalpy flowrates of Category 2. The number of entries for a stream in V is equal to the number of elements of d corresponding to this stream. The measured variable d is replaced by a consistent measured value plus the correction term 6d: d = 0] + 6d) and a new variable 0 is defined as: 0 = V6d. (32) (31)

3.2. Solution using Q - R factorizations

A scheme for the solution of the bilinear reconciliation problem is proposed by Crowe (1986). In this work, the application of Q - R factorizations within this scheme is analyzed. Furthermore, total flowrates are separately considered from component and enthalpy flowrates and energy balances are explicitly taken into account. Following Crowe's procedure, the solution to problem (28) can be accomplished in four steps. 3.2.1. Modification of bilinear constraints. The linear terms in W ( y , z ) = 0 remain unchanged. Bilienar terms are rewritten using the classification of component and enthalpy flowrates. Component flowrates are divided into three categories depending on the combination of total flow rates and concentration measurements in the stream as shown

The terms that contain variable d in equations (29) and (30) are replaced by:

BE Vd = BE0 + B2 Vd E2 Vd = E20 + E2 Vd.

(33)

In order to display unmeasured total flow rates for specific flowrates of Category 2 (Fuz) from equations (33), B4 and E6 matrices are defined as: B4(d)Fu2 = B2 Vd E6(d)Fu2 = E2 Vt]. (34)

Each column of B4 and E6 contains the sum of the columns of B2 and E2 for the stream multiplied by

Orthogonal transformations in data classification-reconciliation the corresponding consistent concentration or specific enthalpy. To group all unmeasured total flowrates, zero columns are added to B4 and F6 if it is necessary. New B5 and E7 are obtained such that:

487

(i) A Q-R decomposition of (rob nb) matrix B33 is accomplished, then: B33II, = [ QB ][ RB ]

Bs(d)Fu = B2V~I ET(d )Fu = E2Vd.

(35)

=[QB, QB2][ RB' 7 2]

(39)

Different linearly independent sets of process constraints can be formulated. One of them may include total mass balances, C - 1 component balances, energy balances and normalization equations. Another one may contain all component and energy balances and normalization equations. Using previous expressions, the last set can be written as:

where, r , = rank(RB1) and QB~ is such that its rows span the null space of B(3 so:

QB rB33 = 0.

(40)

(ii) Equation (37) is multiplied by QB~ so the unmeasured variables v are eliminated and the process constraints are defined as:

QB~Bnt+ QBrB22Fu= QBre.

(41)

(iii) A new (max ha) matrix D is defined and equation (41) is rewritten as: E4 EI E2 E8 E3

=0

(36)

QBrBnt+ DFu= QBre.

(42)

(iv) A Q-R orthogonal trnsformation is performed on matrix D: whereE8 = E7 + Es. If we consider the adjustments of total flow rates 8F and the component and enthalpy flows dr, the general reconciliation problem can be stated as: min ( 6 FM r UklFM -1 O F r M -{- (~T I~If l o T -~- o Tttl o I O )

D I-IF,= [QD ][RD ] =[QD1 QD2] 0

43,

s.t.

[Bn

B22 B33]

= _

O1 BI E4 El

where rf= rank(RDt) and QD r is such that its rows span the null space of D r, then the process constraints can be reduced to:

QD'~QB~Bllt= QD~QBre.

(44)

3.2.3. Estimation of measured variables and unmeasured total flow rates.

where After eliminating unmeasured variables, the reconciliation of measured variables and the estimation of unmeasured total flow rates are accomplished by an iterative procedure: SFM] "Ox B1 B2

Step 1:

Using an estimation of unmeasured total flow rates, tlJ0 is evaluated. The following linear reconciliation problem needs to be solved: min trgtlt Gtt=b (45)

g r u , gt, g 0 and g , are the variance-covariance matrices for FM, f, 0 and d. g 0 is defined as: g 0 = v g , V. (38) where

s.t.

Remark 4. By separating total flowrates from component and enthalpy flowrates, clearer expressions for instrumentation analysis and data reconciliation calculations may be obtained.

Gt= QDrQB~B,, b = QD ~QB re

with solution given by i = Wt Gtr(GtWt G t r )-~b. (47) (46)

3.2.2. Elimination of unmeasured variables.

These variables are eliminated from the modified constraints using Q - R orthogonal transformations as follows.

When the Q-R decomposition of Gt is applied to estimate [, the calculation has the same advantages as indicated for the Linear Case.

488

M. SANCHEZand J. ROMAGNOL!

Step 2:

The estimation of unmeasured total flow rates is done by using the Q-R orthogonal decomposition of matrix D. Equation (42) can be written as:

QBfBui+[QDI

X

QD2] 0 Fv,: q kFuu,~_.,tj

2.3.4. Estimation of vector v. In order to estimate the unmeasured variables contained in v, the matrix B22 is divided in two parts by column permutation. The first fe columns correspond to the determinable total flow rates and the (rid--re) remaining ones belong to indeterminable total flowrates.

B22= [B2d B2,]. (53)

B33 ,

where

Using the Q-R decomposition of matrix of constraints (37) is rewwritten as:

the set

[ Fv,,~ ,iJ

I =I-I~.Fo.

(49)

Bui + B2dFv,,+ B2iFu,+ [ QBl QB2]

X[ where 0

The subset Fv.d ,: corresponds to the indeterminable total flow rates. Regarding the subset Fv,: nothing can be said, since some of these variables can be calulated directly from the measurements and some depends on Fu,d_,. Further information to classify variables in subset F% can be obtained premultiplying equation (48) by QD r and writing the vector Fv,: in terms of the other variables:

RoB2 vn~,

:e

(54)

L Vnb-rv d

Vrv1

55,

Fv, = RDf lQD (QB~e- RDflQD (Q BfBu t

- RD{ IRD2 Fu~ ~f. (50) Notice that if the last term in the RHS of equation (50) is zero, all the Fu,: can be calculated from the available information. In order to classify the variables in Fv,: a matrix RIF is defined as:

The subset vn~ ,, corresponds to the indeterminable variables in v. For the classification of variables in subset v,,, additional information can be obtained by expressing % in terms of the other variables:

v,, = RBliQB~e - RBtlQBrBu i - RB?~QB~B2dFud - RB~ IQB(B2,Fu,- RB{tRB2v,,~_r. (56)

The first three terms of the previous equation are known, so if the last ones are zero, all the variables in % can be evaluated using the available information. In order to classify the variables in vr,, two new matrices are defined:

R~F= RD~IRD2

and the following can be stated:

(51)

(i) a variable in subset F% is determinable if the corresponding row in RF is zero; (ii) a variable in subset Fur: is indeterminable otherwise. At this point the vector Fv can be divided into: F u = L Fu, J where Fvd is the fe-dimensional vector of determinable total flowrates (fe<rf); Fu, is the (nd-fe)-dimensional vector of indeterminable total flowrates; Fve contains the f~ variables in subset Fv,: which satisfy condition (i) while F,, includes the variables in subset Fvr: which satisfy condition (ii) plus the variables in subset Fv,, ,:. After updating the value of determinable total folw rates, the procedure is re-initiated until convergence is achieved.

Rn, = RB? 1RB2 RIF,= RB; ~QBrlBzi

and the following can be stated:

(57) (58)

(i) a variable in subset v,, is determinable if the corresponding rows of Rtv and R m are zero; (ii) a variable in subset v,, is indeterminable otherwise. At this time, the vector v can be divided into: v=

(')

Vi

(59)

Remark 5. If total flowrates are separated from

component and energy flowrates, Crowe's specifications for the calculation of total flowrates corrections are not necessary.

where Vd is the re-dimensional vector of determinable variables in v (Ve~<r,); v~ is the (nb--V,)dimensional vector of indeterminable variables in v; vd contains the ve variables in subset Vr, which satisfy condition (i) while vi includes the variables in subset v,, which satisfy condition (ii) plus the variables in subset v,b_,v. After the calculation of the elements in Vd, unmeasured concentrations and temperatures which correspond to component and enthalpy flows in va

Orthogonal transformations in data classification-reconciliation are determinable if the total flowrate of the stream is measured or determinable. Otherwise, they are indeterminable. The inclusion of intensiive process constraints can change the classification but it is not on the scope of this paper.

489

energy balances are considered. Other equation oriented techniques, such as P L A D A T (S~nchez et al., 1992), can be used to tackle the general problem.

4. EXAMPLES

3.3. Further discussion on energy balances

Through the above discussion, simplified expressions of streamspecific enthapy as function of temperature are used. They have to be updated during process operation to consider changes in steadystate compositions. The application of a more precise expression for enthalpy, at least, as a function of temperature and composition requires a new categorization of enthalpy flowrates. They can be divided into three categories depending on the combination of total flowrates, composition and temperature measurements, as indicated in Table 2. The problem arises for the last measurement combination. It is due to the difficulty of adjusting temperatue measurement values for streams which compositions are unmeasured or partially measured. In this context, the temperature of a stream j may be adjusted only for the following conditions: - - all component molar fractions are unmeasured;

- - rule of mixing: hj =

4.1. Example I--Linear Case: application to a section of an ethylene plant

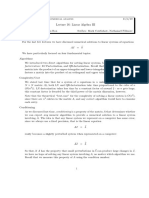

This sector of the Oiefin plant includes the ethylene refrigeration and compression to C2 splitter sections. A simplified node diagram of the process is given in Fig. 1. Cracked gases coming out from the gas compressor enter the pre-cooling and drying sections. The cooled, cracked streams enter the deethaniser colums (nodes 3 and 4) where C3 and higher hydrocarbons are separated as bottom product. The top product of unit 3, consisting of C2 and lower hydrocarbons (C2H6, C2H4, C2H2, CH4, H2, etc.) enters the acetylene hydrogenation reactor where acetylene is hydrogenated to ethylene. The hydrogenated gaseous stream enters the cold section, where it is passed through a number of heat exchangers and separators. A portion of liquid stream from unit 10 is used as the recycle stream. Hydrogen is separated as a gaseous stream in unit 12. The liquid streams from separators 7-11 enter the de-methaniser column (unit 13). The top product of this column is methane, which is sent to fuel gas stream via cold section and drying/pre-cooling section. The bottom product enters the Ca splitter column (unit 15) as a feed. The top product of this column is cooled and compressed and subsequently stored as ethylene product. The bottom product of the C2 splitter column is ethane, which is sent back to the cracking furnace as feed stock through the pre-cooling section. The Q - R factorization is applied to adjust measured flowrates of the whole sector, such that mass balances are satisfied. The section has 31 units and 63 process variables of which only 29 are measured. From the analysis arises that: (a) there are eight redundant equations containing all the 29 measured variables; (b) first the unmeasured flowrates can be divided into:

u , = [ 3 5 10 24 34 35 36 38 39 40 41

m~chjc;

- - h j c is approximated as a linear function of temperature for the steady-state operation range. The following solution scheme can be implemented: (i) estimation of unmeasured total flowrates and unmeasured species flowrates for streams with unmeasured temperatures; (ii) simultaneous elimination of unmeasured variables. A two-stage procedure of decomposition does not give advantages because measurements are involved in Category 3 flowrates; (iii) Least-squares adjustment of measurements; (iv) estimation of unmeasured variables; (v) iteration until convergence is achieved. Hence, factorization methods can be only applied to solve particluar cases of data reconciliation when

Table 2. Categories of enthalpy flowrates Category

1 2 3 3

42 44 45 48 49 50 51 54 55 56 59 61]

m

M M M U

F

M U M/U M/U

T

M M U M

un_,=[4 6 11 43 47 52 57 58 60 62 63]. Furthermore, from the inspection of the Rtu matrix, the flowrates of streams 24, 34-36 and 49 are determinable.

CACE 20:5-8

' l u e l d ~UyZlO u e j o u o g a 9 s e j o tuex~e!p ~ p o u p ~ g ! l d t u i s ' I "g!d

~9

6~

1;

_ _ C ~ '

0

Z

0 < 0

~~,

$~

6~

e. N u~ o Z ,<

~'~ L~

--(

LE l

/.

ut

Orthogonal transformations in data classification-reconciliation Table 3. Data and results for Example 1 Stream 1 2 7 8 9 12 13 14 15 16 17 18 19 20 21 22 23 25 26 27 28 29 30 31 32 33 37 46 53 Variances 10.87 0.2030 2.624 0.3970 5.76 0.922 0.608 5.76 0.23 1.44 0.7060 0.017 0.13 0.09 0.014 0.0002 0.018 0.09 0.014 0.36 0.563 0.023 1.103 0.008 0.397 0.152 0.09 0.13 1.232 Measured values 70.49 7.103 13.04 35.38 53.21 23.90 0.00 0.0765 54.59 12.78 23.42 0.2378 8.657 5.087 1.74 0.0255 3.113 5.407 2.898 11.83 8.197 1.364 20.94 1.051 12.58 4.999 5.73 4.25 16.34 Reconciled values 70.105 7.096 11.980 35.540 53.641 23.560 - 0.024 - 0.150 53.816 11.934 23.005 0.229 8.618 5.413 1.787 0.026 3.178 5.354 2.889 13.239 8.907 1.393 19.872 1.069 13.465 5.338 5.969 4.595 19.608

491

o b t a i n e d from S E P S I M M a n u a l ( A n d e r s e n et al., 1991). It is c o n s i d e r e d t h a t all c o m p o n e n t s (N2, HE, A r a n d NH3) are p r e s e n t in all s t r e a m s except the feed. T h e set of process constraints includes: c o m p o n e n t a n d energy balances a n d n o r m a l i z a t i o n equations. Equality of c o n c e n t r a t i o n s a n d t e m p e r a t u r e s of the splitter streams are not t a k e n into account in this particular example. Expressions of s t r e a m e n t h a l p y as function of t e m p e r a t u r e are o b t a i n e d using t h e r m o d y n a m i c packages for simulated values of presion a n d composition. T h e s e expressions have to b e u p d a t e d to consider changes in steady state. A f t e r modification of bilinear terms, vectors FM, f, Fv, 0 a n d v are:

r T=

IF 3 F5 F6]

F~r= [ e ,

F2F4FTF8F9F,o]... ,fh6fs, 4]

f r = If3, ,f3.4fh3fh5f6.

o T = [ 0 1 , 1 0 h l 02, 1 04,2 04,3 Oh4 07. 1 Oh7 08.1 08 Oh902,4 ]

~ ' = ['1"1,2 /21.3 I)2,21'2.3

vh2 v3.2113,3 V4, 1

1"4,4 116,2 116,3 ~'7,2 117,3 1/8,2 118,3 Vhlo

vhu

8 6

~vs,, v5, 2 vs, 3 116.4118,4 117,4 H,]

w h e r e f/,n a n d fhj are C a t e g o r y 1 c o m p o n e n t a n d e n t h a l p y flowrates, 0r. . a n d Ohj stand for adjustm e n t s of Category 2 c o m p o n e n t and e n t h a l p y flowrates, vj,, a n d vh are Category 3 c o m p o n e n t a n d e n t h a l p y flowrates. F o r variable classification and data reconciliation the following p r o c e d u r e is applied:

ill 9__~'~]

10 _,,.

Fig. 2. Simplified amonia plant. M e a s u r e m e n t values, variances a n d reconciled values for t h e m e a s u r e d flowrates are included in T a b l e 3.

4.2. Example 2--Nonlinear Case: a simplified ammonia plant

T h e process flowsheet is s h o w n in Fig. 2. M e a s u r e d variables for this process are p r e s e n t e d in T a b l e 4. Simulation values for process variables are Table 4. Measured variables for Example 2 Measurements Total flowrate Composition of N2 Composition of H2 Composition of Ar Composition of NH3 Temperature Stream numbers 356 1236 78 4 4 235 1345 6789

(a) Matrices QB~, QB2, RBh RB2, l-I, a n d vectors Vr, a n d V,b-r, are o b t a i n e d by the Q-R d e c o m p o s i t i o n of matrix B33. (b) A f t e r calculating matrix D , a Q-R o r t h o g o n a l d e c o m p o s i t i o n of D gives QD~, QD2, RD~, RD2, FId matrices a n d FUrd, FUnd-rd vectors. R~F inspection allows to classify u n m e a s u r e d total flowrates in: FTd= [F,

F2F, F7 Fs]

F~, = [F9 F,0].

(C)

Bzi, Rtv and RtF, are obtained. The inspection of the last two matrices is used to classify unmeasured variables in v:

Vd = [ ~112,3 V4, I V8,4 113,21)4,4 V3,3 qll 'lJ2, 2

115.1116,4 vh2 v7, 4 Hr] vi= [ ~.'6,2116,3118,2111,3117,3118.3115,211h10111.2].

(d) Matrix Gt is calculated a n d m e a s u r e m e n t classification is accomplished. N o n r e d u n d a n t

492

M. SANCHEa and J. ROMAGNOLI Table 5. Measured and reconciled values for Example 2 (F= [mol kg/h) - T= [K]) Variable F3 F5 F6 c(3, 1) c(3, 4) T3 T5 c(6, 1) T6 c(5, 4) c(l, 1) Mes. value 174.616 25.52 147.263 0.1880 0.2126 700.1 272.7 0.2299 267.1 0.9853 0.2504 Rec. value 172.720 25.1423 147.577 0.1957 0.2144 698.3 270.7 0.2305 266.6 0.9856 0.2504 Variable TI c (2,1) c(4, 2) c(4, 3) T4 c(7, 1) T7 c(8, 1) T8 T9 c(2, 4) Mes. value 701.4 0.2419 0.5821 0.0172 270.5 0.2308 267.1 0.2265 272.5 282.0 0.0359 Rec. value 701.4 0.2389 0.5726 0.01749 269.16 0.2306 266.7 0.2304 272.0 282.0 0.0368

Table 6. Estimated values of unmeasured determinable variables for Example 2 F= [mol kg/h]; o = [Mol kg/h]; ohj,q, Q = [MJ/h] Variable /'1 F2 F4 F7 Fg v (2, 3) Estimation 101.608 202.491 172.720 46.694 100.882 14.885 2.969 Variable v(4, 1) v (8, 4) v (3, 2) v (4, 4) v (3, 3) qll v (2, 2) Estimation 33.801 7.267 98.910 37.039 2.969 2989.72 143.566 Variable 0(5, 1) v (6, 4) Estimation 0.0002 12.2569 2853.141 4.989 915.220

vh2

v (7, 4)

Hr

m e a s u r e m e n t s a r e T3, c(5, 4), c ( 1 , 1), 7"1 a n d Tg. T h e r e m a i n i n g m e a s u r e m e n t s are r e d u n dant. (e) A n i t e r a t i v e p r o c e d u r e is p e r f o r m e d to a d j u s t m e a s u r e m e n t s a n d to e s t i m a t e u n m e a s u r e d determinable total flowrates. Measured and r e c o n c i l e d v a l u e s for this e x a m p l e a r e disp l a y e d in T a b l e 5. (f) T h e n t h e e s t i m a t i o n o f d e t e r m i n a b l e varia b l e s in v is d o n e . In T a b l e 6 t h e e s t i m a t e d values o f u n m e a s u r e d d e t e r m i n a b l e v a r i a b l e s are presented. 5. CONCLUSIONS In this w o r k , t h e a p p l i c a t i o n o f Q - R f a c t o r i z a t i o n to a n a l y z e , d e c o m p o s e a n d solve t h e linear a n d b i l i n e a r r e c o n c i l i a t i o n p r o b l e m is d i s c u s s e d in t h e context of Crowe's projection scheme. The proposed approach has several computational a d v a n t a g e s w h e n c o m p a r e d with r e s p e c t to t h e c o n v e n t i o n a l a p p r o a c h e s . F u r t h e r m o r e , it allows straightforward implementation within the MATLAB environment. T h e s e p a r a t i o n o f total f l o w r a t e s f r o m c o m p o n e n t a n d e n t h a l p y f l o w r a t e s has t w o i m p o r t a n t a d v a n tages: (a) T h e r e is a n o t a t i o n a l c o n v e n i e n c e . It allows to obtain more clear expressions for instrument a t i o n analysis a n d d a t a r e c o n c i l i a t i o n w h i c h a r e n o t explicitly i n c l u d e d in p r e v i o u s w o r k s . T h e e x p r e s s i o n s a r e w r i t t e n in t e r m s o f subproducts of Q - R factorizations.

(b) T h e use o f a s s u m p t i o n s f o r total f l o w r a t e a d j u s t m e n t is a v o i d e d . R e s u l t s o f t h e a p p l i c a t i o n for linear a n d b i l i n e a r s y s t e m s w e r e p r o v i d e d in t e r m s o f t w o f l o w s h e e t i n g e x a m p l e s , o n e o f t h e m b e i n g a n existing o p e r a t i n g plant. NOMENCLATURE

Linear Case

x = V e c t o r of measured variables (g 1) Al = Matrix for measured variables (m x g) P = Projection matrix Gx = Matrix equation (13) [(m - r.) x g] [Qu, Ru, l-I.] = QR(A2) r u= Rank (R.1) u,~, un_,. = Partitions of u lx~, Ix: = Partitions of I for x,x, xg_,. l = [Matrix equation (19) [g x ( g - r~)] u = Vector of unmeasured variables (n x 1) A2 = Matrix for unmeasured variables (m x n)

G= PA1

1 = Identity matrix [Q~, Rx,

nd= QR(Gx)

rx = Rank(R~) x,~, x g _ , = Partitions of x Rw = Matrix equation (23) [r, x (n - r,)]

Non-linear Case

K= k= J= ]= F= S= r= m= h= B, = f= Number of units Unit index Number of streams Stream index Molar total flowrate Stoichiometrix matrix Index of reaction Molar fractions Specific enthalpy Matrices for comp./enthapy balances Specific flowrates in Category 1

Orthogonal transformations in data classification-reconciliation d= v= V= Ei = Fvrf, Fu d = M molar fractions and sp. enthalpy Specific flowrates in Category 3 Diagonal matrix of Fv2 Matrices for normalization equations Partitions of Fu

493

" B = QB~Bzz

C = Number of components c = Comp. index L = Incidence matrix l = Incident matrix index H = Total heat of reaction q = Pure energy flow y = Measured variables z = Unmeasured variables T = Temperature t, w, e = Vectors equation (37) B. = Matrices equation (37) ii=1, 3 O = Zero matrix [QB, RB, Ho ] = O R (B33) [QD, RD, Hd] = O R (D) Gt, b = Equation (46) v,,, v,b ,, = Partitions of v RtF, R~v, R/Fi = Inspection matrices

Romagnoli J. and G. Stephanopoulos, On the rectification of measurement errors for complex chemical plants. Chem. Engng Sci. 35, 1067-1081 (1980). S,'lnchez M. A., A. Bandoni and J. Romagnoli, P L A D A T - - a package for process variable classification and plant data reconciliation. Computers chem. Engng 616 (Suppl.), $499-$506 (1992). Stadtherr M., W. Gifford and L. Scriven, Efficient solution of sparse sets of design equations. Chem. Engng Sci. 29, 1025-1034 (1974). Swartz C. L. E., Data reconciliation for generalized flowsheet applications. Nat. Meeting Am. Chem. Soc., Dallas, TX (1989). Vficlavek V., Studies on system engineeering III. Optimal choice of the balance measurements in complicated chemical engineering systems. Chem. Engng Sci. 24, 947-955 (1969). V~iclavek V. and M. Loucka, Selection of measurements necessary to achieve multicomponent mass balances in chemical plants. Chem. Engng Sci. 31, 1199-1205 (1976).

APPENDIX

Greek letters

e= Wi = = dii= 0= Vector of random errors Variance-covariance matrix of i Vector of extents of reaction Correction of i Vector equation (32)

Let A be a given mn matrix with m>~m and n linearly independent columns. Then there exists a m m unitary matrix Q and a m n matrix R, such that A = QR, where: R = [ R~ ] and R1 is an upper trianglular matrix. If A is rank-deficient, then at least one diagonal entry in Rm is zero. Let us examine why the Q-R factorization approach can fiai in the case when r a n t ( A ) = r < n . The mission of any orthogonalization method is to compute an orthonormal basis for the range of A, R(A). Indeed, if R(A)=R(Q1) where Ql=[ql . . . . . qr] has orthonormal columns then A = Q~N for some Ne3t "n. Unfortunately, if r<n, then the Q-R factorization does not necessarily produce an orthonomral basis for R(A). However, the Q-R decomposition can be modified in a simple way so as to produce an orthonormal basis for A's range. The modified algorithm computes the factorization:

Superscripts

= With measured values /~ = With reconciled values

Subscripts

M, U = Measured or unmeasured variable d, i = Determinable or indeterminable variable

REFERENCES

Andersen P., F. Genovese and J. Perregaard, Manual for Steady State Simulator SEPSIM. Institut for Kemiteknik, 82-104 (1991). Crowe C. M., Reconciliation of process flow rates by matrix projection Part II: Nonlinear Case. A. I. Ch.E. Jl 32, 616-623 (1986). Crowe C. M. Observability and redundancy of process data for steady state reconciliation. Chem. Engng Sci. 44, 2909-2917 (1989). Crowe C M., Y. A. Garcia Campos and A. Hrymak, Reconciliation of process flow rates by matrix projection Part I: Linear Case. A.I.Ch.E. Jl 29, 881-888 (1983). Kretsovalis A. and R. S. H. Mah, Observability and redundancy classification in multicomponent process networks. A.I.Ch.E. Jl 33, 70-82 (1987). Kretsovalis A. and R. S. H. Mah, Observabilty and redundancy classification in generalized process networks I: theorems. Computers chem. Engng 12,671-687 (1988a). Kretsovalis A. and R. S. H. Mah, Observabilty and redundancy classification in generalized process networks II: algorithms. Computers chem. Engng 12, 689-703 (1988b). Mah R. S. H., G. Stanley and D. Dowing, Reconciliation and rectification of process flow and inventory data. Ind. Engng Chem. Process Des. Dev. 15, 175-183 (1976).

AII=[Q~ Q2][R~

~2]

where Q1, Q2, gll and RIz are matrices of dimension (m r), [m (m - r)], (r r) and [r (n - r)] respectively, H is a permutation matrix and R~ is upper trinagular. If: AH=[aq ..... then for k = l , . . . ac] and

Q=[ql . . . . . qm]

, n we have:

min{r, k}

ack= Z

i= 1

rikqiEspan{q1 . . . . . q,}.

Also, it follows that for any vector satisfying Ax = b, then: Flrx=[:] and Q b-[d

T _ C

where y and e are r-dimensional vectors, z is an (n - r)-dimensional vector and d is an (m - r)-dimensional vector.

Das könnte Ihnen auch gefallen

- HHT Alpha MethodDokument22 SeitenHHT Alpha MethodSasi Sudhahar ChinnasamyNoch keine Bewertungen

- Efficient Parallel Non-Negative Least Squares On Multi-Core ArchitecturesDokument16 SeitenEfficient Parallel Non-Negative Least Squares On Multi-Core ArchitecturesJason StanleyNoch keine Bewertungen

- Solving LQR Problems for Rectangular Descriptor Systems Using Semidefinite ProgrammingDokument10 SeitenSolving LQR Problems for Rectangular Descriptor Systems Using Semidefinite ProgrammingDanielle GontijoNoch keine Bewertungen

- Symmetry: Modified Jacobi-Gradient Iterative Method For Generalized Sylvester Matrix EquationDokument15 SeitenSymmetry: Modified Jacobi-Gradient Iterative Method For Generalized Sylvester Matrix EquationEDU CIPANANoch keine Bewertungen

- 1982 - Algorithm 583 LSQR Sparse LinearDokument15 Seiten1982 - Algorithm 583 LSQR Sparse LinearluongxuandanNoch keine Bewertungen

- Loss and recapture of orthogonality in MGSDokument15 SeitenLoss and recapture of orthogonality in MGSS.Abinith NarayananNoch keine Bewertungen

- Linear-Quadratic Optimal Control With Integral Quadratic ConstraintsDokument14 SeitenLinear-Quadratic Optimal Control With Integral Quadratic ConstraintsbenlamNoch keine Bewertungen

- Some Modified Matrix Eigenvalue: E 2 (X), (A I) A (X) - (9) ) - A (A) O'i (A O'2 (A A, (A) 21 (A) 22 (A) 2, (A)Dokument17 SeitenSome Modified Matrix Eigenvalue: E 2 (X), (A I) A (X) - (9) ) - A (A) O'i (A O'2 (A A, (A) 21 (A) 22 (A) 2, (A)Satyavir YadavNoch keine Bewertungen

- Algorithms For Bound Constrained Quadratic Programming ProblemsDokument24 SeitenAlgorithms For Bound Constrained Quadratic Programming ProblemsasdfNoch keine Bewertungen

- Convergence of the generalized-α scheme for constrained mechanical systemsDokument18 SeitenConvergence of the generalized-α scheme for constrained mechanical systemsCesar HernandezNoch keine Bewertungen

- Time Harmonic Maxwell EqDokument16 SeitenTime Harmonic Maxwell Eqawais4125Noch keine Bewertungen

- An Insight Into Noise Covariance Estimation For Kalman Filter DesignDokument6 SeitenAn Insight Into Noise Covariance Estimation For Kalman Filter DesignAzhar IqbalNoch keine Bewertungen

- Interior-Point Methods in Model Predictive Control: Stephen WrightDokument30 SeitenInterior-Point Methods in Model Predictive Control: Stephen WrightIngole DeepakNoch keine Bewertungen

- S1/2 Regularization Methods and Fixed Point Algorithms for Affine Rank MinimizationDokument28 SeitenS1/2 Regularization Methods and Fixed Point Algorithms for Affine Rank MinimizationVanidevi ManiNoch keine Bewertungen

- Augmentad LagrangeDokument45 SeitenAugmentad LagrangeMANOEL BERNARDES DE JESUSNoch keine Bewertungen

- Algebraic Methods To Compute Mathieu Functions - FrenkelDokument11 SeitenAlgebraic Methods To Compute Mathieu Functions - FrenkelJ Jesús Villanueva GarcíaNoch keine Bewertungen

- Incomplete Oblique Projections Method For Solving Regularized Least-Squares Problems in Image ReconstructionDokument22 SeitenIncomplete Oblique Projections Method For Solving Regularized Least-Squares Problems in Image Reconstructionedu_eddyNoch keine Bewertungen

- 2 Denis Mosconi - RevisadoDokument8 Seiten2 Denis Mosconi - RevisadoDenis MosconiNoch keine Bewertungen

- Karimi 2011 ComputationalDokument6 SeitenKarimi 2011 ComputationaljalalhNoch keine Bewertungen

- Power System State Estimation Based On Nonlinear ProgrammingDokument6 SeitenPower System State Estimation Based On Nonlinear ProgrammingBrenda Naranjo MorenoNoch keine Bewertungen

- Higher Order Smoothing Schemes For Inhomogeneous Parabolic Problems With Applications To Nonsmooth Payoff in Option PricingDokument27 SeitenHigher Order Smoothing Schemes For Inhomogeneous Parabolic Problems With Applications To Nonsmooth Payoff in Option PricingRonaldNoch keine Bewertungen

- A Partial Derandomization of Phaselift Using Spherical DesignsDokument38 SeitenA Partial Derandomization of Phaselift Using Spherical DesignsJerimiahNoch keine Bewertungen

- A Scaled Gradient Projection Method For Constrained Image DeblurringDokument28 SeitenA Scaled Gradient Projection Method For Constrained Image DeblurringBogdan PopaNoch keine Bewertungen

- Numerical Integration Methods For Ballistic Rocket Trajectory Simulation ProgramsDokument38 SeitenNumerical Integration Methods For Ballistic Rocket Trajectory Simulation Programsgirithik14Noch keine Bewertungen

- High-Speed Compressible Flow Solutions by Combined Characteristic-Based Split Method and Adaptive Meshing TechniqueDokument6 SeitenHigh-Speed Compressible Flow Solutions by Combined Characteristic-Based Split Method and Adaptive Meshing TechniqueSergi C. CortadaNoch keine Bewertungen

- Gauss Elimination NotesDokument7 SeitenGauss Elimination Notesnavin shuklaNoch keine Bewertungen

- Ieee 1Dokument10 SeitenIeee 1Andrei SteleaNoch keine Bewertungen

- 12 - GanjiDokument10 Seiten12 - GanjiMaziar IraniNoch keine Bewertungen

- The Sample Average Approximation Method Applied To Stochastic Routing Problems A Computational StudyDokument45 SeitenThe Sample Average Approximation Method Applied To Stochastic Routing Problems A Computational StudyJianli ShiNoch keine Bewertungen

- Order Reduction For Large Scale Finite Element Models: A Systems PerspectiveDokument21 SeitenOrder Reduction For Large Scale Finite Element Models: A Systems PerspectiveAnonymous lEBdswQXmxNoch keine Bewertungen

- Learning Reduced-Order Models of Quadratic Dynamical Systems From Input-Output DataDokument6 SeitenLearning Reduced-Order Models of Quadratic Dynamical Systems From Input-Output Datasho bhaNoch keine Bewertungen

- Krylov methods reduce large FEM modelsDokument30 SeitenKrylov methods reduce large FEM modelsgorot1Noch keine Bewertungen

- Correspondence Analysis in RDokument13 SeitenCorrespondence Analysis in RMario ViverosNoch keine Bewertungen

- MPC Integral ActionDokument11 SeitenMPC Integral ActionLionelNoch keine Bewertungen

- Distance Regression by Gauss-Newton-type Methods and Iteratively Re-Weighted Least-SquaresDokument15 SeitenDistance Regression by Gauss-Newton-type Methods and Iteratively Re-Weighted Least-SquaresMárcioBarbozaNoch keine Bewertungen

- An Economical Method For Determining The Smallest Eigenvalues of Large Linear SystemsDokument9 SeitenAn Economical Method For Determining The Smallest Eigenvalues of Large Linear Systemsjuan carlos molano toroNoch keine Bewertungen

- Lecture 16: Linear Algebra III: cs412: Introduction To Numerical AnalysisDokument7 SeitenLecture 16: Linear Algebra III: cs412: Introduction To Numerical AnalysisZachary MarionNoch keine Bewertungen

- Numerical Methods for Nonlinear Dynamic SystemsDokument9 SeitenNumerical Methods for Nonlinear Dynamic SystemsC SzetoNoch keine Bewertungen

- AppendixDokument2 SeitenAppendixrico09001Noch keine Bewertungen

- Cascade Structural Model Approximation of Identified State Space ModelsDokument6 SeitenCascade Structural Model Approximation of Identified State Space ModelsAnonymous rTRz30fNoch keine Bewertungen

- Ad Pap 1Dokument6 SeitenAd Pap 1Riccardo MathisNoch keine Bewertungen

- A Spectral Approach To BandwidthDokument19 SeitenA Spectral Approach To Bandwidthforoud_makvandi1985Noch keine Bewertungen

- Iterative Solution of Algebraic Riccati Equations For Damped SystemsDokument5 SeitenIterative Solution of Algebraic Riccati Equations For Damped Systemsboffa126Noch keine Bewertungen

- Differential Quadrature MethodDokument13 SeitenDifferential Quadrature MethodShannon HarrisNoch keine Bewertungen

- Analysis of Continuous Systems Diffebential and Vabiational FobmulationsDokument18 SeitenAnalysis of Continuous Systems Diffebential and Vabiational FobmulationsDanielNoch keine Bewertungen

- Real Modes ExtractionDokument10 SeitenReal Modes ExtractionrenatobellarosaNoch keine Bewertungen

- Analytical Solutions To Two-Dimensional D@usion Type Problems in H-Regular GeometriesDokument14 SeitenAnalytical Solutions To Two-Dimensional D@usion Type Problems in H-Regular GeometriesflausenNoch keine Bewertungen

- Controllability analysis of exothermic reactorDokument91 SeitenControllability analysis of exothermic reactorCarmen de LeonNoch keine Bewertungen

- Checkerboard Instabilities in Topological Shape Optimization AlgorithmsDokument5 SeitenCheckerboard Instabilities in Topological Shape Optimization Algorithmsvishal kumar sinhaNoch keine Bewertungen

- Tools For Kalman Filter TunningDokument6 SeitenTools For Kalman Filter Tunningnadamau22633Noch keine Bewertungen

- On An Optimal Linear Control of A Chaotic Non-Ideal Duffing SystemDokument7 SeitenOn An Optimal Linear Control of A Chaotic Non-Ideal Duffing SystemJefferson MartinezNoch keine Bewertungen

- Second-Order Projection Scheme for k-epsilon Turbulence ModelDokument7 SeitenSecond-Order Projection Scheme for k-epsilon Turbulence ModelmecharashNoch keine Bewertungen

- Application of Tikhonov Regularization Technique To Investigation of The Electromagnetic Field Scattered by Inclusion in Multilayered MediaDokument3 SeitenApplication of Tikhonov Regularization Technique To Investigation of The Electromagnetic Field Scattered by Inclusion in Multilayered Mediamelike589Noch keine Bewertungen

- On The Existence of Stationary Optimal Policies For The Average Cost Control Problem of Linear Systems With Abstract State-FeedbackDokument6 SeitenOn The Existence of Stationary Optimal Policies For The Average Cost Control Problem of Linear Systems With Abstract State-Feedbackmjksh62Noch keine Bewertungen

- New Predictor-Corrector Method for Optimal Power FlowDokument5 SeitenNew Predictor-Corrector Method for Optimal Power FlowfpttmmNoch keine Bewertungen

- Bosco en El Articulo MatematicoDokument10 SeitenBosco en El Articulo MatematicoartovolastiNoch keine Bewertungen

- The General Least Squares Adjustment TechniqueDokument21 SeitenThe General Least Squares Adjustment Techniquesowmiyanarayanan_k_j88Noch keine Bewertungen

- An Alternative Method For Least-Square Fitting of Parametric Survival ModelsDokument8 SeitenAn Alternative Method For Least-Square Fitting of Parametric Survival ModelsSherlyLestariNoch keine Bewertungen

- Factorization of Boundary Value Problems Using the Invariant Embedding MethodVon EverandFactorization of Boundary Value Problems Using the Invariant Embedding MethodNoch keine Bewertungen

- 3 Kernel-Based Autoregressive Modelingwith A Pre-Image TechniqueDokument4 Seiten3 Kernel-Based Autoregressive Modelingwith A Pre-Image TechniquesavanNoch keine Bewertungen

- Lecture2 HandDokument12 SeitenLecture2 HandNicholas FosterNoch keine Bewertungen

- Least Squares Support Vector Machines: Johan SuykensDokument84 SeitenLeast Squares Support Vector Machines: Johan SuykenssavanNoch keine Bewertungen

- MATLAB ReconciliationDokument8 SeitenMATLAB ReconciliationsavanNoch keine Bewertungen

- Matrix DiffDokument5 SeitenMatrix DiffsavanNoch keine Bewertungen

- Lecture2 HandDokument12 SeitenLecture2 HandNicholas FosterNoch keine Bewertungen

- Matrix DiffDokument5 SeitenMatrix DiffsavanNoch keine Bewertungen

- Lecture2 HandDokument12 SeitenLecture2 HandNicholas FosterNoch keine Bewertungen

- Lecture2 HandDokument12 SeitenLecture2 HandNicholas FosterNoch keine Bewertungen

- Spreadsheet Optimization SolverDokument15 SeitenSpreadsheet Optimization Solvernag728Noch keine Bewertungen

- Recon Read MeDokument1 SeiteRecon Read MesavanNoch keine Bewertungen

- Effects of Biobased Plasticizer on PVC PropertiesDokument10 SeitenEffects of Biobased Plasticizer on PVC PropertiessavanNoch keine Bewertungen

- Higher Algebra - Hall & KnightDokument593 SeitenHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- Getting Done With OLGA InputDokument7 SeitenGetting Done With OLGA InputAkmal_FuadiNoch keine Bewertungen

- Getting StartedDokument17 SeitenGetting StartedexodiahNoch keine Bewertungen

- 8965Dokument8 Seiten8965savanNoch keine Bewertungen

- Alerting FAQ MFMonDokument18 SeitenAlerting FAQ MFMonIndramani M BaraiNoch keine Bewertungen

- Department of Education: Weekly Home Learning PlanDokument56 SeitenDepartment of Education: Weekly Home Learning PlanJaneth Miguel SatrainNoch keine Bewertungen

- Fraction As A Part of A WholeDokument4 SeitenFraction As A Part of A WholeWennyNoch keine Bewertungen

- Analyzing Java OutOfMemory Problems With IBM Heapdump FacilityDokument10 SeitenAnalyzing Java OutOfMemory Problems With IBM Heapdump FacilityNarendra ChoudaryNoch keine Bewertungen

- Software Engineering (210253)Dokument12 SeitenSoftware Engineering (210253)Prathamesh BhagatNoch keine Bewertungen

- Control-Valve Seat Leakage - Hydrocarbon Processing - August 2011 PDFDokument10 SeitenControl-Valve Seat Leakage - Hydrocarbon Processing - August 2011 PDFPiush KumarNoch keine Bewertungen

- Suffah AcademyDokument3 SeitenSuffah AcademyMian Haroon SahilNoch keine Bewertungen

- Assignment Atomic Structure JH Sir-2611Dokument30 SeitenAssignment Atomic Structure JH Sir-2611Shivam KumarNoch keine Bewertungen

- Fast Formula GuideDokument96 SeitenFast Formula GuideRinita BhattacharyaNoch keine Bewertungen

- CHEM 120 Term Test #1 SummaryDokument17 SeitenCHEM 120 Term Test #1 SummaryJames DeenNoch keine Bewertungen

- General Direction: Each Item Below Has Four Choices. Select The Best Answer and Write Only The Letter of YourDokument4 SeitenGeneral Direction: Each Item Below Has Four Choices. Select The Best Answer and Write Only The Letter of Yourmary grace fuegoNoch keine Bewertungen

- 6.1 HWDokument3 Seiten6.1 HWcocochannel2016Noch keine Bewertungen

- 320F Diagrama Hidraulico PDFDokument2 Seiten320F Diagrama Hidraulico PDFRICHARD100% (1)

- ABS RulesDokument172 SeitenABS RulesKrionikaNoch keine Bewertungen

- Operators Manuel International Cub Cadet 72, 104, 105, 124, ZND 125 TractorsDokument44 SeitenOperators Manuel International Cub Cadet 72, 104, 105, 124, ZND 125 Tractorsfundreamer1Noch keine Bewertungen

- Wellbore Flow PerformanceDokument7 SeitenWellbore Flow PerformanceAhmad KoharNoch keine Bewertungen

- Radsys Zond 12e Drone 500a Datasheet PDFDokument4 SeitenRadsys Zond 12e Drone 500a Datasheet PDFISRAEL ILANIENoch keine Bewertungen

- CURE Software PublishedDokument14 SeitenCURE Software PublishedMario GuedesNoch keine Bewertungen

- Bfia Sem 1 SyllabusDokument7 SeitenBfia Sem 1 SyllabusAmity-elearningNoch keine Bewertungen

- TLC 549Dokument19 SeitenTLC 549Farhana ImronNoch keine Bewertungen

- Application Report: Surface Characterization in Biomedical EngineeringDokument2 SeitenApplication Report: Surface Characterization in Biomedical EngineeringGeorge BadescuNoch keine Bewertungen

- Lab 4 Exercise: Data sources and calculated columnsDokument4 SeitenLab 4 Exercise: Data sources and calculated columnsSITI FATIMAH AMALINA ABDUL RAZAKNoch keine Bewertungen

- Internet Technologies (IT)Dokument167 SeitenInternet Technologies (IT)Pramod GedamNoch keine Bewertungen

- Data ArchivingDokument63 SeitenData ArchivingHot_sergio100% (1)

- C Programming LanguageDokument41 SeitenC Programming Languagekazi habibaNoch keine Bewertungen

- FMEA For Manufacturing and Assembly Process: VJTI, Mumbai Siemens LTD., MumbaiDokument9 SeitenFMEA For Manufacturing and Assembly Process: VJTI, Mumbai Siemens LTD., MumbaiKevin JordanNoch keine Bewertungen

- Photon Energy and WavelengthDokument20 SeitenPhoton Energy and WavelengthNeil Joseph LandinginNoch keine Bewertungen

- Save Data in Arabic in MySQL DatabaseDokument2 SeitenSave Data in Arabic in MySQL DatabaseyoussefeNoch keine Bewertungen

- Unit Operations Guide for Chemical Engineering SeparationsDokument38 SeitenUnit Operations Guide for Chemical Engineering SeparationsRenu SekaranNoch keine Bewertungen

- Capital Budgeting Techniques and NPV AnalysisDokument38 SeitenCapital Budgeting Techniques and NPV AnalysisKushNoch keine Bewertungen