Beruflich Dokumente

Kultur Dokumente

Procedure Qualification Records (PQR) : in Accordance With ASME SECTION IX For Power Pipping

Hochgeladen von

Novita Dwi IsnaeniOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Procedure Qualification Records (PQR) : in Accordance With ASME SECTION IX For Power Pipping

Hochgeladen von

Novita Dwi IsnaeniCopyright:

Verfügbare Formate

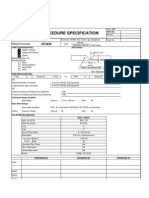

PROCEDURE QUALIFICATION RECORDS (PQR)

In Accordance with ASME SECTION IX for Power Pipping

Company Name WPS No Supporting PQR No.(s) Welding Process (es) : : : : Type(s) : By Date : :

JOINTS (QW-402)

Joint Design Backing (Yes) Backing (No) Backing Material (Type) : : : :

(Refer to both backing and retainers)

JOINT DETAILS

Metal Nonmetalic

P-No. :

Nonfusing Metal Other

Group No. : : : : : Groove Groove : : : Fillet Fillet : : To P-No : Group No. :

BASE METAL (QW-403)

OR Specification Type And Grade To Specification Type And Grade OR Chem. Analysis And Mech. Prop. To Chem. Analysis And Mech. Prop. Thickness Range Base Metal : Pipe Diameter : Other

FILLER METAL (QW-404) ROOT

Spec. No. (SFA) : AWS No. (Class) : A-No. F-No. Size Of Filler Metals: Weld Metal : Thickness Range Groove Fillet Electrode-Flux (Class) : Flux Trade Name : Consumable Insert : Other : : :

FILLER CAPING

POSITIONS (QW-405)

Positions Of Groove Welding Progression Uphill Positions Of Fillet : : : Downhill :

POSTWELD HEAT TREAT. (QW-407)

Time Range Temperature Range : :

PROCEDURE QUALIFICATION RECORDS (PQR)

In Accordance with ASME SECTION IX for Power Pipping

PREHEAT (QW-406)

Preheat Temp. Min. Interpass Temp. Max. Preheat Maintenance : : : C C C ` Shielding Trailing Backing

GAS (QW-408)

Percent Composition Gas Mixture Flow Rate

ELECTRICAL CHARACTERISTICS (QW-409)

Current AC Or DC Amps (Range) Tungsten Electode Size And Type Mode Of Metal Transfer For GMAW Electrode Wire feed Speed Range : : : : : Polarity Volts (Range) : :

TECHNIQUE (QW-410)

String Or Weave Bead Orifice Or Gas Cup Size Method Of Back Gouging Oscillation Contact Tube To Work Distance Multiple Or Single Pass (Perside) Multiple Or Single Electrodes Travel Speed (Range) Peening Others : : : : : : : : : : :

Initial And Interpass Cleaning (Brushing, Grinding, Etc.)

TENSILE TEST (QW - 150)

Specimen No. Width (mm) Thickness (mm) Area (mm) Ultimate Total Load (kgf) Ultimate Stress (Mpa) Type of Failure & Location

GUIDE BEND TEST (QW - 160)

Type and Figure No. Result

Welder's Name Test Conducted By,

: : Travel Speed (mm/min) Ampere (Amp)

Date,

: Stamp No. Voltage (V) :

Clock No. :

Layer Number

Process

Current

Polarity

Electrode AWS Spec AWS Class Dia (mm)

We, certify that the statement in this record are correct and the test welds were prepared, welded, and tested in accordance with the requirements of Section IX of the ASME Code.

Prepared By

Reviewed By

Approved By

Verified By

Dr. Ir. M. Yudi Masduky S., M.BA, M.Si

PROCEDURE QUALIFICATION RECORDS (PQR)

In Accordance with ASME SECTION IX for Power Pipping

Company Name WPS No Supporting PQR No.(s) Welding Process (es) : : : : Type(s) : By Date : :

JOINTS (QW-402) Joint Design Backing (Yes) Backing (No) Backing Material (Type)

JOINT DETAILS

: : : :

(Refer to both backing and retainers)

Metal Nonmeyalic

Nonfusing Metal Other

:

BASE METAL (QW-403) P-No. : Group No.

OR

To P-No.

: : : : :

Group No.

Specification Type And Grade To Specification Type And Grade

OR

Chem. Analysis And Mech. Prop. To Chem. Analysis And Mech. Prop. Thickness Range : Base Metal : Groove Other : FILLER METAL (QW-404)

Fillet

ROOT

FILLER CAPING

Spec. No. (SFA) : AWS No. (Class) : A-No. : F-No. : Size Of Filler Metals: Weld Metal : Thickness Range : Groove : Fillet : Electrode-Flux (Class) : Flux Trade Name : Consumable Insert : Other : POSITIONS (QW-405) Positions Of Groove Welding Progression Up : Positions Of Fillet : POSTWELD HEAT TREAT. (QW-407) Time Range : Temperature Range :

:

: :

Down

WELDING PROCEDURE SPECIFICATION (WPS)

ASME SECTION IX PREHEAT (QW-406) Preheat Temp. Min. Interpass Temp. Max. Preheat Maintenance GAS (QW-408)

: : : C C C

Gas Shielding Trailing Backing

Percent Composition Mixture Flow Rate

ELECTRICAL CHARACTERISTICS (QW-409) Current AC Or DC : Amps (Range) : Tungsten Electode Size And Type Mode Of Metal Transfer For GMAW Electrode Wire Feed Speed Range

: : :

Polarity Volts (Range)

: :

TECHNIQUE (QW-410) String Or Weave Bead : Orifice Or Gas Cup Size : Initial And Interpass Cleaning (Brushing, Grinding, Etc.) Method Of Back Gouging : Oscillation : Contact Tube To Work Diatance Multiple Or Single Pass (Perside) Multiple Or Single Electrodes Travel Speed (Range) : Peening : Others :

: : :

WELDING PARAMETERS Weld Process Layer (s) Filler Metal Class Dia. (mm) (mm) Current Type Amp. Polar. Range Volt Range Travel Speed Range

Others

Prepared By

Reviewed and Approved By

WELDING PROCEDURE SPECIFICATION (WPS)

In Accordance with ASME SECTION IX for Power Pipping

Company Name WPS No Supporting PQR No.(s) Welding Process (es) : : : : Type(s) : By Date : :

JOINTS (QW-402) Joint Design Backing (Yes) Backing (No) Backing Material (Type)

JOINT DETAILS

: : : :

(Refer to both backing and retainers)

Metal Nonmeyalic

Nonfusing Metal Other

:

BASE METAL (QW-403) P-No. : Group No.

OR

To P-No.

: : : : :

Group No.

Specification Type And Grade To Specification Type And Grade

OR

Chem. Analysis And Mech. Prop. To Chem. Analysis And Mech. Prop. Thickness Range : Base Metal : Groove Other : FILLER METAL (QW-404)

Fillet

ROOT

FILLER CAPING

Spec. No. (SFA) : AWS No. (Class) : A-No. : F-No. : Size Of Filler Metals: Weld Metal : Thickness Range : Groove : Fillet : Electrode-Flux (Class) : Flux Trade Name : Consumable Insert : Other : POSITIONS (QW-405) Positions Of Groove Welding Progression Up : Positions Of Fillet : POSTWELD HEAT TREAT. (QW-407) Time Range : Temperature Range :

:

: :

Down

WELDING PROCEDURE SPECIFICATION (WPS)

In Accordance with ASME SECTION IX for Power Pipping

PREHEAT (QW-406) Preheat Temp. Min. Interpass Temp. Max. Preheat Maintenance GAS (QW-408)

: : : C C C

Gas Shielding Trailing Backing

Percent Composition Mixture Flow Rate

ELECTRICAL CHARACTERISTICS (QW-409) Current AC Or DC : Amps (Range) : Tungsten Electode Size And Type Mode Of Metal Transfer For GMAW Electrode Wire Feed Speed Range

: : :

Polarity Volts (Range)

: :

TECHNIQUE (QW-410) String Or Weave Bead : Orifice Or Gas Cup Size : Initial And Interpass Cleaning (Brushing, Grinding, Etc.) Method Of Back Gouging : Oscillation : Contact Tube To Work Diatance Multiple Or Single Pass (Perside) Multiple Or Single Electrodes Travel Speed (Range) : Peening : Others :

: : :

WELDING PARAMETERS Weld Process Layer (s) Filler Metal Class Dia. (mm) (mm) Current Type Amp. Polar. Range Volt Range Travel Speed Range

Others

Prepared By

Revied By

Approved By

Verified By

Dr. Ir. M. Yudi Masduky S., M.BA, M.Si

Das könnte Ihnen auch gefallen

- PQR FormatDokument2 SeitenPQR Formatravi0009880% (5)

- QW-483 BlankDokument2 SeitenQW-483 BlankCraftyBob100% (1)

- P& E WPS Template Rev 00 - OfficialDokument3 SeitenP& E WPS Template Rev 00 - OfficialRiaan PretoriusNoch keine Bewertungen

- Suggested Wps Forms ASME - IX 2010Dokument5 SeitenSuggested Wps Forms ASME - IX 2010Ajay ChodankarNoch keine Bewertungen

- Wps Gtaw Monel b127 b164Dokument2 SeitenWps Gtaw Monel b127 b164Srinivasan Muruganantham67% (3)

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Dokument5 SeitenWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- WTCDokument57 SeitenWTCSarah FrazierNoch keine Bewertungen

- PQRDokument3 SeitenPQRnazirulhakimNoch keine Bewertungen

- WPS GTAW Stainless SteelDokument2 SeitenWPS GTAW Stainless SteelSrinivasan Muruganantham84% (31)

- PQR REV. 2010a Interactive FormDokument2 SeitenPQR REV. 2010a Interactive FormcosmicbunnyNoch keine Bewertungen

- Qw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)Dokument48 SeitenQw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)kamalakarsastry13530% (1)

- Wps - 09 Mt-Imecol Asme304 Gtaw Sheet-Tubesheet Rev 0Dokument5 SeitenWps - 09 Mt-Imecol Asme304 Gtaw Sheet-Tubesheet Rev 0Oscar Iván Duque DíazNoch keine Bewertungen

- 14033Dokument2 Seiten14033Priyanathan ThayalanNoch keine Bewertungen

- PQR FormatDokument2 SeitenPQR FormatBE GNoch keine Bewertungen

- Welding Procedure Specification: Technip KT India LimitedDokument5 SeitenWelding Procedure Specification: Technip KT India LimitedDeepak100% (1)

- PQR Wps WPQ FormatDokument12 SeitenPQR Wps WPQ FormatessnelsonNoch keine Bewertungen

- BPVC Ix QW-483Dokument2 SeitenBPVC Ix QW-483ganesh82Noch keine Bewertungen

- Interactive Form QW-485 PDFDokument1 SeiteInteractive Form QW-485 PDFRama Krishna Reddy DonthireddyNoch keine Bewertungen

- PQR Asme BlankDokument3 SeitenPQR Asme Blankamirul8686Noch keine Bewertungen

- Procedure Qualification Record (PQR)Dokument3 SeitenProcedure Qualification Record (PQR)Gopala krishnaNoch keine Bewertungen

- Welding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectDokument4 SeitenWelding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectwentropremNoch keine Bewertungen

- 1015 To Hastelloy VickoDokument14 Seiten1015 To Hastelloy Vickovgestantyo100% (1)

- Wps For SS 304Dokument3 SeitenWps For SS 304MuraliKrishna87% (23)

- WPS Resrvoire Sous Pression Smaw SawDokument6 SeitenWPS Resrvoire Sous Pression Smaw SawDanem HalasNoch keine Bewertungen

- PQRDokument2 SeitenPQRSreenivas Kamachi Chettiar100% (1)

- Wps A53 Gtaw R00Dokument2 SeitenWps A53 Gtaw R00Richard PeriyanayagamNoch keine Bewertungen

- Welding Procedure Specification Structural-3GDokument3 SeitenWelding Procedure Specification Structural-3Gdndudc78% (9)

- Wps 316L SMAW+GTAW R00Dokument2 SeitenWps 316L SMAW+GTAW R00Richard Periyanayagam86% (14)

- WPS FormatDokument3 SeitenWPS Formatvivek bhangaleNoch keine Bewertungen

- SS312 Type310Dokument4 SeitenSS312 Type310Vimin PrakashNoch keine Bewertungen

- Sample Wps-Carbon Steel GTAW+SMAWDokument2 SeitenSample Wps-Carbon Steel GTAW+SMAWchetan85100% (7)

- PQR Form (Welding)Dokument2 SeitenPQR Form (Welding)jasmineammaNoch keine Bewertungen

- WPS Dissimilar UpdatedDokument3 SeitenWPS Dissimilar UpdatedVimin Prakash100% (1)

- Welding ProceduresDokument29 SeitenWelding ProceduresLaith Salman100% (1)

- PQR TipsDokument4 SeitenPQR TipsWaqas WaqasNoch keine Bewertungen

- WPQRDokument1 SeiteWPQRShani MalikNoch keine Bewertungen

- 653 WPS-PQR PDFDokument4 Seiten653 WPS-PQR PDFETSNoch keine Bewertungen

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Dokument1 SeiteQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNoch keine Bewertungen

- Qw-482 Welding Procedure Specification (WPS)Dokument4 SeitenQw-482 Welding Procedure Specification (WPS)Aldeline Sungahid100% (2)

- Asme PQR DemoDokument3 SeitenAsme PQR DemoMuthusamy AyyanapillaiNoch keine Bewertungen

- Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Co D E)Dokument2 SeitenQw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Co D E)Vaibhav GuptaNoch keine Bewertungen

- Mailam India Limited Qw-482: Welding Procedure Specification (WPS)Dokument2 SeitenMailam India Limited Qw-482: Welding Procedure Specification (WPS)Asad Bin Ala QatariNoch keine Bewertungen

- WPQ 282Dokument1 SeiteWPQ 282proxywarNoch keine Bewertungen

- Essar Constructions Ltd. Hazira.: List of FormatsDokument68 SeitenEssar Constructions Ltd. Hazira.: List of Formatsravi00098Noch keine Bewertungen

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Dokument1 SeiteQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345Noch keine Bewertungen

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsVon EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsBewertung: 4.5 von 5 Sternen4.5/5 (10)

- All-in-One Manual of Industrial Piping Practice and MaintenanceVon EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceBewertung: 5 von 5 Sternen5/5 (1)

- How to prepare Welding Procedures for Oil & Gas PipelinesVon EverandHow to prepare Welding Procedures for Oil & Gas PipelinesBewertung: 5 von 5 Sternen5/5 (1)

- Pipeline and Energy Plant Piping: Design and TechnologyVon EverandPipeline and Energy Plant Piping: Design and TechnologyBewertung: 5 von 5 Sternen5/5 (2)

- Welding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985Von EverandWelding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985Noch keine Bewertungen

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1Von EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Bewertung: 3.5 von 5 Sternen3.5/5 (3)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsVon EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNoch keine Bewertungen

- Fundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationVon EverandFundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationNoch keine Bewertungen

- Applied Welding Engineering: Processes, Codes, and StandardsVon EverandApplied Welding Engineering: Processes, Codes, and StandardsNoch keine Bewertungen

- Chapter 8: Screws, Fasteners and The Design of Nonpermanent JointsDokument31 SeitenChapter 8: Screws, Fasteners and The Design of Nonpermanent JointsHernâniCruzNoch keine Bewertungen

- BrocoDokument14 SeitenBrocoKiyahNoch keine Bewertungen

- WPS - 021Dokument13 SeitenWPS - 021MAT-LIONNoch keine Bewertungen

- 310-19 Fluxometro HelvexDokument2 Seiten310-19 Fluxometro Helvexsamaelkelebra67% (3)

- Text Elsen Cement Finalrevision 17 08Dokument36 SeitenText Elsen Cement Finalrevision 17 08Cynthia EspinosaNoch keine Bewertungen

- Introduction To Arc WeldingDokument36 SeitenIntroduction To Arc WeldingKetan VaghosiNoch keine Bewertungen

- Welding Journal PDFDokument7 SeitenWelding Journal PDFraisalfiansyahNoch keine Bewertungen

- Technical Data Sheet: Utkarsh India LimitedDokument1 SeiteTechnical Data Sheet: Utkarsh India LimitedRAVINDRA DESHMUKHNoch keine Bewertungen

- D10 11M-D10 11-2007PVDokument6 SeitenD10 11M-D10 11-2007PVFiroj KhanNoch keine Bewertungen

- Weller Ungar Parts CatalogDokument108 SeitenWeller Ungar Parts Catalogelfrich60% (5)

- Wi sb4 16Dokument2 SeitenWi sb4 16Ramdan Pramedis SetyaNoch keine Bewertungen

- Tech Data 835Dokument1 SeiteTech Data 835Tibor KeményNoch keine Bewertungen

- Lesker FeedthroughsDokument39 SeitenLesker FeedthroughspericoNoch keine Bewertungen

- Aeroquip How To Identify Ports and ConnectorsDokument48 SeitenAeroquip How To Identify Ports and Connectorsphankhoa83Noch keine Bewertungen

- Ownlight: RD 175 & 225 RN HorizontalDokument27 SeitenOwnlight: RD 175 & 225 RN HorizontalOo HaryatkoNoch keine Bewertungen

- Asignar Ubicacion - 6Dokument53 SeitenAsignar Ubicacion - 6Recepción Pesquera diamanteNoch keine Bewertungen

- 10186590Dokument74 Seiten10186590qualidadesiderNoch keine Bewertungen

- Terminal KasugaDokument16 SeitenTerminal Kasugameida suryani100% (1)

- Component Parts List: DRS 125 Wheel BlockDokument16 SeitenComponent Parts List: DRS 125 Wheel BlockAmazonas ManutençãoNoch keine Bewertungen

- UNC, UNF, & UNEF Thread ANSI B1,1 PDFDokument4 SeitenUNC, UNF, & UNEF Thread ANSI B1,1 PDFGILBERTO YOSHIDA100% (1)

- OpenROV Bill of Materials - Single QuantityDokument13 SeitenOpenROV Bill of Materials - Single QuantityalliejaNoch keine Bewertungen

- Calamba Manpower Development Center Training Plan: Shielded Metal Arc Welding NC IiDokument2 SeitenCalamba Manpower Development Center Training Plan: Shielded Metal Arc Welding NC IiFrinces Marvida0% (1)

- Catalogues .EBERSPÄCHERDokument19 SeitenCatalogues .EBERSPÄCHERyenNoch keine Bewertungen

- "Reliance Industries, Jamnagar": "Refinary Construction Project J3"Dokument4 Seiten"Reliance Industries, Jamnagar": "Refinary Construction Project J3"digvijay singhNoch keine Bewertungen

- Electrolux Girbau h2130Dokument61 SeitenElectrolux Girbau h2130Saúl SolisNoch keine Bewertungen

- Aramco-RTFI Presentation 10-1-21Dokument193 SeitenAramco-RTFI Presentation 10-1-21Mohammad Sazid Alam100% (21)

- Aircraft WeldingDokument3 SeitenAircraft Weldingajrio1785Noch keine Bewertungen

- Metric Fine ThreadDokument3 SeitenMetric Fine ThreadBrendan CreanerNoch keine Bewertungen

- Data Sheet Classic k22 enDokument1 SeiteData Sheet Classic k22 enakshay tapkirNoch keine Bewertungen

- Materials-Lateral Expansion-At Cryogenic TemperatureDokument2 SeitenMaterials-Lateral Expansion-At Cryogenic TemperatureManivannanMudhaliarNoch keine Bewertungen