Beruflich Dokumente

Kultur Dokumente

Gasglass1002 NS How Does It Work

Hochgeladen von

Cristian SabauOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Gasglass1002 NS How Does It Work

Hochgeladen von

Cristian SabauCopyright:

Verfügbare Formate

1

How does it work?

A high voltage spark is ignited inside the IG unit (A). This high voltage spark causes the argon atom to emit light to a spectrometer (2), which measures the light. A microprocessor (3) interprets the information of the spectrometer and calculates an argon percent, which it outputs to a display (4). The result may also be viewed directly on a PC or on a Compaq iPaq. 2 Factors when measuring

To be able to use the instrument in the best way there are some factors influencing the measurement that should be considered. The Gasglass-1001 requires two main things; LIGHT (Optics) and HIGH VOLTAGE (Electricity). If either or both of these factors are disturbed, the measurement might be affected.

2.1

High voltage

The measurement is made using a high voltage spark. The voltage is approx. 50 000 V but the current is very small. Coming into contact with the spark will sting a little but not harm a normal healthy person even though the instrument MAY NOT to be used by a person with a pacemaker or who is in poor physical health. When measuring, the hand unit will create a spark that passes trough Glass 1 and ignites inside the air space. Glass is an electrically insulating material, as is air. This means that the spark needs to be strong enough to jump the air gap. In addition to the other electrically insulated materials, such as laminated glass, plastic films, etc. on either side of Glass 1, this makes it even harder to ignite inside the IG. If there is a metallic coating on Glass 1, it will be impossible for the spark to get trough as the metallic film will cause the spark to stay on the surface. Argon gas is a better conductor for the spark than air. This means that the spark actually ignites easier when the fill level is higher. The other thing that helps the spark "jump" is a Low-E coating on Glass2, which grounds the spark.

2.2

Light

The measurement is dependent on a stable light signal. The light can not be measured if the total light level is too weak or too strong. The total light intensity increases with the background light level as well as with increasing argon percent when measured. If the background light is too strong, e.g. measuring against the sun or a bright lamp, the argon light will drown in the sunlight. If the argon concentration is very low, the signal light is very low causing the spectrometer not to see the light. 2.3 In brief - Factors to consider when measuring

Factors affecting the optics: Coloured glass Tinted glass (minimal effect) Strong background light (Against the sun or other source) Dirt on glass (minimal effect)

Correct conditions: - Stable dark background light - Hand unit NOT moved during measurement

Factors affecting the spark: Thick glass (over 6 mm) Plastic films on Glass 1 (Laminated glass, coatings, etc.) Metallic films on Glass 1 Metallic components in Glass 1 Low Argon fill Wide spacer (over 20mm)

Factors making it easier for the spark to jump - High argon fills - Metallic coating on Surface 3 - Thin glass (6mm or less) - Thin air space (20mm or less)

Measuring

As described above there are different factors that may affect the measurement result. Sparklike has done extensive research on how to obtain the best possible results when measuring with the Gasglass. The following procedures are recommended when measuring with the Gasglass. 3.1 Measure close to the spacer

As the spacer bar of an IG unit is often metallic or contains metal, the spacer bar will help the spark to ignite. It is therefore suggested that the measurement is made close to the spacer. The centre of the hand unit should be approx. 5cm (2) from the inner side of the spacer (Approx. 10mm from the side of the hand unit). There is no difference at which height of the IG it is measured.

3.2

Measure several times: Because you can

When measuring the spark will ignite inside the air space ionizing the gases, leaving the gases ionized for a small period of time. This means that the second measurement will ignite easier and producing a better result. The Gasglass can also be set to average measurements internally. Measuring more than three times on one place may cause the Low-E coating to burn changing the readout of the Gasglass. For repetitive measurements, move the hand unit slightly after two or three measurements.

3.3

Keep the IG upright

Due to the earths magnetic field and the ionization of the gasses, the spark will try to travel up during the measurement. This causes the spark to act more erratically than if the IG would be laying flat down. In this way, however the Low-E is protected better from burning so it is suggested to measure the IG standing up. 3.4 Do not move the hand unit during ONE single measurement During one measurement cycle two individual measurements are being made; one background measurement and one with the spark on. If the hand unit is being moved during the measurement cycle, the background is altered and the results may not be accurate.

3.5

Keep the hand unit flush to the IG unit

If there is space between the spark electrode and the surface of the glass, a big part of the spark burst will occur outside of the IG unit. This means that the instrument is not measuring the spark inside the window but a mix of the inside gas and normal air causing the readings to be too low. The user can easily hear when the hand unit is flush to the IG. 3.6 Non Low-E IG units As the LoW-E coating is metallic, this will act as a ground for the spark. This grounding is being used when the instrument is calibrated. If the window has no Low-E coating, there is no ground to where the spark will ignite producing more erratic readings. These windows should be measured with either a finger on the back of the IG or some other metallic ground for the spark.

3.7

Restrictions

Following is a list of different IG types that can be measured and types that can not or are difficult to measure. Consult your local distributor or Sparklike for any special types.

Most of the restrictions are caused by the Glass 1.

A. IG with Glass 1 = Clear glass and Low E on surface 3

Surface 1

none

Glass 1

Clear max. 6mm

Surface 2

none

Spacer

max. 24mm

Surface 3

Low E

Glass 2

float

Surface 4

none

B. IG with Glass 1 = Clear glass and NO Low E

Surface 1

none

Glass 1

Clear max. 6mm

Surface 2

none

Spacer

max. 24mm

Surface 3

none

Glass 2

max. 6mm

Surface 4

none

C. IG with Glass 1 = Toughened and Low E on surface 3

Surface 1

none

Glass 1

Tgh. max. 6mm

Surface 2

none

Spacer

max. 24mm

Surface 3

Low E

Glass 2

float

Surface 4

none

D. IG with Glass 1 = Toughened glass and NO Low E

Surface 1

none

Glass 1

Tgh. max. 6mm

Surface 2

none

Spacer

max. 24mm

Surface 3

none

Glass 2

max. 6mm

Surface 4

none

E. IG with Glass 1 = Tinted

Same restrictions as for A. and B. but might need separate calibration

F. IG with Glass 1 = Laminated

Laminated windows themselves have more limiting factors such as film thickness, overall Glass 1 thickness etc. It is not suggested to measure laminated IG:s.

G. IG with Glass 1 = Frosted

Same restrictions as for A. and B. but might need separate calibration

H. Triple glazing

Due to different layouts of a triple glazing IG, there are several layouts that are impossible to measure. Consult your distributor or Sparklike for detailed information. If Glass 1 and Glass 3 = Clear glass and Glass 2 has a Low-E coating the measurement can be done easily.

3 CALIBRATION The Gasglass-1002 is factory calibrated. The standard calibration is for Argon but the instrument can also to a limited extent be calibrated to other rare gases. Please contact your distributor for more information. If the circumstances stay ideal, the calibration will not change over time. It is, however recommended to check the calibration on a regular basis. This can be done with proper instrumentation provided by the manufacturer. Please contact your distributor or manufacturer for more information. 5

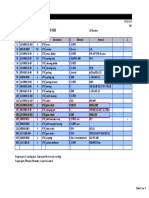

TECHNICAL SPECIFICATIONS

Overall Dimensions: Weight: Operating Conditions: Humidity:

440*350*170 7 +10 - +35 0 - 90 %

mm kg C R.H. Non-condensing VAC VA

Main Power Supply: Power Consumption: Output Connectors:

100 - 240 60

RS232 Serial interface, D-Sub9 Screen power cable 7,0 VDC Sparklike LCD screen One button measurement Gasglass data logging software for PC 100% 90 % 85 % 80% - 90 % 1% - 85 % 1.5% - 80 % 2% Accuracy expected to be within 5% but not guaranteed Lowest measurable concentration is approx. 50% 1% 1.5% 2% Precision expected to be within 5% but not guaranteed For more precise measurements see the Deviation Table NOTE! The precision table is a summary of the deviations in measurement results when measuring different types of IG units See the "Deviation Table" for more information.

Display: Measurement: Software:

Accuracy:

Precision:

100% - 90% 90 % - 85 % 85 % - 80% 80% -

Das könnte Ihnen auch gefallen

- Soldering electronic circuits: Beginner's guideVon EverandSoldering electronic circuits: Beginner's guideBewertung: 4.5 von 5 Sternen4.5/5 (9)

- A Powerful Stun GunDokument13 SeitenA Powerful Stun GunLê Thiên ThanhNoch keine Bewertungen

- Second Advent Herald (When God Stops Winking (Understanding God's Judgments) )Dokument32 SeitenSecond Advent Herald (When God Stops Winking (Understanding God's Judgments) )Adventist_TruthNoch keine Bewertungen

- Smith KJ Student Mathematics Handbook and Integral Table ForDokument328 SeitenSmith KJ Student Mathematics Handbook and Integral Table ForStrahinja DonicNoch keine Bewertungen

- SHGC & SCDokument2 SeitenSHGC & SCVara PrasadNoch keine Bewertungen

- "A Stitch in Time" The Complete Guide To Electrical Insulation TestingDokument67 Seiten"A Stitch in Time" The Complete Guide To Electrical Insulation Testingalisaidii100% (1)

- Lafarge Thermography ProgramDokument17 SeitenLafarge Thermography ProgramDiego AlejandroNoch keine Bewertungen

- Original Sandeha NivariniDokument117 SeitenOriginal Sandeha NivariniHmis BlrNoch keine Bewertungen

- Section13 Spark TestingDokument3 SeitenSection13 Spark TestingGustavoNoch keine Bewertungen

- Secrets of Bushing Oil Level-GoffDokument8 SeitenSecrets of Bushing Oil Level-Goffalexander100% (1)

- Epas ReviewerDokument11 SeitenEpas ReviewerPak YuNoch keine Bewertungen

- DEAD STARS by Paz Marquez BenitezDokument17 SeitenDEAD STARS by Paz Marquez BenitezArmiethazen Khea Page PalarcaNoch keine Bewertungen

- VGScienta Pressure MeasurementDokument16 SeitenVGScienta Pressure Measurementdeaanggraeni_9345Noch keine Bewertungen

- Metal Repairs: Laser WeldingDokument24 SeitenMetal Repairs: Laser WeldingV DhinakaranNoch keine Bewertungen

- Gas Leakage Alarm With Power Failure SystemDokument64 SeitenGas Leakage Alarm With Power Failure Systeminfo8103Noch keine Bewertungen

- Glass and Solar RadiationDokument5 SeitenGlass and Solar RadiationPiotr AdamekNoch keine Bewertungen

- DHPro enDokument17 SeitenDHPro enMohammed JweleyNoch keine Bewertungen

- Arc Tig131Dokument29 SeitenArc Tig131booboostNoch keine Bewertungen

- HGN Iot PDFDokument18 SeitenHGN Iot PDFGagan SinghviNoch keine Bewertungen

- MT Complete Catalog Aug 14, 2012Dokument31 SeitenMT Complete Catalog Aug 14, 2012Gonza PfNoch keine Bewertungen

- Impulse Metal Detector Koschey-5I Instruction ManualDokument5 SeitenImpulse Metal Detector Koschey-5I Instruction ManualDragan PejkicNoch keine Bewertungen

- F2 Finder DP-1 AdjustmentDokument7 SeitenF2 Finder DP-1 AdjustmentLeandro FernándezNoch keine Bewertungen

- Portable Digital Pyrometers For Non-Contact Temperature Measurement Between 250 and 2500 °CDokument4 SeitenPortable Digital Pyrometers For Non-Contact Temperature Measurement Between 250 and 2500 °CJoseph JoeNoch keine Bewertungen

- ETB-0833 Gloss MeterDokument2 SeitenETB-0833 Gloss MeterUn MillimetroNoch keine Bewertungen

- Spin Doctor User GuideDokument4 SeitenSpin Doctor User Guideapi-195490430Noch keine Bewertungen

- Optical Power Meter Detector CharacteristicsDokument5 SeitenOptical Power Meter Detector CharacteristicsAmir SalahNoch keine Bewertungen

- Metal Detector: Instruction ManualDokument2 SeitenMetal Detector: Instruction ManualWeltonRamoneFernandes100% (1)

- PI-MIKRON Pulse Master Pro (VEGA)Dokument9 SeitenPI-MIKRON Pulse Master Pro (VEGA)Erasmo MontesNoch keine Bewertungen

- SP-LITE Silicon Pyranometer: Revision: 7/04Dokument20 SeitenSP-LITE Silicon Pyranometer: Revision: 7/04AdietamaNoch keine Bewertungen

- 333 2SYGDS530 E2 - DatasheetDokument7 Seiten333 2SYGDS530 E2 - Datasheetvikas_ojha54706Noch keine Bewertungen

- Manual TransmitanciaDokument9 SeitenManual TransmitanciaAlfonso TenaNoch keine Bewertungen

- Panasonic - EKMA PaPIRs Motion SensorDokument8 SeitenPanasonic - EKMA PaPIRs Motion Sensorstern33Noch keine Bewertungen

- Mini TOP Views LEDsDokument11 SeitenMini TOP Views LEDsRicky CoxNoch keine Bewertungen

- Infrared Thermometer: Termômetro Infravermelho Termómetro InfrarrojoDokument50 SeitenInfrared Thermometer: Termômetro Infravermelho Termómetro InfrarrojoEdgarNoch keine Bewertungen

- Thermal Radiation Temperature: Principle of OperationDokument2 SeitenThermal Radiation Temperature: Principle of OperationSuresh Kumar PatelNoch keine Bewertungen

- MicroDokument6 SeitenMicroGebrehaweria TamratNoch keine Bewertungen

- LED Test ReportDokument7 SeitenLED Test Reportdevkant88Noch keine Bewertungen

- 4.2 Temperature Sensor (LM35) 4.2.1 DescriptionDokument9 Seiten4.2 Temperature Sensor (LM35) 4.2.1 DescriptionLohit TelaproluNoch keine Bewertungen

- Technical Data Sheet - ThermobelDokument10 SeitenTechnical Data Sheet - ThermobelliceuNoch keine Bewertungen

- Solucionario SAM UD2Dokument6 SeitenSolucionario SAM UD2ScribdTranslationsNoch keine Bewertungen

- H-Hiding Power Charts and Micrometer Adjustable Film ApplicatorDokument7 SeitenH-Hiding Power Charts and Micrometer Adjustable Film Applicatoranon_532167705Noch keine Bewertungen

- Ultrasonic Thickness Gauge ld7015 ld7016 m44Dokument13 SeitenUltrasonic Thickness Gauge ld7015 ld7016 m44AlufioNoch keine Bewertungen

- Impulse: Operation ManualDokument8 SeitenImpulse: Operation ManualRonggo SukmoNoch keine Bewertungen

- Pi-Mikron Stinger 2 (Land Craft)Dokument18 SeitenPi-Mikron Stinger 2 (Land Craft)Erasmo MontesNoch keine Bewertungen

- Anu 2Dokument5 SeitenAnu 2Pugazh VadivuNoch keine Bewertungen

- Industrial Gas and Temperature Protection DeviceDokument50 SeitenIndustrial Gas and Temperature Protection DeviceanupamdubeyNoch keine Bewertungen

- Course:: Thermodynamics I Class Name of ExperimentDokument4 SeitenCourse:: Thermodynamics I Class Name of ExperimentMUHAMMAD AKRAMNoch keine Bewertungen

- Infrared ThermometersDokument6 SeitenInfrared ThermometerskarimaatefNoch keine Bewertungen

- Demagnatization Demagnatization Demagnatization Demagnatization Downhole Tools Downhole Tools Downhole Tools Downhole ToolsDokument4 SeitenDemagnatization Demagnatization Demagnatization Demagnatization Downhole Tools Downhole Tools Downhole Tools Downhole ToolsaadmaadmNoch keine Bewertungen

- Passive Cooker Istruzioni enDokument18 SeitenPassive Cooker Istruzioni enFabio TavanoNoch keine Bewertungen

- A Binder Manual For PHY-307 July-DecDokument66 SeitenA Binder Manual For PHY-307 July-DecAayush RandeepNoch keine Bewertungen

- Callaway 200s Manual enDokument11 SeitenCallaway 200s Manual enJimmy ZettenbergNoch keine Bewertungen

- Steel Alloy Testing OpDokument14 SeitenSteel Alloy Testing OpOm PrakashNoch keine Bewertungen

- Lab 12 Low-Temperature PhysicsDokument4 SeitenLab 12 Low-Temperature Physicsruoxian shenNoch keine Bewertungen

- Magnet GLGDokument2 SeitenMagnet GLGZeeshan SajidNoch keine Bewertungen

- E Beam ManualDokument7 SeitenE Beam ManualMarco SalvatoriNoch keine Bewertungen

- Honeywell Fg1625 Install GuideDokument2 SeitenHoneywell Fg1625 Install GuideAlarm Grid Home Security and Alarm MonitoringNoch keine Bewertungen

- EEE 222L Project - Fire Alarm Circuit - Spring2023 S2Dokument18 SeitenEEE 222L Project - Fire Alarm Circuit - Spring2023 S2Mahmud SazzadNoch keine Bewertungen

- Surface Resistance Checker Surface Resistance Checker (No Electrode)Dokument8 SeitenSurface Resistance Checker Surface Resistance Checker (No Electrode)Benny MaulanaNoch keine Bewertungen

- Non Maintained / Maintained Emergency Luminaires: GR-8/leds GR-9/leds Technical Characteristics (Dokument3 SeitenNon Maintained / Maintained Emergency Luminaires: GR-8/leds GR-9/leds Technical Characteristics (Незнани ЈунакNoch keine Bewertungen

- Projectphase1 03finlDokument20 SeitenProjectphase1 03finlPoojaNoch keine Bewertungen

- The Contactor: Temperature Measurement Discrepancies in The Claus Thermal ReactorDokument2 SeitenThe Contactor: Temperature Measurement Discrepancies in The Claus Thermal ReactorMujeeb AhmadNoch keine Bewertungen

- Jasco J-810Dokument39 SeitenJasco J-810ingenieria seguimietosNoch keine Bewertungen

- Proknow VersionDokument21 SeitenProknow Versionapi-392523563Noch keine Bewertungen

- Scalextric Arc One GuideDokument46 SeitenScalextric Arc One GuidenotifyatpriNoch keine Bewertungen

- Prakab Export 20.8.2018 UkDokument260 SeitenPrakab Export 20.8.2018 UkREN JTNNoch keine Bewertungen

- Burst Abdomen 3Dokument12 SeitenBurst Abdomen 3Satvik BansalNoch keine Bewertungen

- مستر رمضان عوضDokument24 Seitenمستر رمضان عوضSamuel SaadNoch keine Bewertungen

- ReagentsDokument12 SeitenReagentsKimscey Yvan DZ SulitNoch keine Bewertungen

- Product Specifications: MB3F-PSA4-19DEDokument2 SeitenProduct Specifications: MB3F-PSA4-19DEВадим ЧеховскийNoch keine Bewertungen

- 5 160 1 PBDokument13 Seiten5 160 1 PBLotkomoaidone Harahu TukambaNoch keine Bewertungen

- Science7 q2 Mod6of8 Asexual Sexualrep v2Dokument26 SeitenScience7 q2 Mod6of8 Asexual Sexualrep v2Ishi OcheaNoch keine Bewertungen

- Excretory Products and Their EliminationDokument13 SeitenExcretory Products and Their Eliminationaravind kishanNoch keine Bewertungen

- Practical - 2: Preparation of The FixativeDokument14 SeitenPractical - 2: Preparation of The FixativeIseth ISethNoch keine Bewertungen

- مشخصات فنی بیل بکهو فیات کوبلکو b200Dokument12 Seitenمشخصات فنی بیل بکهو فیات کوبلکو b200Maryam0% (1)

- Hydraulics Course FileDokument81 SeitenHydraulics Course FileSwarna LathaNoch keine Bewertungen

- Motor Starting: Why Do The Calculation?Dokument13 SeitenMotor Starting: Why Do The Calculation?carlos_eqnNoch keine Bewertungen

- Pantalla Anterior Bienvenido: Cr080vbesDokument3 SeitenPantalla Anterior Bienvenido: Cr080vbesJuan Pablo Virreyra TriguerosNoch keine Bewertungen

- Company Profile Pt. KPT PDFDokument23 SeitenCompany Profile Pt. KPT PDFfery buyaNoch keine Bewertungen

- Etl 213-1208.10 enDokument1 SeiteEtl 213-1208.10 enhossamNoch keine Bewertungen

- Assignment 1 - Statistics ProbabilityDokument3 SeitenAssignment 1 - Statistics ProbabilityAzel Fume100% (1)

- An Evaluation of The Strength of Slender Pillars G. S. Esterhuizen, NIOSH, Pittsburgh, PADokument7 SeitenAn Evaluation of The Strength of Slender Pillars G. S. Esterhuizen, NIOSH, Pittsburgh, PAvttrlcNoch keine Bewertungen

- Setting Times of ConcreteDokument3 SeitenSetting Times of ConcreteP DhanunjayaNoch keine Bewertungen

- SVR Neuro Quote 2 PROvidoDokument3 SeitenSVR Neuro Quote 2 PROvidoChejarla Naveen KumarNoch keine Bewertungen

- Curso VII Lectura 2. New Rural Social MovementsDokument12 SeitenCurso VII Lectura 2. New Rural Social MovementsFausto Inzunza100% (1)

- Health Problems Vocabulary Esl Matching Exercise Worksheet For KidsDokument2 SeitenHealth Problems Vocabulary Esl Matching Exercise Worksheet For KidsTarisubhNoch keine Bewertungen

- T 1246784488 17108574 Street Lighting Control Based On LonWorks Power Line CommunicationDokument3 SeitenT 1246784488 17108574 Street Lighting Control Based On LonWorks Power Line CommunicationsryogaaNoch keine Bewertungen

- American Pile Driving Equipment Equipment CatalogDokument25 SeitenAmerican Pile Driving Equipment Equipment CatalogW Morales100% (1)

- Annotated Bib-BirthingDokument3 SeitenAnnotated Bib-Birthingapi-312719022Noch keine Bewertungen