Beruflich Dokumente

Kultur Dokumente

T72 S01 Tutorial Notes 8 D

Hochgeladen von

Vishal VisenOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

T72 S01 Tutorial Notes 8 D

Hochgeladen von

Vishal VisenCopyright:

Verfügbare Formate

Tutorial Session 8d: T72S01- Basic Plasticity: Part 4 Relates to T72S01 Knowledge & Skills 1.

13 Last Update 26/2/14 Incremental plasticity; Convexity of the yield surface; Normality of the plastic strain increment; Flow rules; Reverse yielding: kinematic hardening versus isotropic hardening and reality; Hysteresis loops, shakedown, ratcheting, residual stresses Qu.: Is the stress-strain curve the same in tension and compression?

Providing that true stress is plotted against true strain, the tension and compression curves for virgin material can often be very similar (though not invariably). If engineering stress were used, the reduction of the cross section in tension, and the increase of the section in compression, would lead to different curves. Qu.: What is the Bauschinger effect? If a sample of material has yielded in tension, the compressive stress subsequently required to cause reversed yielding is smaller in magnitude than the tensile stress previously applied. This is the Bauschinger effect. A Bauschinger material is merely a material which does not harden isotropically (see below). This is generally the case, i.e., most materials are Bauschinger. Qu.: What is isotropic hardening? Isotropic hardening is the name given to the following behaviour. If a material has been work hardened in tension, so that the yield strength in tension has increased from its virgin value of 0 to some hardened value h > 0 , then unloading followed by reloading in any stress state will cause yielding only when the equivalent stress reaches h . By equivalent stress we mean either Mises or Tresca, whichever criterion is applicable. Thus the yield strength in compression will be at a stress of h , and yield in shear will be at a shear stress of h / 2 for Tresca or h / 3 for Mises. In deviatoric stress space, the yield surface has expanded uniformly in all directions (isotropically) by a factor of h / 0 . Thus, the Mises circle in the deviatoric plane has increased in radius from 2 0 / 3 to 2 h / 3 . Qu.: What is kinematic hardening?

Kinematic hardening is the extreme example of non-isotropic (i.e., Bauschinger) behaviour. Suppose a material has been work hardened in tension, so that the yield strength in tension has increased from its virgin value of 0 to some hardened value h > 0 . In kinematic hardening the yield surface in the deviatoric plane remains the same size and shape but is displaced to accommodate the hardening. This means that the yield strength in compression will now be less (in magnitude) than for the virgin material. Specifically, the yield stress in compression will be at a stress of h 2 0 . The shear yield will differ according to the orientation of the shear, with some orientations showing an elevated shear yield strength and some orientations a reduced shear yield strength. Note that a kinematically hardened material is no longer isotropic after first yield.

Qu.:

How do real materials harden?

Structural steels harden in a manner which is intermediate between isotropic and kinematic hardening. See diagram at end of these notes. There is no universal formulation. For austenitic steels some workers in BE have used a LemaitreChaboche mixed hardening model. Qu.: When do isotropic and kinematic hardening give different results? If the loading is proportional (see below) then all hardening behaviours are the same since the directions of the stress and strain increments never change. Hence, different hardening behaviours can produce different predictions only for non-proportional loading. Qu.: What is proportional loading? Loading is proportional if the relative magnitudes of the stress components remain unchanged during loading, and the same is true of the plastic strain components after yielding. In other words, proportional loading involves moving monotonically along a radial line in deviatoric stress space (and the normal to the yield surface at this point remaining in a fixed direction as hardening occurs, i.e., as the surface moves outward). Qu.: When is loading not proportional? Examples of non-proportional loadings are: (a)if loads are reversed; or, (b)if one type of load is followed by another type of load. In the latter case, the two loads will generally produce stresses in different directions in deviatoric stress space, and hence the loading becomes non-proportional when the second load is applied. Qu.: Is isotropic or kinematic hardening more conservative? It depends upon the type of loading and the failure or degradation mechanism. Kinematic hardening materials will be less tolerant of cycling stresses, being more likely to fatigue and more prone to ratcheting (because larger plastic strains will be developed on reverse yielding). However, for a loading consisting of applied strains, e.g., welding residual stresses, isotropic hardening will result in larger stresses. Hence, isotropically hardening materials will be more prone to reheat cracking, other things being equal. Qu.: What is a flow rule? A flow rule defines the magnitude and direction of the plastic strain increment for a given increment of all the stress components when yielding is taking place. Qu.: What is the direction of plastic flow? The plastic flow direction is the direction of the increment of plastic strain in p deviatoric space, ij - in other words the relative magnitudes of the components of

p ij .

Qu.:

How is the plastic flow direction determined?

The direction of plastic flow is determined by the Normality Rule. This states that p ij is normal to the yield surface at the point in question. Thus, for example, for a

p Mises material which hardens isotropically, ij is radial at the current point on the Mises circle. For a kinematically hardened material, the normal to the displaced Mises p circle also gives the direction of ij , but this will no longer be radial from the origin. p For a Tresca material, ij is normal to whichever side of the hexagon the stress vector currently lies upon.

Qu.:

Where does the Normality Rule come from?

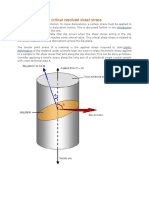

A general proof is provided in the Appendix. Here we derive normality from a plausible, if not rigorous, maximum work principle. Suppose a certain plastic strain p increment, ij , is imposed on a body by an external agency. If we imagine that the material resists the deformation as much as it is able, then the stresses which result will maximise the work which the external agency has to do to impose the p . (We have used a vector notation here since vectors in the deformation, lies on the yield surface, and hence p is deviatoric plane will suffice). But so that p is normal to the surface, since this maximises maximised by choosing in the direction of a given p , thus, the component of

Any other placing of a given p on the yield surface would lead to a small value of p . Hence, the work maximum plastic work implies normality

Qu.: No.

Could a yield surface be any shape at all?

The Convexity Rule says it must be convex. (A convex closed curve is such that the tangent at any point lies entirely outside the curve, except at the point of tangency). Again there is a general proof of convexity in the Appendix. Here we note only that convexity is necessary given the normality rule if any given . A yield surface with a re-entrant p is to correspond to a unique value of stress, part would give rise to an ambiguity of stress state for a specified flow, as illustrated by the diagram which follows:-

C A

A non-convex yield surface would have multiple possible stress states, for a given plastic flow direction, p , all obeying the normality rule. Actually, even a convex surface, part of whose boundary is flat, will have an ambiguity in stress state for a given strain increment. The Tresca hexagon is an example. However, all points on a flat correspond to the same amount of work, p . In contrast, the re-entrant point A, above, corresponds to less work, p , than the points B and C. If we are guided by the principle that the material will resist to the maximum, then point A will be unstable and the material will flip preferentially to B or C. The same argument applies for all points within the re-entrant dimple. So the material will never rest within the re-entrant part. In effect we can flatten off the dimple, as indicated by the red dashed line. In this way the yield surface necessarily becomes convex. In this sense we can also say that, maximum plastic work implies convexity Since the Appendix claims to prove normality and convexity without the use of the maximum plastic work principle, the above argument can be turned around to be a demonstration of the maximum work principle (i.e., that, for a given stress state, plastic flow will be in a direction so as to maximise plastic work).

Qu.:

What is a hysteresis loop?

A hysteresis loop is the locus of the stress-strain points which is generated by a sequence of loads which start and finish at the same loading condition. Repeating the same sequence of loading conditions results in a set of hysteresis loops which may or may not over-plot. Such loops could be plotted for any components of stress and strain, but equivalent stress and strain are most often employed. However, there is an important subtlety in this case because equivalent quantities cannot be negative. To overcome this, a signed equivalent stress is often used, defined as the Mises stress times the sign of the principle stress which has the greatest magnitude (which can be a bit messy, introducing discontinuities). Similarly, the plastic equivalent strain increment is really always a positive quantity, and hence the plastic strain always increases monotonically. This is what ABAQUS gives as PEEQ, for example. But it is convenient to define effective plastic strain increments which are signed, and which thus allow the strain to reduce as well as increase (without which there could be no closed hysteresis loop!). Again, the sign of the effective plastic strain increment can be defined by the sign of the largest principle plastic strain component. By this means, closed, or nearly closed, hysteresis loops can be generated by a finite element analysis from equivalent quantities. R5V2/3 uses signed equivalent quantities for constructing stress-strain hysteresis loops. Qu.: What does the area of a hysteresis loop represent? Assuming the hysteresis loop plots equivalent stress and strain, its area is the plastic energy dissipated per unit volume within the material during the loading cycle. Qu.: If load is applied and then removed, does the stress return to zero? In general, no. Clearly it does if the material remains elastic. Also, in the case of uniaxial tension, the net stress will return to zero. However, in general, the stress at an arbitrary point of a body which has yielded and then had the load removed will not be zero. Take for example, a structure with a local stress concentration such as a notch. Suppose the elastically calculated stresses would be several times the yield stress. Upon unloading the material near the notch will probably yield in compression. The structure will be left with residual stresses, in this case compressive and localised to the notch. Qu.: What is shakedown? If a loading-unloading sequence is repeated over and over, other than purely elastic behaviour three generic behaviours are possible: either, (a)the stress-strain trajectories at all points of the structure settle down to move up and down the elastic line; or, (b)the stress-strain hysteresis loops persist but settle down to repeat the same loop; or, (c)neither of these, i.e., the hysteresis loops persist and do not become repetitive. In case (a) the structure is said to shakedown. Thus, despite the rather misleading name, shakedown is a desirable state of affairs. It means that the structure is essentially elastic after some initial plasticity during the first few load cycles. Qu.: What is ratcheting? Ratcheting is case (c), above. When a repeated load-unload cycle does not produce a repeating hysteresis loop after a few cycles, it will usually be because the loop is progressing steadily to the right, i.e., accumulating more and more plastic deformation on every cycle. Ratcheting is a serious structural threat, indicative of excessive cyclic

stresses. Ratcheting should not occur in a well designed structure. It is likely that a ratcheting structure will fail relatively quickly, if only because something outwith the design basis is occurring, though in principle the ratchet strains could be small and take a large number of cycles to fail. Ratcheting is the extreme opposite of shakedown. Qu.: No. Case (b), above, is the intermediate case: that of a stable hysteresis cycle (stable plastic cycling). This condition will cause fatigue damage to accumulate on each cycle, the amount being sensitive to the strain range of the hysteresis cycles. In principle even structures which shakedown may be subject to fatigue. But the fatigue endurance for strain ranges within the elastic regime (e.g., <0.2%) will generally be enormous. In contrast, when hysteresis cycles occur, the plastic strain range may be the order of several percent strain, which can cause rapid accumulation of fatigue damage. The occurrence of hysteresis cycles, rather than elastic cycling, is even more significant when operation is in the creep temperature regime. In this case the hysteresis cycle can repeatedly re-set creep dwell stresses, leading to creep-fatigue damage accumulation on each cycle a potentially virulent degradation mechanism and one which is often the most relevant to in-reactor components in the upper regions of the reactors and boilers. In practice, it is those structures which lie between strict shakedown [behaviour (a)] and ratcheting [behaviour (c)] which are the chief subject of R5V2/3 crack initiation assessments. Confusingly, perhaps, R5 also introduces the concept of global shakedown. This is a subset of behaviour (b) in which the regions exhibiting cyclic plasticity are confined to <20% of any section of the structure [the rest of the structure exhibiting behaviour (a)]. This is a precaution by R5 to ensure that its recommended procedures for assessing crack initiation are valid. Such procedures apply outside of strict shakedown but within global shakedown. Qu.: No. A given plastic deformation can be achieved in a multitude of ways, in general corresponding to different stress states. For example, a bar may be bent to a given extent by loading and then unloading. However, the same bend may be achieved by initially applying too much load, then unloading and reverse loading enough to correct the over-bend followed by unloading again. The latter procedure will result in residual stresses of opposite sign to the first case. This can happen only because plasticity is an irreversible, incremental theory, and exhibits load order dependence. Can residual stresses be deduced from the deformation of the structure? Do all structures either shakedown or ratchet?

Qu.:

What is the Mises flow rule for isotropic hardening?

The direction of p is defined by the normal to the yield surface, which for the . The magnitude of a small isotropic Mises rule is also the radial direction, i.e., plastic strain increment is proportional to the increment of Mises stress. Hence, so far, d . The rest of the flow rule is defined by the uniaxial stress-strain we have p curve, which can also be interpreted as an equivalent stress-strain curve. Thus, if we assume a power law hardening: = A n , and hence d = An n 1 d , then we get,

ijp = 3 An 2

n2

ij d

The factor of 3/2 is to ensure the uniaxial behaviour is regained, since in this case

2 x = . This is a simple explicit representation of a flow rule. But, for real 3

hardening behaviour, when the yield surface moves, it is harder to specify the rule algebraically.

Schematic Example of Isotropic, Kinematic and Typical Hardening

2 0

2 0

Black reverse yielding curve = isotropic hardening Red reverse yielding curve = kinematic hardening Blue reverse yielding curves = typical true hardening behaviour

APPENDIX

Proof of Convexity & Normality in Plasticity

The cunning thing is to recognise that the agency causing the yielding may not be responsible for the whole state of stress. Suppose a body is initially fully elastic but has various loads, residual stresses, etc 0 , within the yield surface. acting, so that the state of stress at a certain point is ij

0 0 These stresses are in equilibrium with the applied loads, so that ij , j + bi = 0 , where

b 0 is the force per unit volume applied by the initial loads.

Now an external agency, which we call the yielding agency, causes additional 0 stressing, ij , and takes the stress to ij = ij + ij which lies on the yield surface.

p The external agency now causes some plastic straining, ij . Because the yielding

agency has applied only those forces which give rise to ij , the work done by the

p p 0 yielding agency (per unit volume) is ij ij = ij ij ij .

The irreversibility of plasticity means that it is only possible for the yielding agency to do work on the material. It is not possible for any element of the material to do work on the external agency whilst undergoing plastic straining, since this would be p p 0 synonymous with recovery. Consequently ij ij = ij ij ij is everywhere

0 positive indefinite, and this holds for an arbitrary choice of ij within the yield

surface and ij on the yield surface. A little thought shows that this gives us both normality and convexity. The vector ij can be drawn from any point within the yield surface to end at any point on the

p yield surface, but it must always lie behind the strain increment vector, ij , where behind means making an angle >90o. This is only possible if both normality and convexity apply.

WARNING: I am not sure about the status of this proof. I cannot see anything wrong with it, but I previously thought that normality & convexity could not be demonstrated with full mathematical rigor - requiring an irreducible degree of empirical input. Spot the flaw?

Das könnte Ihnen auch gefallen

- BS 5228-4-1992 Noise Control On Construction and Open Sites. Part 4Dokument70 SeitenBS 5228-4-1992 Noise Control On Construction and Open Sites. Part 4Lici001Noch keine Bewertungen

- VNIV - EX5985 - Sprinklers, Automatic and OpenDokument20 SeitenVNIV - EX5985 - Sprinklers, Automatic and OpenjunaidNoch keine Bewertungen

- Komatsu Pc75uu 2 Shop ManualDokument20 SeitenKomatsu Pc75uu 2 Shop Manualthomas100% (50)

- T72S01TutorialNotes8d PDFDokument8 SeitenT72S01TutorialNotes8d PDFManoj MallickNoch keine Bewertungen

- StartDokument10 SeitenStartRohitKalraNoch keine Bewertungen

- 1 D Plasticity by Louie L. YawDokument25 Seiten1 D Plasticity by Louie L. YawshakibbrNoch keine Bewertungen

- Plastic Upper Bound Theorems 'Dokument8 SeitenPlastic Upper Bound Theorems 'STRUCTURE -STRUCTURENoch keine Bewertungen

- Imot 2176 Tensile PropertiesDokument4 SeitenImot 2176 Tensile PropertiesEry KuswantoroNoch keine Bewertungen

- Mechanical Properties of Materials - MechaniCalcDokument11 SeitenMechanical Properties of Materials - MechaniCalcharieduidNoch keine Bewertungen

- Material Properties ReportDokument8 SeitenMaterial Properties ReportazizsaafanNoch keine Bewertungen

- Reference BooksDokument23 SeitenReference BooksIgor Gabriel Teixeira GómezNoch keine Bewertungen

- ME501 L3 Stress-Strain Relations Oct 2017Dokument8 SeitenME501 L3 Stress-Strain Relations Oct 2017Firas RocktNoch keine Bewertungen

- Program A Cao Nao LinearDokument5 SeitenProgram A Cao Nao LinearJerfsonLimaNoch keine Bewertungen

- Members Subjected To Axial ForcesDokument3 SeitenMembers Subjected To Axial ForcesRonald obasieNoch keine Bewertungen

- Stress Strain DiagramDokument4 SeitenStress Strain DiagramMartine CastroNoch keine Bewertungen

- Strain-Hardening of MetalsDokument27 SeitenStrain-Hardening of MetalsAsadUllahNoch keine Bewertungen

- Theory of PlasticityDokument110 SeitenTheory of Plasticitytayyeb803Noch keine Bewertungen

- Stresses in Pressure Vessel Design: Maximum Principal Stress TheoryDokument11 SeitenStresses in Pressure Vessel Design: Maximum Principal Stress TheorybahmanNoch keine Bewertungen

- Tensile PropertiesDokument4 SeitenTensile Propertiesjontylee87Noch keine Bewertungen

- FLAC Basics by MeDokument3 SeitenFLAC Basics by Mesujan95Noch keine Bewertungen

- Advanced Structural BehaviorDokument6 SeitenAdvanced Structural Behaviornedumaran.sNoch keine Bewertungen

- Stress Strain CurveDokument16 SeitenStress Strain CurveMedakayala Nagasravanthi 20PHD7125Noch keine Bewertungen

- Yield Point PDFDokument12 SeitenYield Point PDFengineer bilal100% (1)

- Mechanic FractureDokument9 SeitenMechanic Fracturehengki wibowoNoch keine Bewertungen

- Plastic Analysis of StructuresDokument26 SeitenPlastic Analysis of Structuresomar sayedNoch keine Bewertungen

- Flow PlasticityDokument2 SeitenFlow Plasticitynetname1Noch keine Bewertungen

- Bound TheoremsDokument18 SeitenBound TheoremscizozenatoNoch keine Bewertungen

- Chap06 Mechanical BehaviorDokument14 SeitenChap06 Mechanical BehaviorAli khan7Noch keine Bewertungen

- CrssDokument2 SeitenCrssRekyNoch keine Bewertungen

- SVT Collge of Engg. Structure II Lecture Notes..1245Dokument38 SeitenSVT Collge of Engg. Structure II Lecture Notes..1245Shams KhattakNoch keine Bewertungen

- Stress ConcentrationsDokument0 SeitenStress Concentrations777894292Noch keine Bewertungen

- Lecture 4Dokument45 SeitenLecture 4SAIF ULLAHNoch keine Bewertungen

- CH 12Dokument64 SeitenCH 12LeonardoMadeira11Noch keine Bewertungen

- Schematic Models of Constitutive Behavior of Solid MaterialsDokument4 SeitenSchematic Models of Constitutive Behavior of Solid MaterialschoopoNoch keine Bewertungen

- What Is Fixed SupportDokument7 SeitenWhat Is Fixed SupportvshapiroNoch keine Bewertungen

- Experiment Tensile Properities of MaterialsDokument8 SeitenExperiment Tensile Properities of MaterialsDr.L.V.PRASAD MeesaragandaNoch keine Bewertungen

- Strain-Life Approach Ek KaynakDokument14 SeitenStrain-Life Approach Ek KaynakKALIDASS DNoch keine Bewertungen

- Understanding The Bauschinger Effect: Posted: October 7, 2009Dokument2 SeitenUnderstanding The Bauschinger Effect: Posted: October 7, 2009skluxNoch keine Bewertungen

- 4 - Mechanical Properties of MaterialsDokument28 Seiten4 - Mechanical Properties of MaterialsYusf ari jerjisNoch keine Bewertungen

- Stress-Strain Diagram (Curve)Dokument4 SeitenStress-Strain Diagram (Curve)kevinNoch keine Bewertungen

- 1 Preliminary Considerations: 1.1 Mechanical Characteristics of SteelDokument2 Seiten1 Preliminary Considerations: 1.1 Mechanical Characteristics of SteelBill HNoch keine Bewertungen

- Mechanics of Fracturing An Faulting Theory and Experiment: Type Equation HereDokument17 SeitenMechanics of Fracturing An Faulting Theory and Experiment: Type Equation HereHamza AhsanNoch keine Bewertungen

- Stress and Strain: Elastic ModulusDokument20 SeitenStress and Strain: Elastic Moduluslaura sageNoch keine Bewertungen

- Plastic Analysis PresnetationDokument123 SeitenPlastic Analysis PresnetationMisganaw YeshiwasNoch keine Bewertungen

- Compressive Strength Is The Capacity of A Material or Structure ToDokument5 SeitenCompressive Strength Is The Capacity of A Material or Structure ToMarie Fe BermidoNoch keine Bewertungen

- Material Basics On Plastic Deformation F, RDokument33 SeitenMaterial Basics On Plastic Deformation F, RRaj KumarNoch keine Bewertungen

- Plasticity: Monotonic Stress / Strain Diagram For Elastic-Plastic BehaviourDokument15 SeitenPlasticity: Monotonic Stress / Strain Diagram For Elastic-Plastic Behaviourkarrar333 ALIYAHIANoch keine Bewertungen

- 08 Plasticity 06 Strain HardeningDokument15 Seiten08 Plasticity 06 Strain Hardeningmicael_89Noch keine Bewertungen

- Stress-Strain CurveDokument7 SeitenStress-Strain CurveR BNoch keine Bewertungen

- Stress Strain CurveDokument12 SeitenStress Strain CurveGlerommie CastroNoch keine Bewertungen

- Fig.1 Stress-Strain Curve Typical of A Low Carbon SteelDokument7 SeitenFig.1 Stress-Strain Curve Typical of A Low Carbon SteelFredNoch keine Bewertungen

- CE2155 - Stress and Strain Transformation (Part 1)Dokument44 SeitenCE2155 - Stress and Strain Transformation (Part 1)JuliaNoch keine Bewertungen

- Loadings and Concept of Normal StressDokument12 SeitenLoadings and Concept of Normal StressG. Dancer GhNoch keine Bewertungen

- Mechanics of Materials II: UET, Taxila Lecture No.Dokument48 SeitenMechanics of Materials II: UET, Taxila Lecture No.danemsalNoch keine Bewertungen

- Chapter 3 Mechanical Properties of MaterialsDokument9 SeitenChapter 3 Mechanical Properties of MaterialsNevin SongduanNoch keine Bewertungen

- Stress Concentration and FatigueDokument22 SeitenStress Concentration and FatiguelosoceNoch keine Bewertungen

- Anglais Technique Et Terminologie - Load, Stress and StrainDokument2 SeitenAnglais Technique Et Terminologie - Load, Stress and StrainhasniloubakiNoch keine Bewertungen

- Stress and StrainDokument14 SeitenStress and StrainGetachew AbebeNoch keine Bewertungen

- The Mechanical Properties of Wood: Including a Discussion of the Factors Affecting the Mechanical Properties, and Methods of Timber TestingVon EverandThe Mechanical Properties of Wood: Including a Discussion of the Factors Affecting the Mechanical Properties, and Methods of Timber TestingNoch keine Bewertungen

- CC603 Topik 1Dokument55 SeitenCC603 Topik 1farrita95Noch keine Bewertungen

- 8 - House BigDokument32 Seiten8 - House Biggiovanni100% (1)

- On Expansive SoilsDokument18 SeitenOn Expansive SoilsSrijaJuluru100% (1)

- KKT KrausDokument24 SeitenKKT KrausDaniel TibreaNoch keine Bewertungen

- Mazzella WireRopeAtAGlance 0919Dokument5 SeitenMazzella WireRopeAtAGlance 0919Tarek HareedyNoch keine Bewertungen

- Ale Building Technology and MaterialsDokument2 SeitenAle Building Technology and MaterialsiloilocityNoch keine Bewertungen

- Price List DT 10.09.20 PDFDokument48 SeitenPrice List DT 10.09.20 PDFIshan Goel100% (1)

- List of Jsce Stands 2010Dokument3 SeitenList of Jsce Stands 2010dsbisht100% (1)

- Consolidation Settlement Examples 3 - Solutions (2) - 2Dokument6 SeitenConsolidation Settlement Examples 3 - Solutions (2) - 2Sujani MaarasingheNoch keine Bewertungen

- Papercrete4 PDFDokument9 SeitenPapercrete4 PDFPrasad TekadeNoch keine Bewertungen

- Trosten Ahu CatalogueDokument88 SeitenTrosten Ahu Cataloguehanimamoo7Noch keine Bewertungen

- Pow 17J00012Dokument41 SeitenPow 17J00012amroussyNoch keine Bewertungen

- Sprinkler CalculationDokument14 SeitenSprinkler CalculationJMVNoch keine Bewertungen

- Conut Shell: A Substitute For Aggregate in Mix Proportioning of CementDokument17 SeitenConut Shell: A Substitute For Aggregate in Mix Proportioning of CementStephanie SilaoNoch keine Bewertungen

- Stay Wire SpecificationDokument4 SeitenStay Wire Specificationshivaanem100% (1)

- Focus On Caustic Stress Corrosion CrackingDokument2 SeitenFocus On Caustic Stress Corrosion Crackingcoolguy12345Noch keine Bewertungen

- LUS-HSE-MA1-400-001.05 - Lusail HSE Fire Management System Framework PDFDokument18 SeitenLUS-HSE-MA1-400-001.05 - Lusail HSE Fire Management System Framework PDFJaijeev PaliNoch keine Bewertungen

- Tender For Carrying Out Construction of Compound W Tender Notice 22486835 HPCL UttaranchalDokument5 SeitenTender For Carrying Out Construction of Compound W Tender Notice 22486835 HPCL UttaranchalVeena NageshNoch keine Bewertungen

- Base Isolation For Multi Storey Buildings PDFDokument311 SeitenBase Isolation For Multi Storey Buildings PDFRal GLNoch keine Bewertungen

- Investigation of Methods of Improving The Application Workmanship of WaterproofingDokument16 SeitenInvestigation of Methods of Improving The Application Workmanship of Waterproofingniran_udayangaNoch keine Bewertungen

- Is 2062 E350 - Fe 490 Steel Plate - Steel PlateDokument4 SeitenIs 2062 E350 - Fe 490 Steel Plate - Steel PlateAmit GauravNoch keine Bewertungen

- ANSI Thread Series DesignationsDokument1 SeiteANSI Thread Series DesignationsAbby BurchNoch keine Bewertungen

- 4.8 Appendix-3h Color CodeDokument4 Seiten4.8 Appendix-3h Color CodeSubrata DasNoch keine Bewertungen

- A436-2020 Standard Specification For Austenitic Gray Iron CastingsDokument5 SeitenA436-2020 Standard Specification For Austenitic Gray Iron CastingsPablo C. T.Noch keine Bewertungen

- Lesson 7 Construction Dewatering and Ground FreezingDokument17 SeitenLesson 7 Construction Dewatering and Ground FreezingRsjBugtongNoch keine Bewertungen

- Cau 2014Dokument25 SeitenCau 2014vinay1999Noch keine Bewertungen

- Fish Market - HyderabadDokument4 SeitenFish Market - HyderabadsalemmanojNoch keine Bewertungen