Beruflich Dokumente

Kultur Dokumente

(Bio Inspired) Jonkersabstract FINAL

Hochgeladen von

Hilary WatsonOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

(Bio Inspired) Jonkersabstract FINAL

Hochgeladen von

Hilary WatsonCopyright:

Verfügbare Formate

BioConcrete - A Novel Bio-based Material Henk M.

Jonkers Department of Materials and Environment Faculty of Civil Engineering and Geosciences Delft University of Technology

The motivation to implement sustainable practices in the Geo- and Civil Engineering sector is becoming more and more noticeable in recent years. Environmental pressure of engineering practices due to emission of waste products and depletion of natural resources such as raw materials and fossil fuels forces the sector to search for more sustainable alternatives. One partial solution is the utilization of industrial byproducts like silica fume, fly-ash and blast furnace slag as cement replacement in concrete mixtures. Ordinary Portland cement is quantitatively an important constituent of concrete mixtures but represents a typical non-sustainable product as for its production large amounts of clay and limestone need to be burned at a high temperature resulting in substantial carbon dioxide production what roughly amounts to 7% of total anthropogenic CO2 emissions. If available, industrial byproducts can replace a significant amount of cement. For example in the Netherlands cement blends are produced in which up to 80% of ordinary Portland cement is replaced by blast furnace slag what is produced as byproduct during manufacturing of steel. However, as on a global scale availability of suitable industrial byproducts is too limited to cover the production of sustainable cements, alternatives need to be developed. At the Delft University of Technology two scientific programs aiming to develop more durable and sustainable materials and techniques are currently running in parallel. One program initiated by the Delft centre for Materials (DCMat) focuses on the development of self-healing materials, i.e. materials featuring an inbuilt repair system what becomes activated upon damage formation, and what can manage autonomous repair of the material. The principle of material selfhealing was developed in analogy to self-healing capacity of living (biological) tissues and materials and thus represents an example of bio-mimicry. In the other research program named 'Bio-based Geo- and Civil Engineering' bio-mimicry is actually taken one step further in the sense that biological processes and materials are actually used to mitigate environmental pressure of geo- and civil-engineering practices. One example of a research project that fits both programs will be discussed here in more detail, i.e. the development of bacteria-based self-healing concrete. BioConcrete, or bacteria-based self-healing concrete, is produced by adding a two-component biochemical self-healing agent to the concrete mixture. The two individual components, i.e. bacterial spores and a bio-mineral precursor compound, are immobilized in expanded clay particles prior to addition to the concrete mixture. The expanded clay particles are relatively porous and can thus act as a reservoir system for the biochemical healing agent. The homogenously distributed particles will, after setting of the concrete mixture, release the encapsulated biochemical agent when hit and opened by a crack forming in the concrete matrix. Crack ingress water subsequently disperses the biochemical agent over the crack surface and activates the bacterial spores which

germinate to become metabolically active vegetative cells which convert the organic biomineral precursor compound to insoluble inorganic calcium-carbonate-based minerals. Copious production of bacteria-mediated bio-minerals subsequently results in clogging and crack closure (Figure 1) reducing material permeability and leakage. Concrete what is able to autonomously reduce matrix permeability substantially will be less susceptible to leakage and reinforcement corrosion what not only saves manual maintenance and repair considerably but also increases the service life of a construction. These phenomena will reduce the need of raw materials, energy consumption and emission of waste products particularly due to increased service life and reduced consumption of synthetic repair materials which are traditionally used for manual maintenance and repair of damaged concrete constructions. Self-healing BioConcrete thus represents a more durable and particularly moreover sustainable alternative to classical types of concrete.

Figure 1. Close up microphotograph of crack-healing in bacteria-based self-healing concrete. Micro-crack and cavity (arrow) visible in left picture partly running through embedded expanded clay particles (black circular aggregates) filled with bio-chemical healing agent, become completely filled with calcium-carbonate based inorganic minerals after immersion in water for several days (right picture). The inorganic minerals are precipitated due to bacterial metabolic conversion of organic bio-mineral precursor compounds.

Das könnte Ihnen auch gefallen

- Article English 1Dokument5 SeitenArticle English 1Alexander ArauzNoch keine Bewertungen

- Eco-efficient Rendering Mortars: Use of Recycled MaterialsVon EverandEco-efficient Rendering Mortars: Use of Recycled MaterialsNoch keine Bewertungen

- Article English 1 Alexander ArauzDokument5 SeitenArticle English 1 Alexander ArauzAlexander ArauzNoch keine Bewertungen

- Clean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementVon EverandClean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementNoch keine Bewertungen

- Henk Jonkers Delft University of Technology, Microlab, Stevinweg 1, NL-2628 CN Delft, The NetherlandsDokument8 SeitenHenk Jonkers Delft University of Technology, Microlab, Stevinweg 1, NL-2628 CN Delft, The NetherlandsEvaggelos StampolisNoch keine Bewertungen

- Answers To QuestionsDokument8 SeitenAnswers To QuestionsAbigail VNoch keine Bewertungen

- Henk JonkersDokument25 SeitenHenk Jonkersestld2Noch keine Bewertungen

- Microbial Healing of Cracks in ConcreteDokument15 SeitenMicrobial Healing of Cracks in ConcreteasdasdasdasNoch keine Bewertungen

- Bio Cement - An Eco Friendly Construction Material: Research ArticleDokument4 SeitenBio Cement - An Eco Friendly Construction Material: Research ArticleTUSHAR DASH100% (1)

- What Is Bacterial ConcreteDokument1 SeiteWhat Is Bacterial Concretejahremade jahremadeNoch keine Bewertungen

- Feasibility-Study-of-the-Bacteria-Based-Self-Healing 2Dokument25 SeitenFeasibility-Study-of-the-Bacteria-Based-Self-Healing 2MK design and ArchitectureNoch keine Bewertungen

- Cebacom 2020 91Dokument7 SeitenCebacom 2020 91Ananjana cNoch keine Bewertungen

- Self Healing ConcreteDokument13 SeitenSelf Healing ConcreteAbigail VNoch keine Bewertungen

- A Review On The Potential of Filamentous Fungi For5Dokument13 SeitenA Review On The Potential of Filamentous Fungi For5pampanasanjeevkumarc046Noch keine Bewertungen

- 1 s2.0 S2352710218310994 MainDokument19 Seiten1 s2.0 S2352710218310994 MainJulian Leonardo AcevedoNoch keine Bewertungen

- Self-Healing Concrete and Cementitious Materials: Tanvir Qureshi Abir Al-TabbaaDokument25 SeitenSelf-Healing Concrete and Cementitious Materials: Tanvir Qureshi Abir Al-TabbaaRamón RamalhoNoch keine Bewertungen

- SEMINARDokument12 SeitenSEMINARVishala SharmaNoch keine Bewertungen

- Biochar From Wood Waste As Additive For Structural ConcreteDokument14 SeitenBiochar From Wood Waste As Additive For Structural ConcretefatihaNoch keine Bewertungen

- A Review On The Potential of Filamentous Fungi For Microbial Self-Healing of ConcreteDokument12 SeitenA Review On The Potential of Filamentous Fungi For Microbial Self-Healing of Concretepampanasanjeevkumarc046Noch keine Bewertungen

- A Review On Architecture With Fungal BiomaterialsDokument10 SeitenA Review On Architecture With Fungal BiomaterialsAnukruti NigamNoch keine Bewertungen

- Ijri Cce 02 008Dokument8 SeitenIjri Cce 02 008ijripublishersNoch keine Bewertungen

- Characterization of Concrete Coating Using Bacteria As A Floor Regeneration AgentDokument15 SeitenCharacterization of Concrete Coating Using Bacteria As A Floor Regeneration AgentJéssica SouzaNoch keine Bewertungen

- Hizami Abdullah 2018 IOP Conf. Ser. Mater. Sci. Eng. 431 062003Dokument10 SeitenHizami Abdullah 2018 IOP Conf. Ser. Mater. Sci. Eng. 431 062003MOHAMMED HASHIRNoch keine Bewertungen

- Bacterial ConcreteDokument8 SeitenBacterial ConcreteJames WattNoch keine Bewertungen

- Green Concrete For Sustainable ConstructionDokument5 SeitenGreen Concrete For Sustainable ConstructionInternational Journal of Research in Engineering and TechnologyNoch keine Bewertungen

- Self Healing Concrete Synopsis PrintDokument7 SeitenSelf Healing Concrete Synopsis PrintASHEESH KUMAR SRIVASTAVANoch keine Bewertungen

- Self Healing ConcreteDokument12 SeitenSelf Healing ConcreteVivek Makhecha100% (1)

- Bioconcrete Next Generation of Self-Healing Concrete, Mostafa Seifan A, Ali Khajeh Samani A, Aydin Berenjian ADokument19 SeitenBioconcrete Next Generation of Self-Healing Concrete, Mostafa Seifan A, Ali Khajeh Samani A, Aydin Berenjian AGR DesignsNoch keine Bewertungen

- Self-Healing Concrete: Definition, Mechanism and Application in Different Types of StructuresDokument5 SeitenSelf-Healing Concrete: Definition, Mechanism and Application in Different Types of StructuresPriyank GodhatNoch keine Bewertungen

- Journal of Building Engineering: SciencedirectDokument17 SeitenJournal of Building Engineering: SciencedirectShimizu KokuruNoch keine Bewertungen

- Self-Healing Concrete: A Seminar SynopsisDokument5 SeitenSelf-Healing Concrete: A Seminar SynopsisK SandeepNoch keine Bewertungen

- Self Healing Concrete: KEYWORDS: Concrete, Cracks, Formation, Building, Permeability, Repair, Carbon DioxideDokument10 SeitenSelf Healing Concrete: KEYWORDS: Concrete, Cracks, Formation, Building, Permeability, Repair, Carbon DioxidehbldjshfleNoch keine Bewertungen

- Full Projects (1) - Green ConcreteDokument19 SeitenFull Projects (1) - Green ConcreteIbrahim Abshir JamaNoch keine Bewertungen

- Bio ConcreteDokument3 SeitenBio ConcreteKabeer AliNoch keine Bewertungen

- Literature Review On Bacterial ConcreteDokument7 SeitenLiterature Review On Bacterial Concretexcjfderif100% (1)

- 1 s2.0 S0950061820338046 MainDokument15 Seiten1 s2.0 S0950061820338046 MainGMC SEMECNoch keine Bewertungen

- Workability Tests On Fresh Concrete Formulated With Eco-Friendly AdmixtureDokument7 SeitenWorkability Tests On Fresh Concrete Formulated With Eco-Friendly AdmixtureElena JavierNoch keine Bewertungen

- Biochar-Augmented Carbon-Negative ConcreteDokument12 SeitenBiochar-Augmented Carbon-Negative ConcreteNutchanon BuapimNoch keine Bewertungen

- Siliguri Institute of TechnologyDokument13 SeitenSiliguri Institute of Technologykmbd SiliguriNoch keine Bewertungen

- Wang 2011Dokument11 SeitenWang 2011Andres CuadrosNoch keine Bewertungen

- Eco Concrete Opportunities and ChallengesDokument22 SeitenEco Concrete Opportunities and ChallengesVinay Gupta100% (1)

- Bacterial Concrete: A Review: Pappupreethi K, Rajishavelluva AmmakunnothDokument7 SeitenBacterial Concrete: A Review: Pappupreethi K, Rajishavelluva AmmakunnothIAEME PublicationNoch keine Bewertungen

- Development of Composite Material Based On Cement and Polyethylene Tereftalate (Pet)Dokument12 SeitenDevelopment of Composite Material Based On Cement and Polyethylene Tereftalate (Pet)PauloDyerNoch keine Bewertungen

- Self Healing ConcreteDokument15 SeitenSelf Healing ConcreteJohnNoch keine Bewertungen

- Ucc 2019 205Dokument10 SeitenUcc 2019 205DeepaNoch keine Bewertungen

- From Selenium To Tellurium Based Glass Optical Fibers For Infrared SpectroscopiesDokument9 SeitenFrom Selenium To Tellurium Based Glass Optical Fibers For Infrared SpectroscopiessunitarajeshparmarNoch keine Bewertungen

- The Construction of A Footbridge Prototype With Biological Self-Healing Concrete, A Field Study in A Humid Continental Climate RegionDokument11 SeitenThe Construction of A Footbridge Prototype With Biological Self-Healing Concrete, A Field Study in A Humid Continental Climate Regionac2686Noch keine Bewertungen

- Application of Bacterial SporesDokument13 SeitenApplication of Bacterial SporesasdasdasdasNoch keine Bewertungen

- Bio ConcreteDokument3 SeitenBio ConcreteJason royNoch keine Bewertungen

- Self Healing Concretre SITDokument36 SeitenSelf Healing Concretre SITgaurav jhaNoch keine Bewertungen

- Use of Photocatalytic Products For Sustainable Construction DevelopmentDokument7 SeitenUse of Photocatalytic Products For Sustainable Construction DevelopmentMortezaNoch keine Bewertungen

- Self-Healing Concrete (Wiktor2011)Dokument8 SeitenSelf-Healing Concrete (Wiktor2011)Jhon Smit Gonzales UscataNoch keine Bewertungen

- Bacterial Carbonate Precipitation As An Alternative Surface Treatment For ConcreteDokument11 SeitenBacterial Carbonate Precipitation As An Alternative Surface Treatment For ConcreteeliNoch keine Bewertungen

- Ijciet 08 02 061Dokument8 SeitenIjciet 08 02 061Ki KiethNoch keine Bewertungen

- Ijciet 08 02 061Dokument8 SeitenIjciet 08 02 061vikasNoch keine Bewertungen

- Synopsis: Bio Materials in Design and ArchitectureDokument5 SeitenSynopsis: Bio Materials in Design and ArchitectureakshitNoch keine Bewertungen

- Industrial Crops and Products: R.M. Mors, H.M. JonkersDokument8 SeitenIndustrial Crops and Products: R.M. Mors, H.M. JonkersDaniel M-BNoch keine Bewertungen

- Sports ClubDokument1 SeiteSports ClubHilary WatsonNoch keine Bewertungen

- Journal of International Academic Research For MultidisciplinaryDokument5 SeitenJournal of International Academic Research For MultidisciplinaryHilary WatsonNoch keine Bewertungen

- VOL 4 Drawings PDFDokument17 SeitenVOL 4 Drawings PDFHilary WatsonNoch keine Bewertungen

- Effect of Delayed Oven Dried Curing On Compressive Strength of Geopolymer ConcreteDokument5 SeitenEffect of Delayed Oven Dried Curing On Compressive Strength of Geopolymer ConcreteHilary WatsonNoch keine Bewertungen

- Seismic Analysis of Single Degree of Freedom StructureDokument12 SeitenSeismic Analysis of Single Degree of Freedom StructureIAEME PublicationNoch keine Bewertungen

- Payment Approval From The World Bank UK.: These Are The Requested Information's For ClaimsDokument1 SeitePayment Approval From The World Bank UK.: These Are The Requested Information's For ClaimsHilary WatsonNoch keine Bewertungen

- Annexure 17 Tool For Rate Analysis-DI PVC HDPE MDPE Pipe Supply Laying JointingDokument8 SeitenAnnexure 17 Tool For Rate Analysis-DI PVC HDPE MDPE Pipe Supply Laying Jointinghareesh13h100% (1)

- Sizing of 125 Ton Gum Silo: ShellDokument1 SeiteSizing of 125 Ton Gum Silo: ShellHilary WatsonNoch keine Bewertungen

- Analysis & Design of Prestressed Shell Type Structure Using Finite Element MethodDokument7 SeitenAnalysis & Design of Prestressed Shell Type Structure Using Finite Element MethodHilary WatsonNoch keine Bewertungen

- Ijaerd Paper FormatDokument2 SeitenIjaerd Paper FormatHilary WatsonNoch keine Bewertungen

- Vodafone BSMP3595118071Dokument1 SeiteVodafone BSMP3595118071Hilary WatsonNoch keine Bewertungen

- Elevated Rectangular Water TankDokument3 SeitenElevated Rectangular Water TankHilary WatsonNoch keine Bewertungen

- List of Eligible Candidates For The Post of Executive (HR) : SR No. Roll No Confirmation No. NameDokument3 SeitenList of Eligible Candidates For The Post of Executive (HR) : SR No. Roll No Confirmation No. NameHilary WatsonNoch keine Bewertungen

- Geopolymer Concrete A ReviewDokument5 SeitenGeopolymer Concrete A ReviewHilary WatsonNoch keine Bewertungen

- Reactivity, Workability and Strength of Potassium Versus Sodium-Activated High Volume Fly Ash-Based GeopolymersDokument8 SeitenReactivity, Workability and Strength of Potassium Versus Sodium-Activated High Volume Fly Ash-Based GeopolymersHilary WatsonNoch keine Bewertungen

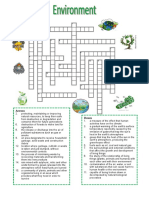

- Environment Crossword PuzzleDokument2 SeitenEnvironment Crossword Puzzleamrinarizan48Noch keine Bewertungen

- Course PDFDokument2 SeitenCourse PDFRoanne CadangNoch keine Bewertungen

- 5Rs of Waste ManagementDokument18 Seiten5Rs of Waste ManagementJan Adrielle VeniceNoch keine Bewertungen

- Reaction Paper GeologyDokument4 SeitenReaction Paper Geologyclarissa bibatNoch keine Bewertungen

- Fluvial Processes and LandformsDokument77 SeitenFluvial Processes and LandformsFa LikitswatNoch keine Bewertungen

- Learning Task 9 (Module 6)Dokument11 SeitenLearning Task 9 (Module 6)Christel Joy Dela CruzNoch keine Bewertungen

- NSTP ResearchDokument2 SeitenNSTP ResearchKaye PurificacionNoch keine Bewertungen

- Final - Building Service (Assignment)Dokument28 SeitenFinal - Building Service (Assignment)Chee Ming Lee100% (1)

- 2018 2019 Worldwide Emissions Standards Passenger Cars Light DutyDokument128 Seiten2018 2019 Worldwide Emissions Standards Passenger Cars Light DutySivakumar AmbikapathyNoch keine Bewertungen

- Brake Wear Calculation MethodologyDokument8 SeitenBrake Wear Calculation MethodologyAuwdi FernandoNoch keine Bewertungen

- Coastal Site Solutions GuideDokument35 SeitenCoastal Site Solutions GuideSandy PaceNoch keine Bewertungen

- Role of Media in Health AwarenessDokument13 SeitenRole of Media in Health AwarenessJesse JhangraNoch keine Bewertungen

- Implementation of Swachh Bharat in MysoreDokument13 SeitenImplementation of Swachh Bharat in MysoreDipyaman ChoudhuryNoch keine Bewertungen

- Estimation of Morphometric Parameters andDokument7 SeitenEstimation of Morphometric Parameters andInternational Journal of Research in Engineering and TechnologyNoch keine Bewertungen

- Sampling and Field Testing at Wastewater Treatment FacilitiesDokument11 SeitenSampling and Field Testing at Wastewater Treatment FacilitiesSundarapandiyan SundaramoorthyNoch keine Bewertungen

- Acetic AnhydrideDokument5 SeitenAcetic AnhydrideChern YuanNoch keine Bewertungen

- Daniels P., (2010) - Economics Buddhism - Part1 An Integrated Environmental Analysis Framework PDFDokument10 SeitenDaniels P., (2010) - Economics Buddhism - Part1 An Integrated Environmental Analysis Framework PDFChechoReyesNoch keine Bewertungen

- Accomplished Written Report 4Dokument3 SeitenAccomplished Written Report 4MA. CHARMIA SAMATRANoch keine Bewertungen

- Quiz-1 (Answer Key)Dokument3 SeitenQuiz-1 (Answer Key)sikicNoch keine Bewertungen

- Effects of Industrialization On Environment FinalDokument16 SeitenEffects of Industrialization On Environment FinalPranay Patil100% (3)

- Reflection Paper ScienvpDokument3 SeitenReflection Paper ScienvpAira AmorosoNoch keine Bewertungen

- International Coral Reef Symposium - Program BookDokument151 SeitenInternational Coral Reef Symposium - Program BookTheAgapeIncNoch keine Bewertungen

- ARRB Permeable Pavements 23rdDokument14 SeitenARRB Permeable Pavements 23rdPWQGroupNoch keine Bewertungen

- Aspects of The Geomorphology and Limnology of Some Molluscinhabited Freshwater Bodies in Northern NigeriaDokument10 SeitenAspects of The Geomorphology and Limnology of Some Molluscinhabited Freshwater Bodies in Northern NigeriaIOSRjournalNoch keine Bewertungen

- Safety Data Sheet For MluIDokument6 SeitenSafety Data Sheet For MluINabilahNoch keine Bewertungen

- Environmental Science Midterm Study GuideDokument15 SeitenEnvironmental Science Midterm Study GuideAshley EgglestonNoch keine Bewertungen

- If I Were Harry Potter - Task 4 School ArticelDokument2 SeitenIf I Were Harry Potter - Task 4 School ArticelFitri AfiqNoch keine Bewertungen

- Recode Case Studies For Ecological SanitationDokument20 SeitenRecode Case Studies For Ecological SanitationMolly DanielssonNoch keine Bewertungen

- BisleriDokument6 SeitenBisleriMonika SinhaNoch keine Bewertungen

- 7 Ways To Protects The EnvironmentDokument16 Seiten7 Ways To Protects The EnvironmentHikariNoch keine Bewertungen

- Process Plant Equipment: Operation, Control, and ReliabilityVon EverandProcess Plant Equipment: Operation, Control, and ReliabilityBewertung: 5 von 5 Sternen5/5 (1)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresVon EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresBewertung: 1 von 5 Sternen1/5 (2)

- Piping Engineering Leadership for Process Plant ProjectsVon EverandPiping Engineering Leadership for Process Plant ProjectsBewertung: 5 von 5 Sternen5/5 (1)

- Well Control for Completions and InterventionsVon EverandWell Control for Completions and InterventionsBewertung: 4 von 5 Sternen4/5 (10)

- To Engineer Is Human: The Role of Failure in Successful DesignVon EverandTo Engineer Is Human: The Role of Failure in Successful DesignBewertung: 4 von 5 Sternen4/5 (138)

- Sodium Bicarbonate: Nature's Unique First Aid RemedyVon EverandSodium Bicarbonate: Nature's Unique First Aid RemedyBewertung: 5 von 5 Sternen5/5 (21)

- An Applied Guide to Water and Effluent Treatment Plant DesignVon EverandAn Applied Guide to Water and Effluent Treatment Plant DesignBewertung: 5 von 5 Sternen5/5 (4)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersVon EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNoch keine Bewertungen

- Guidelines for Chemical Process Quantitative Risk AnalysisVon EverandGuidelines for Chemical Process Quantitative Risk AnalysisBewertung: 5 von 5 Sternen5/5 (1)

- Onshore Structural Design Calculations: Power Plant and Energy Processing FacilitiesVon EverandOnshore Structural Design Calculations: Power Plant and Energy Processing FacilitiesBewertung: 4.5 von 5 Sternen4.5/5 (13)

- Bridge Engineering: Classifications, Design Loading, and Analysis MethodsVon EverandBridge Engineering: Classifications, Design Loading, and Analysis MethodsBewertung: 4 von 5 Sternen4/5 (16)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsVon EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNoch keine Bewertungen

- Lees' Process Safety Essentials: Hazard Identification, Assessment and ControlVon EverandLees' Process Safety Essentials: Hazard Identification, Assessment and ControlBewertung: 4 von 5 Sternen4/5 (4)

- Structural Cross Sections: Analysis and DesignVon EverandStructural Cross Sections: Analysis and DesignBewertung: 4.5 von 5 Sternen4.5/5 (19)

- Troubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersVon EverandTroubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Distillation Design and Control Using Aspen SimulationVon EverandDistillation Design and Control Using Aspen SimulationBewertung: 5 von 5 Sternen5/5 (2)

- Fundamentals of Risk Management for Process Industry EngineersVon EverandFundamentals of Risk Management for Process Industry EngineersNoch keine Bewertungen

- Advanced Modelling Techniques in Structural DesignVon EverandAdvanced Modelling Techniques in Structural DesignBewertung: 5 von 5 Sternen5/5 (3)

- The Perfumed Pages of History: A Textbook on Fragrance CreationVon EverandThe Perfumed Pages of History: A Textbook on Fragrance CreationBewertung: 4 von 5 Sternen4/5 (1)

- Handbook of Cosmetic Science: An Introduction to Principles and ApplicationsVon EverandHandbook of Cosmetic Science: An Introduction to Principles and ApplicationsH. W. HibbottBewertung: 4 von 5 Sternen4/5 (6)

- Fun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksVon EverandFun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksNoch keine Bewertungen

- Fun Facts about Carbon : Chemistry for Kids The Element Series | Children's Chemistry BooksVon EverandFun Facts about Carbon : Chemistry for Kids The Element Series | Children's Chemistry BooksNoch keine Bewertungen