Beruflich Dokumente

Kultur Dokumente

Gpu Yamaha Edl20000te, Edl26000te - q9c 28197 E0

Hochgeladen von

Moni Gote del OrtusOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Gpu Yamaha Edl20000te, Edl26000te - q9c 28197 E0

Hochgeladen von

Moni Gote del OrtusCopyright:

Verfügbare Formate

SUPPLEMENTARY SERVICE MANUAL

WARNING

CAUTION:

NOTE:

FOREWORD

This Supplementary Service Manual has been

prepared to introduce electrical new service

and electrical new data for the EDL20000TE,

EDL26000TE. For complete information, on

service procedures, it is necessary to use this

Supplementary Service Manual together with

diesel engine workshop manual:

DIESEL ENGINE WORKSHOP MANUAL:

(97897-01644) E.F.D. June 2002

NOTICE

This manual was written by the Yamaha Motor

Company primarily for use by Yamaha dealers

and their qualified mechanics. It is not possible

to put an entire mechanics education into one

manual, so it is assumed that persons using this

book to perform maintenance and repairs on

Yamaha generators have a basic understand-

ing of the mechanical concepts and procedures

inherent in generators repair. Without such

knowledge, attempted repairs or service to this

model may render it unfit to use and/ or unsafe.

Yamaha Motor Company, Ltd. is continually

striving to improve all models manufactured by

Yamaha. Modifications and significant changes

in specifications or procedures will be for-

warded to all Authorized Yamaha dealers and

will, where applicable, appear in future editions

of this manual.

OE022

EDL20000TE, EDL26000TE

SUPPLEMENTARY SERVICE MANUAL

2002 by Yamaha Motor Co., Ltd.

1st Edition, September 2002

All rights reserved. Any reprinting or

unauthorized use without the written

permission of Yamaha Motor,

Co., Ltd. is expressly prohibited.

Printed in Japan.

HOW TO USE THIS MANUAL

Particularly important information is distin-

guished in this manual by the following nota-

tions:

The Safety Alert Symbol means ATTENTION!

BE ALERT!

YOUR SAFETY IS INVOLVED!

Failure to follow WARNING instructions could

result in severe injury or death to the machine

operator, a bystander, or a person inspecting or

repairing the machine.

A CAUTION indicates special precautions that

must be taken to avoid damage to the machine.

A NOTE provides key information that can

make procedures easier or clearer.

MANUAL FORMAT

All of the procedures in this manual are orga-

nized in a sequential, step-by-step format. The

information has been compiled to provide the

mechanic with an easy to read, handy reference

that contains comprehensive explanations of all

inspection, repair, assembly, and disassembly

operations.

If this revised format, the condition of a faulty

component will precede an arrow symbol and

the course of action required to correct the prob-

lem will follow the symbol, e.g.,

S Bearings

Pitting/ Damage ! Replace.

EXPLODED DIAGRAM

Each chapter provides exploded diagrams be-

fore each disassembly section to facilitate cor-

rect disassembly and assembly procedures.

CONTENTS

ELECTRICAL

GENERATOR ASSEMBLY 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHECKING OUTPUT VOLTAGE OF STATOR COIL 2 . . . . . . . . . . . . .

CHECKING EXCITER FIELD COIL RESISTANCE 3 . . . . . . . . . . . . . . .

CHECKING STATOR COIL RESISTANCE 3 . . . . . . . . . . . . . . . . . . . . . .

CHECKING OUTPUT VOLTAGE DETECTION CIRCUIT

RESISTANCE 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ROTOR FIELD COIL RESISTANCE 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EXCITER COIL RESISTANCE 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERATOR (EDL20000TE) 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

POWER SOURCE (EDL20000TE) 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERATOR (EDL26000TE) 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

POWER SOURCE (EDL26000TE) 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CONTROL FUNCTION 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CONTROL BOX 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.C OUTPUT TERMINAL 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PANEL WIRING DIAGRAM (380/ 220 V) 13 . . . . . . . . . . . . . . . . . . . . . . .

PANEL WIRING DIAGRAM (220/ 127 V) 14 . . . . . . . . . . . . . . . . . . . . . . .

WIRING DIAGRAM (380/ 220 V) 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WIRING DIAGRAM (220/ 127 V) 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WIRING DIAGRAM (D.C 12 V) 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERATOR TROUBLESHOOTING 18 . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE CAN BE STARTED AND NO OUTPUT VOLTAGE 18 . . .

DIFFICULT TO TAKE OFF OUTPUT VOLTAGE

CONTINUOUSLY 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TROUBLESHOOTING 19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL INFORMATION

MACHINE IDENTIFICATION 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERIAL NUMBER 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STARTING SERIAL NUMBER 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PERIODIC INSPECTIONS AND ADJUSTMENTS

INTRODUCTION 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PERIODIC MAINTENANCE/ LUBRICATION INTERVALS 22 . . . . . . . .

SPECIAL TOOLS/ TESTERS 23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIAL TOOLS 23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TESTERS 24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PISTON RING COMPRESSOR 24 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OIL/ FUEL FILTER WRENCH 25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EDL20000TE SPECIFICATIONS 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL SPECIFICATIONS 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE SERVICE DATA 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERATOR SERVICE DATA 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EDL26000TE SPECIFICATIONS 28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL SPECIFICATIONS 28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE SERVICE DATA 29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERATOR SERVICE DATA 29 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WIRING DIAGRAM (380-220 V/ 50Hz) 30 . . . . . . . . . . . . . . . . . . . . . . . . .

WIRING DIAGRAM (220-127 V/ 60Hz) 32 . . . . . . . . . . . . . . . . . . . . . . . . .

1

Order Job/ Part Qty Remarks

Disassembling the generator

Bracket

EX field coil assembly

Cover

Stator assembly

Bearing

Rectifier assembly

Rotor assembly

1

1

1

1

1

1

1

1

2

3

4

5

6

7

ELECTRICAL

GENERATOR ASSEMBLY

2

CAUTION:

CHECKING OUTPUT VOLTAGE

OF STATOR COIL

When the alternator is revolved at 3000

r/ min. (50 Hz)/ 3600 r/ min. (60 Hz) with DC

12 V connected on the exciter field coil (F+)

(F).

Terminals Generated voltage

(U) (V)

(V) (W)

(W) (U)

380/ 220 V model:

Approx. 480 V

220/ 127 V model:

Approx. 290 V

(O) (U)

(O) (V)

(O) (W)

380/ 220 V model:

Approx. 277 V

220/ 127 V model:

Approx. 170 V

To perform this test, remove A.V.R.

When the alternator is revolved at 3000

r/ min. (50 Hz)/ 3600 r/ min. (60 Hz) with

A.V.R and other lead wire disconnected.

Terminals Generated voltage

(U) (V)

(V) (W)

(W) (U)

380/ 220 V model:

Approx. 90 V

220/ 127 V model:

Approx. 50 V

(O) (U)

(O) (V)

(O) (W)

380/ 220 V model:

Approx. 52 V

220/ 127 V model:

Approx. 29 V

3

CHECKING EXCITER FIELD

COIL RESISTANCE

Check the resistance between (F+) (F)

terminals in the control panel.

Resistance (@ 20_C)

24.90 (22.41 X 27.39 )

Out of specification ! Repair wiring or re-

place the coil.

CHECKING STATOR COIL

RESISTANCE

Check the resistance between (U) (V), (V)

(W), (W) (U) terminals in the control pan-

el.

Resistance (@ 20_C)

EDL20000TE: 0.97 (0.87 X 1.07 )

EDL26000TE: 0.62 (0.55 X 0.69 )

Out of specification ! Repair wiring or re-

place the coil.

CHECKING OUTPUT VOLTAGE

DETECTION CIRCUIT

RESISTANCE

Check the resistance between (3) (4) ter-

minals in the control panel.

Resistance (@ 20_C)

EDL20000TE: 0.24 (0.21 X 0.27 )

EDL26000TE: 0.16 (0.14 X 0.18 )

Out of specification ! Repair wiring or re-

place stator coil.

ROTOR FIELD COIL

RESISTANCE

Check the resistance between two terminals

on the rotor.

Resistance (@ 20_C)

EDL20000TE: 9.35 (8.42 X 12.24 )

EDL26000TE: 10.90 (9.81 X 14.27 )

Out of specification ! Replace the rotor as-

sembly.

4

A

B

C

EXCITER COIL RESISTANCE

Check the resistance between (U) (V), (V)

(W), (W) (U) terminals on the rotor.

Resistance (@ 20_C)

0.713 (0.64 X 0.79 )

Out of specification ! Replace the rotor as-

sembly.

A (U) (V)

B (V) (W)

C (W) (U)

1 (U) terminal

2 (V) terminal

3 (W) terminal

5

GENERATOR (EDL20000TE)

Unit EDL20000TE

A.C Output:

Rated Voltage V 380/ 220 220/ 127

Type Brush-less A.C generator self-exciting

Frequency Hz 50 60

Rated output KVA (kW) 15.5 (12.4) 17.5 (14.0)

Maximum output KVA (kW) 17.0 (13.6) 19.0 (15.2)

Rated voltage V 380/ 220 220/ 127

Rated current A 23.6 45.9

Number of pole 2

Phase 3 phase 4 wire

Excitation method Self-excitation with magnetized

Voltage regulator A.V.R. (Automatic Voltage Regulator)

Power factor 0.8

Driving method Direct coupling

Safety device (type) N.F.B. (Non Fuse Breaker)

N.F.B capacity A 25 45

A.C Output method Terminal

Recommended battery capacity V/ Ah 12/ 65 (65B26R)

Voltage fluctuation % Less than 2.5

Frequency fluctuation % Less than 5

POWER SOURCE (EDL20000TE)

Frequency Power Source

Max. power take off

Frequency Power Source

EDL20000TE

60 Hz 220 V 17500VA

50 Hz 380 V 15500VA

60 Hz 127 V 5800 W

50 Hz 220 V 5100 W

60 Hz 220 V 10000 W

50 Hz 380 V 8900 W

6

GENERATOR (EDL26000TE)

Unit EDL26000TE

A.C Output:

Rated Voltage V 380/ 220 220/ 127

Type Brush-less A.C generator self-exciting

Frequency Hz 50 60

Rated output KVA (kW) 21.0 (16.8) 24.0 (19.2)

Maximum output KVA (kW) 23.0 (18.4) 26.0 (20.8)

Rated voltage V 380/ 220 220/ 127

Rated current A 31.9 63

Number of pole 2

Phase 3 phase 4 wire

Excitation method Self-excitation with magnetized

Voltage regulator A.V.R. (Automatic Voltage Regulator)

Power factor 0.8

Driving method Direct coupling

Safety device (type) N.F.B. (Non Fuse Breaker)

N.F.B capacity A 32 63

A.C Output method Terminal

Recommended battery capacity V/ Ah 12/ 70 (75B31R)

Voltage fluctuation % Less than 2.5

Frequency fluctuation % Less than 5

POWER SOURCE (EDL26000TE)

Frequency Power Source

Max. power take off

Frequency Power Source

EDL26000TE

60 Hz 220 V 24000VA

50 Hz 380 V 21000VA

60 Hz 127 V 8000 W

50 Hz 220 V 7000 W

60 Hz 220 V 13800 W

50 Hz 380 V 12000 W

7

CONTROL FUNCTION

1 Fuel tank cap

2 Control box

3 Radiator

4 Oil drain plug

5 Fuel filter

6 Generator assembly

7 Fuel tank

8 Fuel gauge

9 Battery housing

10 Battery (Not included in the package)

11 Oil filter

12 Reserve tank

13 A.C output terminal

14 Oil filler cap

15 Exhaust outlet

16 Air filter

17 Fuel cock

8

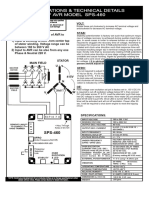

CONTROL BOX

1 Warning lamp

2 Voltage meter

3 Frequency meter

4 Ampere meter

5 Pilot lamp

6 Key switch

7 Voltage adjuster

8 Hour meter

9 A.C switch (N.F.B)

10 A.C output terminals

9

Order Job/ Part Qty Remarks

Disassembly control box

Panel

Panel

Panel cover

Panel cover

Key switch

Voltage adjuster

A.C switch (N.F.B)

Pilot lamp

Ampere meter

Frequency meter

Voltage meter

Hour meter

Warning lamp

A.V.R

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

10

Order Job/ Part Qty Remarks

Fuse holder

Fuse holder

Terminal 2

Terminal 1

Lamp timer

Timer relay

1

1

1

1

1

1

15

16

17

18

19

20

11

Order Job/ Part Qty Remarks

Disassembly A.C output terminal

Panel

Terminal

Cover

Cover

1

4

1

1

1

2

3

4

A.C OUTPUT TERMINAL

12

1 Warning lamp

2 Key switch

3 Fuse holder

4 A.V.R.

5 Terminal 1

6 Lamp timer

7 Timer relay

8 Terminal 2

9 A.C switch (N.F.B.)

10 Pilot lamp

11 Ampere meter

12 Frequency meter

13 Hour meter

14 Voltage meter

15 Voltage adjuster

13

3

0

5

0

A

C

1

9

1

2

3

4

5

6

7

8

4 5 6

321

2 4

31

F

-

F

+

4

3

2

0

0

E

3

2

0

0

3

O

W

V

U

G

1

.2

5

W

1

.2

5

R

2

W

/B

1

.2

5

G

1

.2

5

B

1

.2

5

B

1

.2

5

G

/W

1

.2

5

Y

1

.2

5

Y

3

L

1

.2

5

L

1

.2

5

Y

1

.2

5

R

3

W

/R

1

.2

5

R

1

.2

5

-4

S

Y1.2 5

Y1.2 5 Y1.2 5

R 1 . 2 5

R

1

.2

5

-4

R

1

.2

5

-4

R1.2 5 - 4 S

L M F C

W

/R

1

.2

5

R1.2 5 - 4

R

1

.2

5

-6

T

M

E

D

6

3

0

8

2

0

F

6

7

R

1

.2

5

-4

R

1

.2

5

-3

R 1 . 2 5

L 1 . 2 5

Y 1 . 2 5

Y 1 . 2 5

L 1 . 2 5

W 1 . 2 5

W 1 . 2 5

L

M

F

C

L M F C

B

/R

1

.2

5

R

1

.2

5

G

/W

1

.2

5

G

/B

1

.2

5

W

/B

1

.2

5

L

1

.2

5

L

1

.2

5

G

/R

1

.2

5

W

/G

1

.2

5

R

1

.2

5

W 1 . 2 5

R 1 . 2 5

Y 1 . 2 5

Y

3

W

1

. 2

5

Y

1

. 2

5

P

1

. 2

5

R

1

. 2

5

G

Y

1

. 2

5

O

1

. 2

5

B

R

1

. 2

5

P

1

. 2

5

U

A

A

VW

U

N

.

F

.

B

A

.

V

.

R

VW

1

A

1

A

1

A

1

A

1

A

1

A

1

A

1

A

2

A

-+

B

B

PANEL WIRING DIAGRAM (380/220 V)

14

R 1 . 2 5

R

1

.2

5

-4

R

1

.2

5

-4

R

1

.2

5

-6

R

1

.2

5

-4

R 1 . 2 5

L 1 . 2 5

Y 1 . 2 5

Y 1 . 2 5

L 1 . 2 5

W 1 . 2 5

W 1 . 2 5

G

1

.2

5

W

1

.2

5

-+ T

M

E

D

6

3

0

8

2

0

F

R

1

.2

5

-3

L

1

.2

5

L

1

.2

5

1

2

3

4

5

6

7

8

3

0

5

0

A

C

1

9

Y

3

L

1

.2

5

L

1

.2

5

Y

1

.2

5

R

3

W

/R

1

.2

5

Y1.2 5

Y1.2 5 Y1.2 5

R1.2 5 - 4 S

R1.2 5- 4

G

/B

1

.2

5

1

A

1

A

1

A

1

A

1

A

1

A

1

A

1

A

2

A

W

/B

1

.2

5

L

1

.2

5

Y 1 . 2 5

F

-

F

+

4

3

2

0

0

E

3

R

1

.2

5

-4

S

Z

P

1

. 2

5

. 2

5P

1

. 2

5

W

1

. 2

5

Y

1

. 2

G

Y

1

. 2

5

O

1

. 2

5

B

R

1

. 2

5

R

1

5

4 5 6

321

B

1

.2

5

G

/W

1

.2

5

Y

1

.2

5

W

/R

1

.2

5

2 4

31

2

0

0

3

O

W

V

U

R

2

W

/B

1

.2

5

G

1

.2

5

B

1

.2

5

L

M

F

C

W 1 . 2 5

R 1 . 2 5

B

/R

1

.2

5

R

1

.2

5

G

/R

1

.2

5

W

/G

1

.2

5

R

1

.2

5

Y

3

L M F C

L M F C

G

/W

1

.2

5

B

B

U

A

A

VW

UV

N

.

F

.

B

A

.

V

.

R

W

PANEL WIRING DIAGRAM (220/127 V)

15

E

X

.

2

A

1

H

z

V

R

E

2

0

0

34

F

-

F

+

R

O

R

YW

G

L

R

O

R

YW

G

L

B

R

6 7

P P

L

A

V

UV

W

O

UV

W

O

k

l

K

L

6

234

5

7

1

4

1

2

1

1

1

0

9

8

1

3

1

5

WIRING DIAGRAM (380/220 V)

16

E

X

.

2

A

2

A

H

z

L

A

k

l

K

L

VV

R

UV

W

O

UV

W

O

E

2

0

0

34

F

-

F

+

R

O

R

YW

G

L

R

O

R

YW

G

L

B

R

6 7

P P

6

2

1

34

5

7

1

4

1

2

1

1

1

0

9

8

1

3

1

5

WIRING DIAGRAM (220/127 V)

17

W

a

t

e

r

t

e

m

p

e

r

a

t

u

r

e

l

a

m

p

O

i

l

p

r

e

s

s

u

r

e

l

a

m

p

B

a

t

t

e

r

y

c

h

a

r

g

e

l

a

m

p

G

l

o

w

l

a

m

p

B

A

C

1

9

5

0

O

F

F

O

N

G

L

O

W

S

T

A

R

T

M L F C 2 2

M L F C 2 2

S

T

B

R

3

1 A

1 A

1 A

1 A

1 A

1 A

1 A

B

A

C

5

0

1

9

6

5

4

3

2

1

3

4

1

2

M

4

M

8

M

6

L

I

G

Y

3

M

4

B

B

Y

Y

Y

Y

Y

Y

W

/

R

W

/

R

L

L

L

2

R

3

R

3

R

2

R

2

W

/

B

R

B

/

R

W

/

B

L

2

R

2

R

2

L

2

R

L

2

G

G

B

/

R

R

G

/

L

W

G

/

W

Y

G

/

W

Y

W

/

R

W

L

2

W

/

B

W

/

B

G

/

W

R

W

/

R

G

/

L

G

/

R

W

/

G

W

/

G

G

/

R

Y

3

L

2

Y

1 A

1

7

1

6

2

9

1

8

1

9

2

7

2

0

2

1

2

2

2

3

2

4

2

5

2

8

2

6

WIRING DIAGRAM (D.C 12 V)

18

GENERATOR TROUBLESHOOTING

ENGINE CAN BE STARTED AND NO OUTPUT VOLTAGE

Phenomena Check point Cause Remedy

DVolt meter

i di ti i OK

No output voltage

t t t t i l

N.F.B position Position is OFF Set to ON

indication is OK

and pilot lamp is

at output terminals

N.F.B operation (shutting off

t ti ll )

Overloaded Connecting less load

and ilot lam is

ON.

automatically)

Inspect a short circuit

Continuity of N.F.B No continuity: Defective

N.F.B

Replace N.F.B

Continuity: Output terminal

is OK.

Wire lead connected to (U)

or (O) is broken. (Volt meter

is connected to (V) and (W).)

Inspect the wiring at control

panel.

Continuity: Defective output

terminal

Replace the terminal

There is out put

voltage at output

t i l

Connected terminal or

receptacle at the load

No voltage: Defective

extension cord

Inspect or replace the

extension cord

terminals.

There is voltage: Detective

load equipment

Inspect or repair the load

equipment

DVolt meter

i di ti

Low voltage Fuse from stator Fuse is burned out Replace the fuse

indication

Defective A.V.R Replace A.V.R

Rotor field coil and exciter

coil (U)-(V), (V)-(W), (W)-(U)

Coil is broken or burnt Repair or replace the coil

Exciter Field Coil (F+)-(F) Coil is broken or burnt Repair or replace the coil

Rectifier Defective Rectifier Repair or replace the

rectifier

Fuse for A.V.R Fuse is burned out Replace the fuse

No voltage (0 V)

No residual magnetism on

the rotor.

Excite the field coil manually

by connecting battery

voltage.

Main Coil (Stator) Main Coil (Stator) is broken. Replace the stator

Wiring between alternator

and output terminals

Defective wire Repair or replace

DIFFICULT TO TAKE OFF OUTPUT VOLTAGE CONTINUOUSLY

Phenomena Check point Cause Remedy

DN.F.B shut off

automatically

Output voltage is

normal

Connected load Overloaded Connecting less load

Output voltage is

high

Terminal connection on

A.V.R

Improper connection on

A.V.R

Repair or replace the

connection

Detective A.V.R Replace A.V.R

Wiring and connection Wrong connection Connect rightly.

DLess output than

t d t t

Engine revolution

i l

Lead wire on A.V.R Wire is broken Repair or replace the wire.

rated output is normal.

Terminal connection on

A.V.R

Improper connection on

A.V.R

Repair or replace the

connection

Unstable engine

l ti

Rotor bearing Defective bearing Replace bearing

revolution

Lower engine power Inspect and repair the

engine

Governor of injection pump Defective governor function Inspect and repair the

governor system

Unstable load

DConnected load

equipment

DAlternator

Inspect load equipment.

Inspect and repair the

alternator

Engine revolution Lower engine revolution Adjust to rated engine

revolution

Low voltage Defective A.V.R Replace A.V.R

Fuse for A.V.R Fuse is burned out Replace the fuse

Fuse from stator FUse is burned out Replace the fuse

Exciter Field Coil (F+)-(F) Coil is broken or burnt Repair or replace the coil

Rotor filed coil and exciter

coil (U)-(V), (V)-(W), (W)-(U)

Coil is broken or burnt Repair or replace the coil

19

TROUBLESHOOTING

20

21

NOTE:

NOTE:

GENERAL INFORMATION

MACHINE IDENTIFICATION

SERIAL NUMBER

The serial number is stamped label 1 which

is affixed to the generator as shown.

The first three characters of this number are

for model identification, the remaining digits

are the unit production number.

STARTING SERIAL NUMBER

EDL 20000TE (380 220 V/ 50 Hz)

Q9C2 800101 X . . . .

EDL20000TE (220 127 V/ 60Hz)

Q9C2 700101 X . . . .

EDL 26000TE (380 220 V/ 50Hz)

Q9C3 800101 X . . . .

EDL 26000TE (220 127 V/ 60Hz)

Q9C3 700101 X . . . .

Designs and specifications are subject to

change without notice.

22

PERIODIC INSPECTIONS AND ADJUSTMENTS

INTRODUCTION

This chapter includes all information necessary to perform recommended inspections and adjust-

ments. These preventive maintenance procedures, if followed, will ensure more reliable machine op-

eration and a longer service life. The need for costly overhaul work will be greatly reduced. This in-

formation applies to machines already in service as well as new machines that are being prepared for

sale. All service technicians should be familiar with this entire chapter.

PERIODIC MAINTENANCE/LUBRICATION INTERVALS

Item Remarks

PreOpera-

tion check

(daily)

Initial

50 Hr

Every

100 Hr

Every

200 Hr

Every

500 Hr

Engine Oil:

Check oil level. F

Engine Oil:

Replace. F F

Engine Oil Filter

Cartridge:

Replace. F

Air Filter:

Clean.

Replace if necessary.

F

Clean fuel cock and fuel tank filter. F

Fuel Filter:

Replace.

F

(400 Hr)

Check coolant level and leaks. F

Clean radiator fin. F

Check fan belt tension. F

C li S t

Replace fan belt. F

Cooling System:

Check radiator hose and clamps.

Replace if necessary.

F

F

Replace

(2 years)

Replace coolant; Clean radiator.

F

(2 years)

Valve Clearance: Check and adjust when engine is cold.

F

(800 Hr)

Fuel Line:

Check fuel hose for cracks or damage.

Replace if necessary.

F

F

Replace

(2 years)

Fuel Tank: Check and remove sediment. F

Injection Nozzle: Check and clean. Adjust if necessary.

F

(1500 Hr)

Exhaust System:

Check for leakage.

Retighten or replace gasket if necessary.

F

Starting System: Check operation. F

Decarbonization: More frequently if necessary. F

Generator: Check the pilot light turns on. F

Check battery fluid level. Add distilled

water.

F

Battery:

Check specific gravity and breather pipe

operation. Correct if necessary.

F

Replace

battery af-

ter 2 years.

Fittings/Fasteners:

Check all fittings and fasteners.

Correct if necessary.

F

23

SPECIAL TOOLS/TESTERS

SPECIAL TOOLS

No special tools have been made. Make

them by referring to the following figures.

Valve guide replacing tool

Application: Use to press out and press fit

the valve guide.

Crankshaft bearing 1 replacing tool

Application: Use to press out the crankshaft

bearing 1.

S Indication without [ ]: When press out or

same as press fit.

S Indication with [ ]: When press fit.

Governor gear holder bushing replacing

tool

Application: Use to press out and press fit

the crankshaft bearing 1.

Bushing replacing tool

Application: Use to press out and to press fit

the bushing.

S Indication without [ ]: For small end

bushing.

S Indication with [ ]: For idle gear bushing.

24

Flywheel stopper

Application: Use to loosen and tighten the

flywheel screw.

TESTERS

There are no testers only for use with the die-

sel engine (D722)

Purchase commercially available testers

1 Diesel engine compression tester

2 Engine oil pressure tester

3 Injection nozzle tester

4 Radiator tester

5 Valve seat cutter set

6 Engine oil filter wrench

Injection pump pressure tester

Make this tester by referring to the following

figure.

Application: Use to check the fuel tightness.

A Pressure gauge full scale: more than

29.4 MPa (300 kgf / cm

2

, 4267 psi)

B Copper gasket

C Flange (Material: Steel)

D Hex. Nut, 27 mm (1.06 in.) across the flat

(Material: Steel)

E Injection pipe

a Adhesive application

b Fillet welding on the enter circumference

PISTON RING COMPRESSOR

1 Piston ring compressor

90890-05158 H19 (50 X 90 mm)

25

OIL/ FUEL FILTER WRENCH

1 Oil filter / Fuel filter (80)

2 Wrench

26

EDL20000TE SPECIFICATIONS

GENERAL SPECIFICATIONS

DIMENSIONS

UNIT 380-220 V/ 50 Hz 220-127 V/ 60 Hz

Overall length Overall width

Overall height

mm 1380 700 945

Dry weight kg 340

ENGINE

Type

Vertical, Liquid cooled,

4cycle diesel engine

Total displacement cm

3

1001

Number of cylinder-Bore Stroke mm 3 76 73.6

Compression ratio 23 : 1

Rated output kW (PS) / rpm 14.0 (19.0) / 3000 16.5 (22.5) / 3600

Operating hours Hr 17 14.8

Cooling system Pressurized Radiator, Forced circulation with water pump

Cooling water (coolant) capacity 5.1 (Radiator: 2.0 + cylinder block: 3.1)

Fuel Automobile Type Diesel fuel No.2-D (ASTMD975)

Fuel tank capacity (Full) 80

Engine oil grade API service CD or CE, SAE: 10W30

Engine oil capacity 5.1

Lubrication system Forced lubrication with trochoide pump

Air cleaner type Filter-paper cyclone

Starting system Electric starter (with glow plug)

Noise level

Measured at rated operation

from 7 m distance

db A 79 83

GENERATOR

Type Brush-less AC generator self-exciting

Frequency Hz 50 60

Rated output KVA (kW) 15.5 (12.4) 17.5 (14.0)

Maximum output KVA (kW) 17.0 (13.6) 19.0 (15.2)

Rated voltage V 380/ 220 220/ 127

Rated current A 23.6 45.9

Number of pole 2

Phase 3 phase 4 wire

Excitation method Self-excitation with magnetized

Voltage regulator A.V.R. (Automatic Voltage Regulator)

Power factor 0.8

Driving method Direct coupling

Safety device (type) N.F.B. (Non Fuse Breaker)

N.F.B. capacity A 25 45

AC Output method Terminal

Recommended battery capacity V/ Ah 12/ 65 (65B26R)

Voltage fluctuation % Less than 2.5

Frequency fluctuation % Less than 5

27

- U V

- V W

- W U

-

U V

-

F+ F-

-

V W

-

W U

-

O U

-

O V

-

O W

ENGINE SERVICE DATA

UNIT 380-220 V/ 50 Hz 220-127 V/ 60 Hz

Model D1005

Type Vertical Liquid cooled 4-cycle diesel engine

Number of cylinders 3

Bore Stroke mm 76 73.6

Total displacement cm

3

1001

Rated output kW (PS) / rpm 14.0 (19.0) / 3000 16.5 (22.5) / 3600

Idling speed (without the load) rpm 3850

Combustion chamber Spherical type (E-TVCS), Indirect injection

Fuel injection pump BOSCH MD type mini. pump

Governor Centrifugal Ball Mechanical Governor

Direction of rotation Counter-clockwise (viewed from flywheel)

Injection nozzle BOSCH DN-0PD mini. Nozzle, Throttle type

Injection timing 19_ before T.D.C.

Injection order 123

Injection pressure Mpa (kg/ cm

2

) 13.73 (140)

Compression ratio 23 : 1

Lubrication system Forced lubrication with trochoid pump

Oil Pressure Indication Electrical Type Switch

Lubricating filter Full Flow Paper Filter (Cartridge Type)

Cooling system Pressurized Radiator, Forced circulation with water pump.

Starting system

Electric starter

Starting system

V-kW 12-1.0

Starting support device by Glow Plug in Combustion Chamber

Recommended battery capacity V/ Ah 12/ 65 (65B26R)

Generator for Battery charging V-W 12-480

Fuel Automobile Type Diesel fuel No.2-D (ASTMD975)

Engine oil API service CD or CE, SAE: 10W-30

Engine oil capacity 5.1

Weight kg 89 (Only engine)

Application General Power Source

Fuel consumption ratio g/ kWSh (g/ PSSh) 285 (210)

Cooling water (coolant) capacity 5.1 (Radiator: 2.0 + Cylinder block: 3.0)

Reservoir tank capacity Upper level: 0.6, Lower level: 0.1

Ambient temperature range _C (_F) 15 X 40 (5 X 104)

GENERATOR SERVICE DATA

380-220 V/ 50Hz 220-127 V/ 60Hz

Coil resistance ( 10% at 20_C)

Stator Main coil

Rotor Main field coil

Rotor Exciter armature coil U-V, V-W, W-U

Exciter field coil

0.97

0.97

0.97

9.35

0.713

24.90

0.24

0.24

0.24

9.35

0.713

24.90

Stator main coil generated voltage (AC-V)

S Without A.V.R. (Disconnected all lead wire)

S Engine should be operated at rated speed.

D , ,

D , ,

Approx. 90

Approx. 52

Approx. 50

Approx. 29

28

EDL26000TE SPECIFICATIONS

GENERAL SPECIFICATIONS

DIMENSIONS

UNIT 380-220 V/ 50 Hz 220-127 V/ 60 Hz

Overall length Overall width

Overall height

mm 1380 700 945

Dry weight kg 380

ENGINE

Type

Vertical, Liquid cooled,

4cycle diesel engine

Total displacement cm

3

1335

Number of cylinder-Bore Stroke mm 4 76 73.6

Compression ratio 23 : 1

Rated output kW (PS) / rpm 18.8 (25.5) / 3000 22.0 (30.0) / 3600

Operating hours Hr 12.9 11.1

Cooling system Pressurized Radiator, Forced circulation with water pump

Cooling water (coolant) capacity 6.0 (Radiator: 2.0 + cylinder block: 4.0)

Fuel Automobile Type Diesel fuel No.2-D (ASTMD975)

Fuel tank capacity (Full) 80

Engine oil grade API service CD or CE, SAE: 10W30

Engine oil capacity 6.0

Lubrication system Forced lubrication with trochoide pump

Air cleaner type Filter-paper cyclone

Starting system Electric starter (with glow plug)

Noise level

Measured at rated operation

from 7 m distance

db A 81 85

GENERATOR

Type Brushless AC generator self-exciting

Frequency Hz 50 60

Rated output KVA (kW) 21.0 (16.8) 24.0 (19.2)

Maximum output KVA (kW) 23.0 (18.4) 26.0 (20.8)

Rated voltage V 380/ 220 220/ 127

Rated current A 31.9 63

Number of pole 2

Phase 3 phase 4 wire

Excitation method Self-excitating with magnetized

Voltage regulator A.V.R. (Automatic Voltage Regulator)

Power factor 0.8

Driving method Direct coupling

Safety device (type) N.F.B. (Non Fuse Breaker)

N.F.B. capacity A 32 63

AC Output method Terminal

Recommended battery capacity V/ Ah 12/ 70 (75B31R)

Voltage fluctuation % Less than 2.5

Frequency fluctuation % Less than 5

29

- U V

- V W

- W U

-

U V

-

F+ F-

-

V W

-

W U

-

O U

-

O V

-

O W

ENGINE SERVICE DATA

UNIT 380-220 V/ 50 Hz 220-127 V/ 60 Hz

Model V1305

Type Vertical Liquid cooled 4-cycle diesel engine

Number of cylinders 4

Bore Stroke mm 76 73.6

Total displacement cm

3

1335

Rated output kW (PS) / rpm 18.8 (25.5) / 3000 22.0 (30.0) / 3600

Idling speed (without the load) rpm 3850

Combustion chamber Spherical type (E-TVCS), Indirect injection

Fuel injection pump BOSCH MD type mini. pump

Governor Centrifugal Ball Mechanical Governor

Direction of rotation Counter-clockwise (viewed from flywheel)

Injection nozzle BOSCH DN-0PD mini. Nozzle, Throttle type

Injection timing 19_ before T.D.C.

Injection order 1342

Injection pressure Mpa (kg/ cm

2

) 13.73 (140)

Compression ratio 23 : 1

Lubrication system Forced lubrication with trochoid pump

Oil Pressure Indication Electrical Type Switch

Lubricating filter Full Flow Paper Filter (Cartridge Type)

Cooling system Pressurized Radiator, Forced circulation with water pump.

Starting system

Electric starter

Starting system

V-kW 12-1.2

Starting support device by Glow Plug in Combustion Chamber

Recommended battery capacity V/ Ah 12/ 70 (75B31R)

Generator for Battery charging V-W 12-480

Fuel Automobile Type Diesel fuel No.2-D (ASTMD975)

Engine oil API service CD or CE, SAE: 10W-30

Engine oil capacity 6.0

Weight kg 110.0 (Only engine)

Application General Power Source

Fuel consumption ratio g/ kWSh (g/ PSSh) 285 (210)

Cooling water (coolant) capacity 6.0 (Radiator: 2.0 + Cylinder block: 4.0)

Reservoir tank capacity Upper level: 0.6, Lower level: 0.1

Ambient temperature range _C (_F) 15 X 40 (5 X 104)

GENERATOR SERVICE DATA

380-220 V/ 50Hz 220-127 V/ 60Hz

Coil resistance ( 10% at 20_C)

Stator Main coil

Rotor Main field coil

Rotor Exciter armature coil U-V, V-W, W-U

Exciter field coil

0.62

0.62

0.62

10.9

0.713

24.90

0.16

0.16

0.16

10.9

0.713

24.90

Stator main coil generated voltage (AC-V)

S Without A.V.R. (Disconnected all lead wire)

S Engine should be operated at rated speed.

D , ,

D , ,

Approx. 90

Approx. 52

Approx. 50

Approx. 29

30

G

E

N

E

R

A

T

O

R

C

O

N

T

R

O

L

B

O

X

S

T

A

T

O

R

A

S

S

Y

R

O

T

O

R

A

S

S

Y

E

N

G

I

N

E

M

6

R

W

/

B

B

/

R

L

R

G

W

/

B

Y

B

G

/

W

W

/

R

Y

L

L

W

/

R

Y

2

A

1

A

Y

Y

Y

Y

Y

Y

Y

Y

L

L

R

Y

W

/

R

W

/

R

1

9

A

C

5

0

B

R

R

G

W

G

/

L

G

/

W

Y

Y

G

/

L

G

/W

B

/W

G

/

R

W

/B

W

/B

Y

/B

B

/Y

W

/R

W

/G

R

/B

R

R

A

C

1

9

5

0

B

O

F

F

O

N

G

L

O

W

S

T

A

R

T

W

RW

L

RW

L

UVWO

L

K

L

H

z

A

V

W

a

t

e

r

t

e

m

p

e

r

a

t

u

r

e

l

a

m

p

O

i

l

p

r

e

s

s

u

r

e

l

a

m

p

B

a

t

t

e

r

y

c

h

a

r

g

e

l

a

m

p

G

l

o

w

l

a

m

p

G

/

W

Y

G

/

W

G

/

W

W

/

B

R

N

F

B

R

R

W

/

R

W

/

B

B

/

R

B

/

W

Y

/

B

Y

/

B

B

/

Y

YR

R

/

B

W

/

B

R

G

/

R

G

/

L

W

/

G

W

/

B

W

/

R

G

R

L

M

4

R

M

8

M

4

G

/

R

L

R

L

R

B

/

R

R

G

Y

W

Y

O

R

A

-

V

-

R

R

B

R

P

P

2 0 0 3 O W V U

V

R

F

-

F

+

4

3

E

3

6

7

2

0

0

1

234

5

6

1

7

1

6

2

9

1

9

2

7

2

5

2

4

2

3

7

2

1

2

0

1

5

2

8

1

8

2

6

2

2

1

4

1

3

1

2

1

1

1

0

9

8

WIRING DIAGRAM (380-220 V/50Hz)

31

32

G

E

N

E

R

A

T

O

R

C

O

N

T

R

O

L

B

O

X

S

T

A

T

O

R

A

S

S

Y

R

O

T

O

R

A

S

S

Y

E

N

G

I

N

E

M

6

M

4

M

4

R

B

/

R

R

R

R

W

/

B

B

/

R

G

/

R

L

R

L

R

G

W

/

B

Y

B

G

/

W

W

/

R

G

Y

W

Y

O

R

A

-

V

-

R

R

B

R

P

P

L

L

W

/

R

Y

Y

2

A

1

A

Y

Y

Y

Y

Y

Y L

L

R

Y

W

/

R

R

R

W

/

R

1

9

A

C

5

0

B

R

R

B

/

R

G

W

G

/

L

G

/

W

Y Y

G

/

L

G

/W

B

/W

G

/

R

W

/B

W

/B

Y

/B

B

/Y

W

/R

W

/G

R

/B

R

R

W

/

B

A

C

1

9

5

0

B

O

F

F

O

N

G

L

O

W

S

T

A

R

T

W

RW

L

R

N

F

B

W

L

UVWO

L

K

V

R

L

H

z

A

V

W

a

t

e

r

t

e

m

p

e

r

a

t

u

r

e

l

a

m

p

O

i

l

p

r

e

s

s

u

r

e

l

a

m

p

B

a

t

t

e

r

y

c

h

a

r

g

e

l

a

m

p

G

l

o

w

l

a

m

p

G

/

W

Y

G

/

W

G

/

W

W

/

R

Y

M

8

R

G

/

R

G

/

L

W

/

G

B

/

W

B

/

W

B

/

Y

YR

W

/

R

W

/

B

W

/

R

L

R

G

W

/

B

L

R

2 0 0 3 O W V U

F

-

F

+

4

3

E

3

6

7

2

0

0

1

234

5

6

1

71

6

2

9

1

9

2

7

2

5

2

4

2

3

7

2

1

2

0

1

5

2

8

1

8

2

6

2

2

1

4

1

3

1

2

1

1

1

0

9

8

WIRING DIAGRAM (220-127 V/60Hz)

33

PRINTED ON RECYCLED PAPER

PRINTED IN JAPAN

02.08 1

(E)

ITP

Das könnte Ihnen auch gefallen

- DSE8680 Operators ManualDokument51 SeitenDSE8680 Operators ManualSon DoNoch keine Bewertungen

- Gu601a En0507 PDFDokument30 SeitenGu601a En0507 PDFChhoan Nhun100% (2)

- DST 4600A: Electronic Control CardDokument2 SeitenDST 4600A: Electronic Control Cardmuhammad arif100% (2)

- DG 04 003-E 08-04 Formular Communication Order PDFDokument17 SeitenDG 04 003-E 08-04 Formular Communication Order PDFTegas Shidik PermanaNoch keine Bewertungen

- Specifications of Avr - SMR (Mosfet)Dokument4 SeitenSpecifications of Avr - SMR (Mosfet)Александр ЩеблыкинNoch keine Bewertungen

- ATS 22 ManualDokument44 SeitenATS 22 ManualOrlando Velado100% (3)

- DSE7110MKII DSE7120 MKII Wiring Diagram PDFDokument3 SeitenDSE7110MKII DSE7120 MKII Wiring Diagram PDFNave GanteNoch keine Bewertungen

- Dst4400 EngDokument20 SeitenDst4400 EngFrancisco Stonly Amador Rodriguez33% (3)

- User Manual Commander C-08 - GB PDFDokument76 SeitenUser Manual Commander C-08 - GB PDFbac89% (9)

- SX440 Manual enDokument4 SeitenSX440 Manual enAnsoriNoch keine Bewertungen

- Regulador de Tension Analogico, Manual de Instalacion Operacion y MantenimientoDokument79 SeitenRegulador de Tension Analogico, Manual de Instalacion Operacion y MantenimientoFix0% (1)

- Voltage Regulator AVC63-7 Manual PDFDokument4 SeitenVoltage Regulator AVC63-7 Manual PDFEduardo A. CottaniNoch keine Bewertungen

- Linz - New Product - AlumenDokument4 SeitenLinz - New Product - AlumenTTIBCCANoch keine Bewertungen

- ATS Manual HMI Asco-300Dokument40 SeitenATS Manual HMI Asco-300Stalin Omar100% (1)

- Control Unit For Autonomous Genset TYPE CAM-325: GE/FO-150604Dokument2 SeitenControl Unit For Autonomous Genset TYPE CAM-325: GE/FO-150604FCO ANTONIO CHACONNoch keine Bewertungen

- General Information: Drilling Template (MM)Dokument4 SeitenGeneral Information: Drilling Template (MM)Bruno MarianoNoch keine Bewertungen

- ONAN DJC MEP 003A ManualDokument243 SeitenONAN DJC MEP 003A ManualscyrosNoch keine Bewertungen

- 5210 ManualDokument4 Seiten5210 ManualBuck AbellaNoch keine Bewertungen

- SS460 InstructionsDokument4 SeitenSS460 InstructionsDiego Fernando Sanchez FlorezNoch keine Bewertungen

- Governor Controller (GAC ESD5111) - DatasheetDokument5 SeitenGovernor Controller (GAC ESD5111) - Datasheetazhan77Noch keine Bewertungen

- Aux101 Service ManualDokument98 SeitenAux101 Service ManualKaiser lqbalNoch keine Bewertungen

- Operator Manual: DGBB, DGBC, Dgca, DGCB, DGCC, Dgda, DGDB, DGDK, Dgea, Dgfa, DGFB, DGFCDokument67 SeitenOperator Manual: DGBB, DGBC, Dgca, DGCB, DGCC, Dgda, DGDB, DGDK, Dgea, Dgfa, DGFB, DGFCLuis Batlle Aguilera100% (2)

- Newage Sx460 Automatic Voltage RegulatorDokument5 SeitenNewage Sx460 Automatic Voltage RegulatorLuis Alberto Lopez100% (1)

- Zenith ZTG SeriesDokument8 SeitenZenith ZTG SeriesFlo MircaNoch keine Bewertungen

- Dse 704-4120Dokument3 SeitenDse 704-4120Jose Daniel Garcia RodriguezNoch keine Bewertungen

- Operation Decisionmaker 3000Dokument128 SeitenOperation Decisionmaker 3000sonxNoch keine Bewertungen

- Regulador Avc63-4 Basler ElectricDokument4 SeitenRegulador Avc63-4 Basler ElectricJose Manuel Bautista MartinezNoch keine Bewertungen

- Manual de Instalacion de GeneracDokument142 SeitenManual de Instalacion de Generacsolounsiervo100% (2)

- Ea16 Manual enDokument6 SeitenEa16 Manual enabuzer1981Noch keine Bewertungen

- Regulador de Voltaje GAVR8AhDokument2 SeitenRegulador de Voltaje GAVR8AhcrecosiroNoch keine Bewertungen

- Cummins DFHA DFHB DFHC DFHD Generator Set Parts Manual Powercommand 3100 ControllerDokument114 SeitenCummins DFHA DFHB DFHC DFHD Generator Set Parts Manual Powercommand 3100 ControllerVictor Gustavo de Carvalho100% (1)

- Model E & Pe RegulatorsDokument5 SeitenModel E & Pe RegulatorsMiguel Angel NajeraNoch keine Bewertungen

- GE MX-150 ManualDokument28 SeitenGE MX-150 ManualCristian Munoz60% (5)

- Catalogue of Permanent Company PDFDokument8 SeitenCatalogue of Permanent Company PDFJaimeCoelloNoch keine Bewertungen

- Ec5000 6-09 PDFDokument5 SeitenEc5000 6-09 PDFHusi NihaNoch keine Bewertungen

- Three-Phase Synchronous Generator AVR WT-2: VOLT - Potentiometer For Adjusting The OutputDokument3 SeitenThree-Phase Synchronous Generator AVR WT-2: VOLT - Potentiometer For Adjusting The OutputBradNoch keine Bewertungen

- GCM01 Mu GB 12.2Dokument33 SeitenGCM01 Mu GB 12.2carrettiNoch keine Bewertungen

- Regulador Woodward 8290-184Dokument4 SeitenRegulador Woodward 8290-184kinosi100% (1)

- (نسخة) JB-WD-DSE 6120 MKIII - 12.5-200 (1106)Dokument1 Seite(نسخة) JB-WD-DSE 6120 MKIII - 12.5-200 (1106)Mahmood NabilNoch keine Bewertungen

- IL NT MRS3,4 AMF8,9 2.2 Reference GuideDokument86 SeitenIL NT MRS3,4 AMF8,9 2.2 Reference GuideoveladoNoch keine Bewertungen

- Acd175 SeriesDokument8 SeitenAcd175 SeriesRobertoSoaresNoch keine Bewertungen

- AVR EA 16-Manual-EnDokument6 SeitenAVR EA 16-Manual-EnSyed Mohammad NaveedNoch keine Bewertungen

- GCP and 4G Diagnostic ManualDokument305 SeitenGCP and 4G Diagnostic ManualRolando Gonzalez ArmasNoch keine Bewertungen

- C10 C15 C20 D6 Cummins Power PDFDokument216 SeitenC10 C15 C20 D6 Cummins Power PDFUrsae Ingenieria100% (1)

- MQ2 ManualDokument30 SeitenMQ2 ManualTecnologia WilconNoch keine Bewertungen

- WEG Regulador de Tensao Grt7 Th4 10040217 Manual Portugues BRDokument50 SeitenWEG Regulador de Tensao Grt7 Th4 10040217 Manual Portugues BRJuan I. Meza Lozano100% (1)

- GAVR15Dokument2 SeitenGAVR15HerbertNoch keine Bewertungen

- Avr Conversion InstructionsDokument2 SeitenAvr Conversion InstructionsJose PirulliNoch keine Bewertungen

- DEC 4000 Brochure APDokument8 SeitenDEC 4000 Brochure APAndré Venâncio Dequito100% (1)

- Diagram LCG2Dokument1 SeiteDiagram LCG2Edgar De50% (2)

- Owners+Manual Speed+controller (DGC-2013) (ENG)Dokument7 SeitenOwners+Manual Speed+controller (DGC-2013) (ENG)Quang PhamNoch keine Bewertungen

- Sps 460Dokument1 SeiteSps 460BrianHazeNoch keine Bewertungen

- Asco Series 300 Ats Operators ManualDokument20 SeitenAsco Series 300 Ats Operators ManualGera Ortiz Martinez100% (1)

- Min ArikDokument84 SeitenMin AriklalociscoNoch keine Bewertungen

- Yamaha FZ6-N 2004 (Europe) Supplementary Service ManualDokument77 SeitenYamaha FZ6-N 2004 (Europe) Supplementary Service Manualm.kelleci7248Noch keine Bewertungen

- Servomex 1800-1900 ManualDokument122 SeitenServomex 1800-1900 ManualMohammed AaseemNoch keine Bewertungen

- LAW 420 LAW 520: Service ManualDokument46 SeitenLAW 420 LAW 520: Service ManualquangppNoch keine Bewertungen

- Variable Speed DriveDokument66 SeitenVariable Speed DriveRamaNoch keine Bewertungen

- Servomex 1800 1900 Manual PDFDokument122 SeitenServomex 1800 1900 Manual PDFbrunolacerdajrNoch keine Bewertungen

- Irrigation Pump ERBA EIP 2 - Service ManualDokument56 SeitenIrrigation Pump ERBA EIP 2 - Service ManualDodik E. PrasetyoNoch keine Bewertungen

- Mitsubishi s6s PDFDokument48 SeitenMitsubishi s6s PDFMoni Gote del OrtusNoch keine Bewertungen

- Wh1602b Ygk CPDokument20 SeitenWh1602b Ygk CPMoni Gote del OrtusNoch keine Bewertungen

- (500g PDFDokument33 Seiten(500g PDFMoni Gote del OrtusNoch keine Bewertungen

- Tiristores PDFDokument288 SeitenTiristores PDFMoni Gote del OrtusNoch keine Bewertungen

- Tiristores PDFDokument288 SeitenTiristores PDFMoni Gote del OrtusNoch keine Bewertungen

- Control Del Motor MR-PLD de Mercedes Benz PDFDokument150 SeitenControl Del Motor MR-PLD de Mercedes Benz PDFMoni Gote del Ortus53% (32)

- TLD ASU-600 180-300 Jet Engine Air StarterDokument2 SeitenTLD ASU-600 180-300 Jet Engine Air StarterMoni Gote del Ortus100% (1)

- Pin Macho 39000082 para Conector 39012141 DatasheetDokument4 SeitenPin Macho 39000082 para Conector 39012141 DatasheetMoni Gote del OrtusNoch keine Bewertungen

- Curtis TurbineDokument18 SeitenCurtis TurbineDivya Prakash SrivastavaNoch keine Bewertungen

- FT450 FT550 Ft550lite FT600Dokument158 SeitenFT450 FT550 Ft550lite FT600juan c GimenoNoch keine Bewertungen

- Unit Injector Replacement D12DDokument17 SeitenUnit Injector Replacement D12DMahdi E100% (3)

- 3gr-Fse Engine MechanicalDokument20 Seiten3gr-Fse Engine MechanicalHuỳnh Minh ĐứcNoch keine Bewertungen

- 2.0l EngineDokument312 Seiten2.0l EngineMike Sumaya Jr.Noch keine Bewertungen

- сорт 2Dokument3 Seitenсорт 2FL КИЛЛАNoch keine Bewertungen

- 3516a Cat Engine Moh Part List Sheet1Dokument4 Seiten3516a Cat Engine Moh Part List Sheet1Shubham KhandelwalNoch keine Bewertungen

- Waukesha VHP L5794gsi Product SheetDokument2 SeitenWaukesha VHP L5794gsi Product SheetUmair A. KhanNoch keine Bewertungen

- Service ManualDokument582 SeitenService ManualBogdan Popescu100% (5)

- Merit of UploadDokument2 SeitenMerit of UploadSowndhar RajendranNoch keine Bewertungen

- Pump CalculationsDokument6 SeitenPump CalculationsAshenafi Gebremeskel MezgeboNoch keine Bewertungen

- POWERSHIFTDokument383 SeitenPOWERSHIFTMplachouras-Plachouras Nikolaos100% (3)

- Slick Jute Elk ItDokument2 SeitenSlick Jute Elk ItkrarNoch keine Bewertungen

- A Few Words About Safety: How To Use This ManualDokument124 SeitenA Few Words About Safety: How To Use This ManualMarco David Cabrera CarranzaNoch keine Bewertungen

- 325D and 325D L Excavator: Service Repair ManualDokument28 Seiten325D and 325D L Excavator: Service Repair ManualDana CarvajalNoch keine Bewertungen

- The Gas Turbine Engin1Dokument9 SeitenThe Gas Turbine Engin1esutjiadiNoch keine Bewertungen

- Operator's ManualDokument64 SeitenOperator's ManualMarcos Lugo SanchezNoch keine Bewertungen

- Glamour Fi Nov 2013 Price ListDokument84 SeitenGlamour Fi Nov 2013 Price ListSANTOSH KUMARNoch keine Bewertungen

- Jarvi 2010-Methane Slip Reduction in Wartsila Lean Burn Gas EnginesDokument11 SeitenJarvi 2010-Methane Slip Reduction in Wartsila Lean Burn Gas EnginessestoubosNoch keine Bewertungen

- Mercruiser Warning HornsDokument10 SeitenMercruiser Warning Hornssivan_sg1800100% (1)

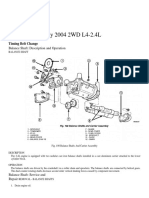

- Jeep Truck Liberty 2004 2WD L4-2.4L: Timing Belt ChangeDokument15 SeitenJeep Truck Liberty 2004 2WD L4-2.4L: Timing Belt ChangeJuan vaizNoch keine Bewertungen

- Yanmar 4jH4E BrochureDokument2 SeitenYanmar 4jH4E Brochuretowndock67% (3)

- Honda Diagnostic CodesDokument10 SeitenHonda Diagnostic CodesAngela Easter100% (1)

- Parts Manual: Engine &22/3$&Dokument56 SeitenParts Manual: Engine &22/3$&Dany_Wally67% (3)

- HITACHI ZX-3 ISUZU Engine Training TextDokument142 SeitenHITACHI ZX-3 ISUZU Engine Training TextPHÁT NGUYỄN THẾ89% (28)

- PO VolvoDokument1 SeitePO VolvoTyler GoodwinNoch keine Bewertungen

- A319 - A321 - LAA - and - LUS - A321NX - (Trouble Shooting Manual)Dokument13 SeitenA319 - A321 - LAA - and - LUS - A321NX - (Trouble Shooting Manual)A WongNoch keine Bewertungen

- Genrator Dosent StartDokument21 SeitenGenrator Dosent StartMohammad AmerNoch keine Bewertungen

- KIT OMEGAS (4 Cyl.) : FeaturesDokument2 SeitenKIT OMEGAS (4 Cyl.) : FeaturesAngel GarciaNoch keine Bewertungen